Patents

Literature

36 results about "Photodarkening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

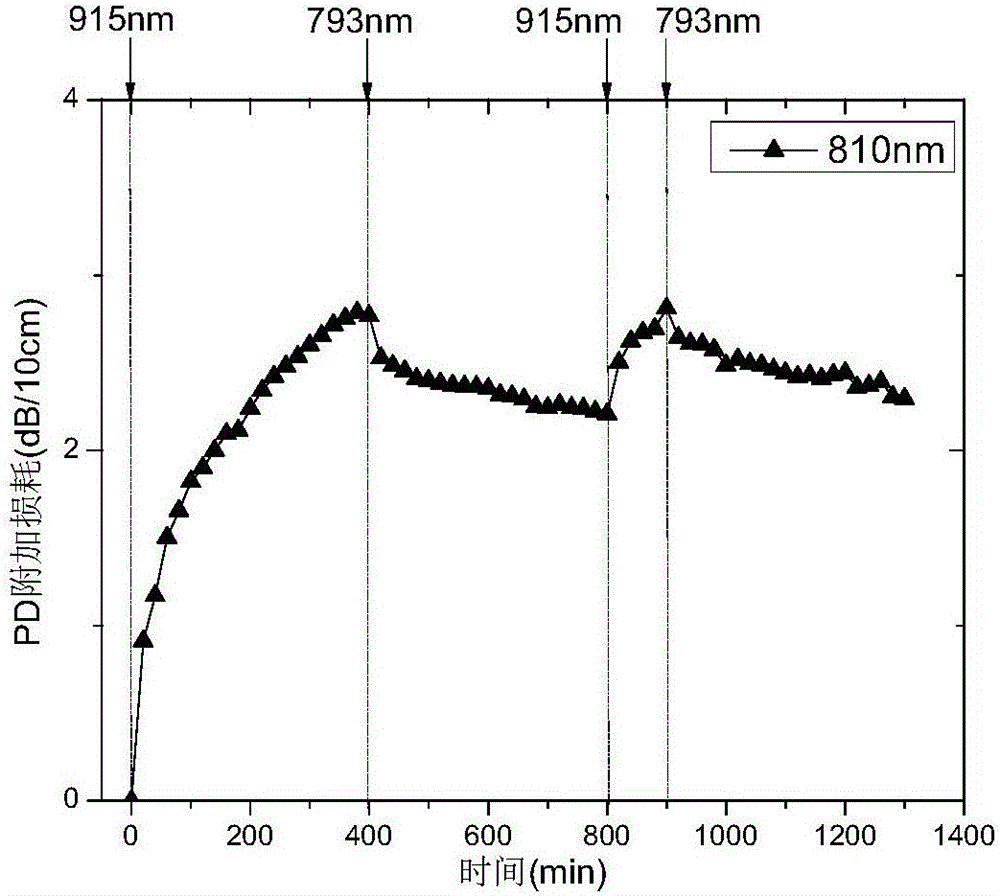

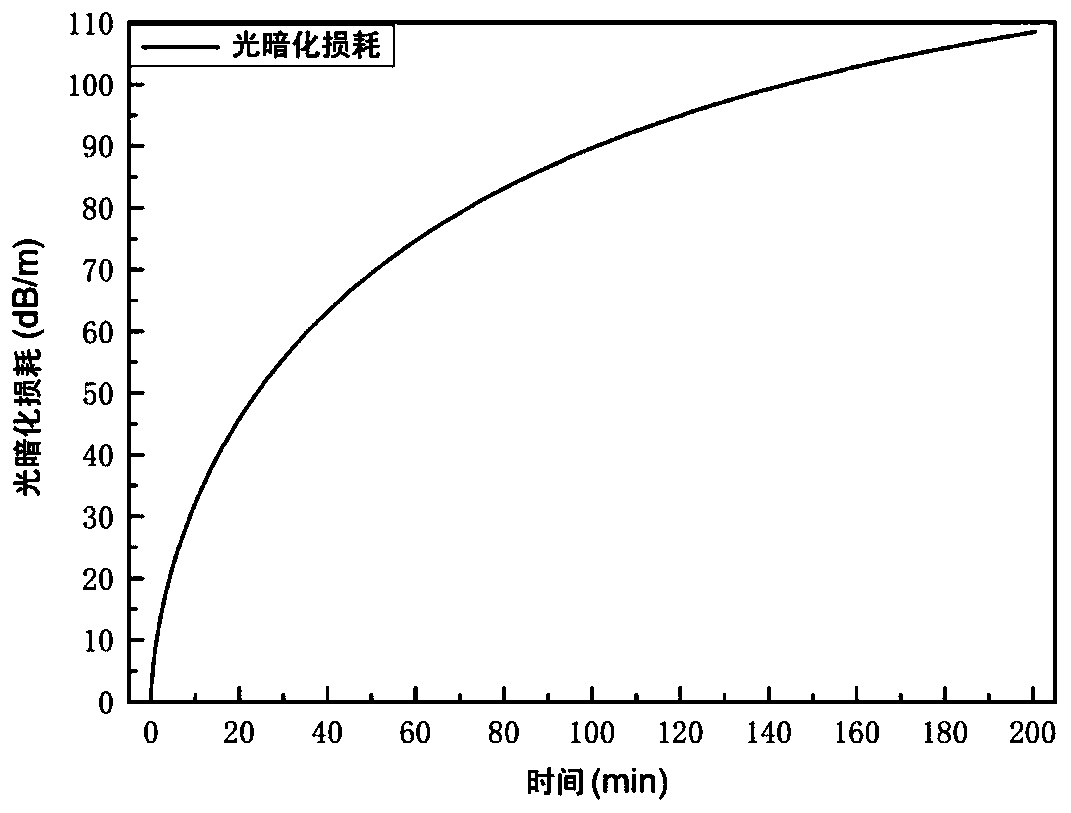

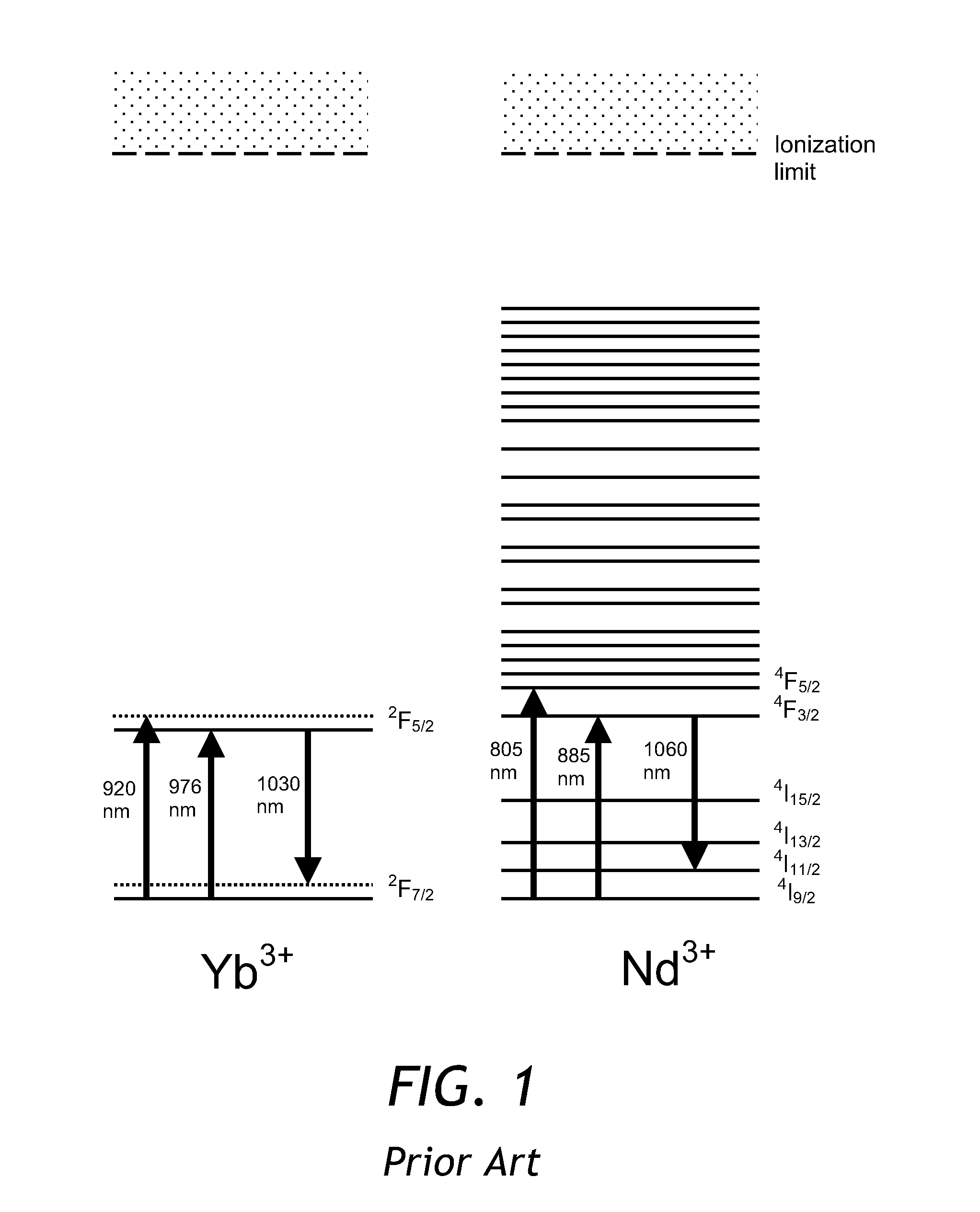

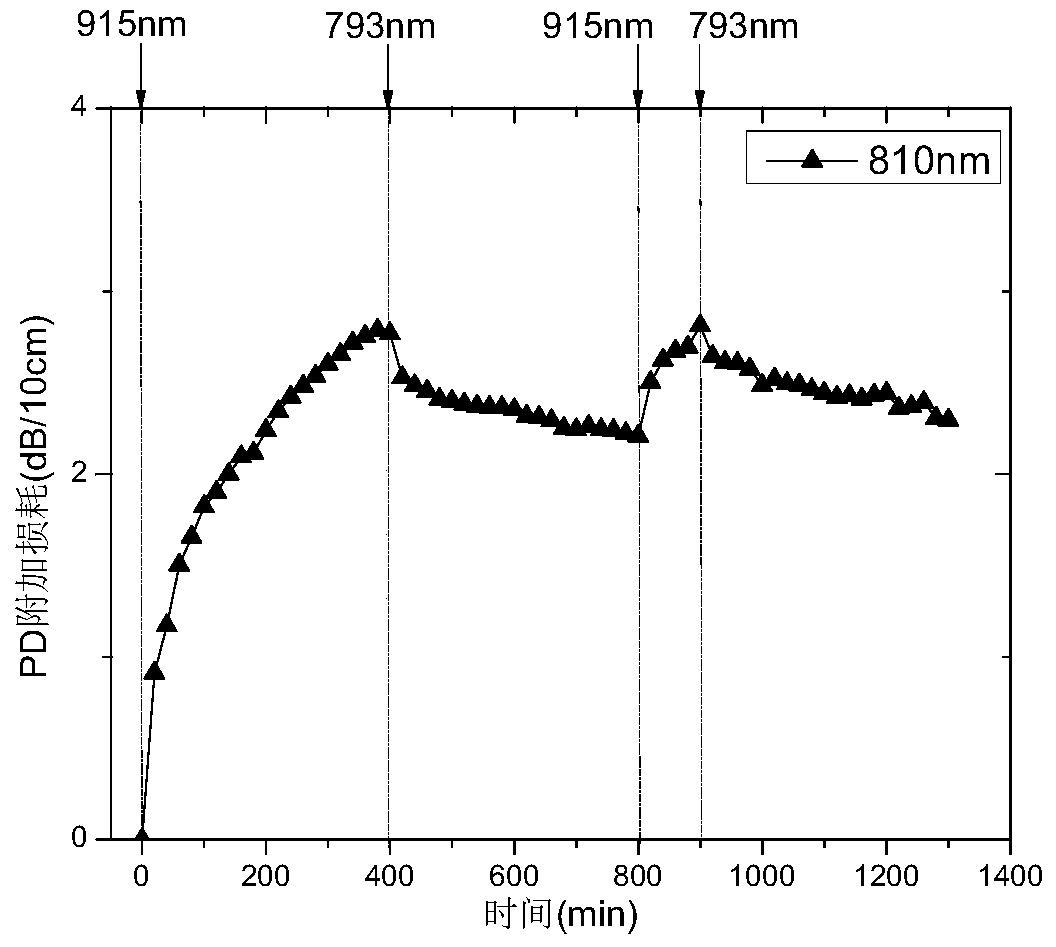

Photodarkening is an optical effect observed in the interaction of laser radiation with amorphous media (glasses) in optical fibers. Until now, such creation of color centers was reported only in glass fibers . Photodarkening limits the density of excitations in fiber lasers and amplifiers. The experimental results suggest that operating at a saturated regime helps to reduce photodarkening.

