Environmentally friendly low-dispersion chalcogenide glass and preparation method thereof

A technology of chalcogenide glass and low dispersion, which is applied in the field of environment-friendly low dispersion chalcogenide glass and its preparation, can solve the problems of easy photodarkening, photobleaching effect, poor optical stability, etc., and achieve good infrared transmission performance, Uniform optical quality and good infrared light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation of the chalcogenide glass of embodiment 1-5, taking embodiment 1 as an example, comprises the following steps:

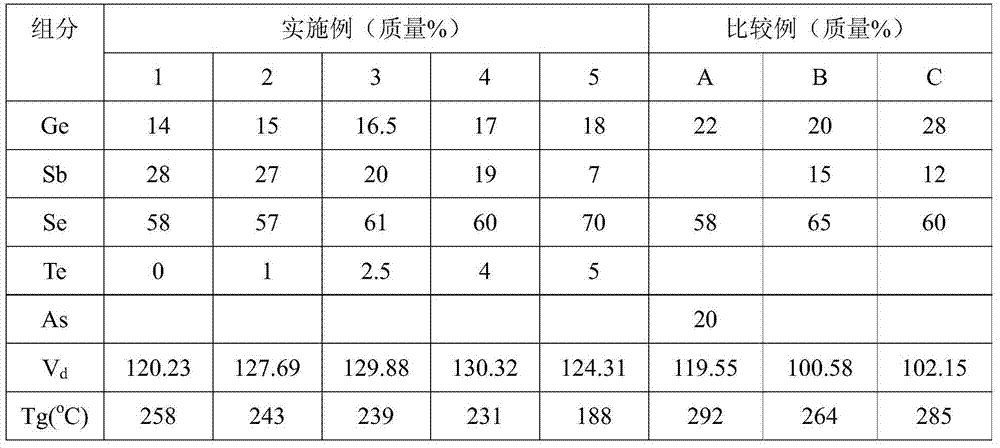

[0023] 1) Pretreatment: prepare a rocking furnace body and quartz ampoule with front and rear rocking functions, the rocking furnace body is provided with a first furnace and a second furnace, the first furnace and the second furnace have independent temperature control and heating systems, The first furnace and the second furnace are connected to each other through the filter area, and the quartz ampoule includes a glass raw material tube and a purified glass tube, and the glass raw material tube and the purified glass tube are connected to each other through a connecting tube; each component of the chalcogenide glass is carried out according to the mass percentage in Table 1 Weigh and put into the glass raw material tube, at the same time, put the magnesium bar with the total amount of chalcogenide glass raw material 0.03wt%-0.07wt% in the gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com