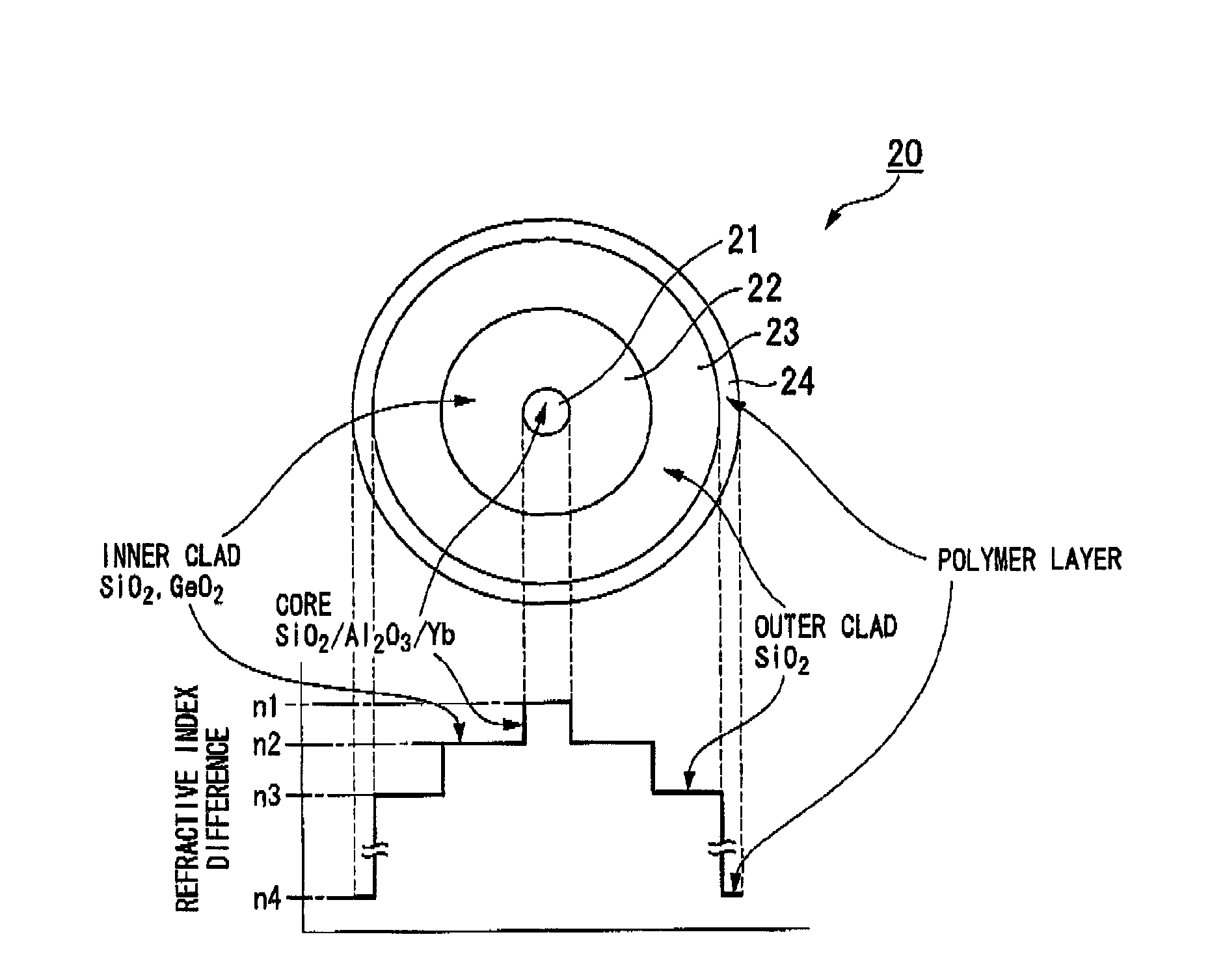

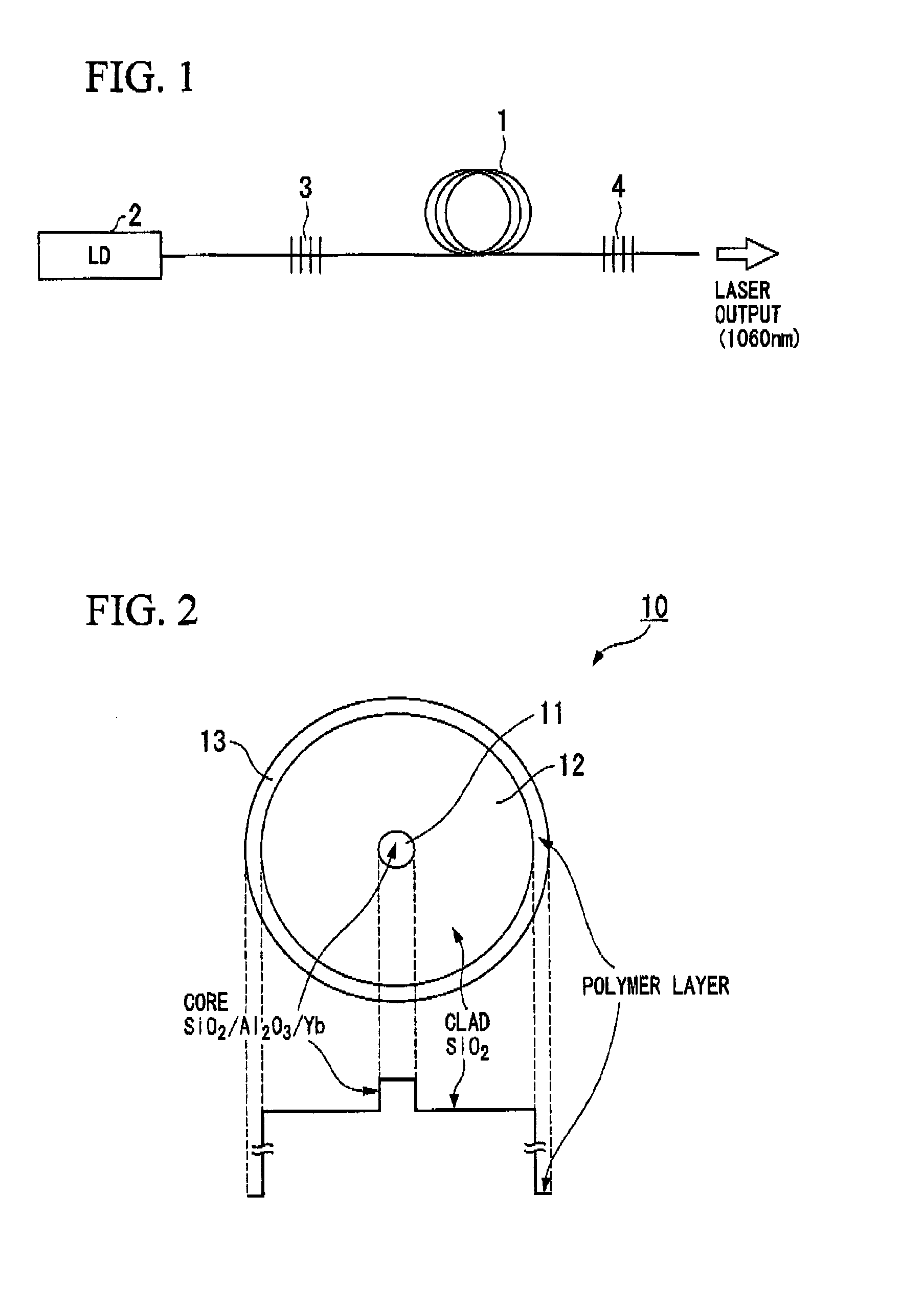

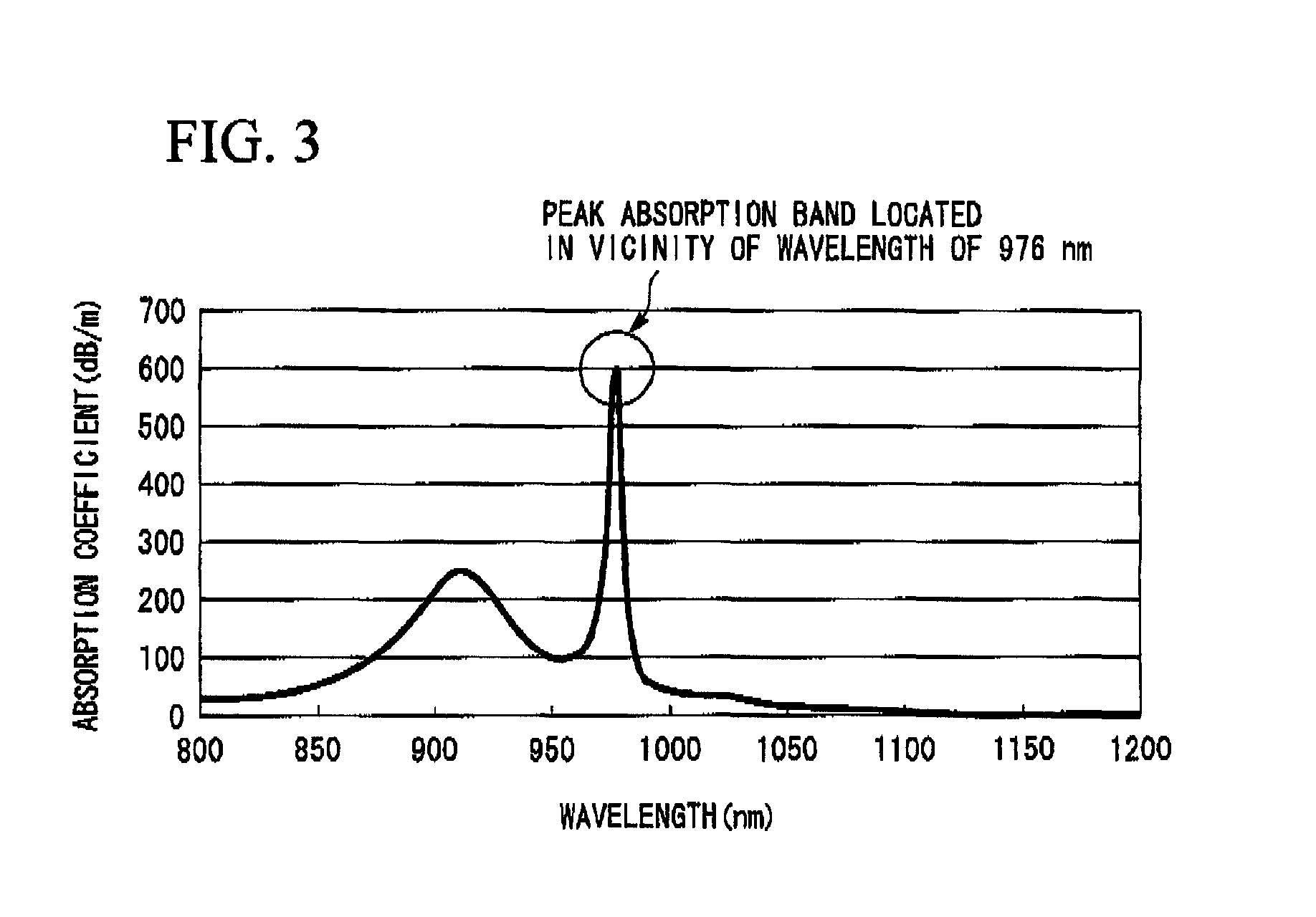

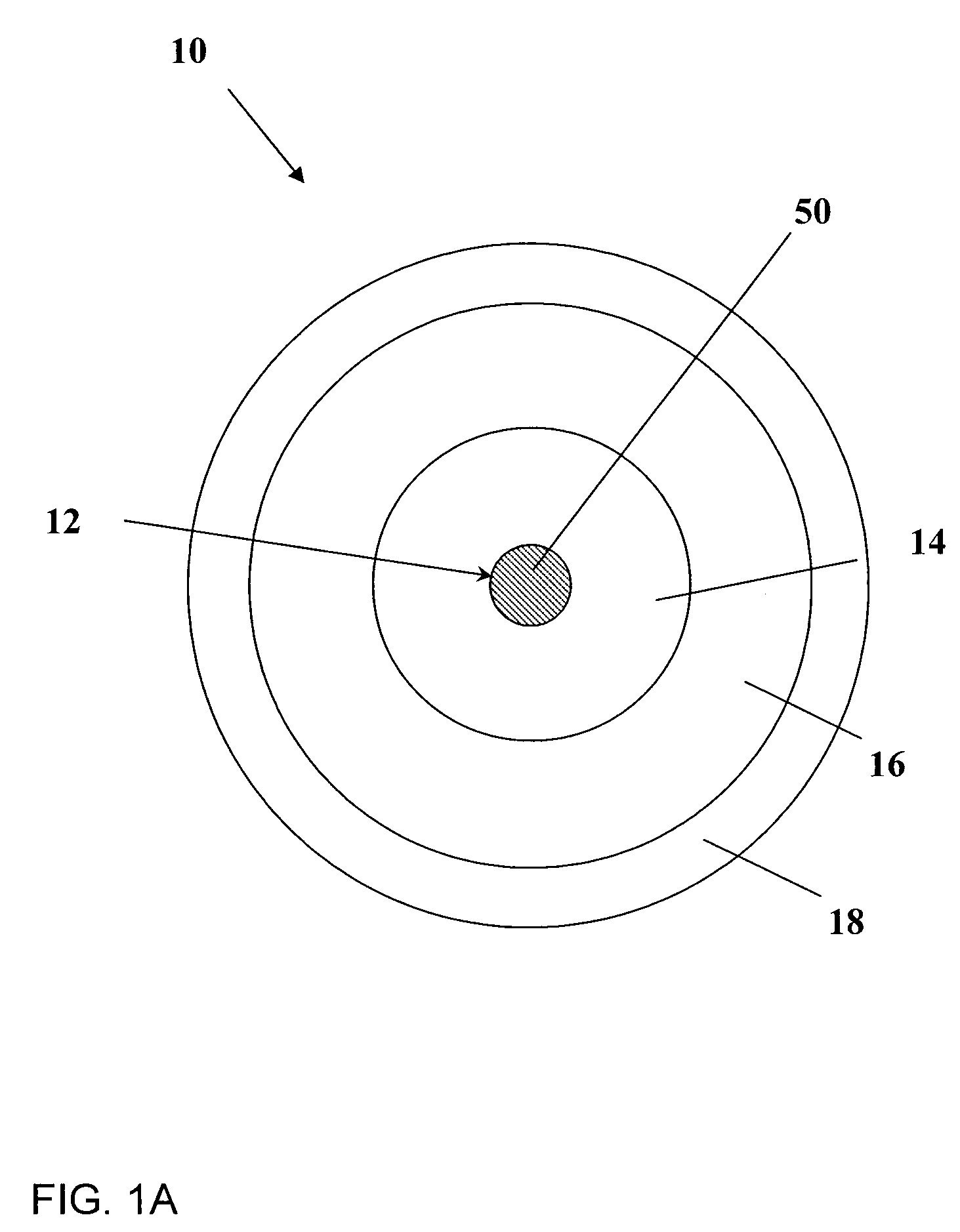

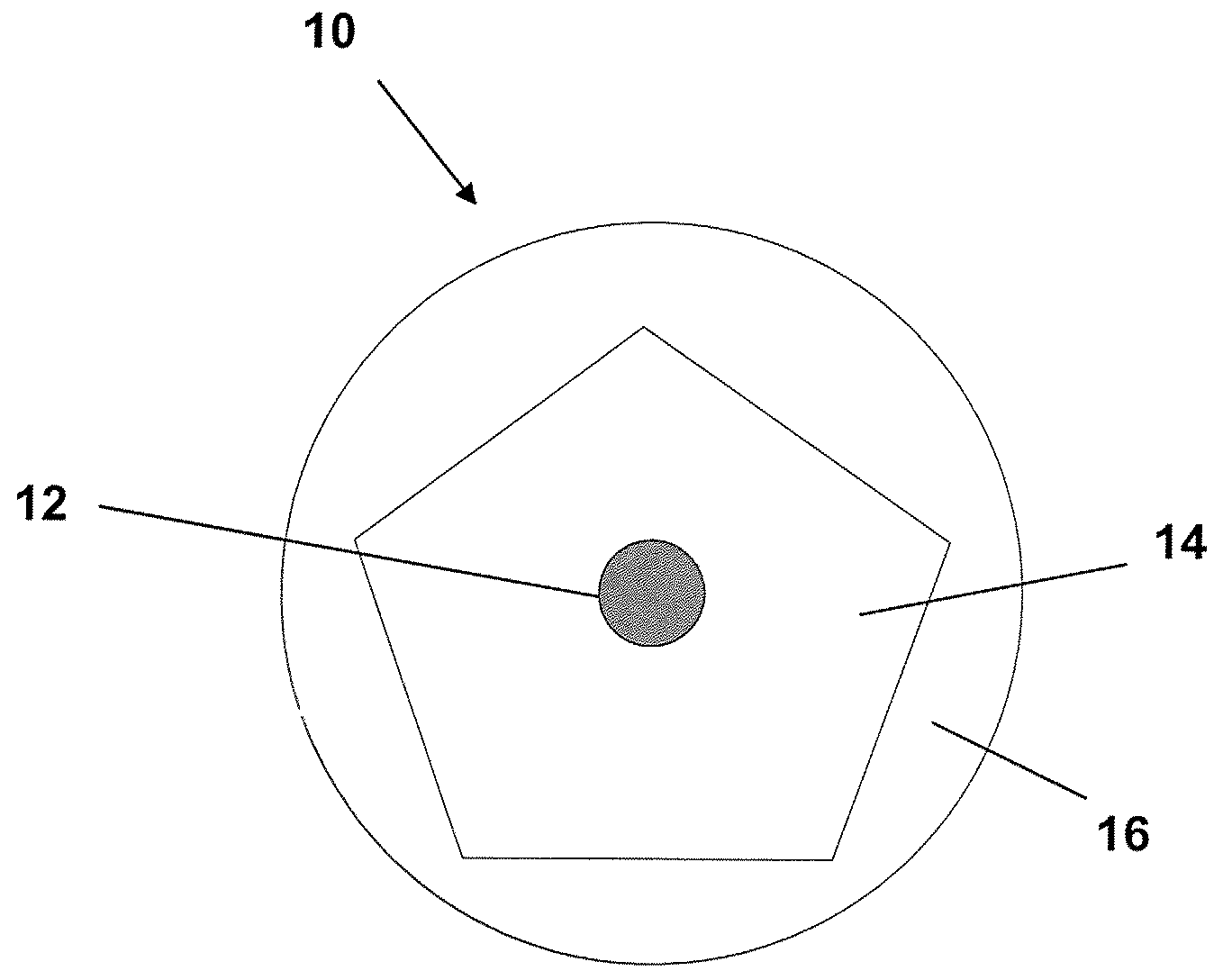

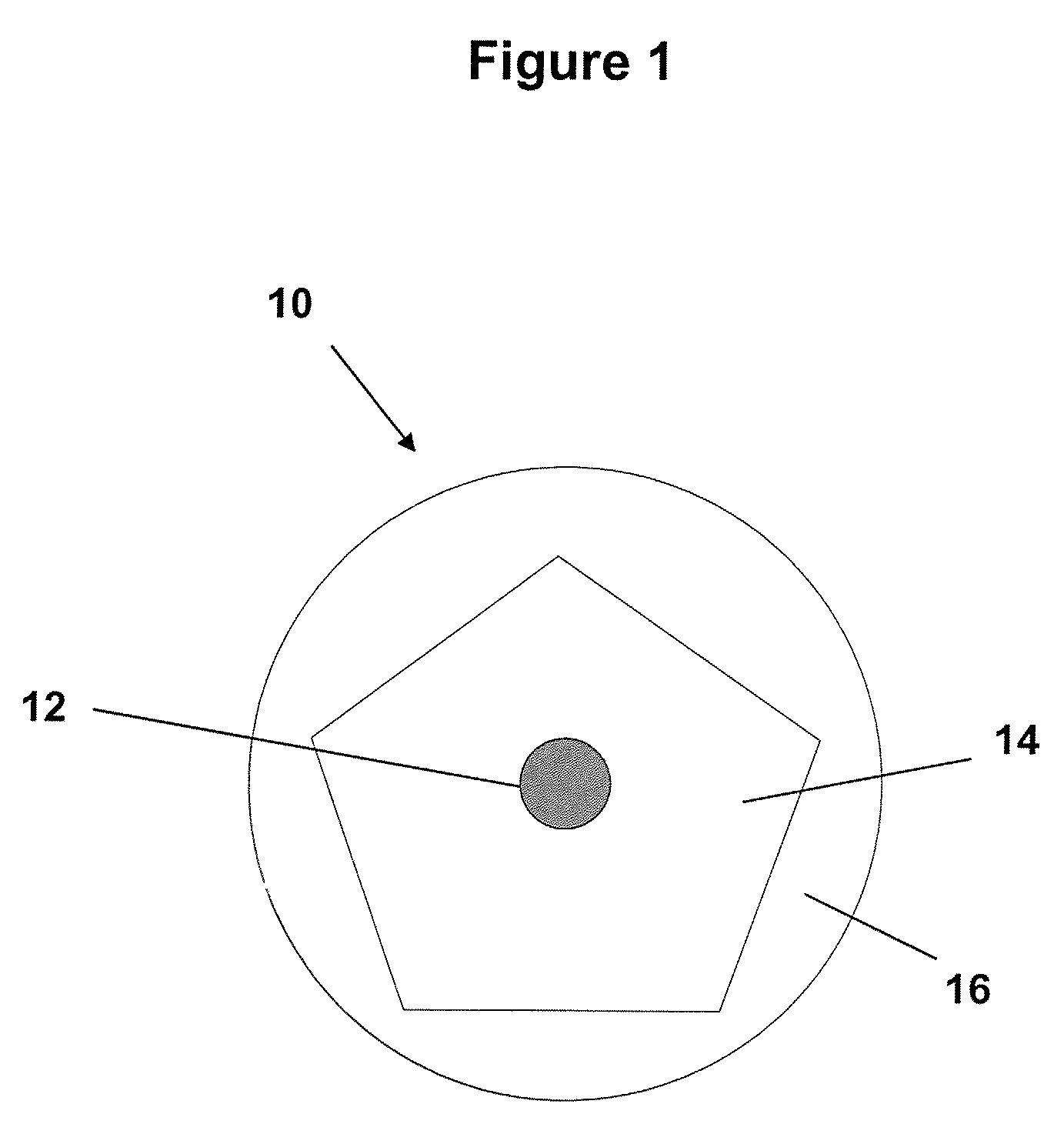

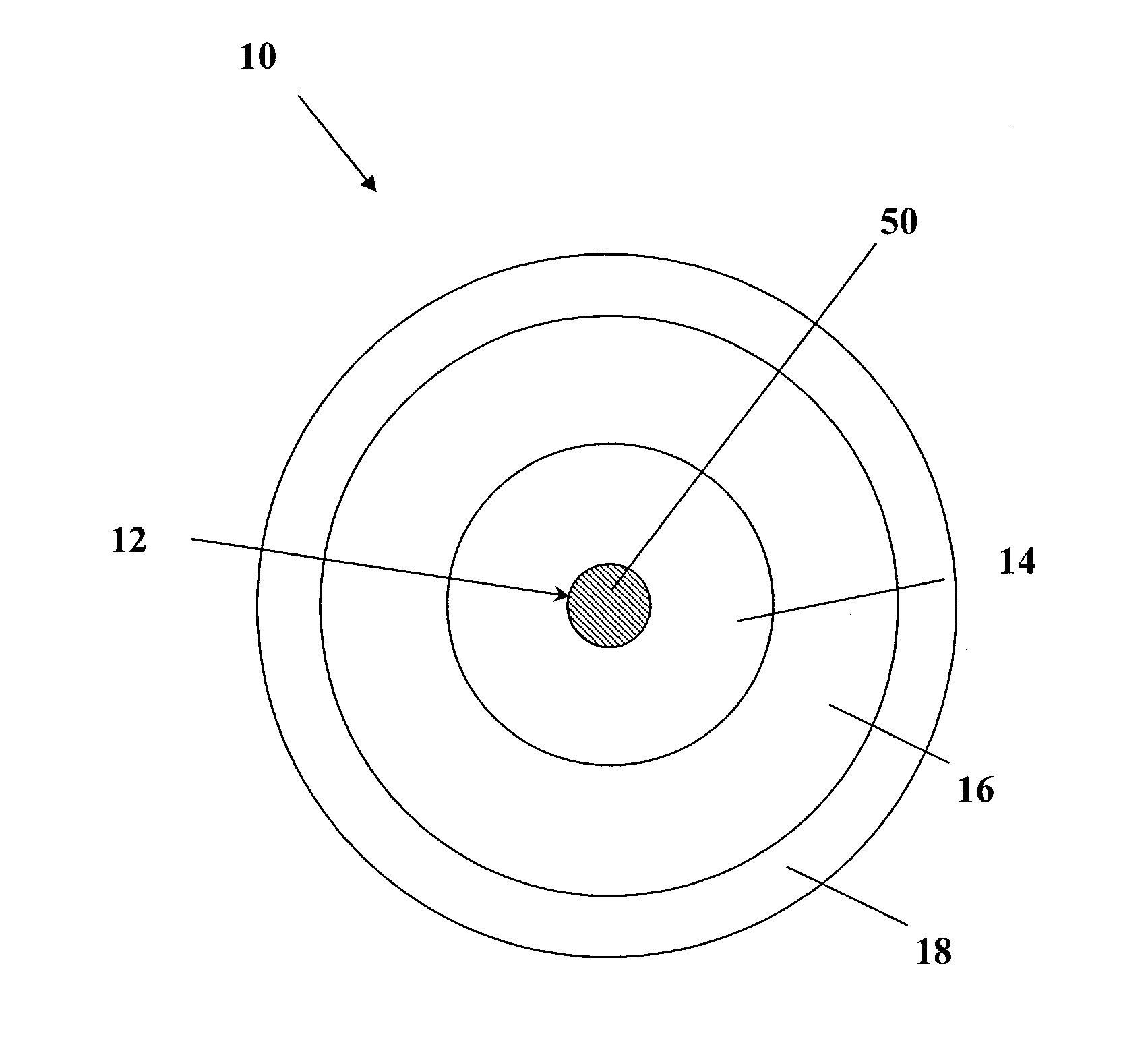

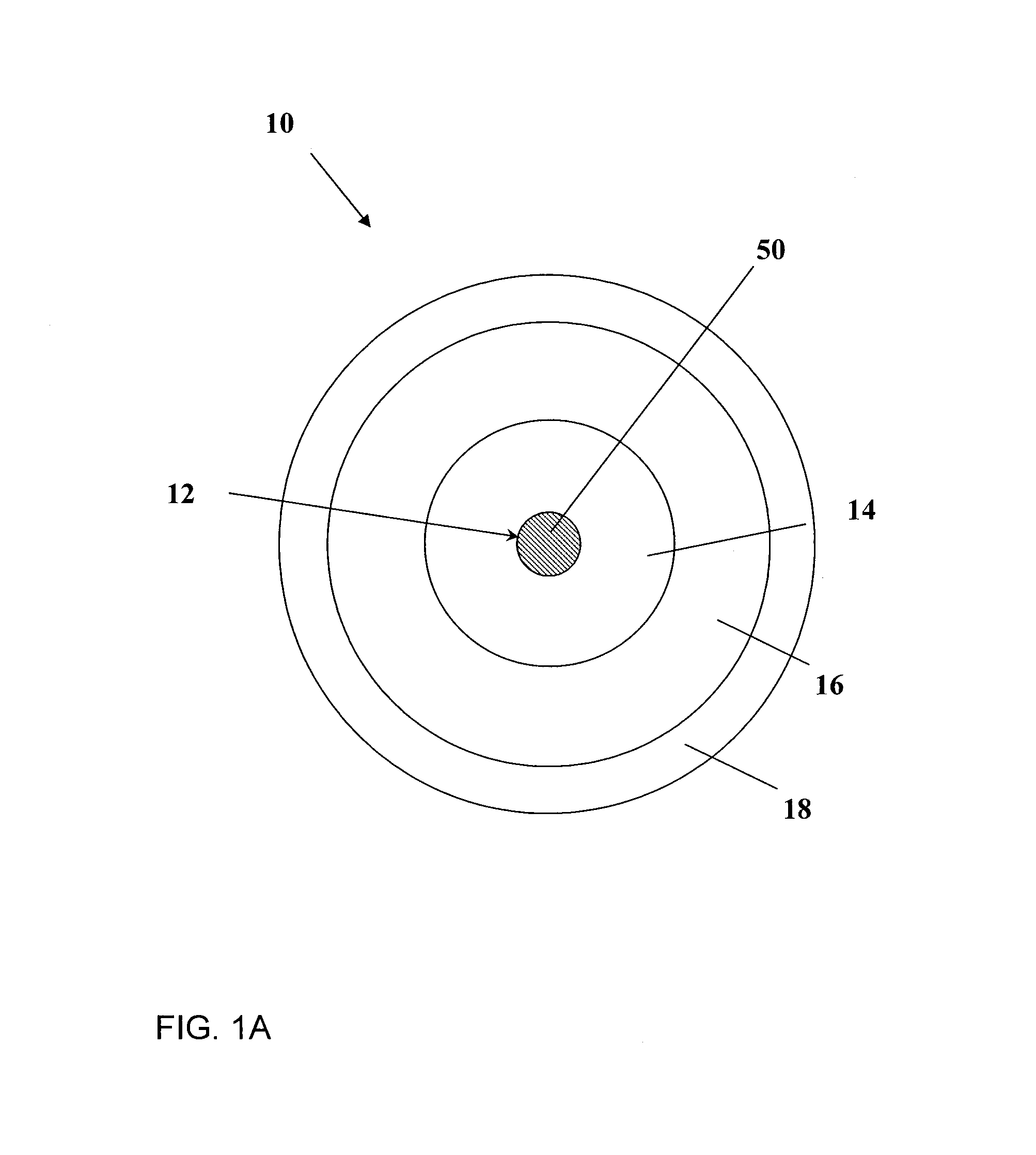

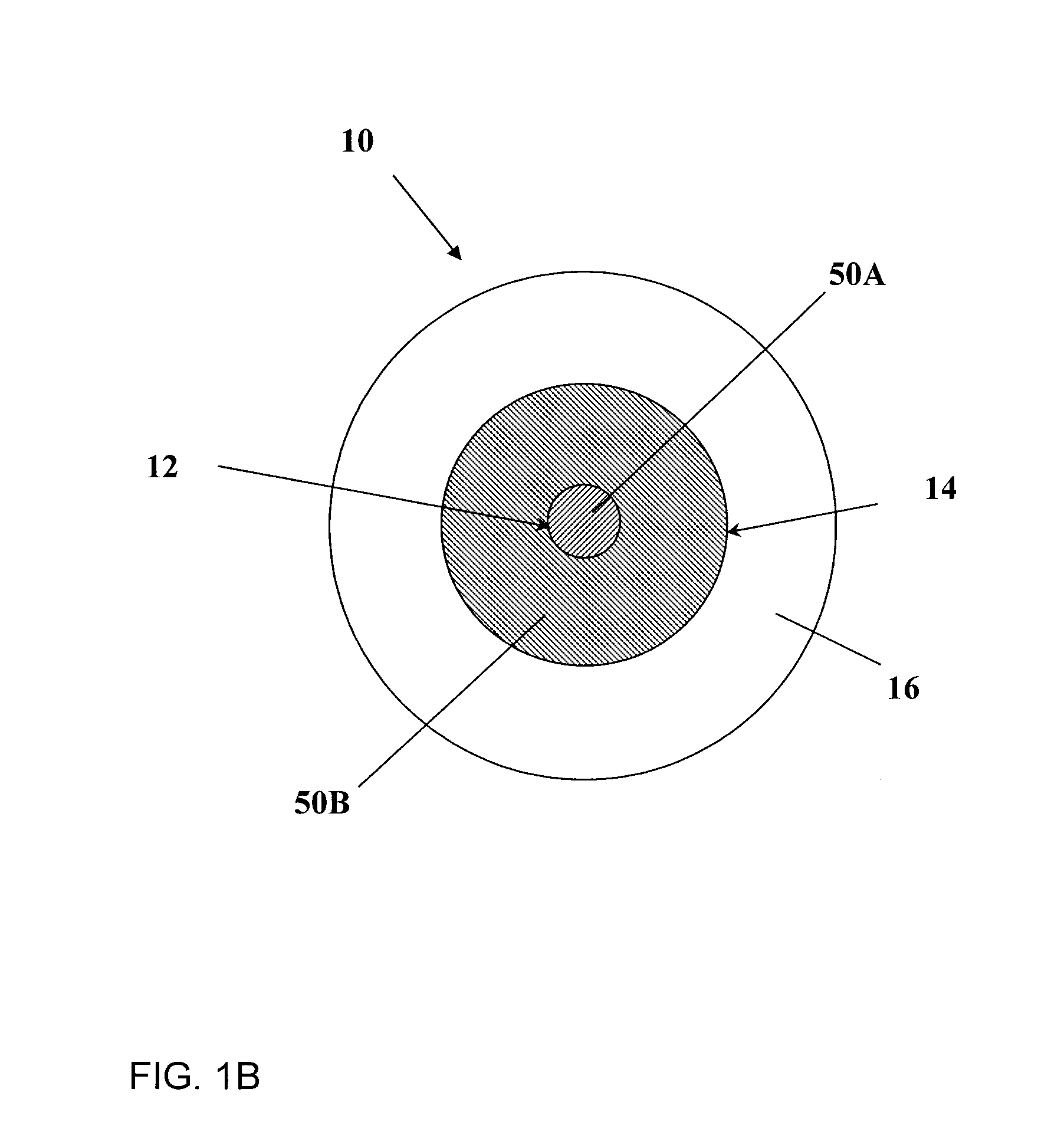

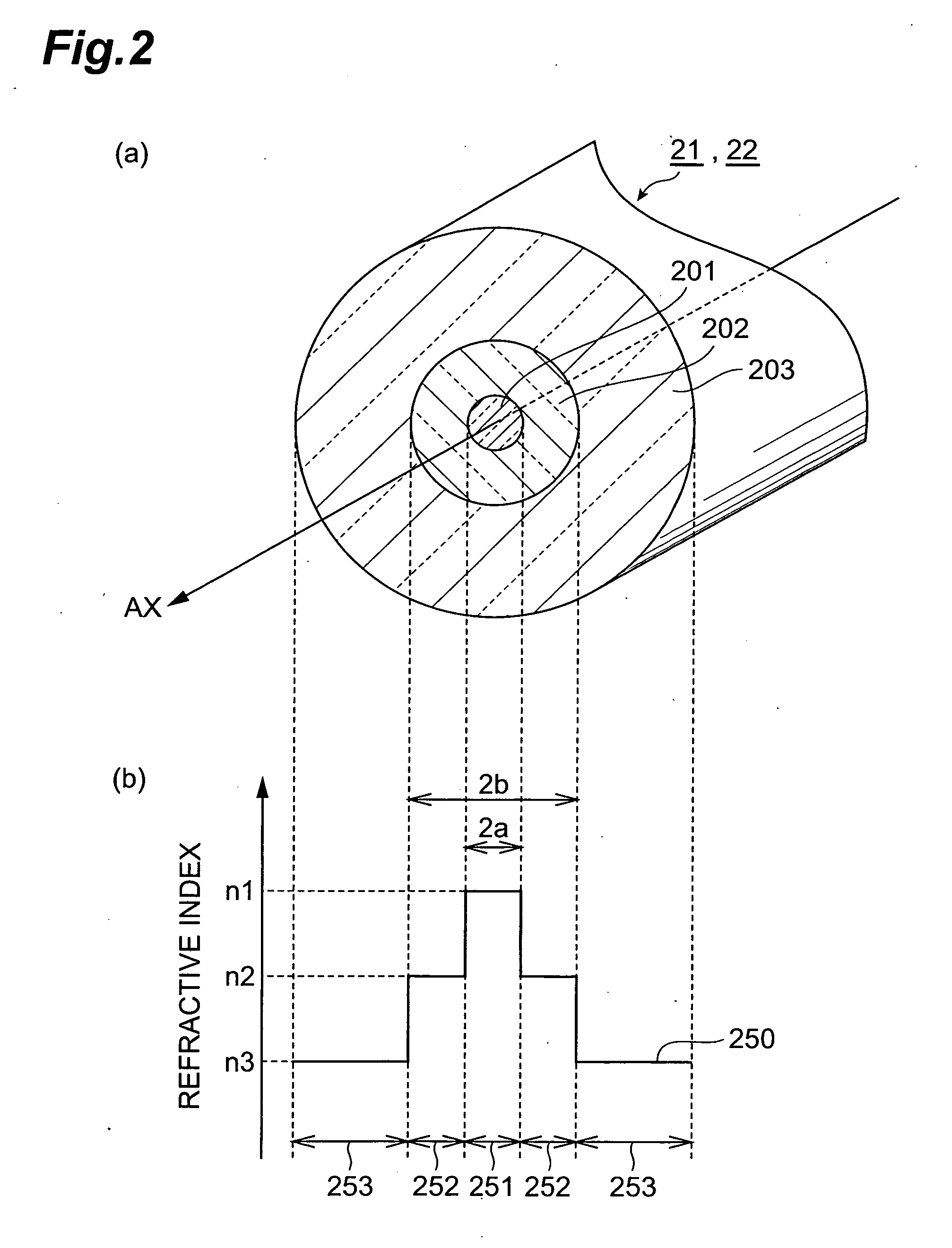

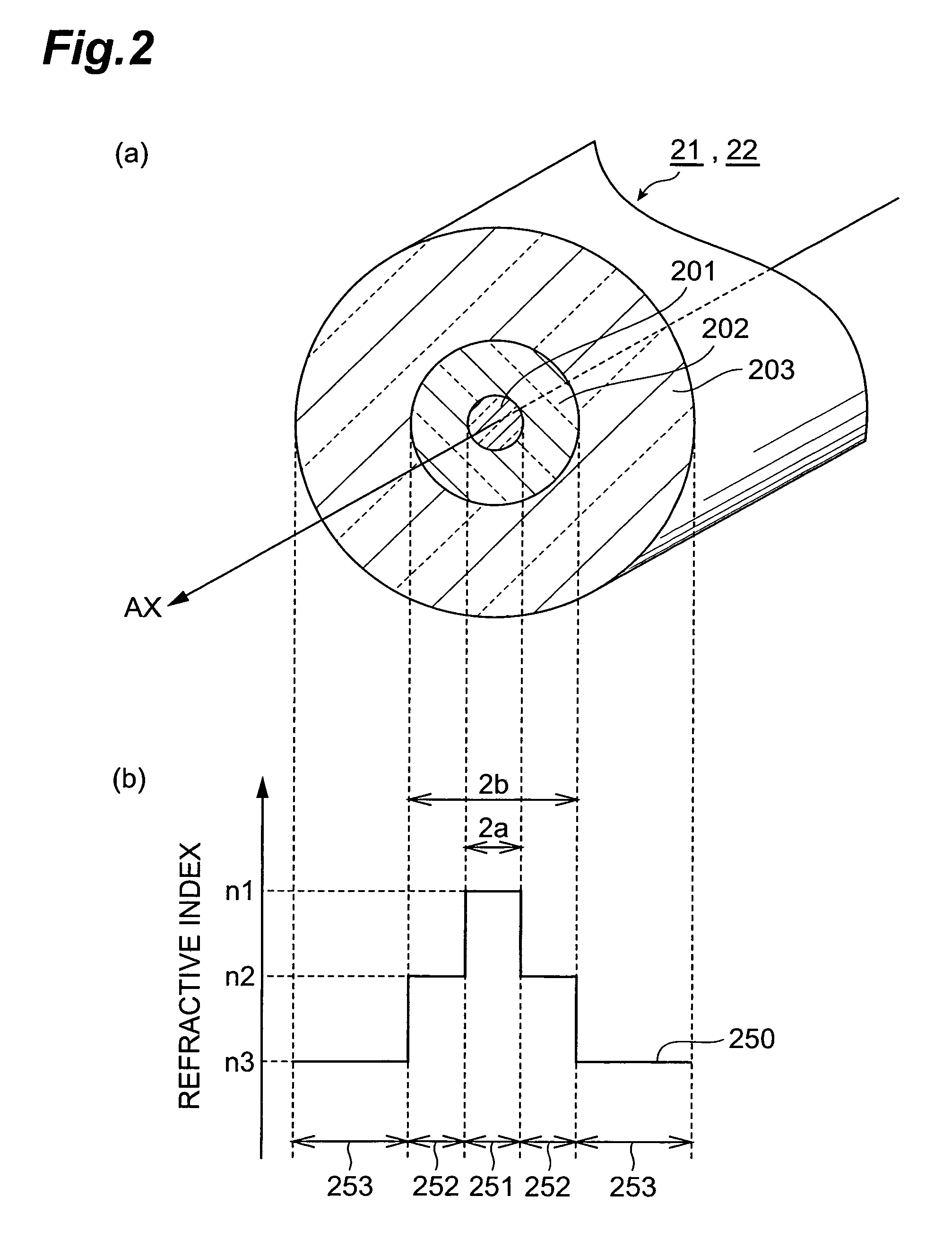

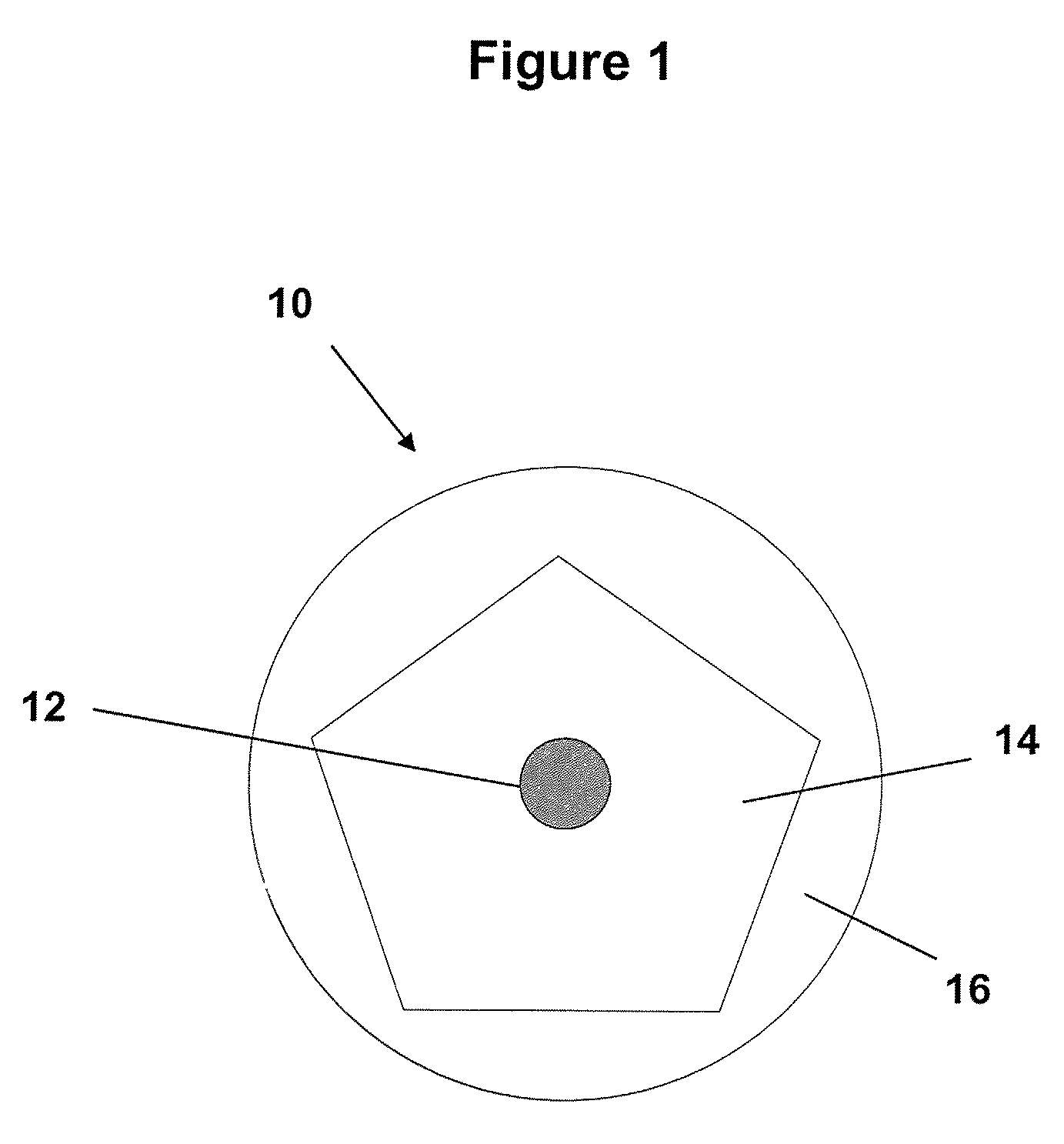

Rare earth-doped core optical fiber

InactiveUS20100067860A1Lower refractive indexSufficient powerLaser detailsOptical fibre with multilayer core/claddingRefractive indexRare earth

A rare earth-doped core optical fiber includes a core comprising a silica glass containing at least aluminum and ytterbium, a clad provided around the core and comprising a silica glass having a lower refraction index than that of the core, and a polymer layer provided on the outer circumference of the clad and having a lower refractive index than that of the clad, wherein aluminum and ytterbium are doped into the core such that a loss increase by photodarkening, TPD, satisfies the following inequality (A). By this rare earth-doped core optical fiber, it is possible to manufacture an optical fiber laser capable of maintaining a sufficient laser oscillation output even when used for a long period of time.TPD≧10{−0.655*(D<sub2>Al< / sub2>)−4.304*exp{−0.00343*(A<sub2>Yb< / sub2>)}+1.274} (A)

Owner:THE FUJIKURA CABLE WORKS LTD

Light emitting devices with phosphosilicate glass

ActiveUS8270445B2Reduce impactLaser using scattering effectsActive medium materialDopantSilicate glass

A light-emitting device is provided which includes a gain medium having an optically-active phosphosilicate glass, wherein the phosphosilicate glass includes at least one active ion dopant and from about 1 to 30 mol % of phosphorus oxide. The phosphorous oxide may be present in an effective amount for reducing any photodarkening effect and increasing the saturation energy of the system. The active ion dopant may be a rare earth dopant. The light-emitting device may include an optical waveguide, the optical waveguide including the gain medium. The optical waveguide may have a core and at least one cladding, and the gain medium having the phosphosilicate glass may be found in the core and / or in one of the cladding.

Owner:CORACTIVE HIGH TECH

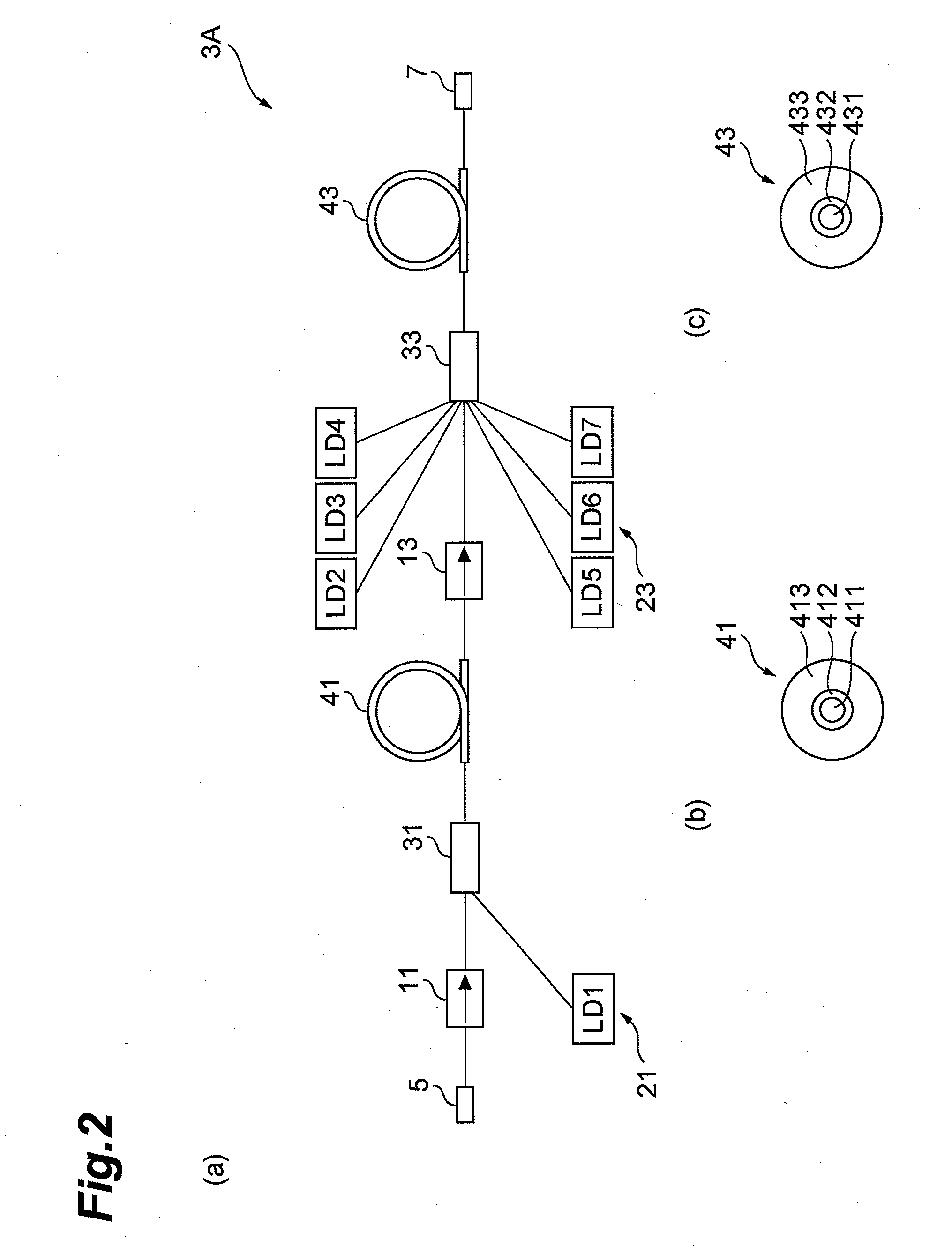

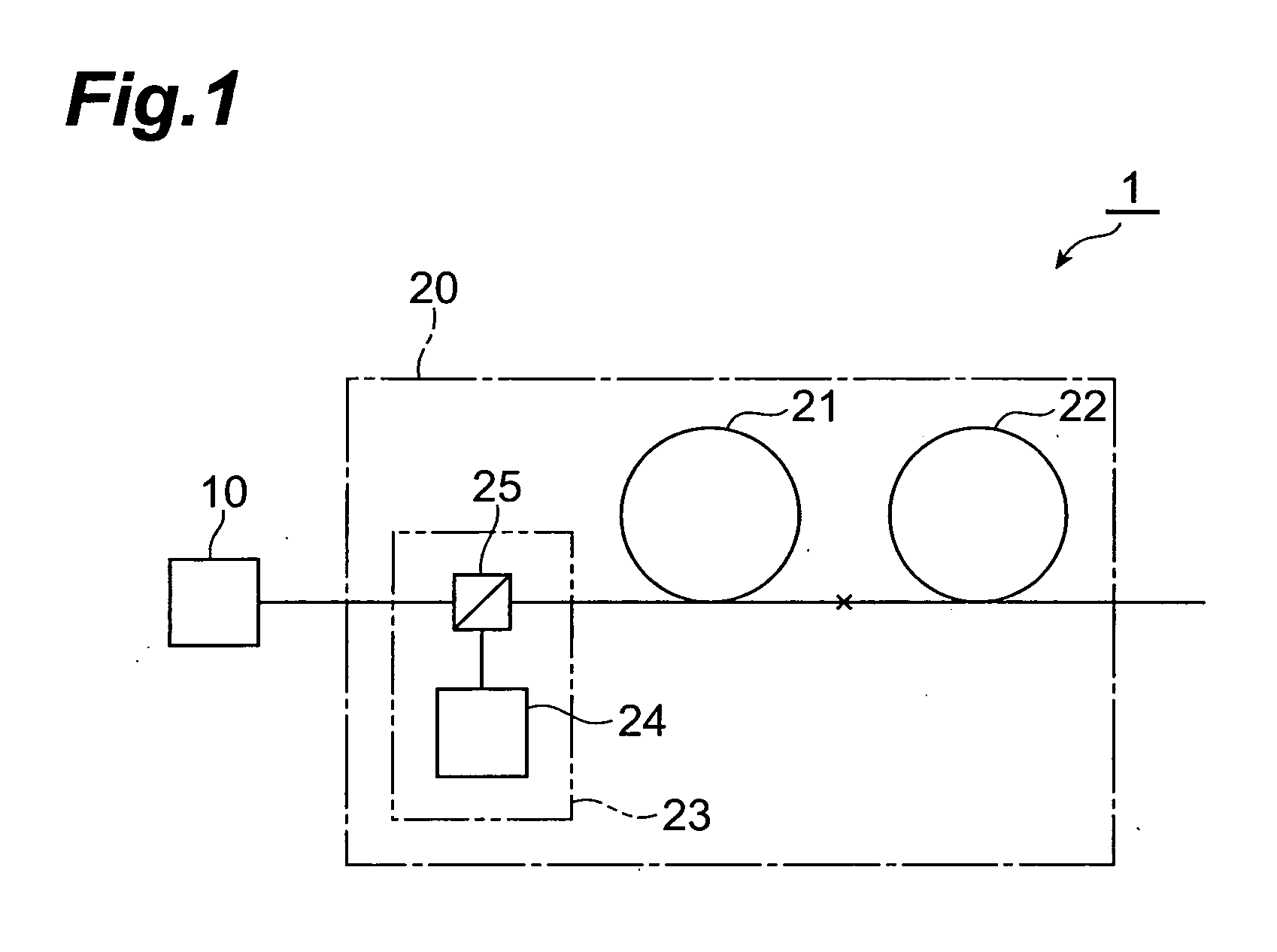

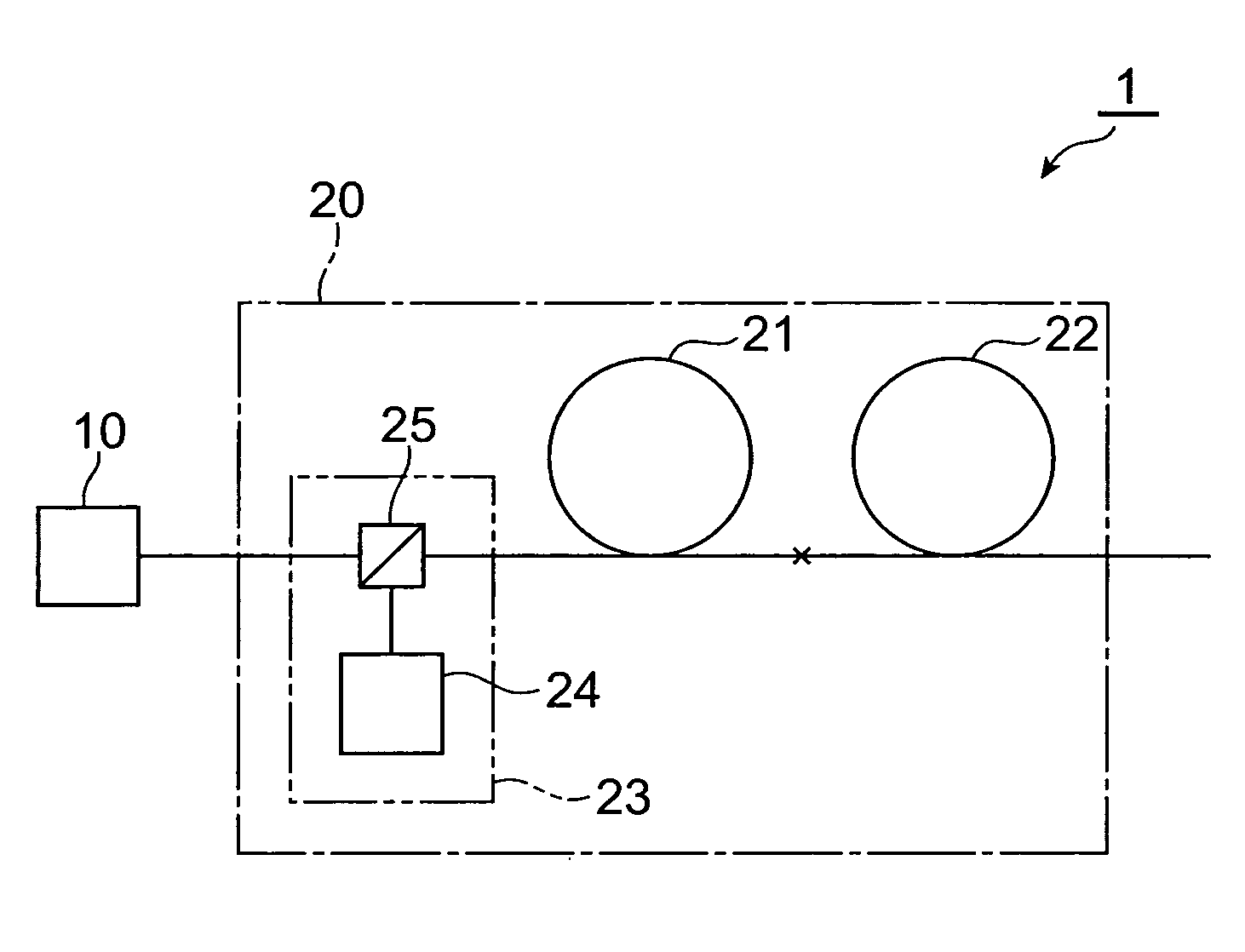

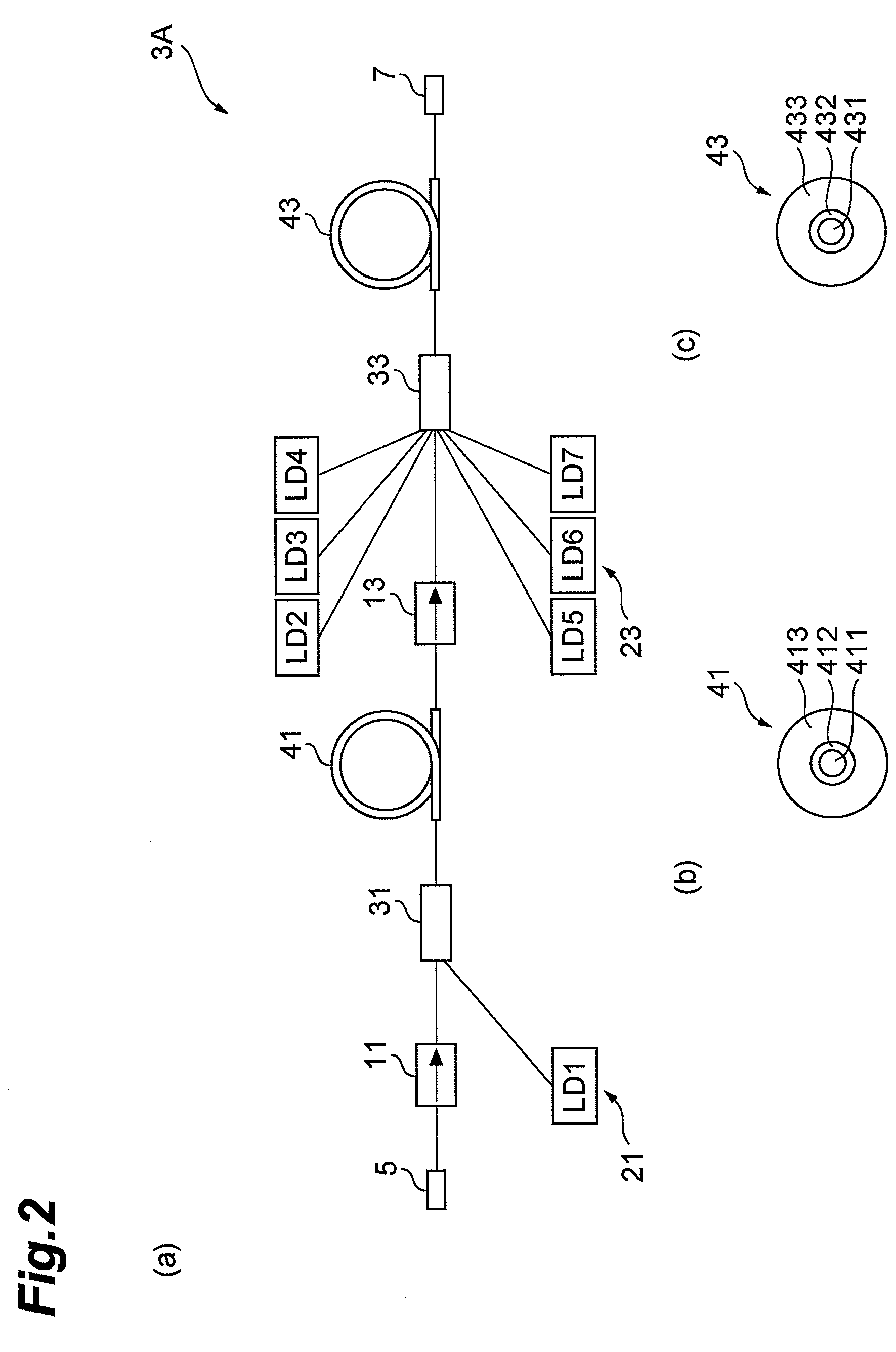

Optical amplification module and laser light source apparatus

InactiveUS20090274183A1Inhibition is effectiveEfficient optical amplificationExcitation process/apparatusActive medium materialAudio power amplifierLaser light

The present invention relates to an optical amplifier module, or the like, having a structure for enabling effective suppression of photodarkening and efficient optical amplification. The optical amplifier module comprises a first optical amplification waveguide which is comprised of a phosphate glass as a main component and includes a ytterbium-doped first optical waveguide region, a second optical amplification waveguide which is optically coupled to the first optical amplification waveguide and includes a ytterbium-doped second optical waveguide region which is co-doped with aluminum, and pumping light source units which supply pumping light respectively to the first optical amplification waveguide and the second optical amplification waveguide. The light to be amplified, having inputted to the first optical amplification waveguide, is amplified only once by means of the pumping light, in each of the first optical amplification waveguide and the second optical amplification waveguide.

Owner:MEGAOPTO

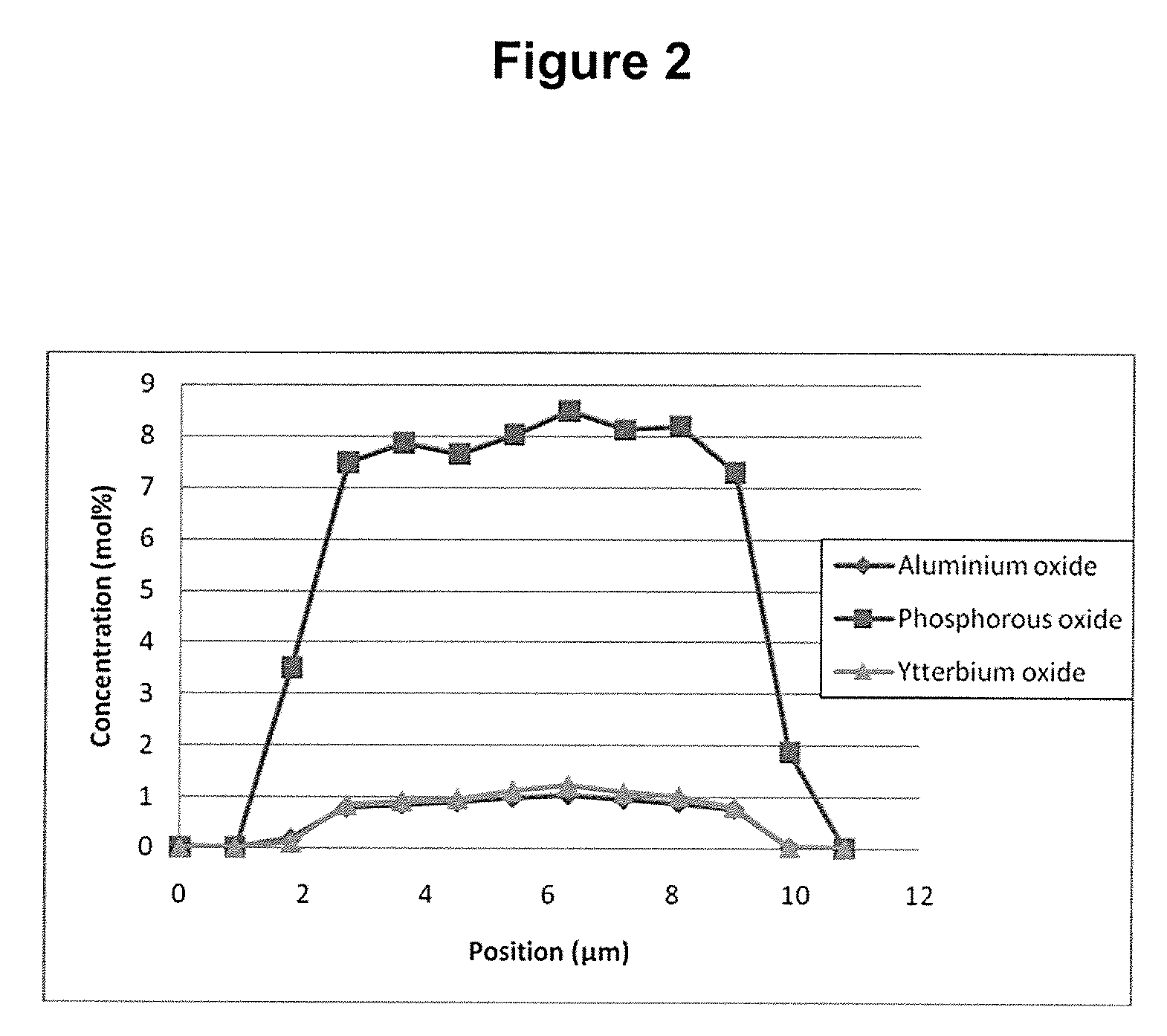

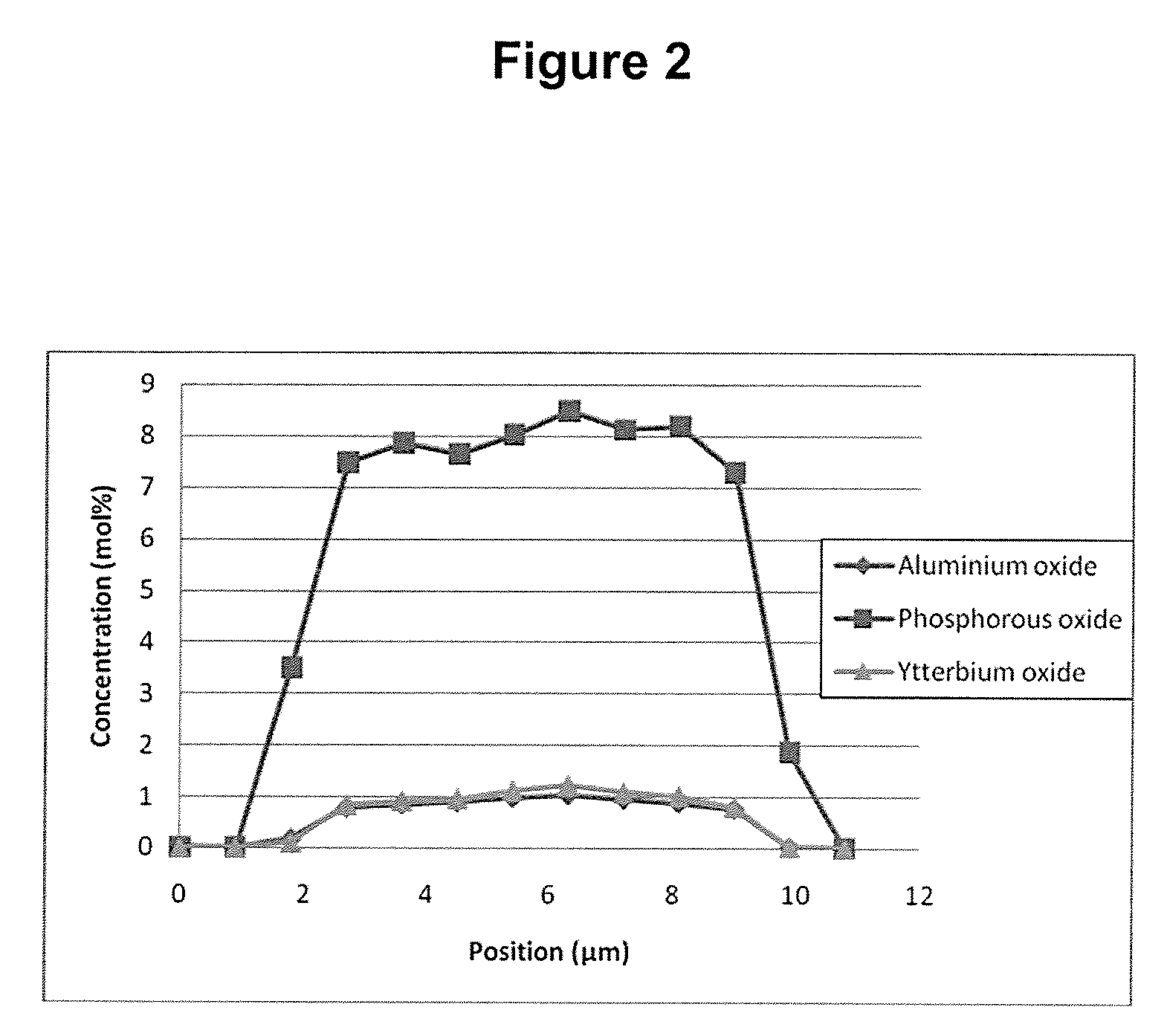

Optically active glass and optical fiber with reduced photodarkening and method for reducing photodarkening

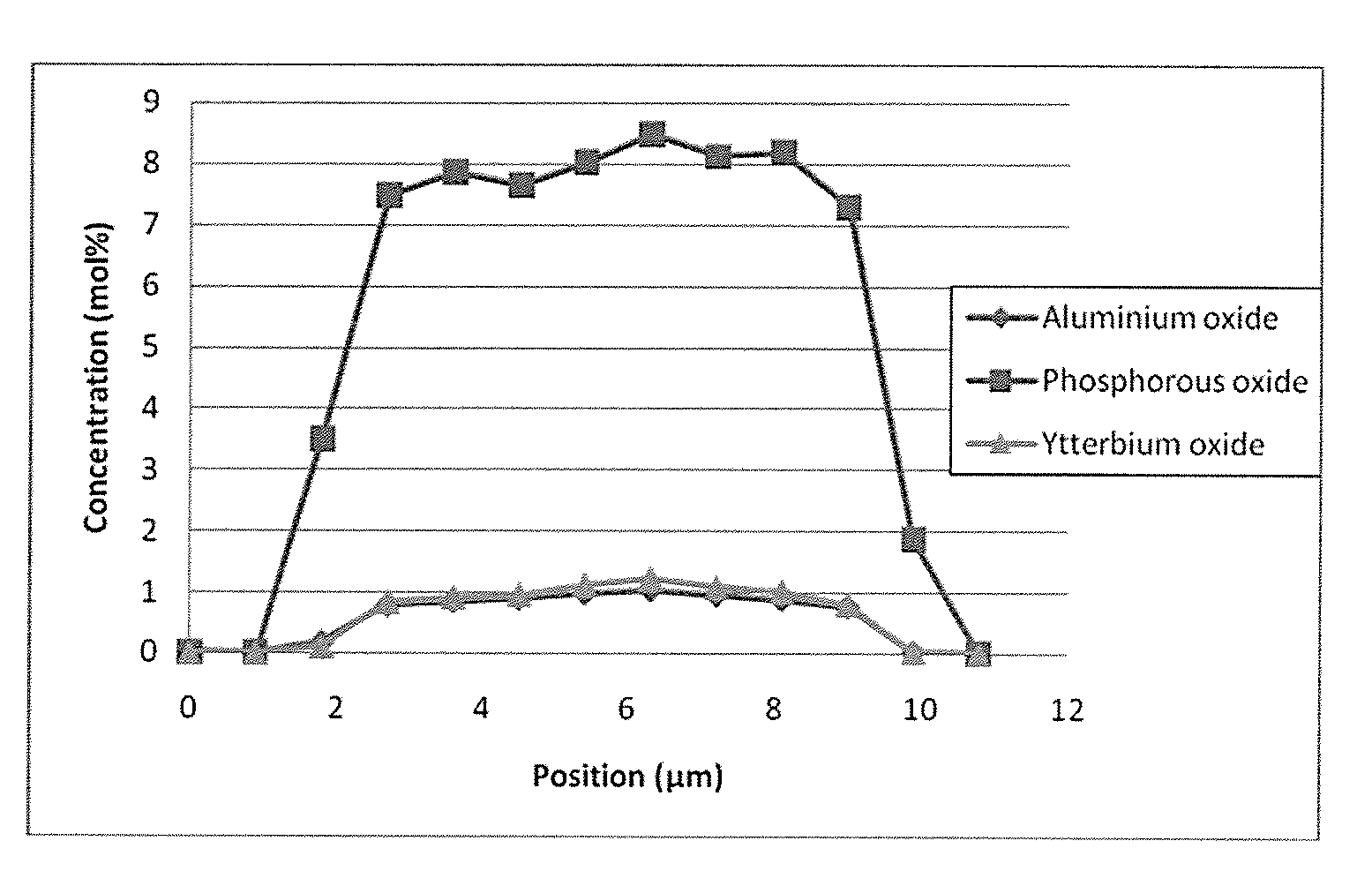

ActiveUS20090011233A1Reduced photodarkening propertyReduce impactGlass making apparatusGlass/slag layered productsOptical propertySilicon dioxide

An optically active glass and an optical fiber comprising such glass, having reduced photodarkening properties are provided. The optically active glass is mainly composed of silica representing from about 50 to 98 mol % of the glass. It also includes at least one active ion, such as a rear-earth ion, which induces a photodarkening effect in optical properties of the glass. Moreover, the glass includes an effective amount of phosphorus oxide providing the photodarkening reducing effect, preferably in an amount of from about 1 to 30 mol %. A method for reducing a photodarkening effect in optical properties of an optically active glass including the step of introducing phosphorus oxide to the glass is also provided.

Owner:CORACTIVE HIGH TECH

Light emitting devices with phosphosilicate glass

ActiveUS20100202481A1Reducing photodarkening effectReduce impactLaser using scattering effectsActive medium materialRare earthWaveguide

A light-emitting device is provided which includes a gain medium having an optically-active phosphosilicate glass, wherein the phosphosilicate glass includes at least one active ion dopant and from about 1 to 30 mol % of phosphorus oxide. The phosphorous oxide may be present in an effective amount for reducing any photodarkening effect and increasing the saturation energy of the system. The active ion dopant may be a rare earth dopant. The light-emitting device may include an optical waveguide, the optical waveguide including the gain medium. The optical waveguide may have a core and at least one cladding, and the gain medium having the phosphosilicate glass may be found in the core and / or in one of the cladding

Owner:CORACTIVE HIGH TECH

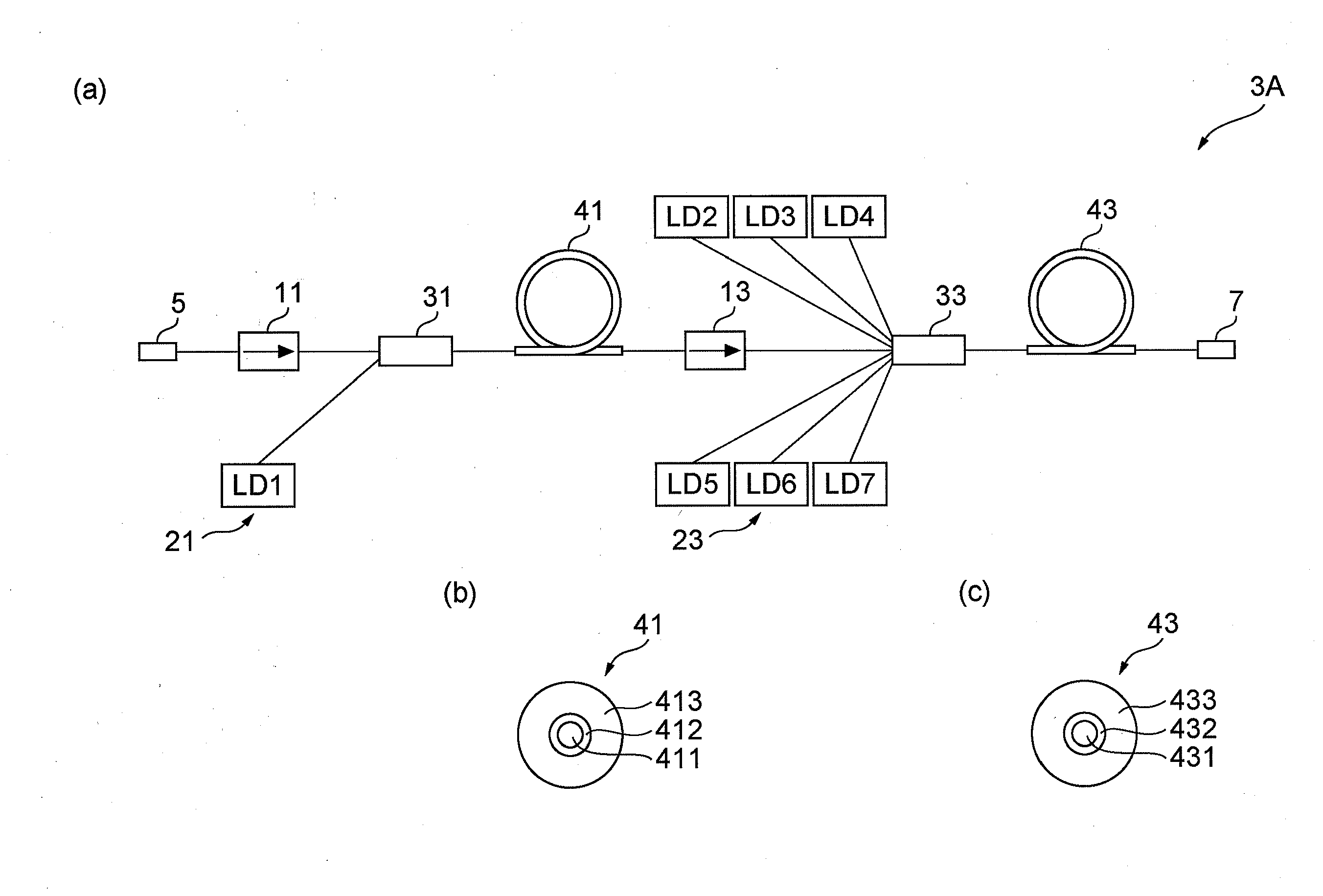

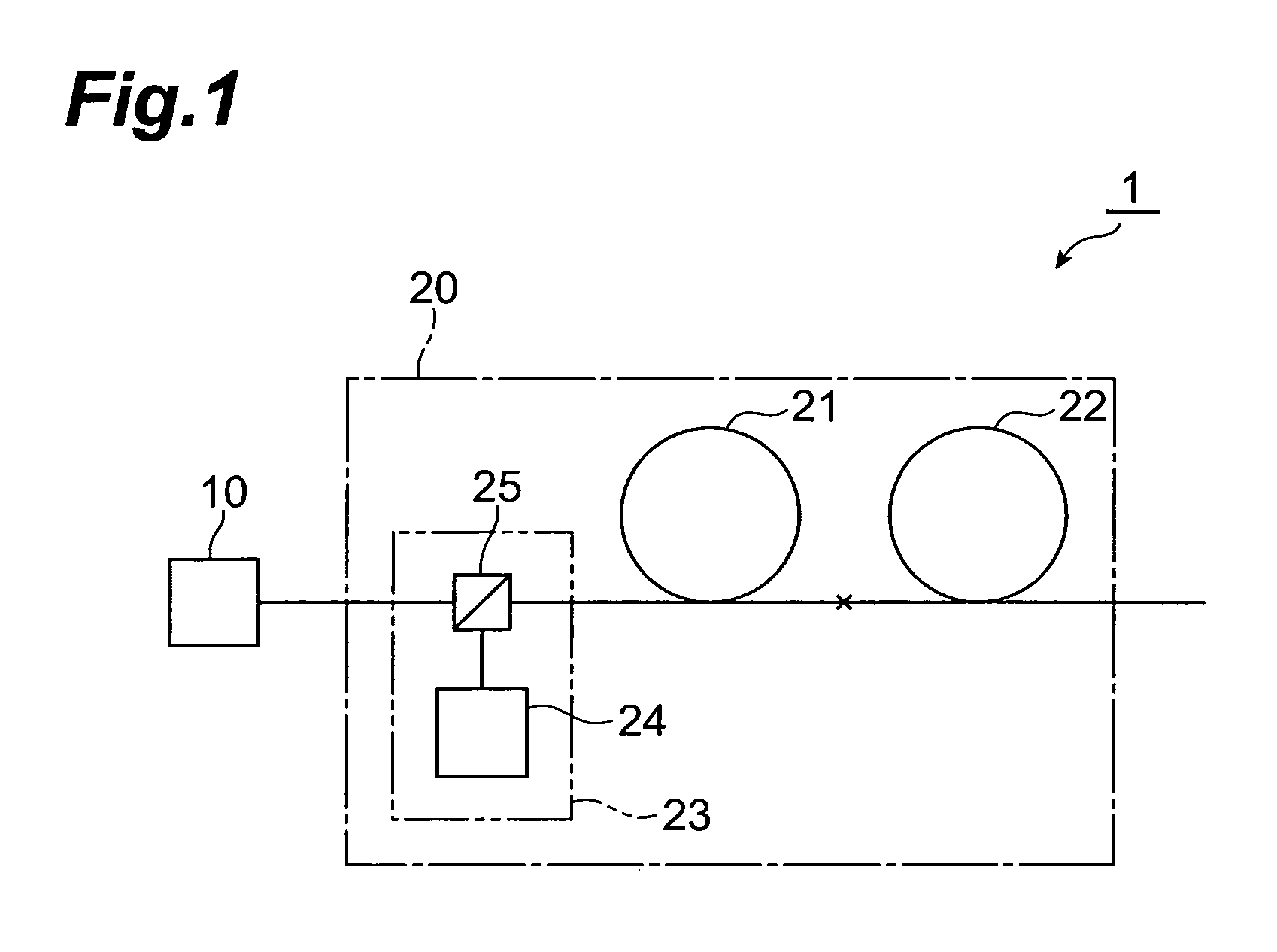

Optical amplification module and laser light source including the same

InactiveUS20070171516A1Avoid low lightIncreasing loss of the optical fiber itselfLaser using scattering effectsFibre transmissionHigh concentrationRare-earth element

The present invention relates to an optical amplification module having a construction which effectively suppresses photodarkening, and to a laser light source including the same. The laser light source comprises a light source for outputting light to be amplified, and an optical amplification module. The optical amplification module comprises two types of optical amplification media having different rare earth element concentrations, and a pumping light source. The low concentration medium and the high concentration medium are disposed in the propagation direction of pumping light such that the population inversion of the low concentration medium is higher than that of the high concentration medium. Hence, by arranging two types of optical amplification media with different rare earth concentrations such that the population inversion of the low concentration medium is higher than that of the high concentration medium, sufficient overall gain of the laser light source can be obtained while effectively suppressing photodarkening in the two types of optical amplification media.

Owner:MEGAOPTO

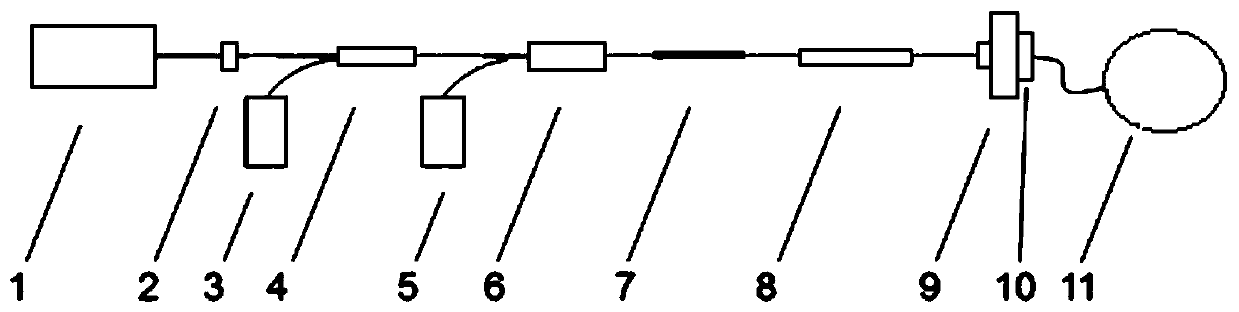

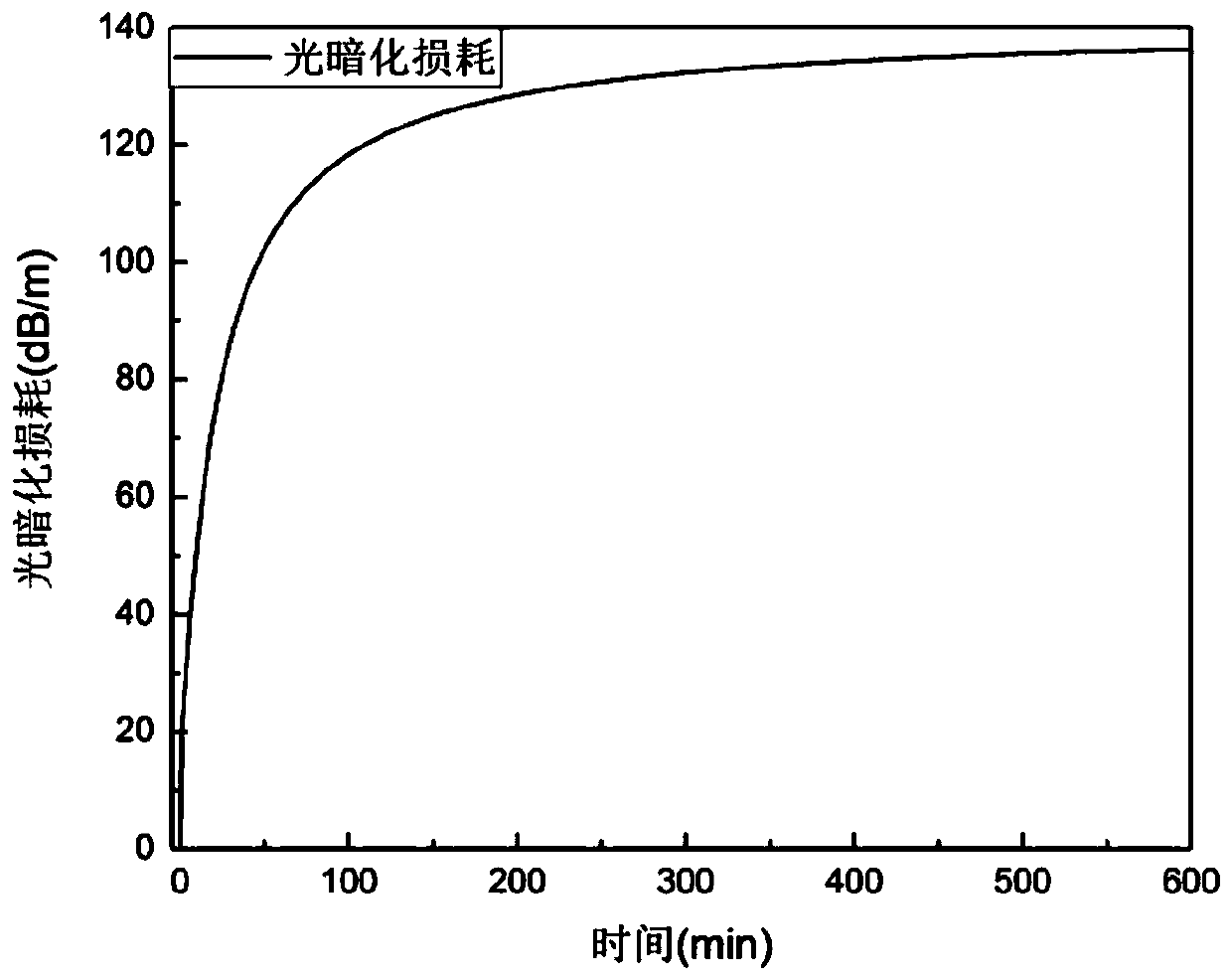

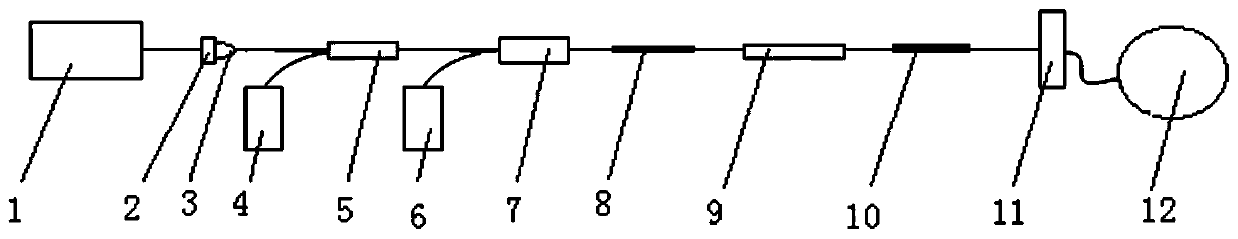

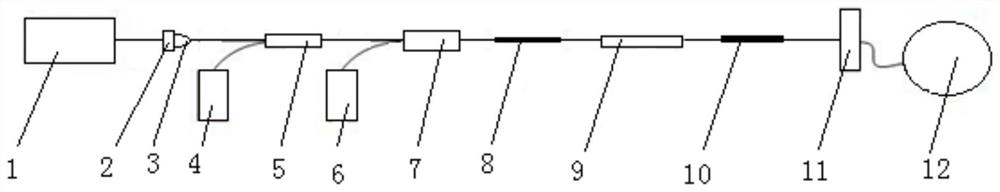

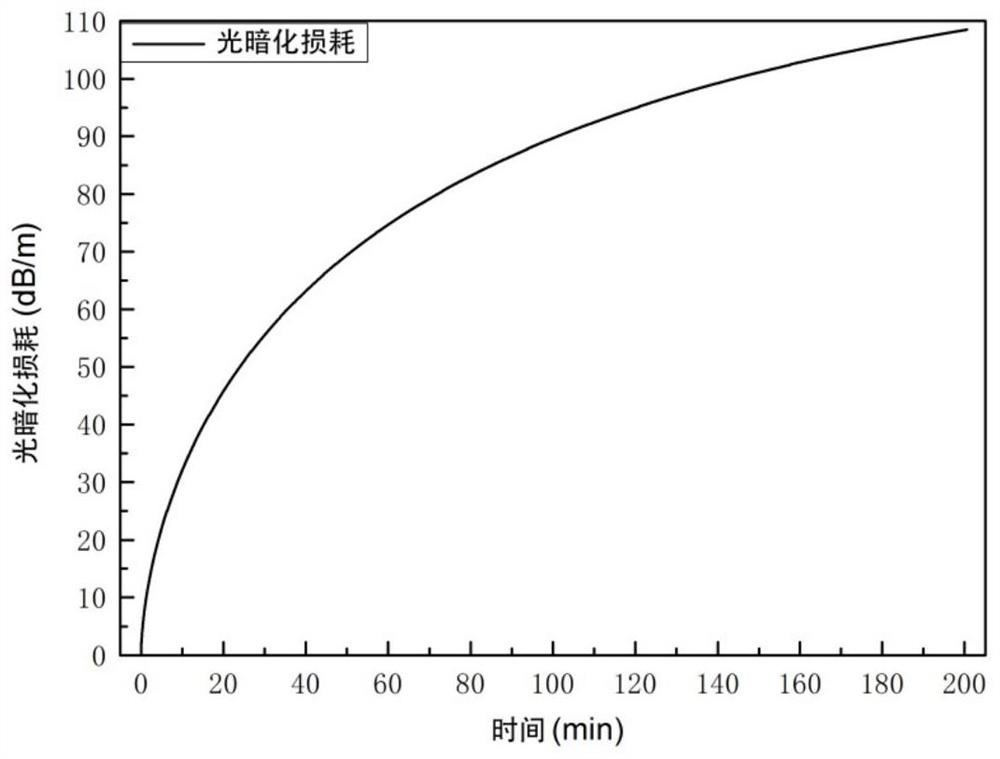

Ytterbium-doped silica fiber light darkening test device and method

InactiveCN110987368AGood optical stabilityHigh ion reversal rateTesting optical propertiesMultiplexerPower detector

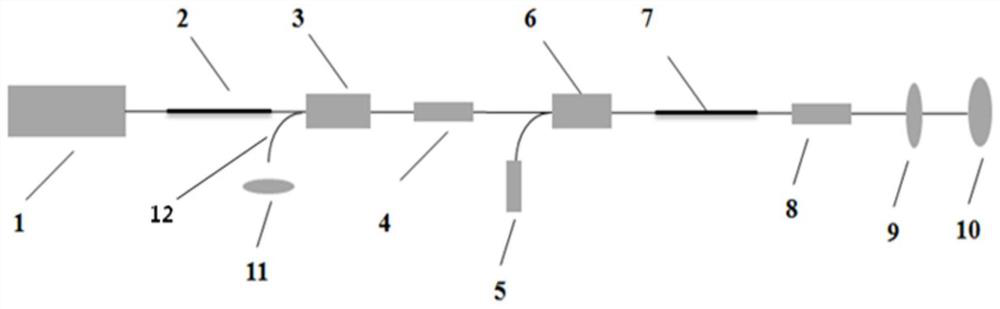

The invention discloses a ytterbium-doped silica fiber light darkening test device and method. The device comprises a signal source, an optical fiber flange, a pumping source, a wavelength division multiplexer, an ytterbium-doped fiber, an optical fiber beam combiner and a power detector, and laser output by the signal source passes through the optical fiber flange and then is combined with pumping light output by a first pumping source through the wavelength division multiplexer to form combined light. The combined light and the pump light output by the second pump source are respectively input through the signal end and the pump end of the optical fiber beam combiner. The output light of the optical fiber beam combiner is transmitted along the ytterbium-doped optical fiber, the output end of the ytterbium-doped optical fiber is welded with the input end of the cladding light stripper, and the output light beam of the cladding light stripper enters the power detector through the filter. The device has the beneficial effects that the ion inversion rate in the light darkening test is higher, the time for testing the light darkening loss is shorter, and the precision of the tested light darkening loss is higher. The structure is simple and compact, and the test stability is better. Different pumping injection modes are adopted, and the light darkening performance under several test conditions is compared.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

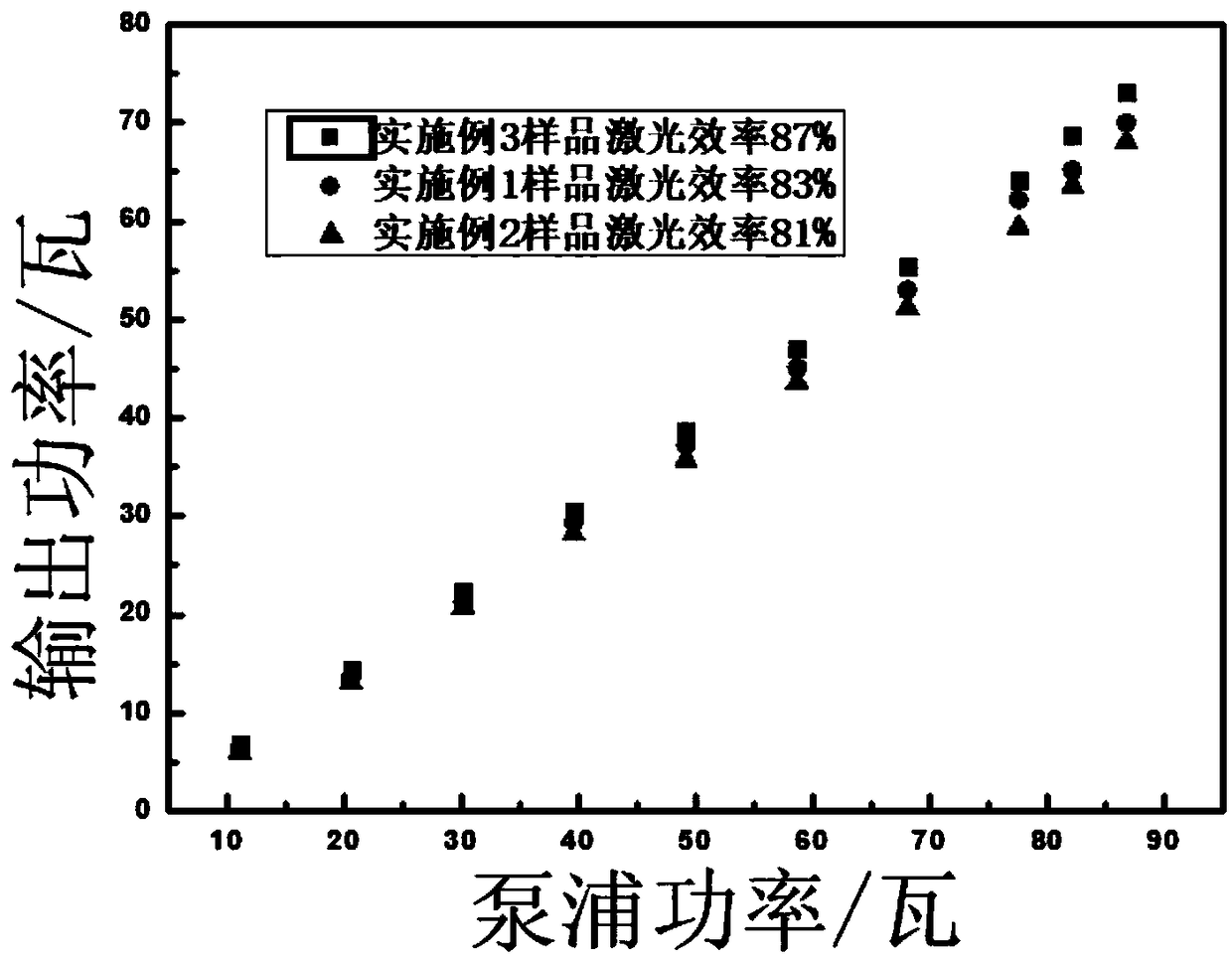

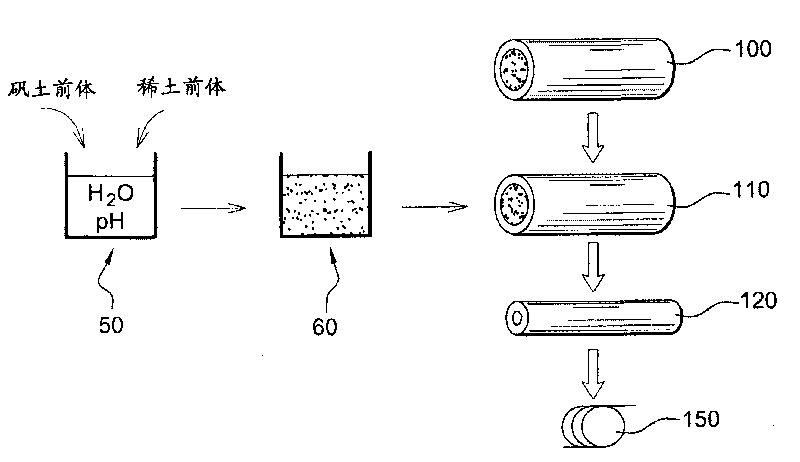

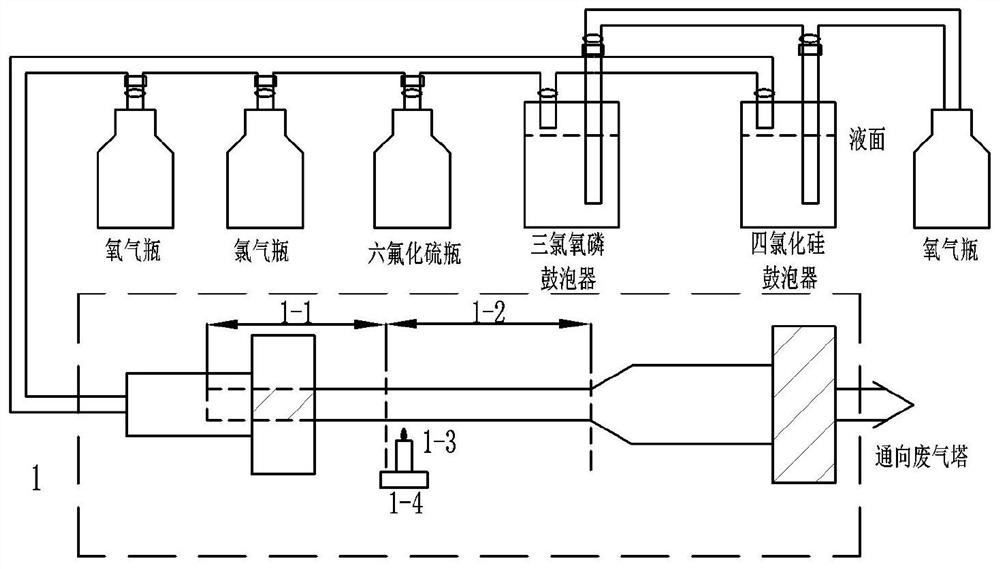

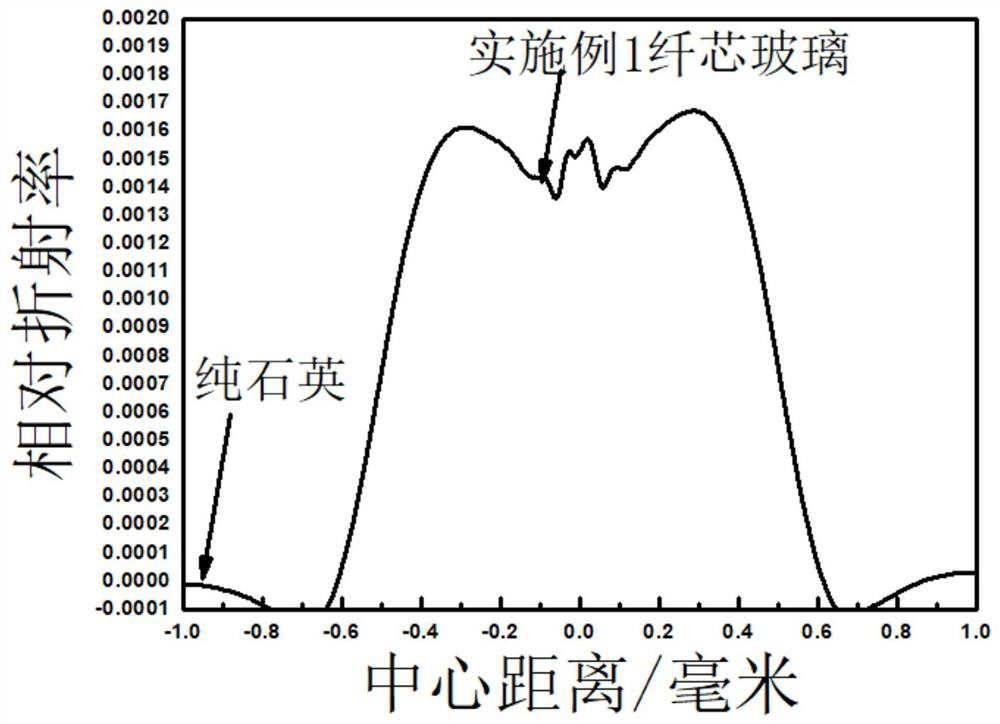

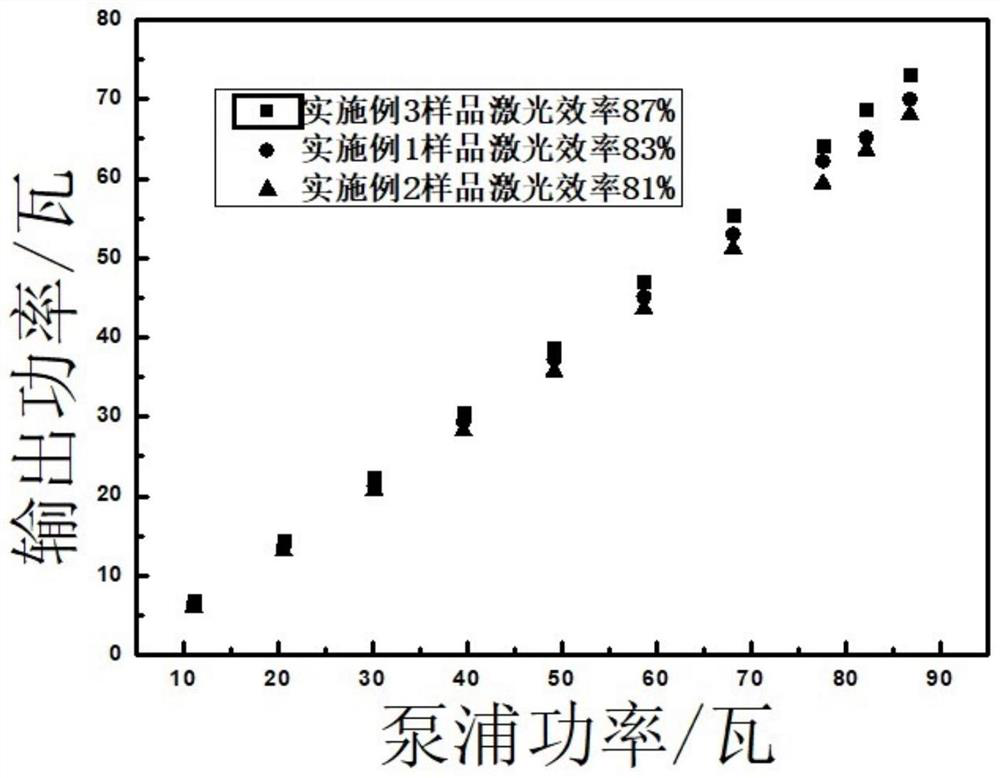

Anti-photodarkening ytterbium-doped quartz optical fiber and preparation method thereof

The invention relates to an anti-photodarkening ytterbium-doped quartz optical fiber and a preparation method thereof. According to the anti-photodarkening ytterbium-doped quartz optical fiber, glassof an optical fiber core rod is at least prepared from Yb2O3, Al2O3, P2O5 and SiO2, wherein the ratio of the Yb2O3 in the whole substance is 0.05-0.3 mol%, the ratio of the Al2O3 in the whole substance is 1-3 mol%, and the ratio of the P2O5 in the whole substance is 1-5 mol%. According to the preparation method for the anti-photodarkening ytterbium-doped quartz optical fiber, a sol-gel method andan improved chemical vapor deposition method are combined, the molecular-level doping uniformity and the low-loss preparation advantages are utilized, ytterbium ions, aluminum ions and phosphorus ionsare effectively doped in a quartz matrix, and therefore the problem of high optical fiber loss, photodarkening caused by the reasons such as cluster and refractive index center depression can be effectively solved.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Optical amplification module and laser light source designed to suppress photodarkening

InactiveUS7532391B2Avoid low lightIncreasing loss of the optical fiber itselfLaser using scattering effectsFibre transmissionHigh concentrationRare-earth element

The present invention relates to an optical amplification module having a construction which effectively suppresses photodarkening, and to a laser light source including the same. The laser light source comprises a light source for outputting light to be amplified, and an optical amplification module. The optical amplification module comprises two types of optical amplification media having different rare earth element concentrations, and a pumping light source. The low concentration medium and the high concentration medium are disposed in the propagation direction of pumping light such that the population inversion of the low concentration medium is higher than that of the high concentration medium. Hence, by arranging two types of optical amplification media with different rare earth concentrations such that the population inversion of the low concentration medium is higher than that of the high concentration medium, sufficient overall gain of the laser light source can be obtained while effectively suppressing photodarkening in the two types of optical amplification media.

Owner:MEGAOPTO

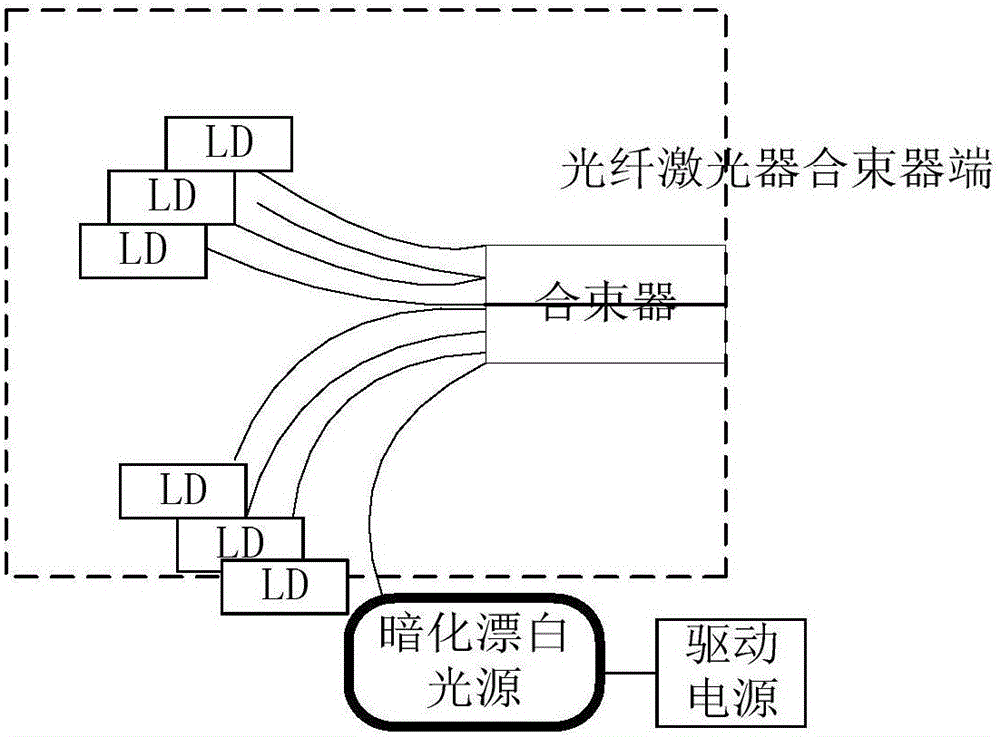

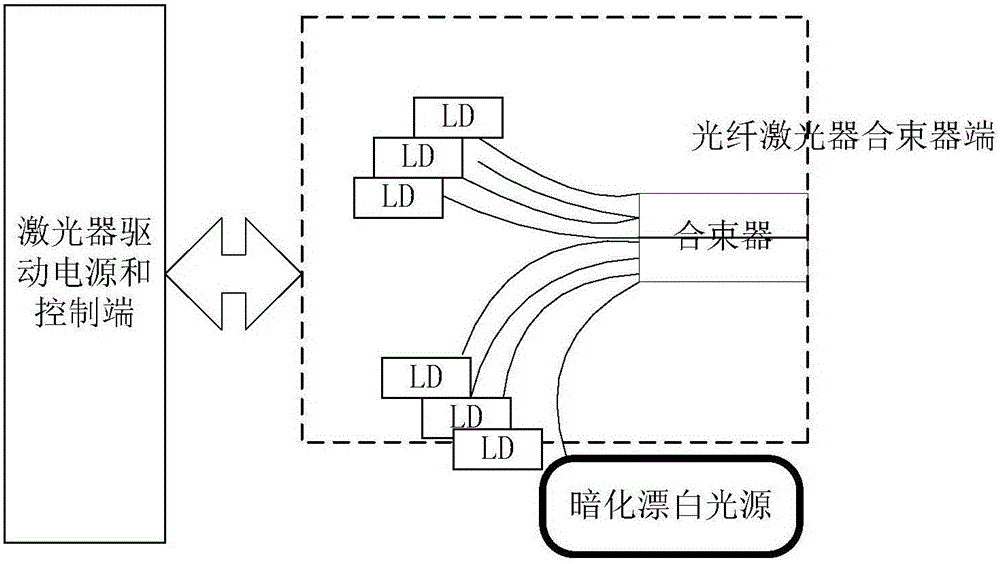

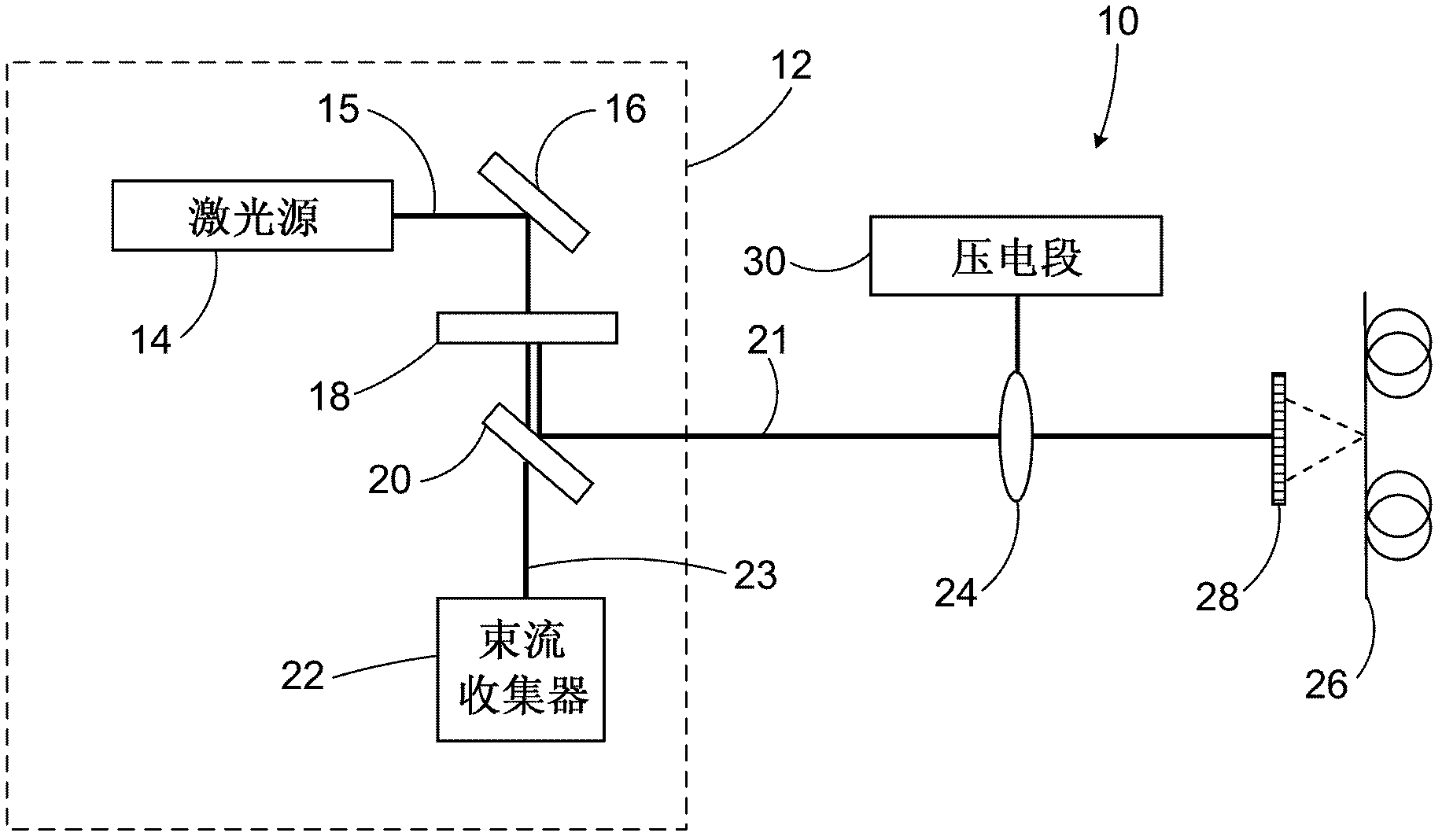

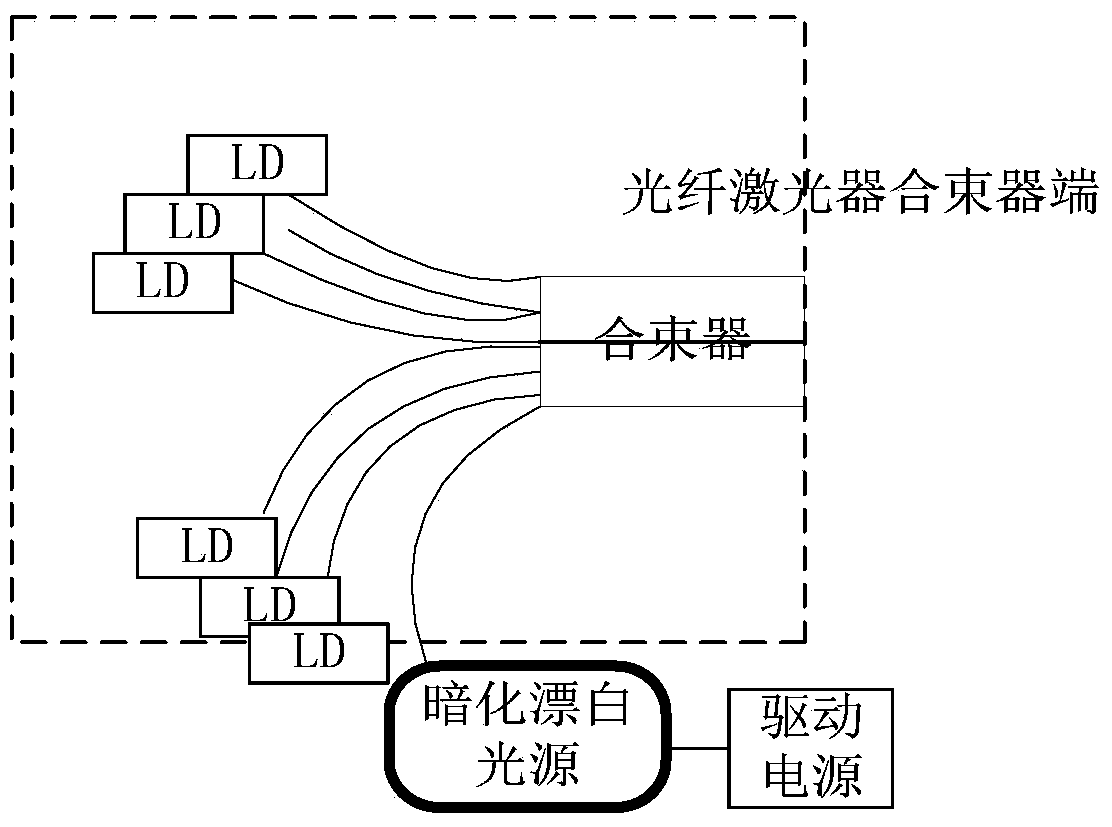

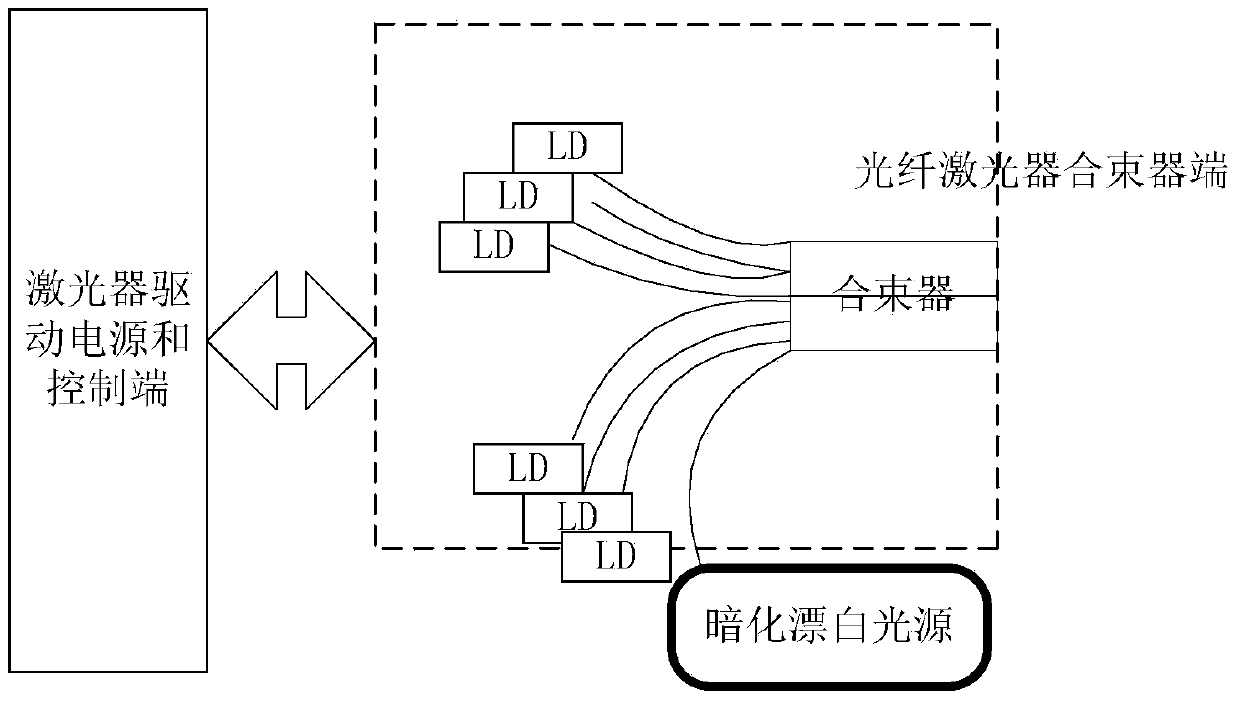

Darkening bleaching device and method based on fiber laser darkening maintenance

ActiveCN104993369AImprove stabilityImprove adaptabilityActive medium shape and constructionEngineeringPhotodarkening

The invention discloses a photodarkening bleaching device, so as to solve the problem that at present a photodarkening phenomenon lacks intervention in a ytterbium-doped fiber laser running process. The photodarkening bleaching device includes a darkening bleaching light source and a driving power supply thereof. A darkening bleaching device is added to the inside of a ytterbium-doped fiber laser, a main body structure of the fiber laser is not changed, and high applicability is achieved. The device provided by the invention is particularly suitable for performing bleaching on fiber laser darkening periodically in working, promotes stability of power in a using process of the fiber laser, slows down a photodarkening process of the laser, and prolongs the service life of the laser.

Owner:HUAZHONG UNIV OF SCI & TECH

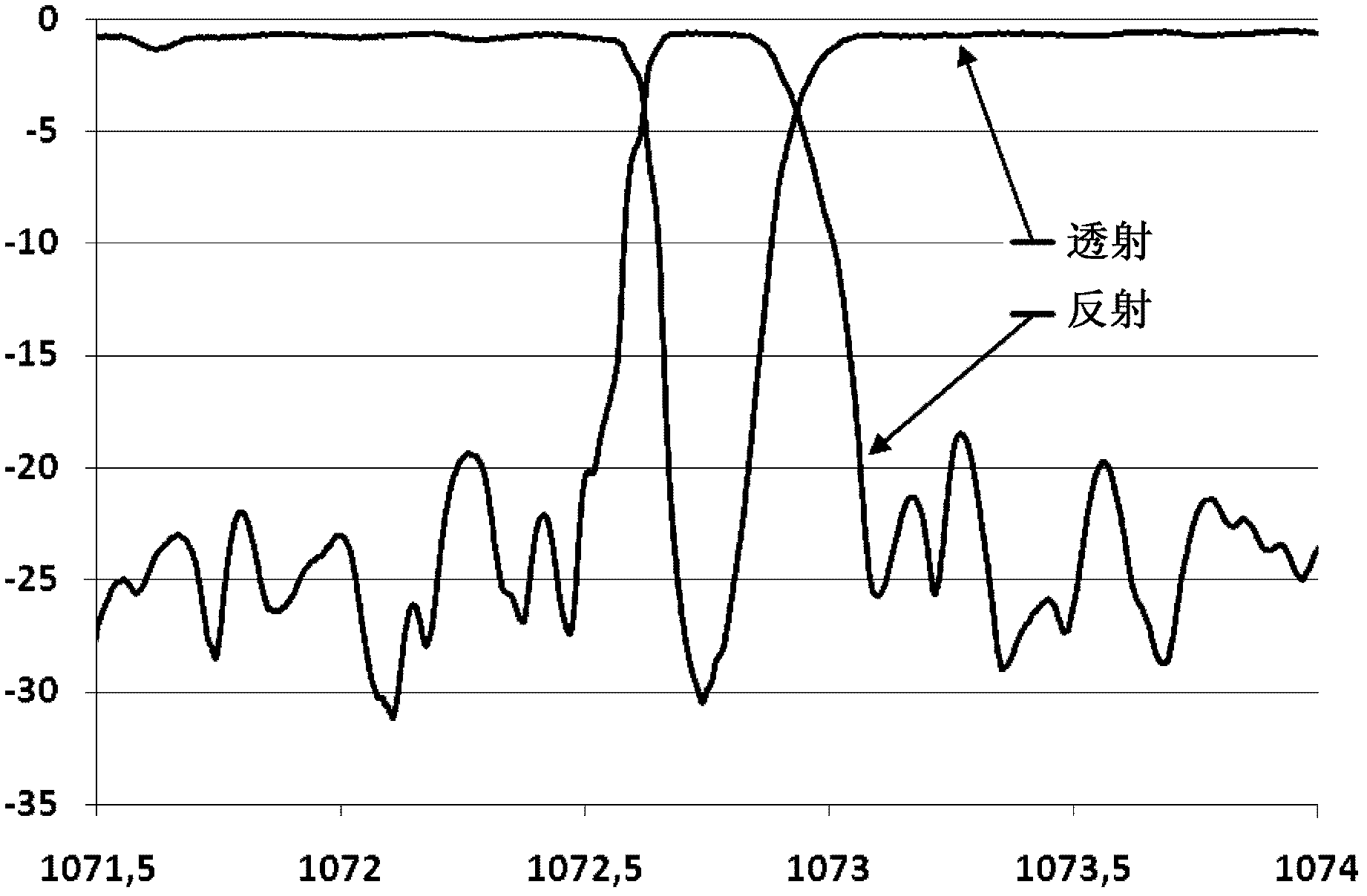

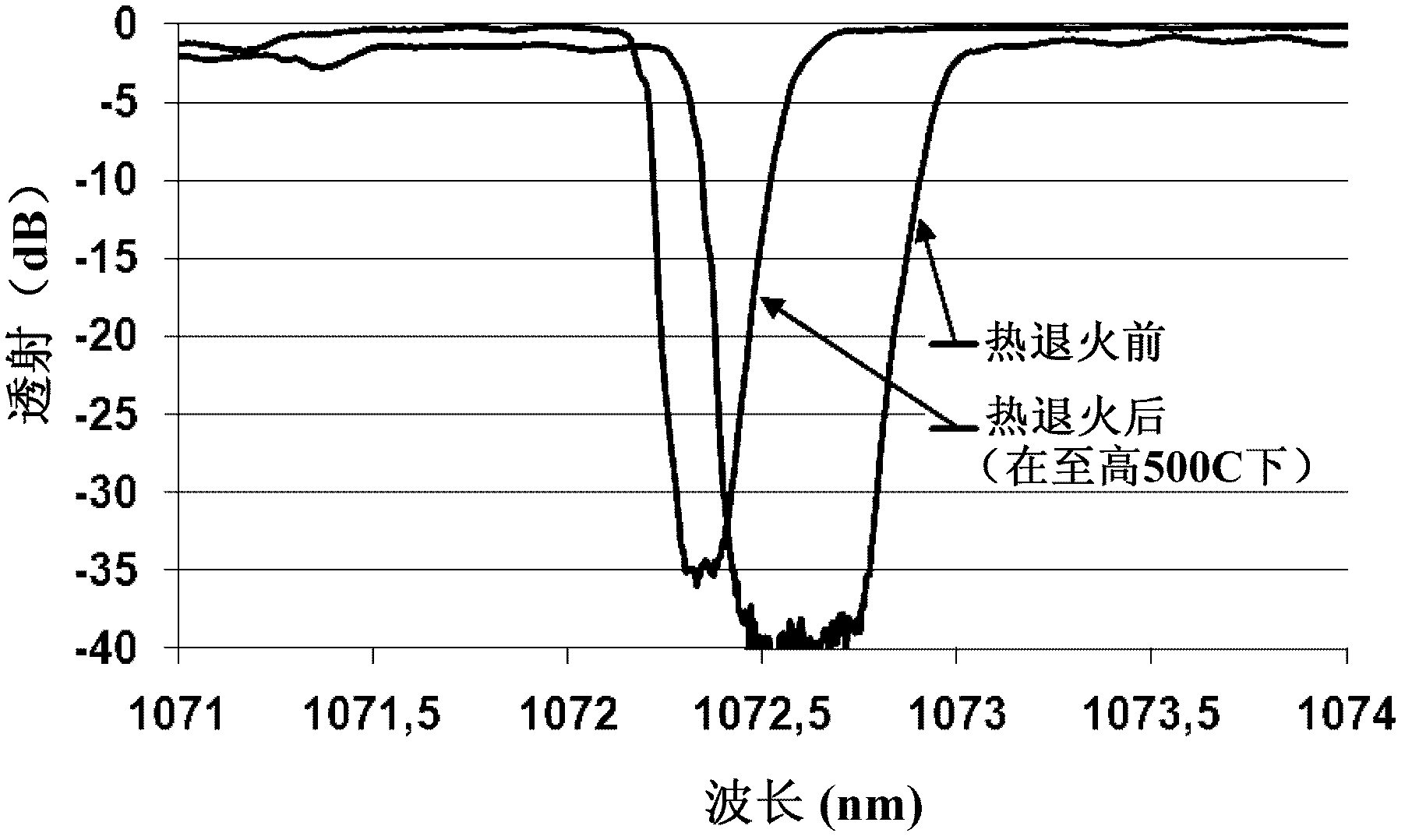

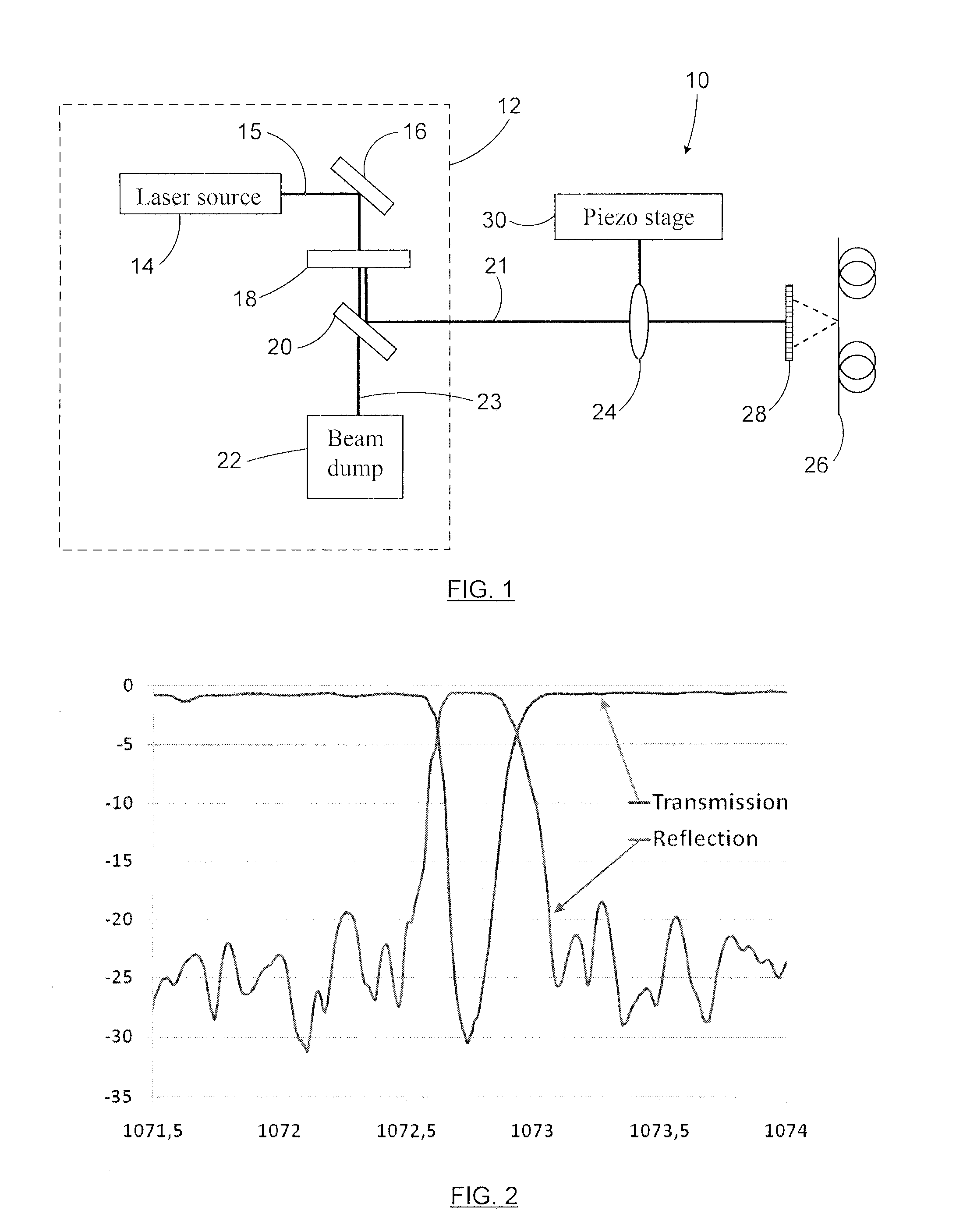

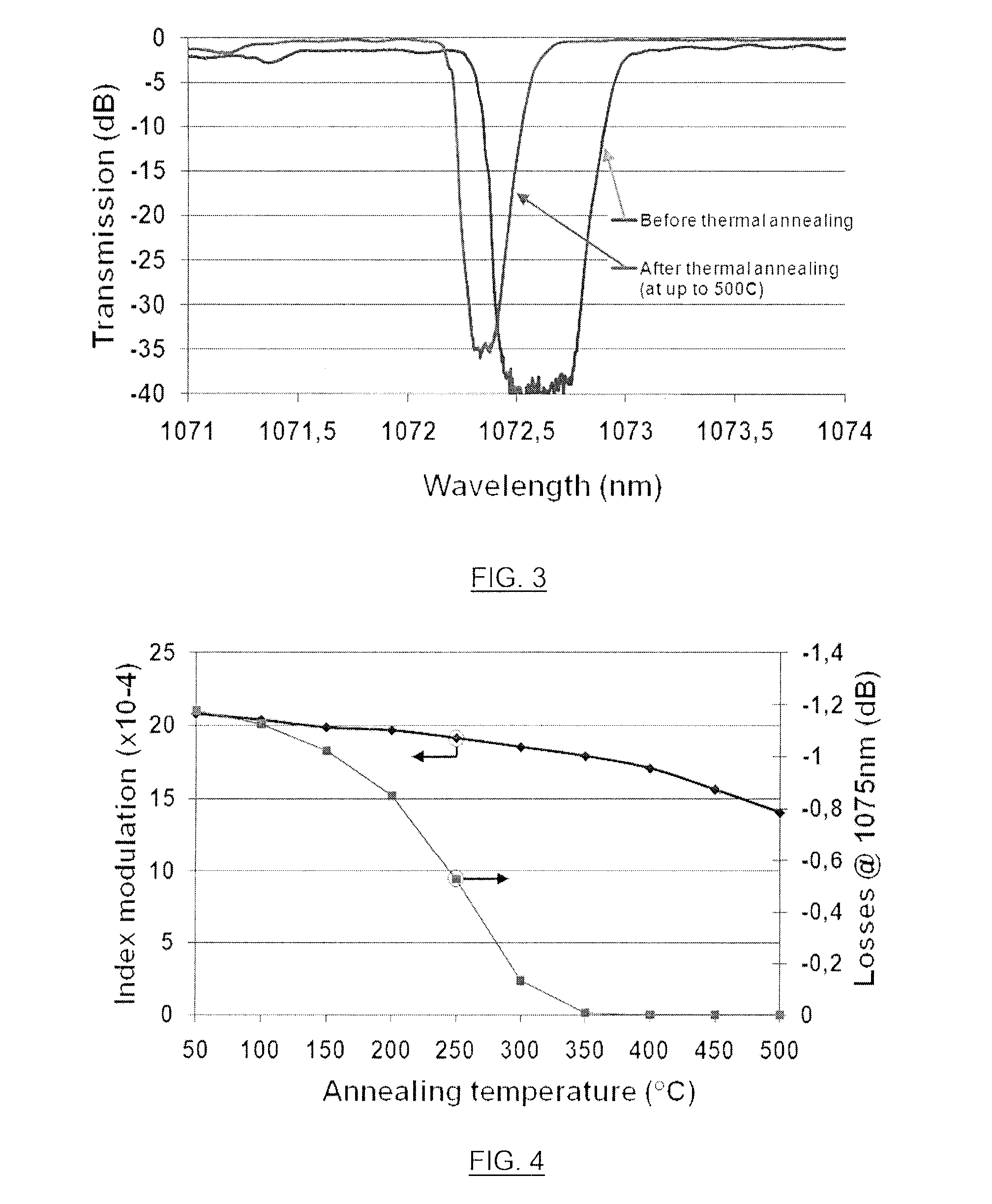

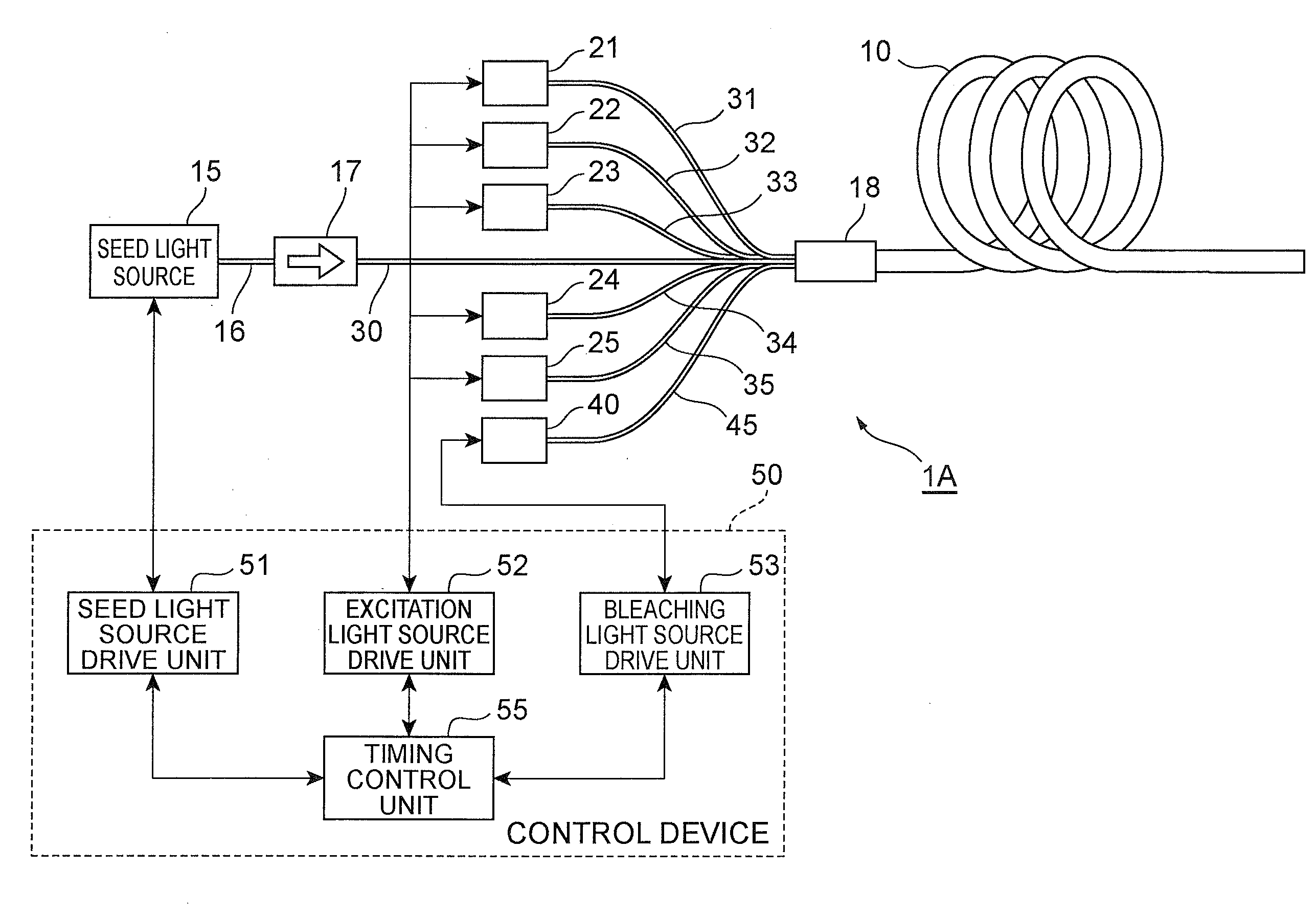

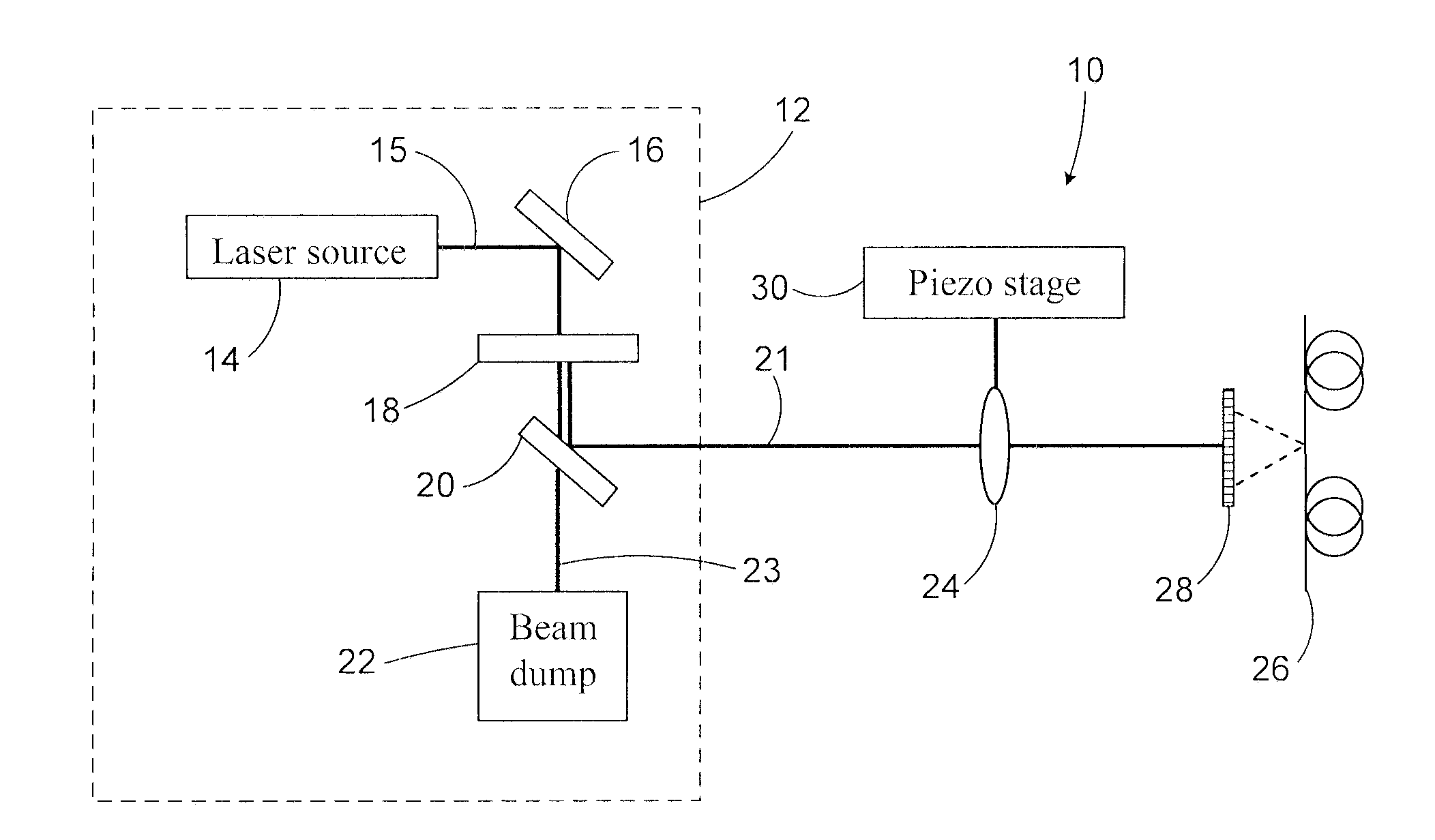

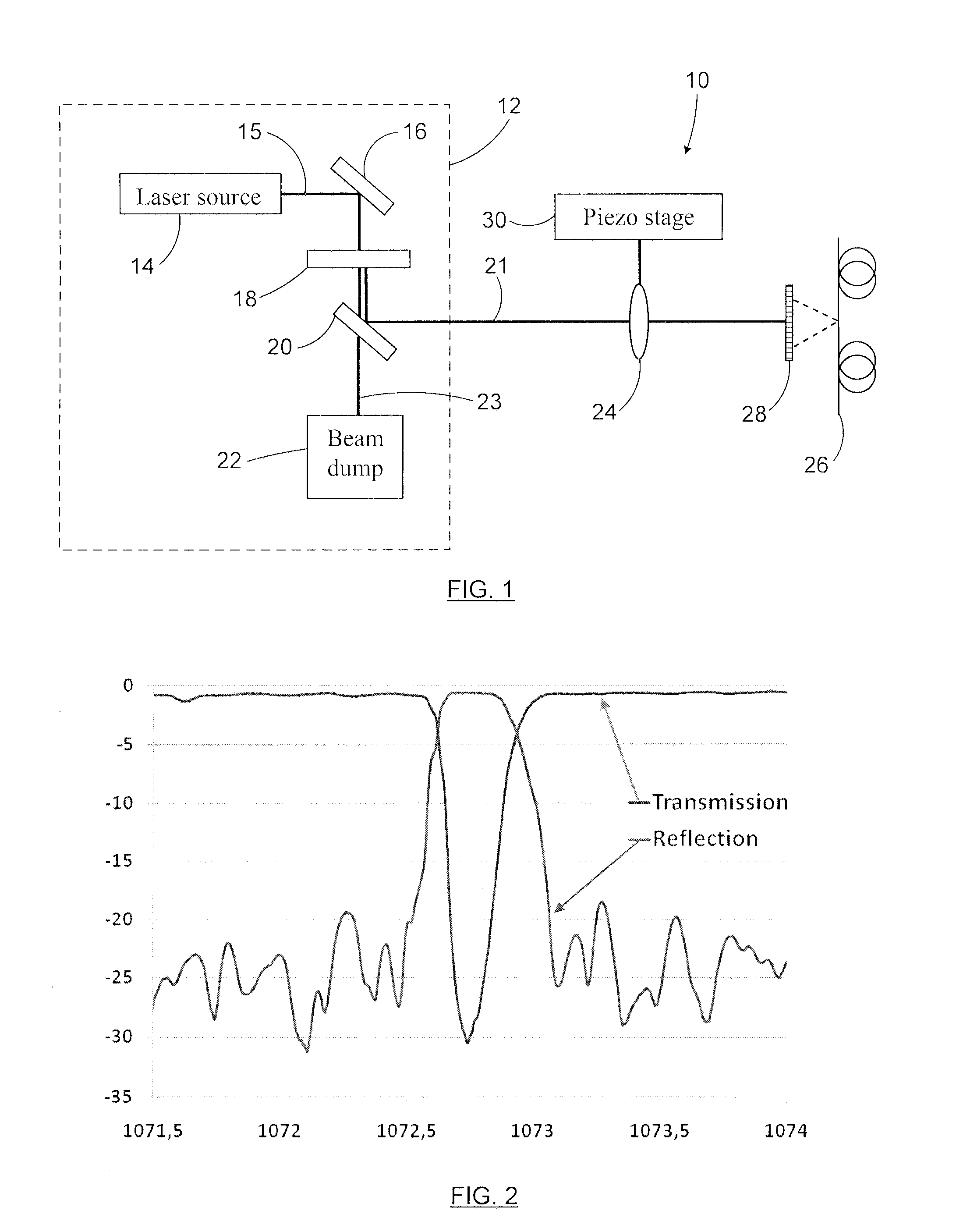

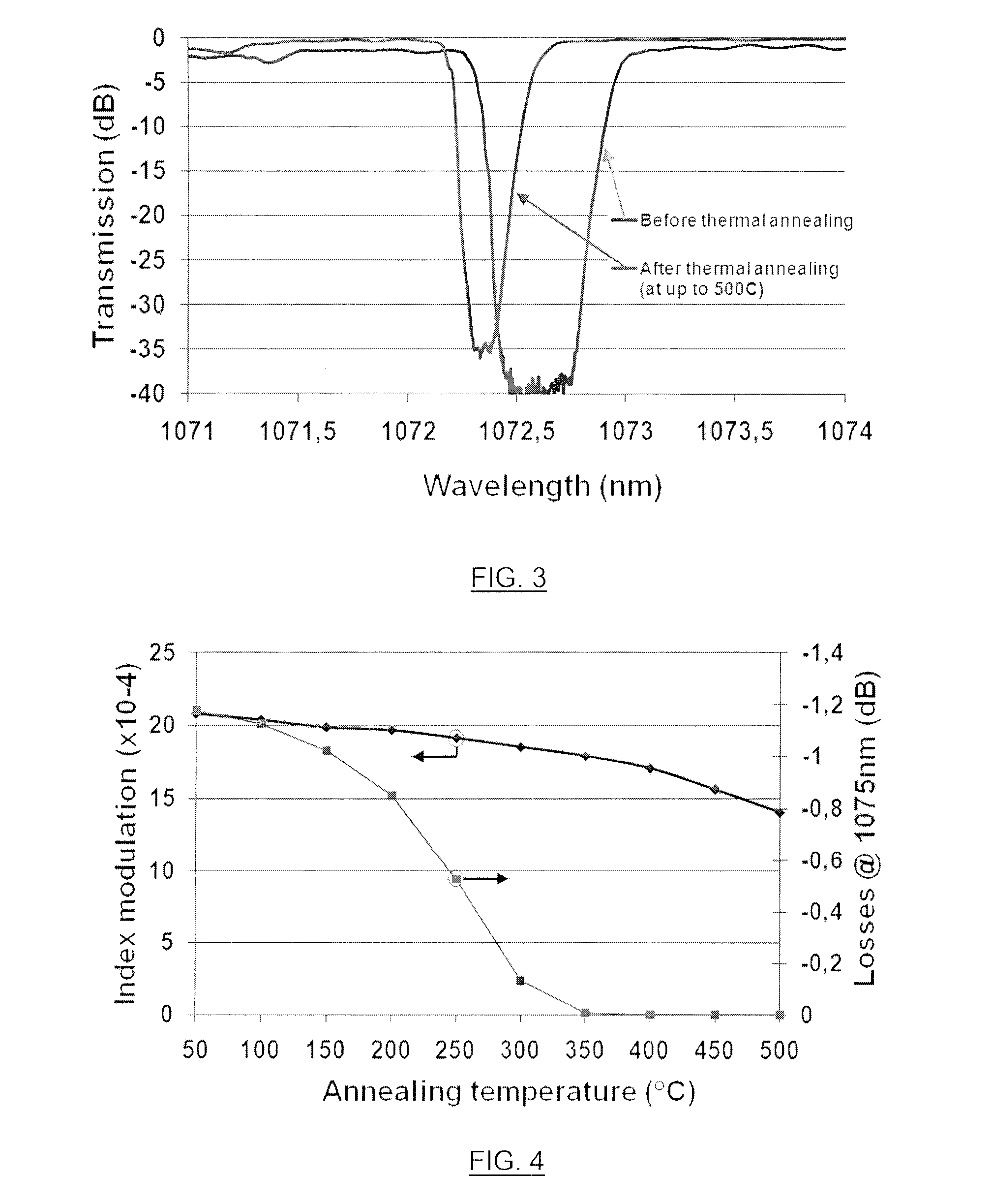

Method for writing high power resistant Bragg gratings using short wavelength ultrafast pulses

A method for writing a Bragg grating in a rare-earth doped glass optical waveguide is provided. Ultrafast optical pulses are generated, preferably in the femtosecond range and having a writing wavelength in the range of 300nm to 700nm and an intensity sufficient to induce a change of refractive index in the rare-earth doped glass waveguide through densification. The optical pulses are diffracted using a phase mask, to generate an interference pattern having a pitch providing a fundamental Bragg resonance corresponding to the target wavelength to be reflected by the grating. The interference pattern is impinged on a region of the rare-earth doped glass waveguide, which is heated to a temperature above a threshold of about 350 DEG C, for a predetermined heating period. Advantageously, the heating step allows the elimination of photodarkening effects which would otherwise be present in the waveguiding properties of the waveguide.

Owner:UNIV LAVAL

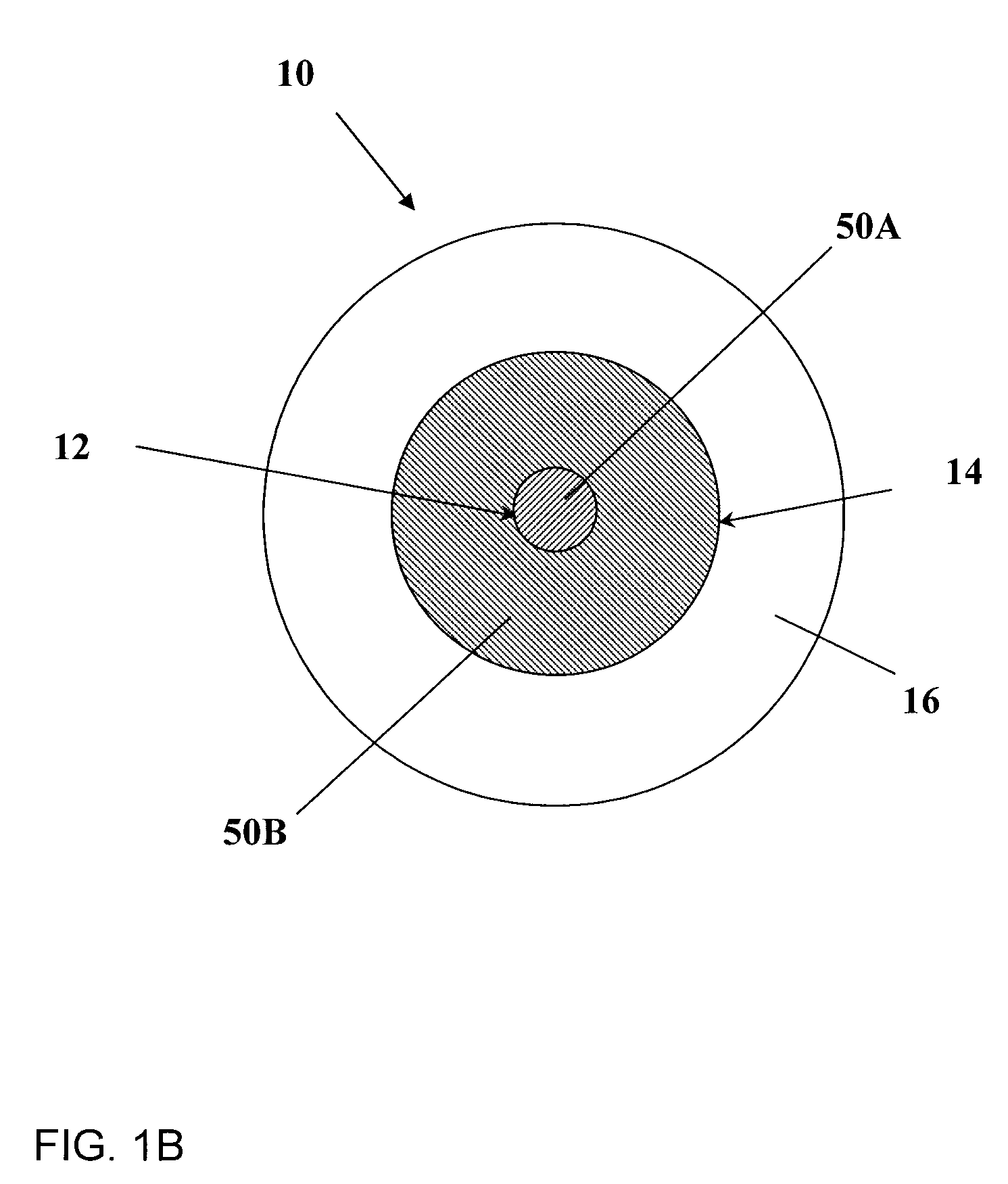

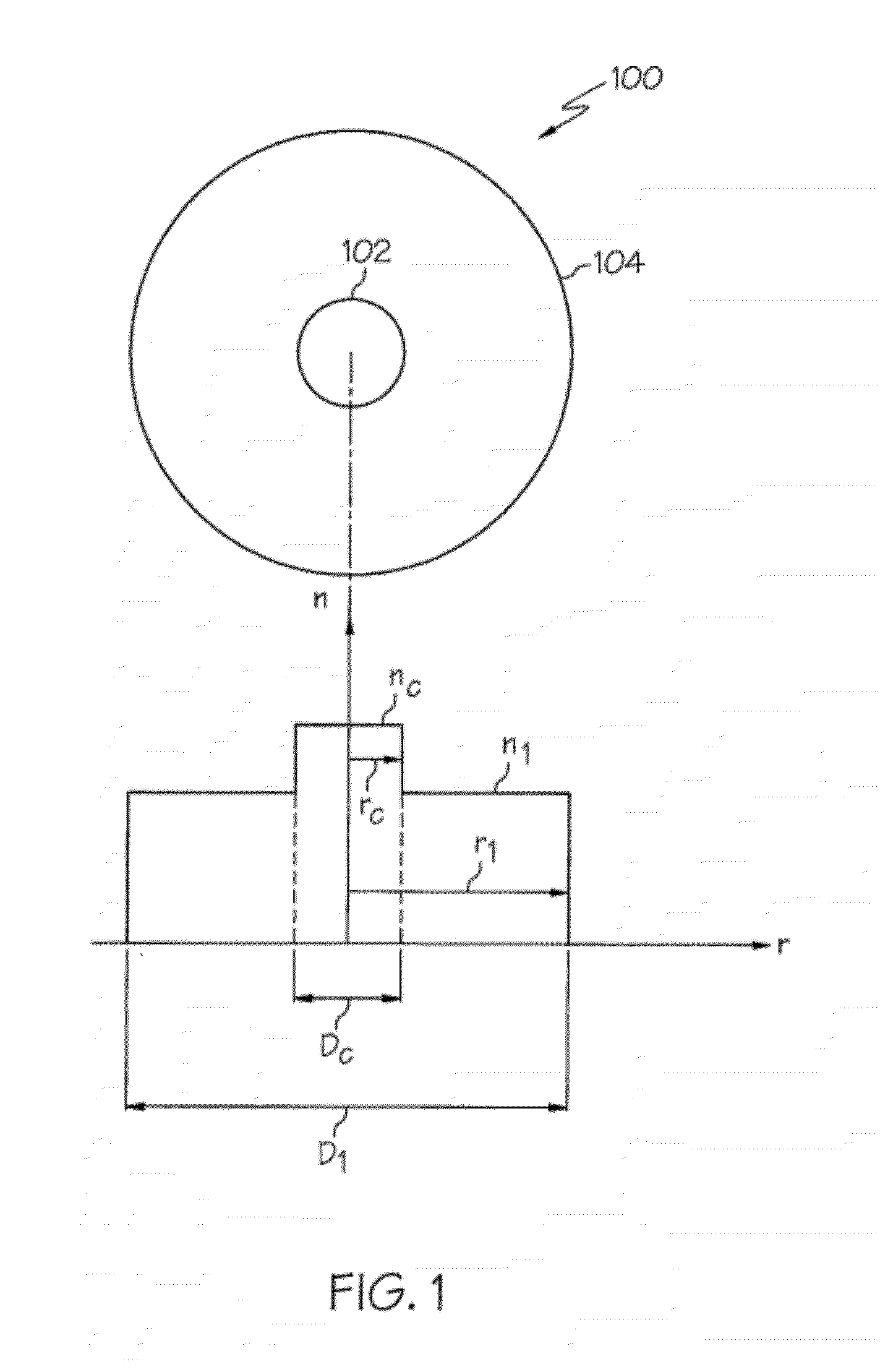

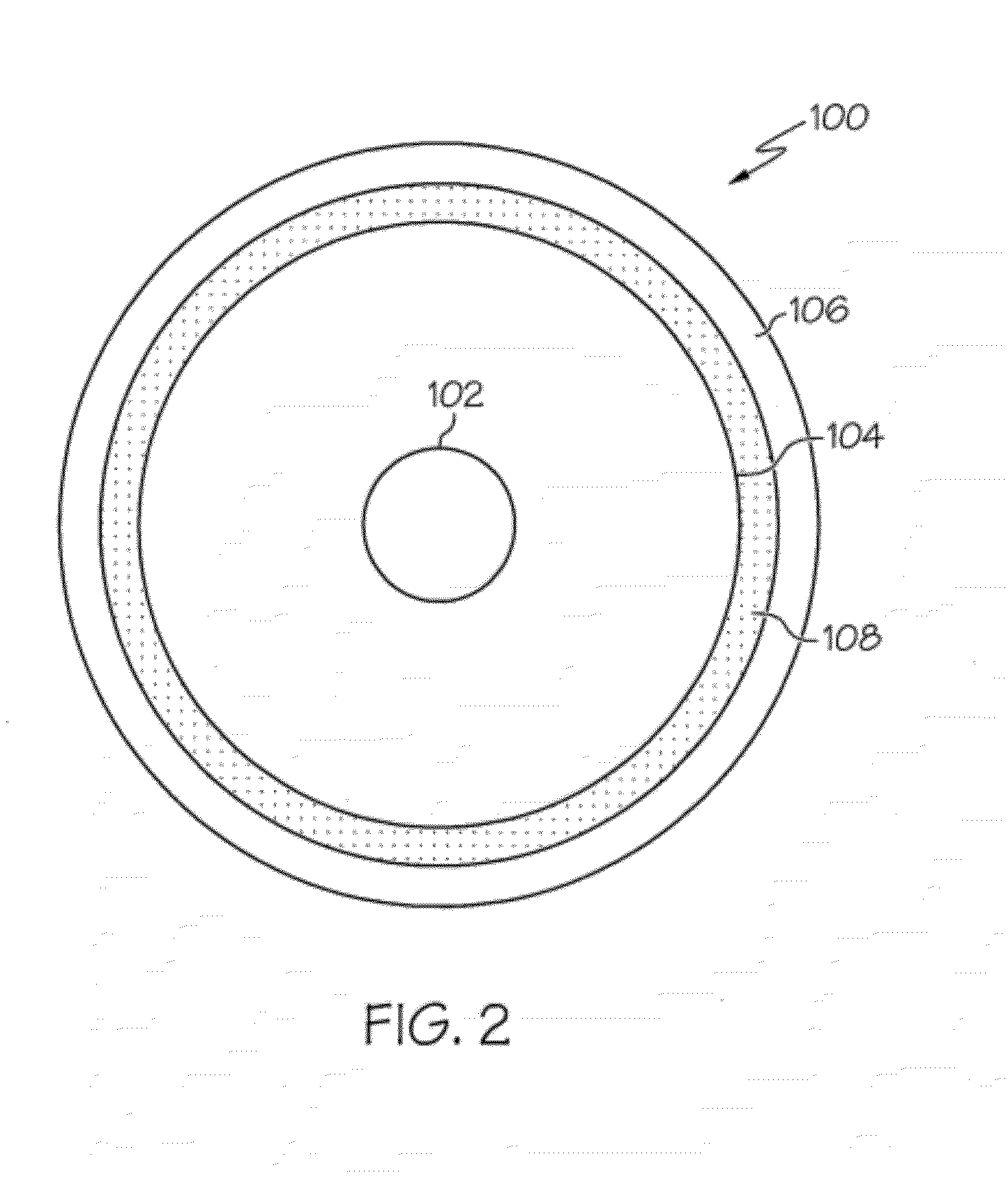

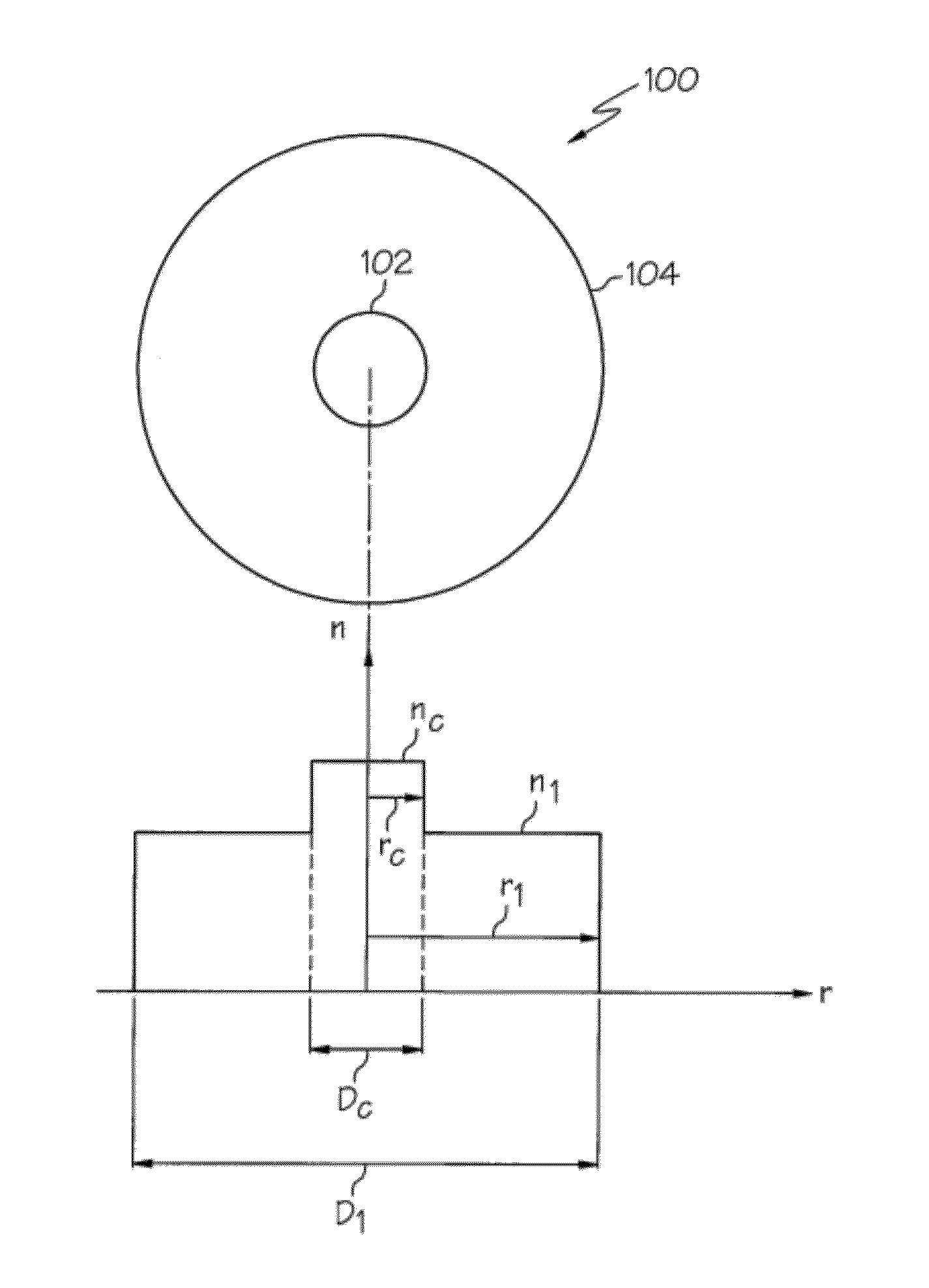

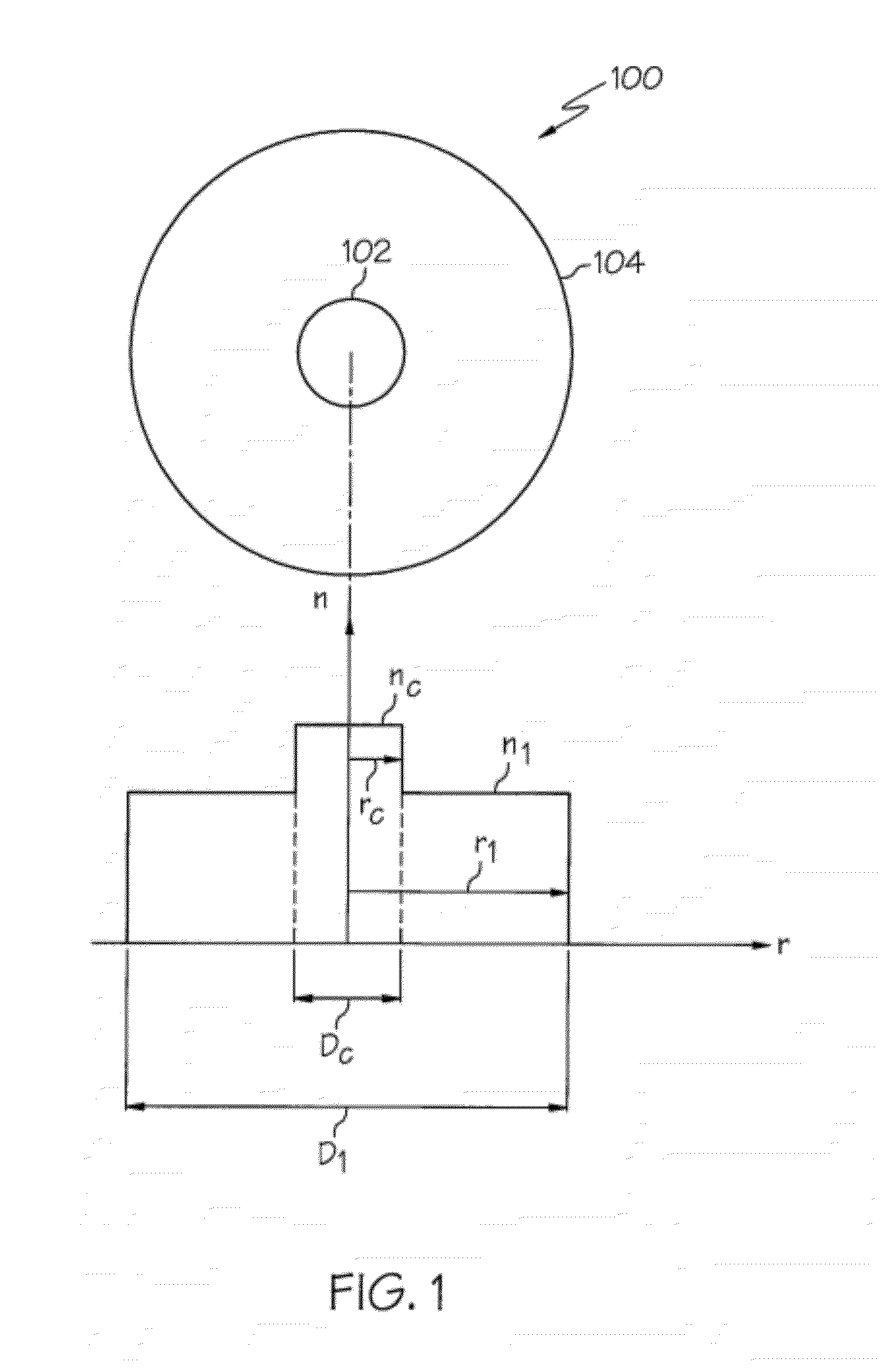

Photodarkening Resistant Optical Fibers and Fiber Lasers Incorporating the Same

Photodarkening resistant optical fiber lasing media and fiber lasers incorporating the same are disclosed. In one embodiment, an optical fiber lasing medium includes a core portion formed from silica-based glass comprising a rare-earth dopant and deuterium, the core portion having an index of refraction nc, a numerical aperture NAc. A concentration of defect color centers in the core portion is less than 1×1016 / cm3. Deuterium is combined with the defect color centers to form reacted defect color centers that do not absorb ultraviolet and visible wavelengths of light. A first cladding portion is formed from silica-based glass, the first cladding portion surrounding and directly contacting the core portion and having an index of refraction n1, wherein the index of refraction n1 of the first cladding portion is less than the index of refraction ncof the core portion. Methods of forming the photodarkening resistant optical fiber lasing media are also disclosed.

Owner:CORNING INC

PROCESSING METHOD FOR SUPPRESSING PHOTODARKENING IN Yb-DOPED OPTICAL FIBERS, PHOTODARKENING-SUPPRESSED Yb-DOPED OPTICAL FIBER, AND FIBER LASER

ActiveUS20090231683A1Suppress photodarkening in Yb-dopedImprove long-term reliabilityCladded optical fibreLaser using scattering effectsHydrogenX-ray

A processing method for suppressing photodarkening in an Yb-doped optical fiber, comprising: a first step of preparing the Yb-doped optical fiber by doping a core with Yb, and irradiating at least one of a gamma ray, a X-ray, or an electron beam onto the Yb-doped optical fiber with an energy greater than a light to be transmitted through the optical fiber when a laser is being oscillated; a second step of measuring a loss spectrum of an infrared region of the optical fiber after the first step, and selecting an optical fiber with the loss in a specific wavelength falling within a predetermined range; and a third step of treating the optical fiber selected in the second step in an atmosphere containing hydrogen to obtain an Yb-doped optical fiber with suppressed photodarkening.

Owner:THE FUJIKURA CABLE WORKS LTD

Method For Writing High Power Resistant Bragg Gratings Using Short Wavelength Ultrafast Pulses

ActiveUS20120128301A1Eliminate photodarkening effectEliminate the effects ofCoupling light guidesBragg resonanceGrating

A method for writing a Bragg grating in a rare-earth doped glass optical waveguide is provided. Ultrafast optical pulses are generated, preferably in the femtosecond range and having a writing wavelength in the range of 300 nm to 700 nm and an intensity sufficient to induce a change of refractive index in the rare-earth doped glass waveguide through densification. The optical pulses are diffracted using a phase mask, to generate an interference pattern having a pitch providing a fundamental Bragg resonance corresponding to the target wavelength to be reflected by the grating. The interference pattern is impinged on a region of the rare-earth doped glass waveguide, which is heated to a temperature above a threshold of about 350° C., for a predetermined heating period. Advantageously, the heating step allows the elimination of photodarkening effects which would otherwise be present in the waveguiding properties of the waveguide.

Owner:UNIV LAVAL

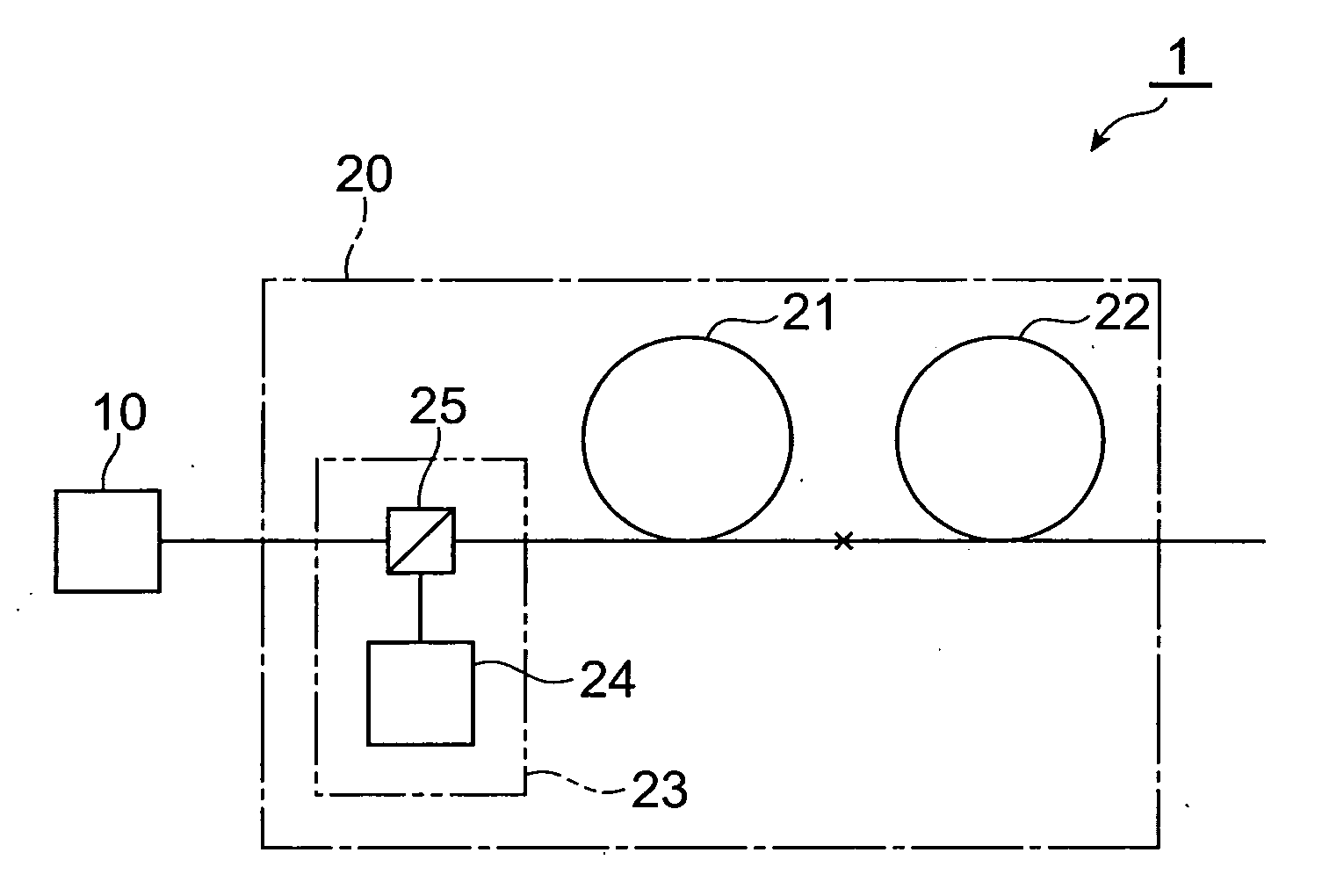

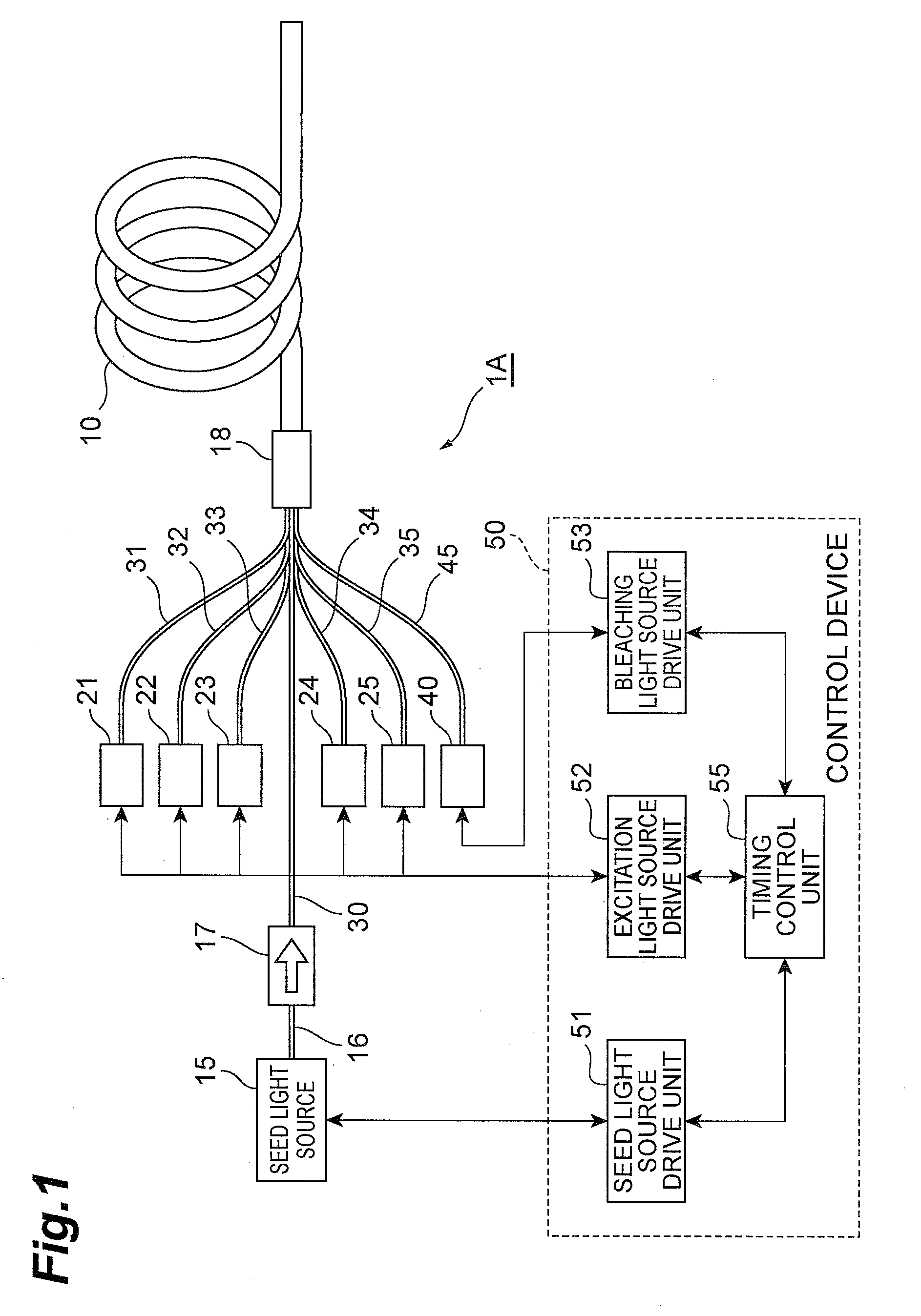

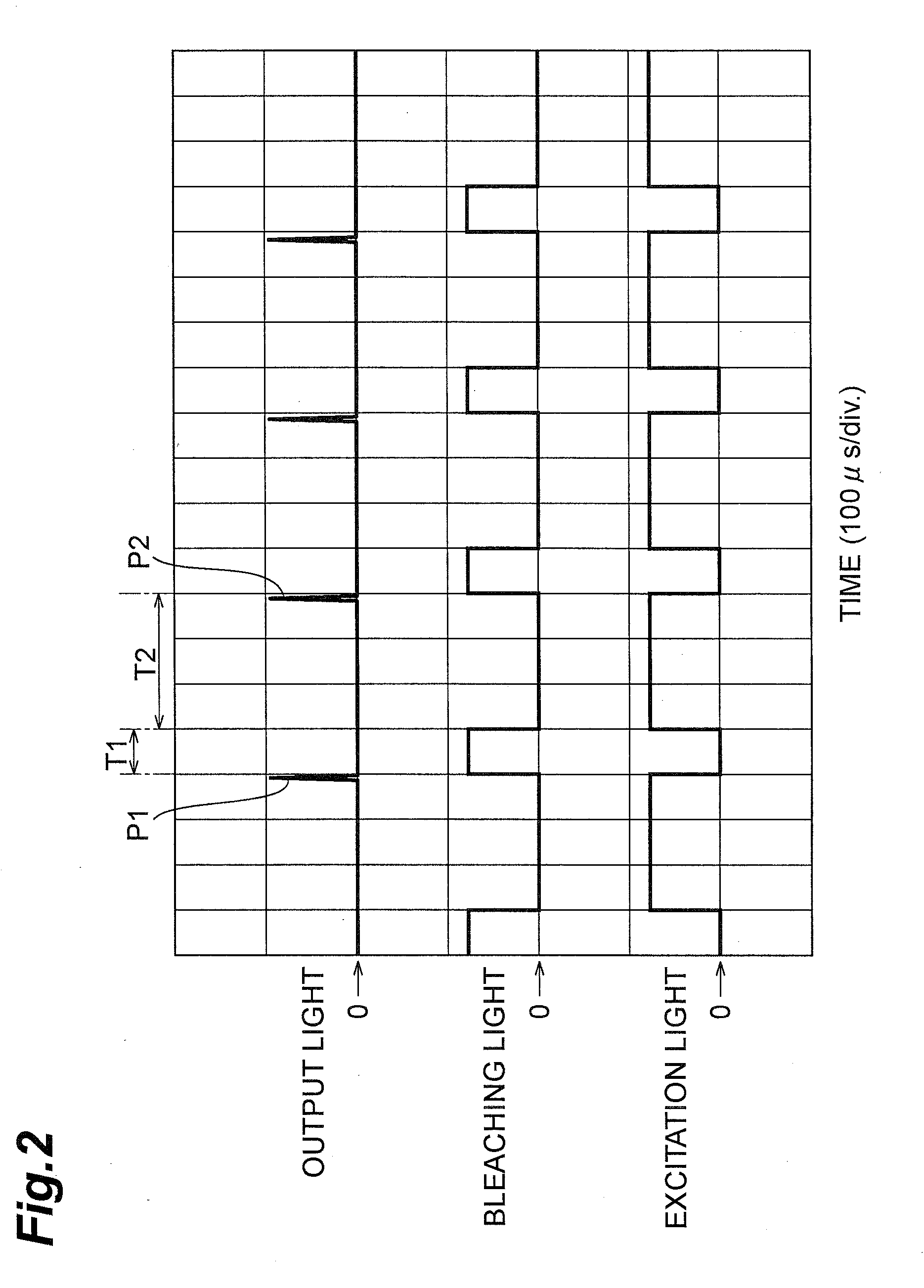

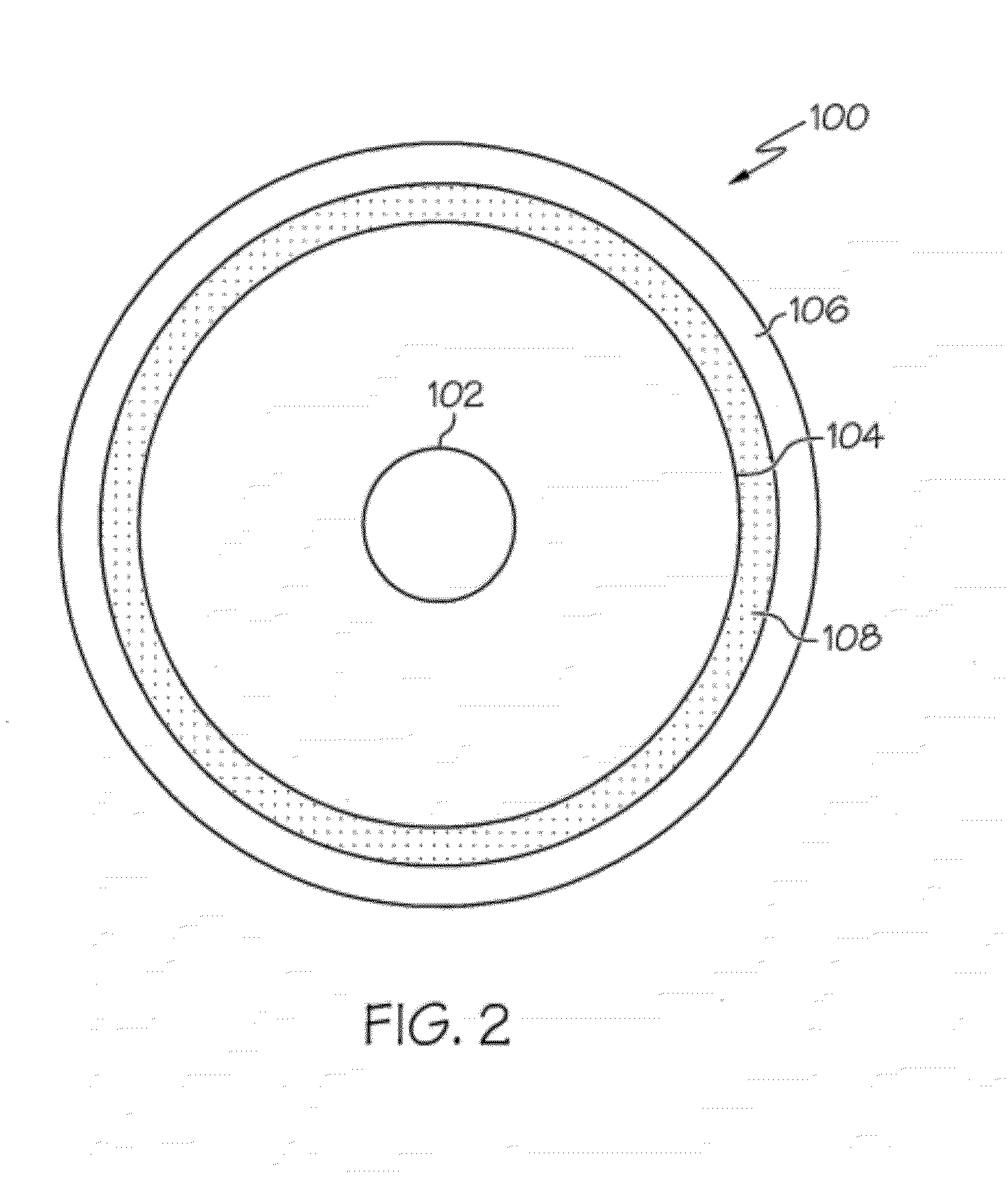

Fiber optical device and method of driving the same

InactiveUS20100290107A1Fibre transmissionActive medium shape and constructionFiberLight transmission

A fiber optical device 1A includes an amplification optical fiber 10, a seed light source 15 for supplying pulse seed light to the optical fiber 10, excitation light sources 21 to 25 for supplying excitation light, a bleaching light source 40 for supplying bleaching light for reducing a light transmission loss caused by photodarkening, and a control device 50 that controls the operations of individual portions. The control device 50 divides a period between a first output light pulse and a succeeding second output light pulse into a first period which includes a time point immediately after the output of the first output light pulse and during which the population inversion is unsaturated, and a second period which includes a time point immediately before the output of the second output light pulse, and, to the optical fiber 10, supplies the bleaching light in the first period and supplies the excitation light in the second period. Thus, it is possible to provide a fiber optical device and the method of driving it that can suitably restore the characteristics of the amplification optical fiber by photobleaching.

Owner:HAMAMATSU PHOTONICS KK

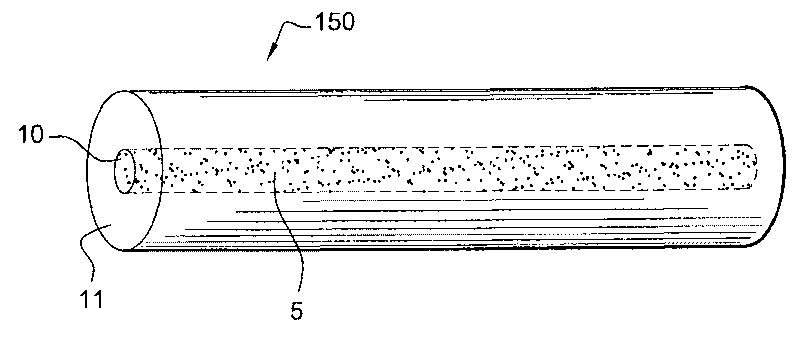

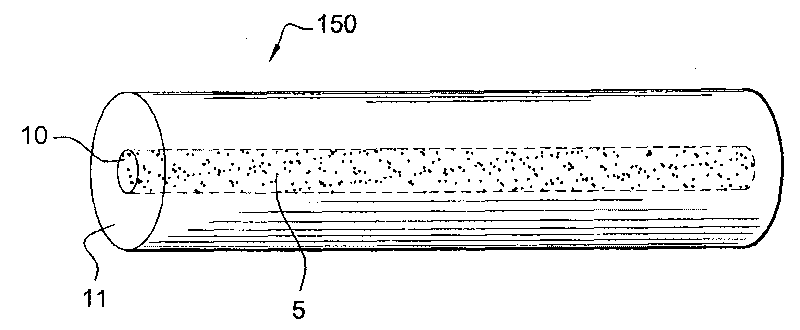

Amplifying optical fibre and production method

InactiveCN101762843ACladded optical fibreActive medium shape and constructionFiberRare-earth element

The fiber (150) has a central core (10) for transmitting and amplifying a visible signal. An optical sheath (11) surrounds the core and confines an optical signal transmitted to the core. The core is formed of a main matrix and contains nanoparticles (5) doped with a rare earth element. Concentration in weight of the element in each nanoparticle is comprised between 1 and 20 percent. Concentration of the nanoparticles in the matrix is comprised between 0.05 and 1 percent in volume. The matrix is made of alumina, silica and phosphorus. The element is one among erbium, ytterbium or thulium.

Owner:DRAKA COMTEQ BV

Method for writing high power resistant bragg gratings using short wavelength ultrafast pulses

ActiveUS8515224B2Eliminate photodarkening effectEliminate the effects ofCoupling light guidesBragg resonanceElectrical resistance and conductance

A method for writing a Bragg grating in a rare-earth doped glass optical waveguide is provided. Ultrafast optical pulses are generated, preferably in the femtosecond range and having a writing wavelength in the range of 300 nm to 700 nm and an intensity sufficient to induce a change of refractive index in the rare-earth doped glass waveguide through densification. The optical pulses are diffracted using a phase mask, to generate an interference pattern having a pitch providing a fundamental Bragg resonance corresponding to the target wavelength to be reflected by the grating. The interference pattern is impinged on a region of the rare-earth doped glass waveguide, which is heated to a temperature above a threshold of about 350° C., for a predetermined heating period. Advantageously, the heating step allows the elimination of photodarkening effects which would otherwise be present in the waveguiding properties of the waveguide.

Owner:UNIV LAVAL

Light darkening test device and method for ytterbium-doped silica fiber of all-fiber structure

ActiveCN111006848AHigh reversal rateImprove testing flexibilityTesting fibre optics/optical waveguide devicesSignal lightMaterials science

The invention discloses an ytterbium-doped silica fiber light darkening test device of an all-fiber structure. Signal light output by a signal source is attenuated by an optical fiber flange and an optical fiber attenuator in sequence, and then is combined with pump light output by a first pump source through a wavelength division multiplexer to form combined beam light; the combined light and thepump light output by the second pump source are respectively input through the signal end and the pump end of an optical fiber beam combiner; output light of the optical fiber beam combiner is transmitted along the ytterbium-doped optical fiber, the output end of the ytterbium-doped optical fiber is connected with the input end of a cladding light stripper in a welded mode, and an output light beam of the cladding light stripper enters an optical power detector through a low-photon darkening filtering optical fiber. The low-photon darkening filtering optical fiber is a Yb-doped optical fiber;and the concentration of doped Yb2O3 is not higher than 0.1 wt%. The light darkening test device has the beneficial effects that the light darkening test device is of the all-fiber structure, a testsystem is compact in structure, the test method is simple, the device cost is low, the signal source power can be accurately regulated and controlled, the test condition is optimized, and the test signal-to-noise ratio is high.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

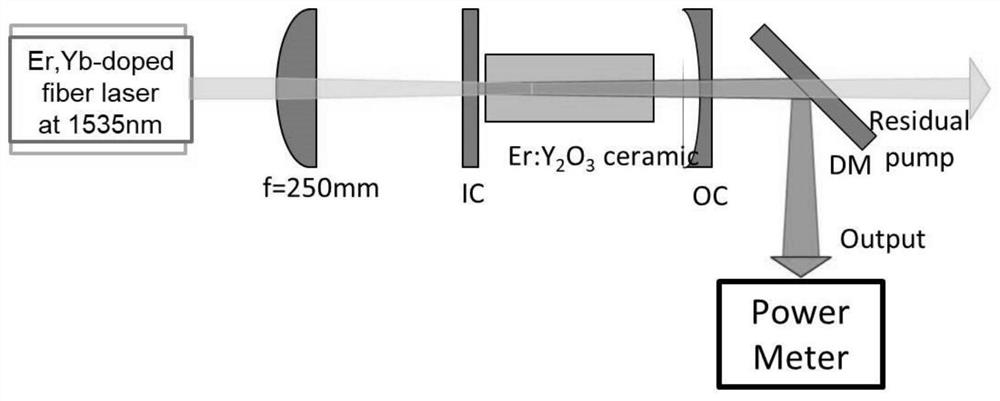

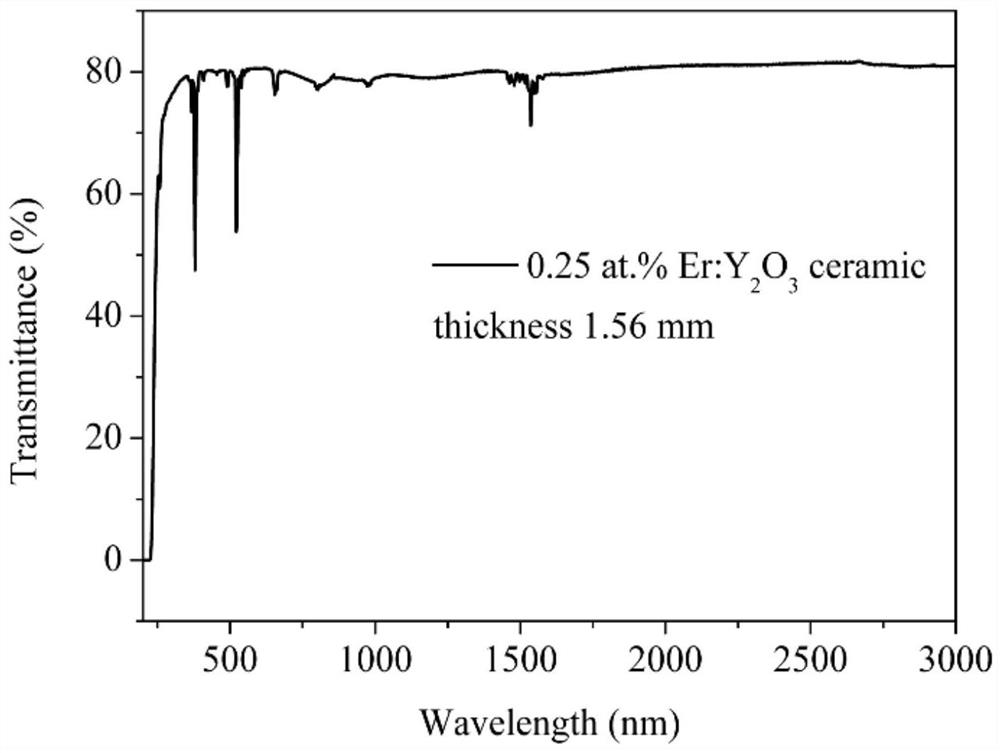

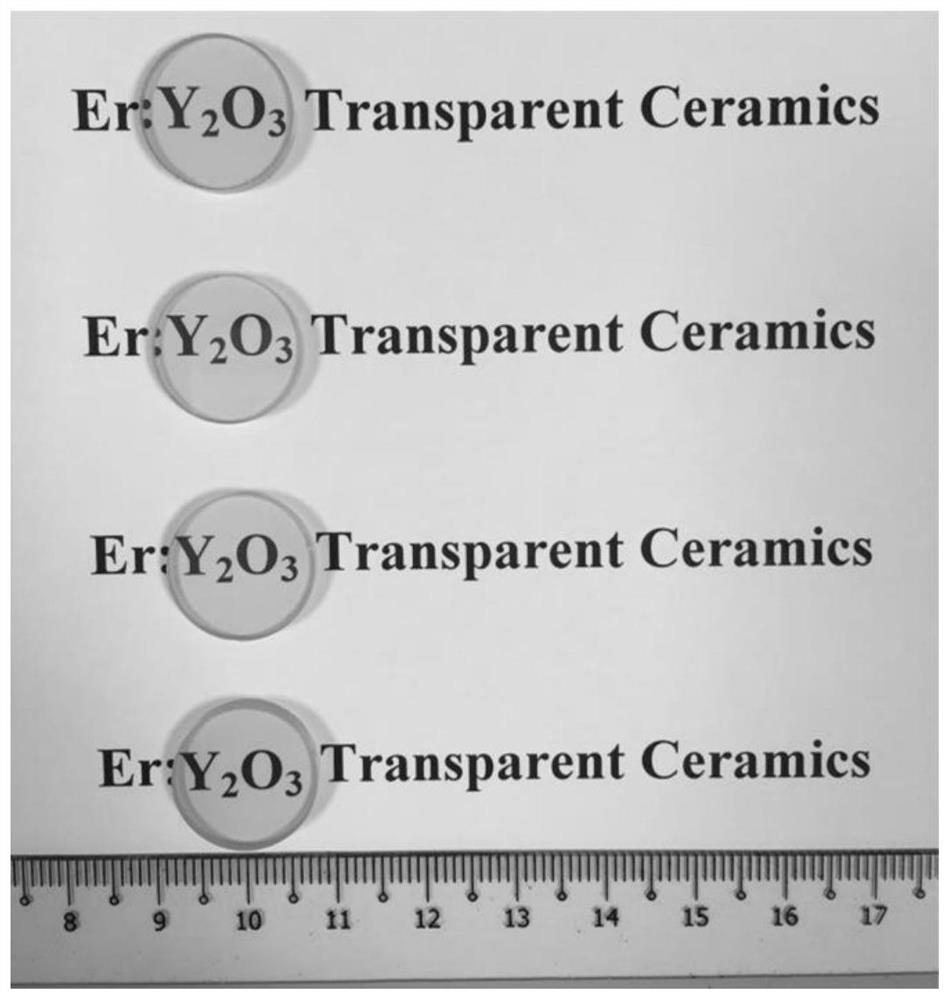

Transparent ceramic and preparation method thereof

The invention discloses a transparent ceramic which is prepared by the following steps of: weighing and mixing Y2O3 and a doping agent containing Er according to a chemical formula (Er<x>Y<1-x>)2O3 (x is more than or equal to 0.0005 and less than or equal to 0.005), and sequentially carrying out ball milling, drying, grinding, sieving and calcining treatment to obtain Er: Y2O3 powder; carrying out molding treatment on the Er: Y2O3 powder to obtain a green body; and placing the green body in a vacuum environment of 1400-1800 DEG C for sintering for 0.5-50 h, then performing hot isostatic pressing sintering in inert gas of 1400-1800 DEG C for 0.5-8 h, finally annealing in air or oxygen atmosphere of 600-1300 DEG C for 0.5-30 h, and performing two-side polishing to obtain Er: Y2O3 transparent ceramic. The Er: Y2O3 transparent ceramic with high optical quality can be prepared by adopting a mode of combining vacuum sintering and hot isostatic pressing treatment on the premise of not additionally adding a sintering aid. Under excitation of a proper pumping source, <4>I<13 / 2>-><4>I<15 / 2> energy level transition of Er < 3 + > ions can be utilized, and under the condition that a pump light darkening effect is not generated, 1.6 [mu] m laser which can be safely absorbed by human eyes can be output.

Owner:XUZHOU NORMAL UNIVERSITY

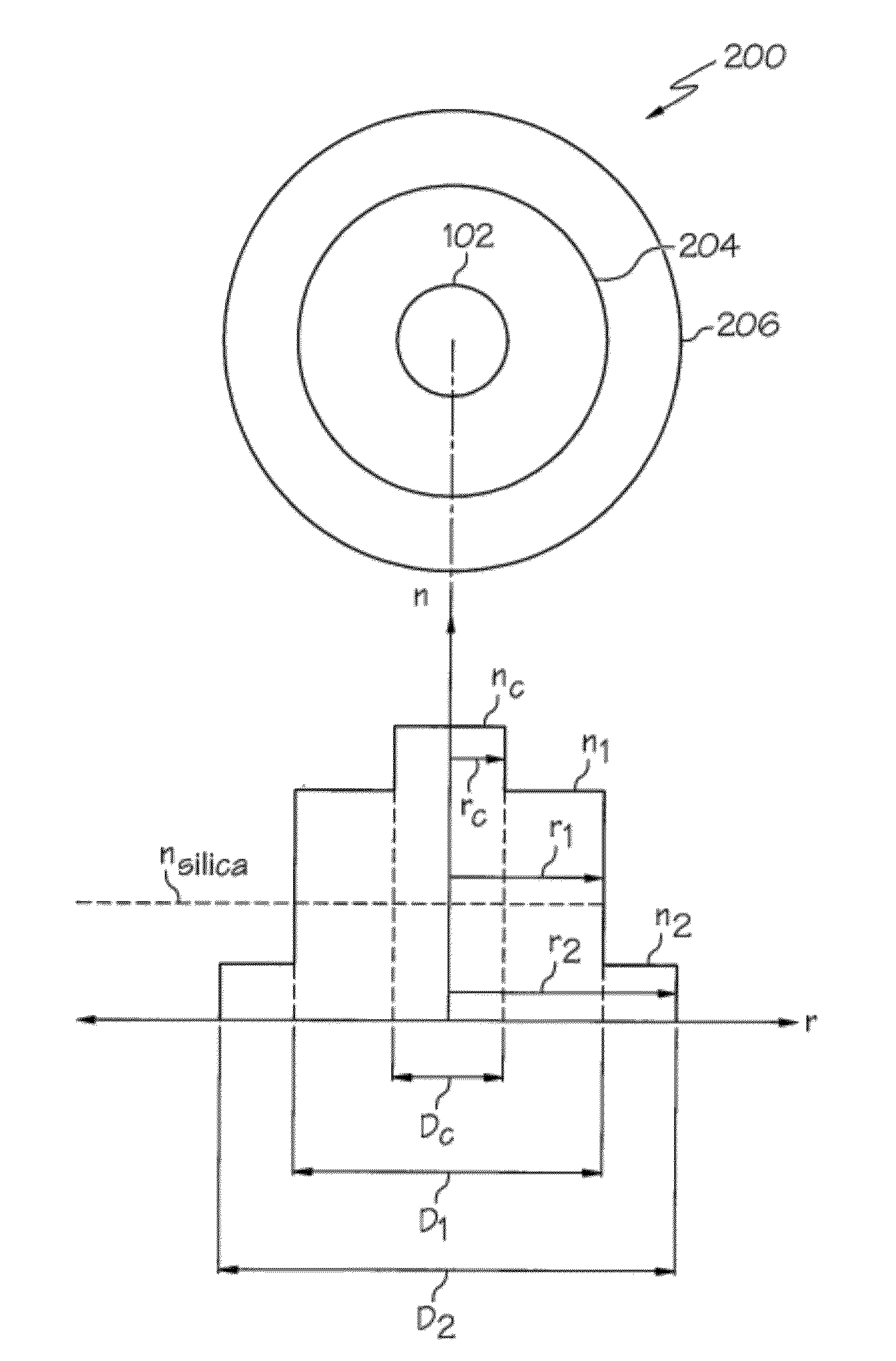

Photodarkening resistant optical fibers and fiber lasers incorporating the same

Photodarkening resistant optical fiber lasing media and fiber lasers incorporating the same are disclosed. In one embodiment, an optical fiber lasing medium includes a core portion formed from silica-based glass comprising a rare-earth dopant and deuterium, the core portion having an index of refraction nc, a numerical aperture NAc. A concentration of defect color centers in the core portion is less than 1×1016 / cm3. Deuterium is combined with the defect color centers to form reacted defect color centers that do not absorb ultraviolet and visible wavelengths of light. A first cladding portion is formed from silica-based glass, the first cladding portion surrounding and directly contacting the core portion and having an index of refraction n1, wherein the index of refraction n1 of the first cladding portion is less than the index of refraction nc of the core portion. Methods of forming the photodarkening resistant optical fiber lasing media are also disclosed.

Owner:CORNING INC

Optical amplification module and laser light source apparatus

InactiveUS8009708B2Inhibition is effectiveEfficient optical amplificationLaser detailsFibre transmissionAudio power amplifierLaser light

The present invention relates to an optical amplifier module, or the like, having a structure for enabling effective suppression of photodarkening and efficient optical amplification. The optical amplifier module comprises a first optical amplification waveguide which is comprised of a phosphate glass as a main component and includes a ytterbium-doped first optical waveguide region, a second optical amplification waveguide which is optically coupled to the first optical amplification waveguide and includes a ytterbium-doped second optical waveguide region which is co-doped with aluminum, and pumping light source units which supply pumping light respectively to the first optical amplification waveguide and the second optical amplification waveguide. The light to be amplified, having inputted to the first optical amplification waveguide, is amplified only once by means of the pumping light, in each of the first optical amplification waveguide and the second optical amplification waveguide.

Owner:MEGAOPTO

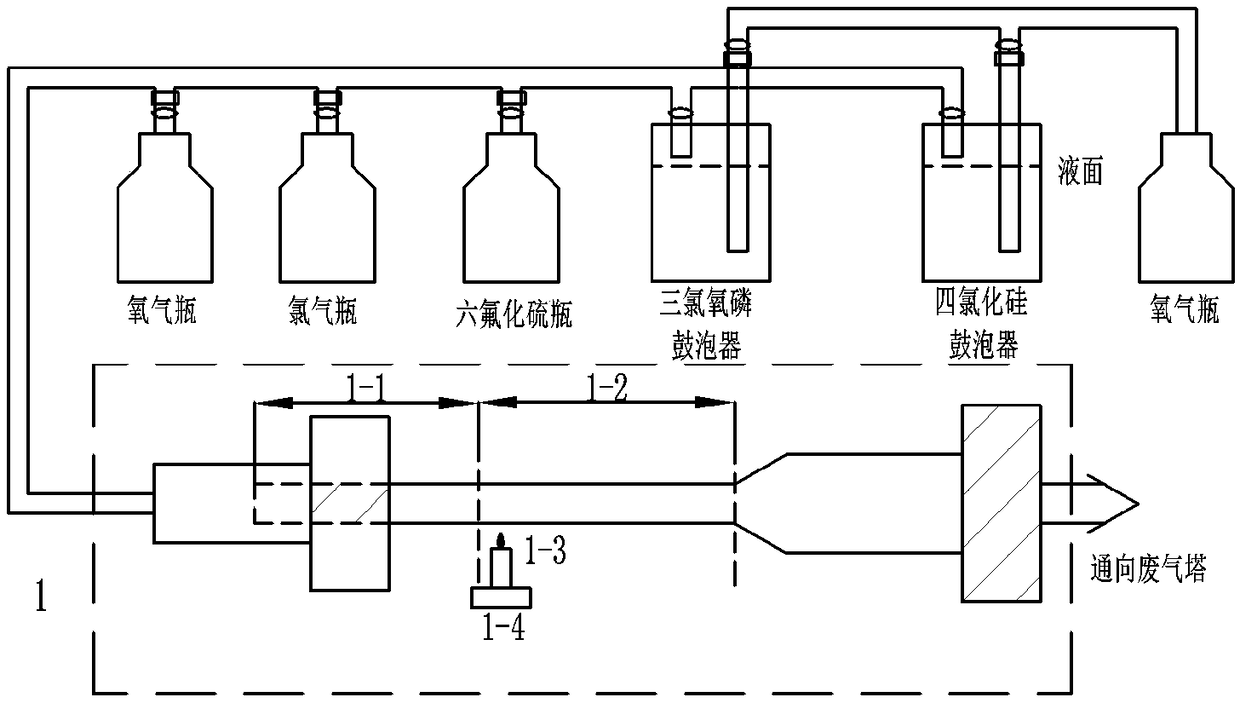

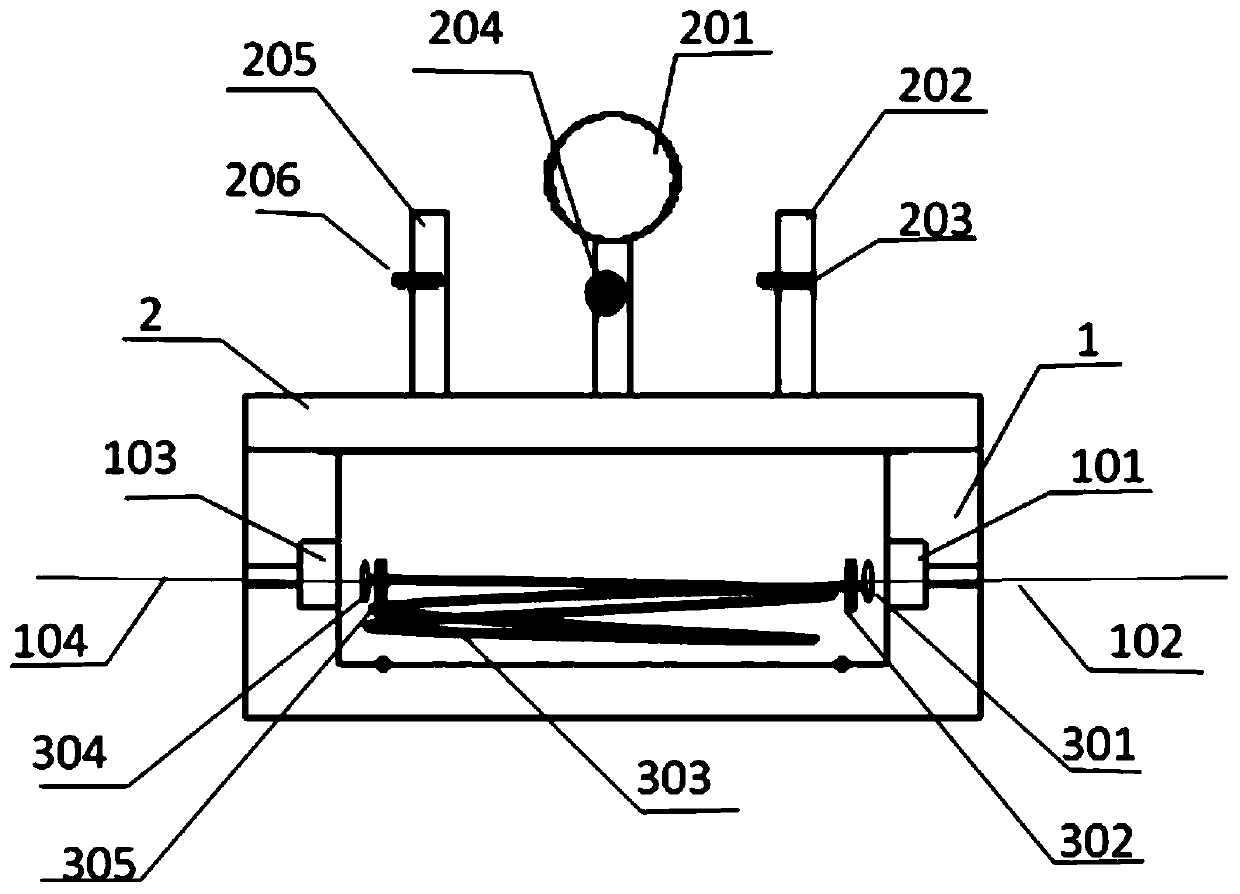

Deep ultraviolet single-mode polarization maintaining optical fiber manufacturing device and method

ActiveCN111410418APrevent leakageImprove transmission performanceGlass making apparatusOptical fibre with polarisationPolarization-maintaining optical fiberUltraviolet lights

The invention discloses a deep ultraviolet single-mode polarization maintaining optical fiber manufacturing device comprising an autoclave, a laser input port and a laser output port are respectivelyformed in two opposite sides of the autoclave main cavity; an input port quartz glass window and an output port quartz glass window are respectively mounted on the inner side of the laser input port and the inner side of the laser output port of the autoclave main cavity. The laser input port, the input port quartz glass window, a first optical fiber coupling lens and a first optical fiber flangeplate are sequentially distributed and coaxial, and the second optical fiber flange plate, the second optical fiber coupling lens, the output port quartz glass window and the laser output port are sequentially distributed and coaxial. The invention further discloses a manufacturing method of the deep ultraviolet single-mode polarization maintaining optical fiber, the manufacturing method is not limited to research and development of the ultraviolet single-mode polarization maintaining optical fiber, and is also suitable for hydrogen carrying and delight darkening processes of other types of optical fibers (such as single-mode, multi-mode, non-polarization-maintaining and some special optical fibers), and the ultraviolet light transmission performance of the optical fiber is improved.

Owner:INNOVATION ACAD FOR PRECISION MEASUREMENT SCI & TECH CAS

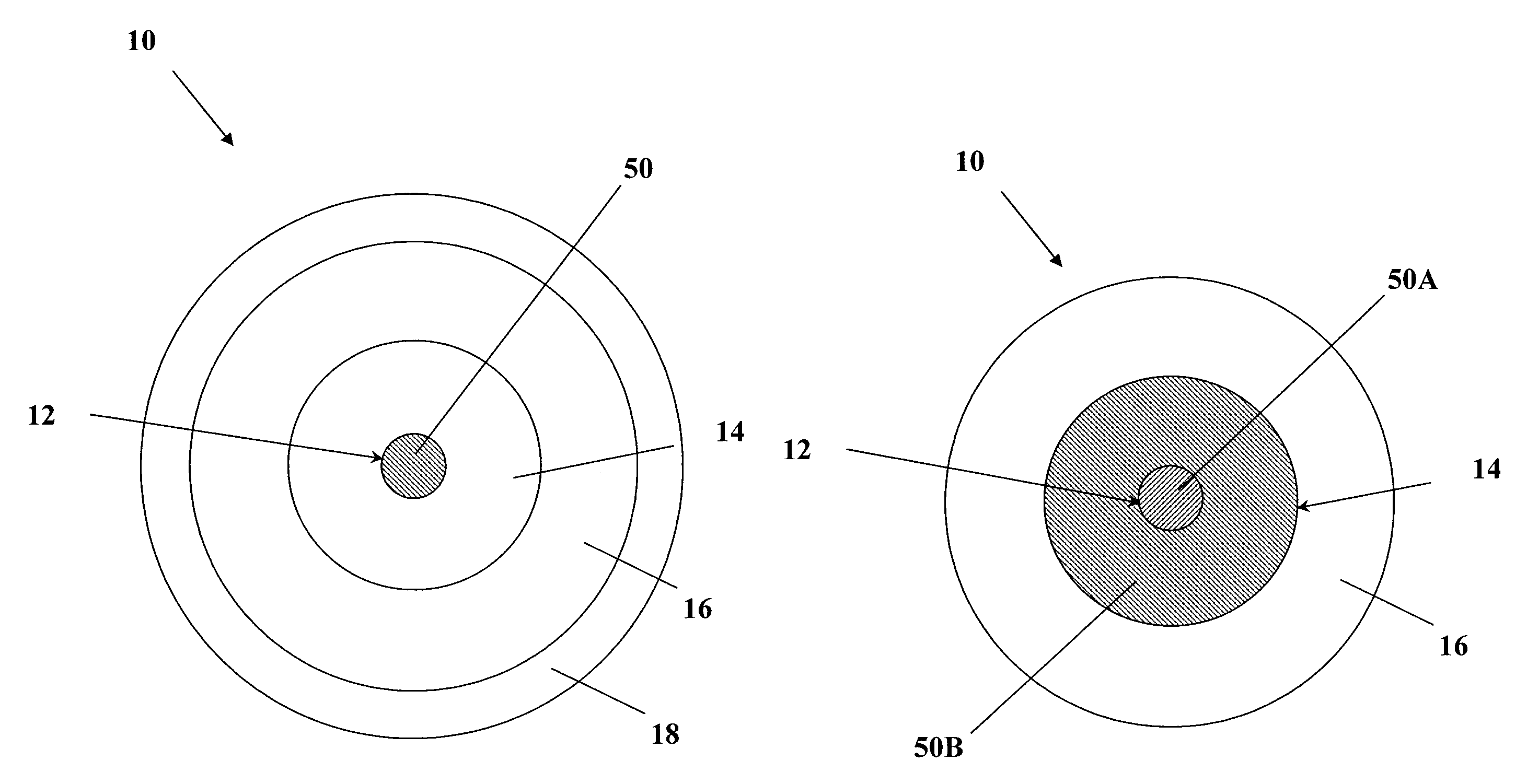

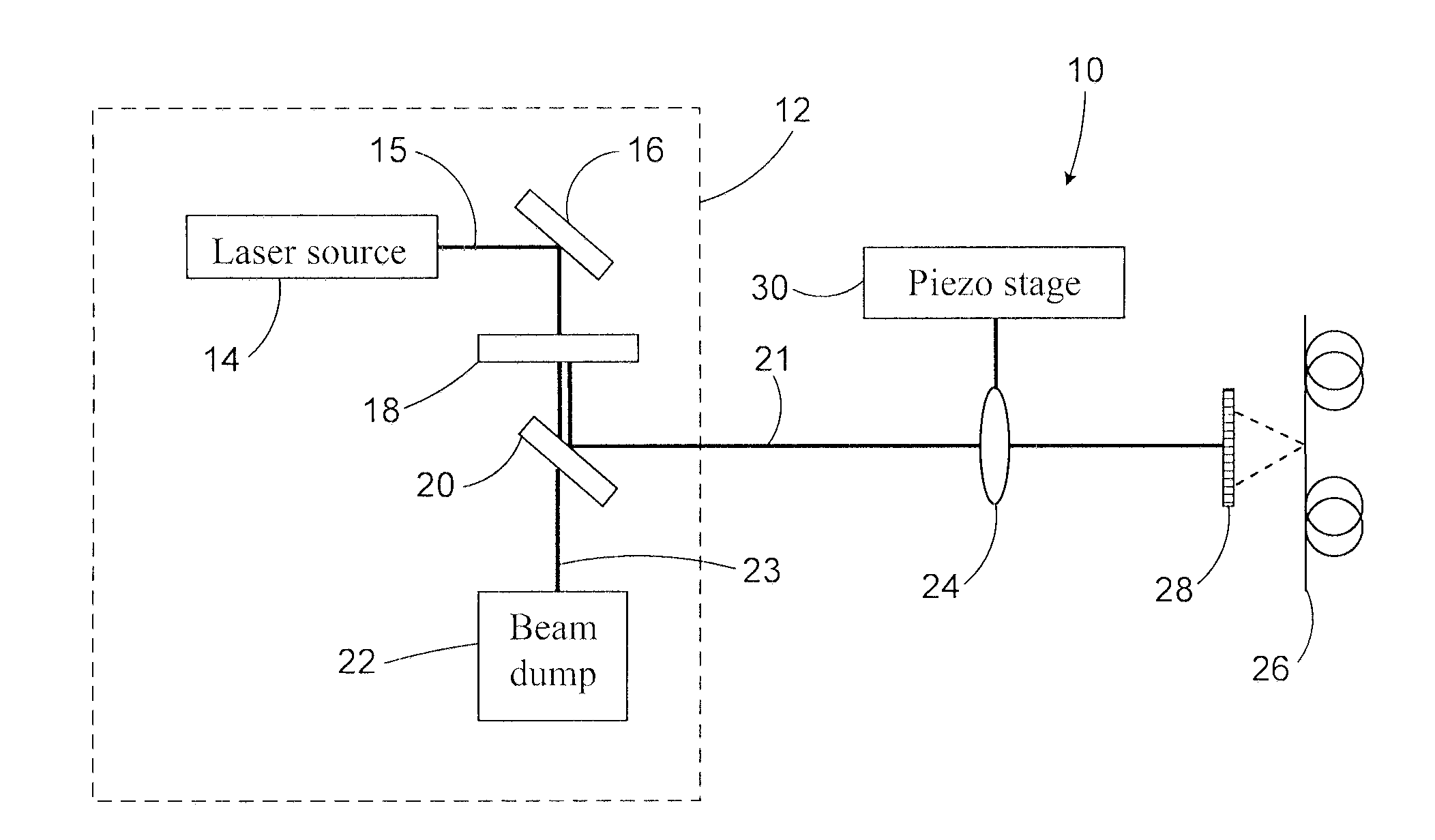

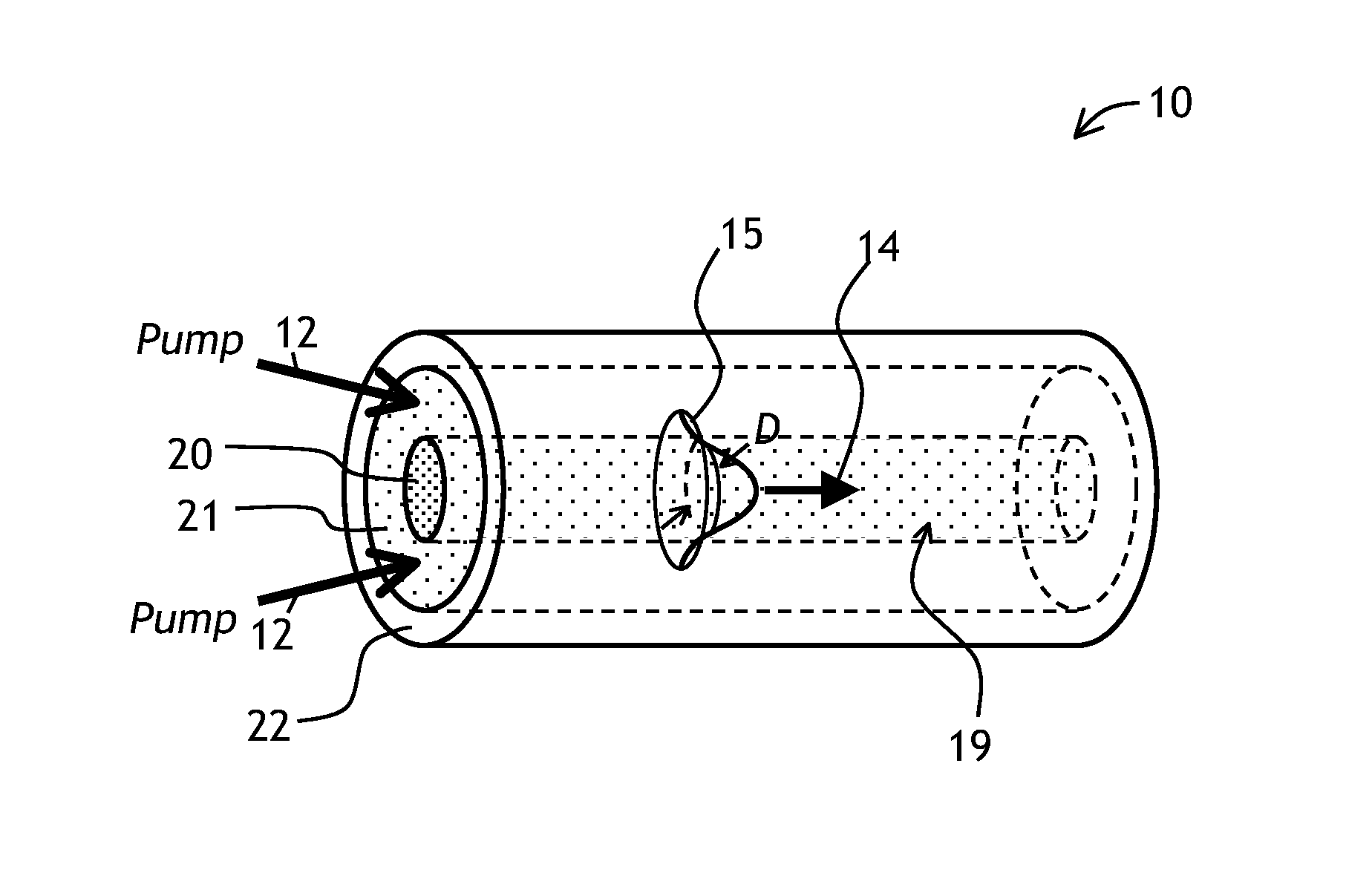

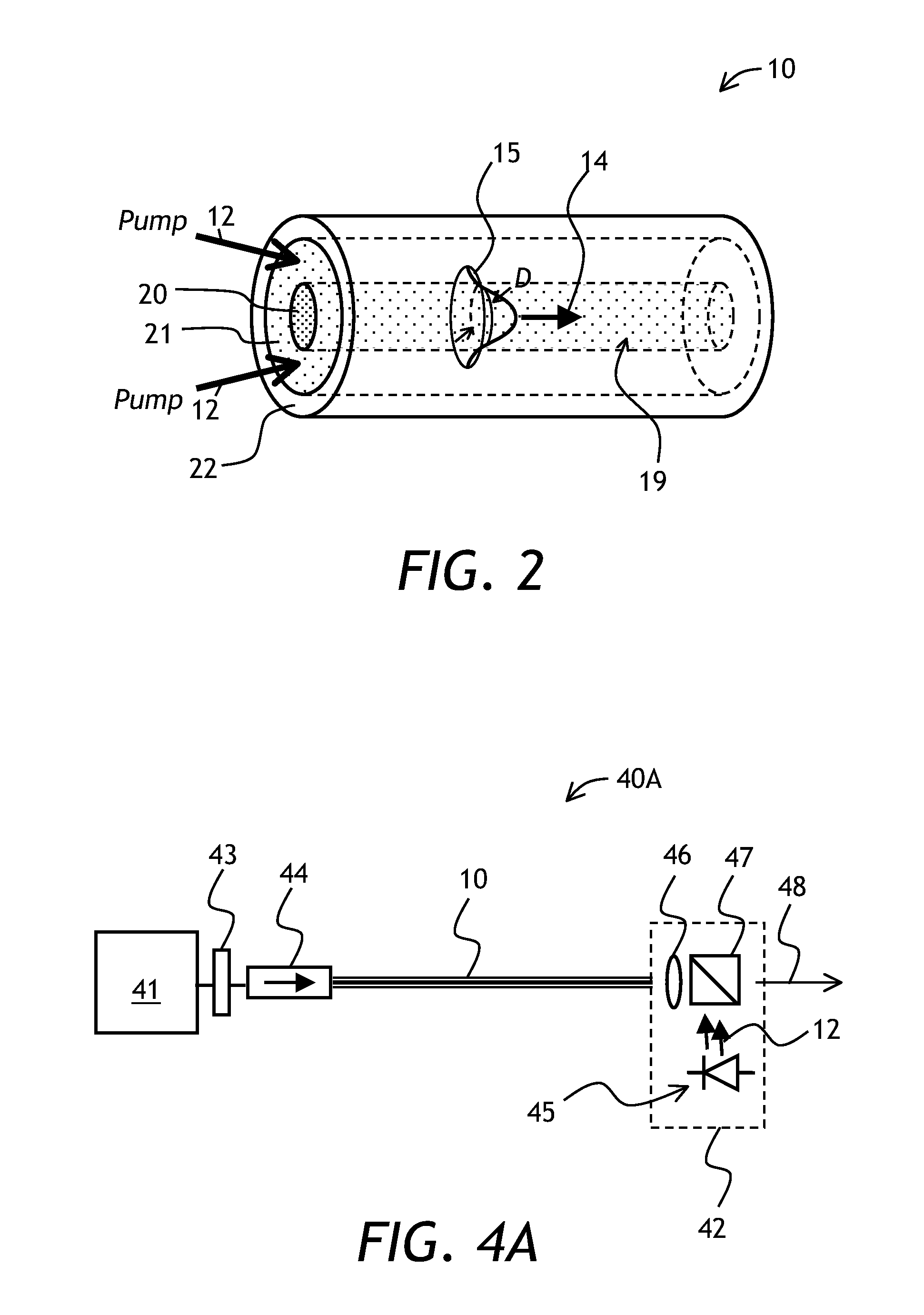

Large mode area optical waveguide devices

Owner:LUMENTUM OPERATIONS LLC

Light darkening testing device for rare earth-doped optical fiber

PendingCN113281015AImprove test accuracyTesting optical propertiesTesting fibre optics/optical waveguide devicesPower detectorLight beam

The invention discloses a light darkening testing device for a rare earth-doped optical fiber, wherein the device comprises a visible light signal source, a passive matching optical fiber, a cladding light filter, a beam combiner, a tested rare-earth-doped optical fiber and a pump light filter which are sequentially connected; the input end of the beam combiner is further connected with a semiconductor laser; and a visible light beam emitted by the visible light signal source passes through the cladding light filter, the beam combiner, the measured optical fiber, the pump light filter and a wave filter and then enters a first power detector, and laser emitted by the semiconductor laser passes through the beam combiner, the tested optical fiber and the pump light filter and then is cut off at the position of the wave filter. According to the invention, the light darkening loss of a to-be-tested optical fiber at the laser working wavelength is indirectly calculated by using the power change after the visible light passes through the to-be-tested optical fiber, and compared with the prior art, the test can be completed in a shorter time. By arranging the cladding light filter and the pump light filter, cladding light from a signal source and pump light which is not absorbed and converted can be filtered, so that the test accuracy is improved.

Owner:JIANGSU HENGTONG OPTICAL FIBER TECH +2

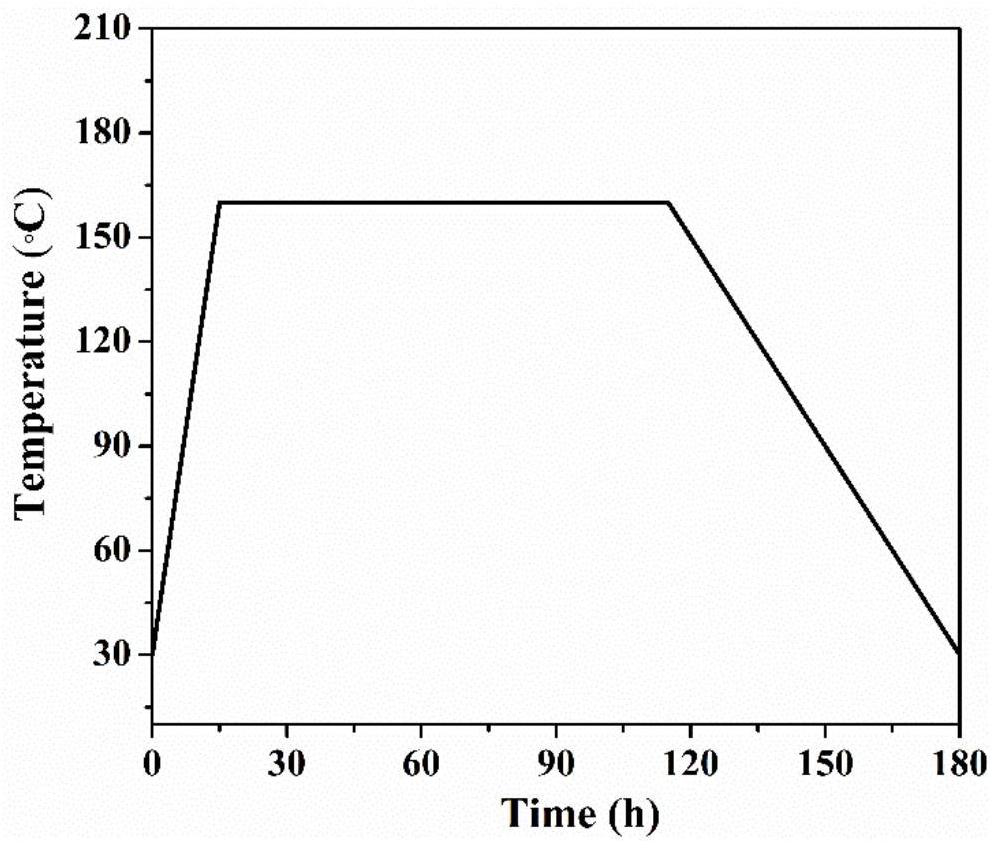

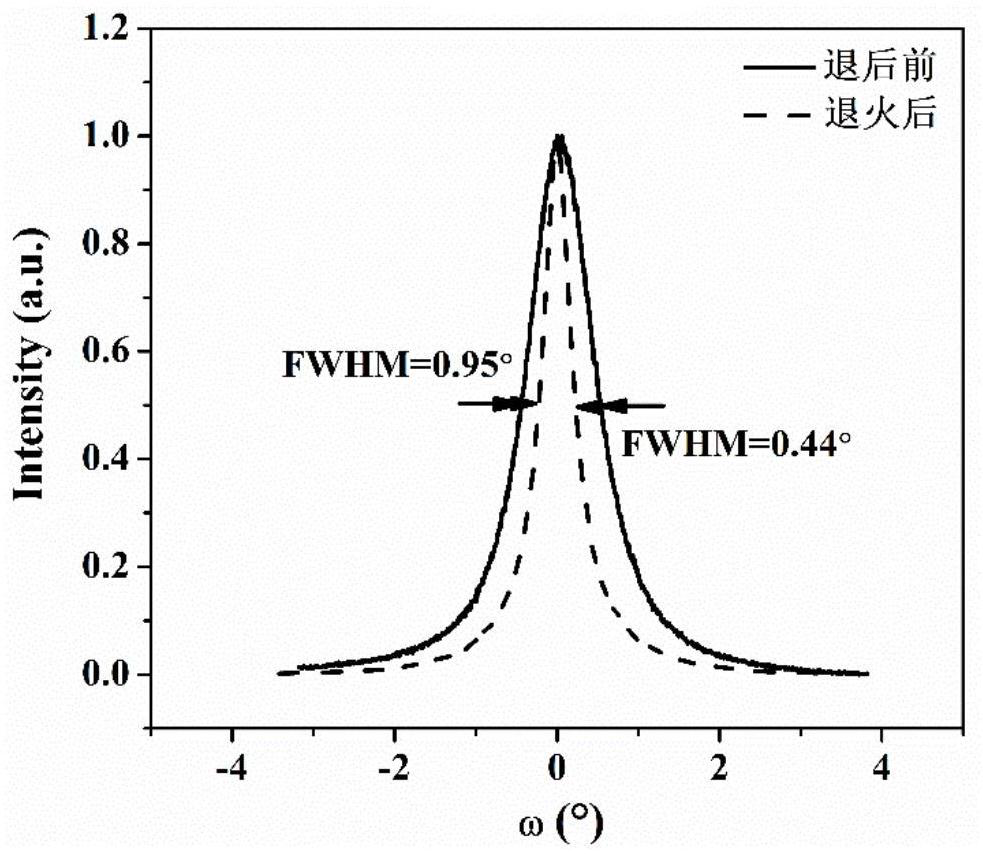

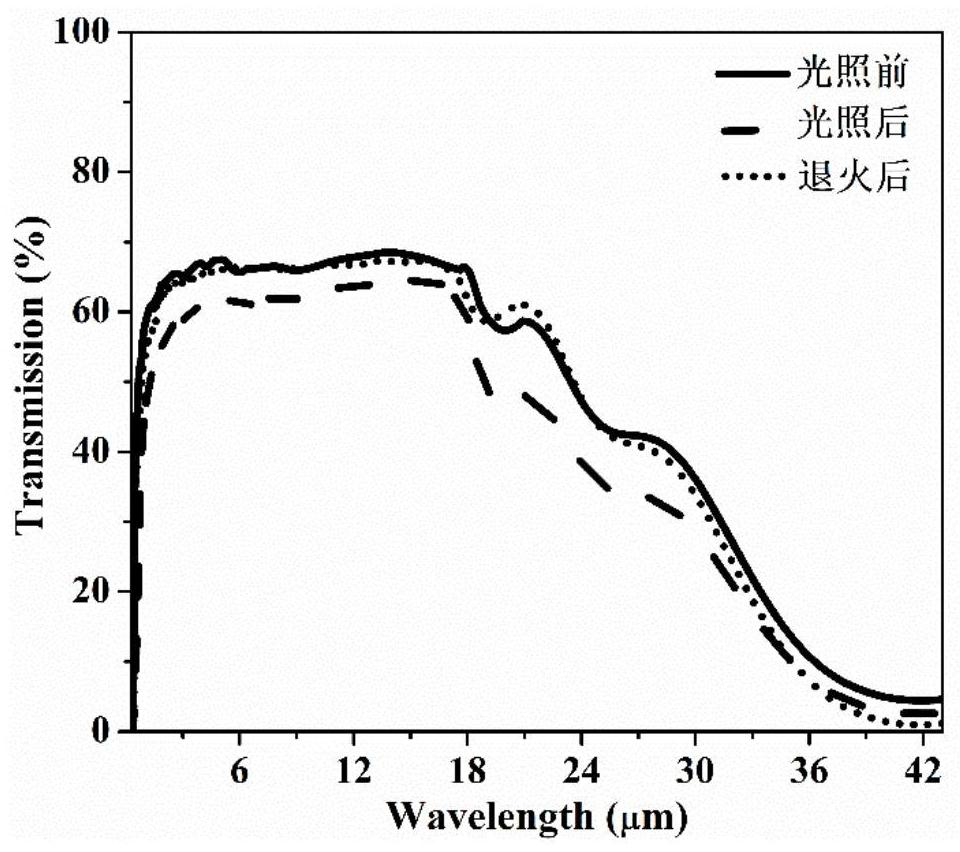

Treatment method for improving crystallinity and optical transmittance of mercurous halide single crystal

ActiveCN112647134AAvoid crackingHigh crystallinityPolycrystalline material growthAfter-treatment detailsOptical transmittanceSingle crystal

The invention relates to a treatment method for improving crystallinity and optical transmittance of a mercurous halide single crystal, which comprises the following steps: placing the mercurous halide single crystal in a multi-temperature-zone vacuum annealing furnace, heating to 150-180 DEG C, and carrying out annealing treatment for 90-120 hours; and slowly cooling the annealed mercurous halide single crystal to room temperature. The half-peak width of an X-ray single crystal swing curve of the annealed mercurous halide crystal is obviously reduced, the crystallinity of the crystal is greatly improved, crystal defects are eliminated to a certain extent, and the optical transmittance of the mercurous halide crystal darkened in light is recovered through annealing aftertreatment, so that the optical transmittance of the mercurous halide crystal which is darken when meeting light is recovered, and the crystal transmittance is obviously improved. The method has low requirements on temperature, and has the advantages of simplicity, convenience and easiness in control. By adopting the method, the mercurous halide crystal with high crystallinity and optical transmittance can be obtained, which is of great significance to the preparation and application of a mercurous halide crystal acousto-optic device.

Owner:SHANDONG UNIV

A photo-darkening test device and method for ytterbium-doped silica fiber with all-fiber structure

ActiveCN111006848BImprove stabilityCompact structureTesting fibre optics/optical waveguide devicesEngineeringMaterials science

The invention discloses a photo-darkening test device for ytterbium-doped silica fiber with an all-fiber structure. The signal light output by the signal source passes through the optical fiber flange and the optical fiber attenuator in turn, and then passes through the pump light output by the first pumping source. The combined beam is synthesized by the wavelength division multiplexer; the combined beam and the pump light output by the second pump source are respectively input through the signal end and the pump end of the fiber combiner, and the output light of the fiber combiner is passed along the ytterbium-doped fiber For transmission, the output end of the ytterbium-doped fiber is fused with the input end of the cladding light stripper, and the output beam of the cladding light stripper enters the optical power detector through the low photon darkening filter fiber; the low photon darkening filter fiber is the doped Yb fiber; doped with Yb 2 o 3 The concentration is not higher than 0.1%wt. The beneficial effect of the invention is that the light-darkening test device has an all-fiber structure, the test system has a compact structure, the test method is simple, the device cost is low, the power of the signal source can be precisely adjusted, the test conditions can be optimized, and the test signal-to-noise ratio is high.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

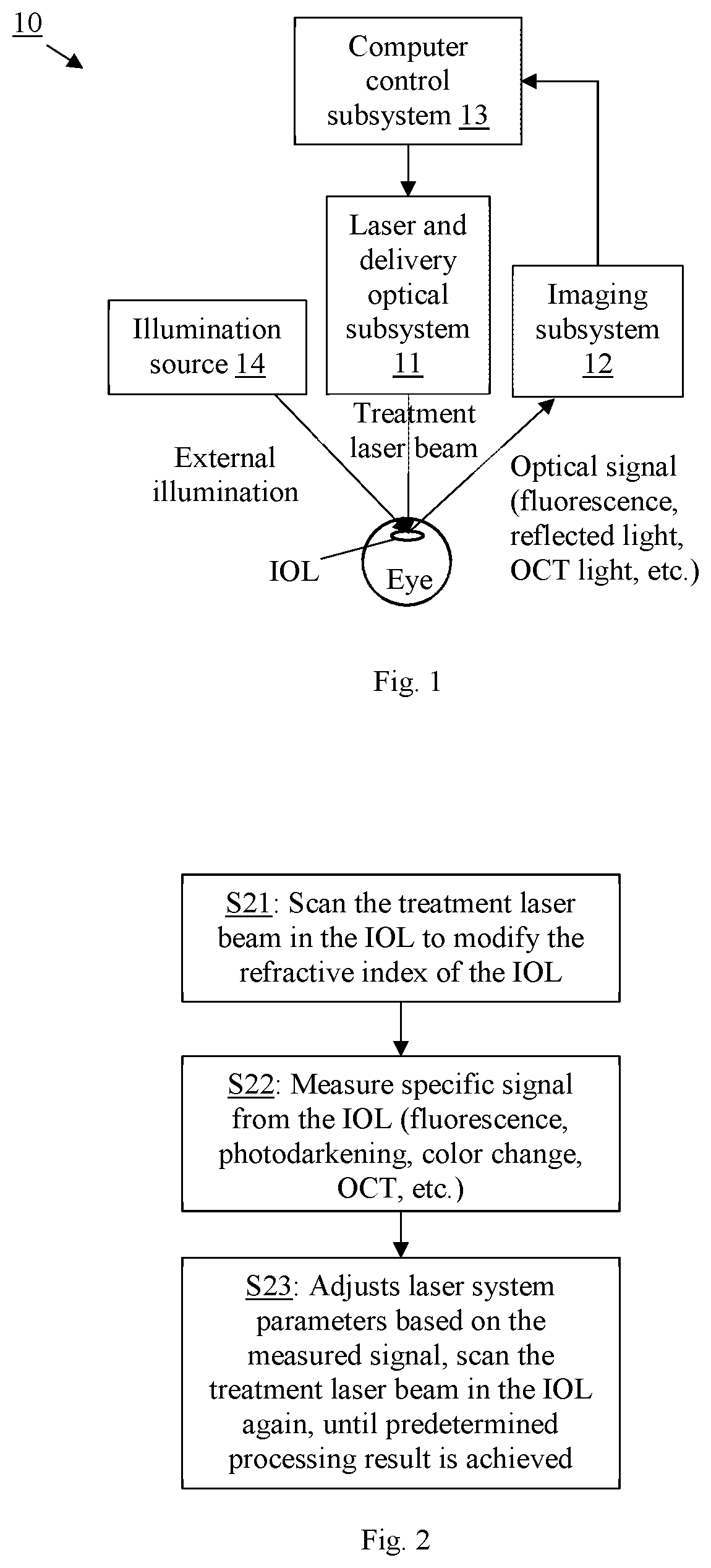

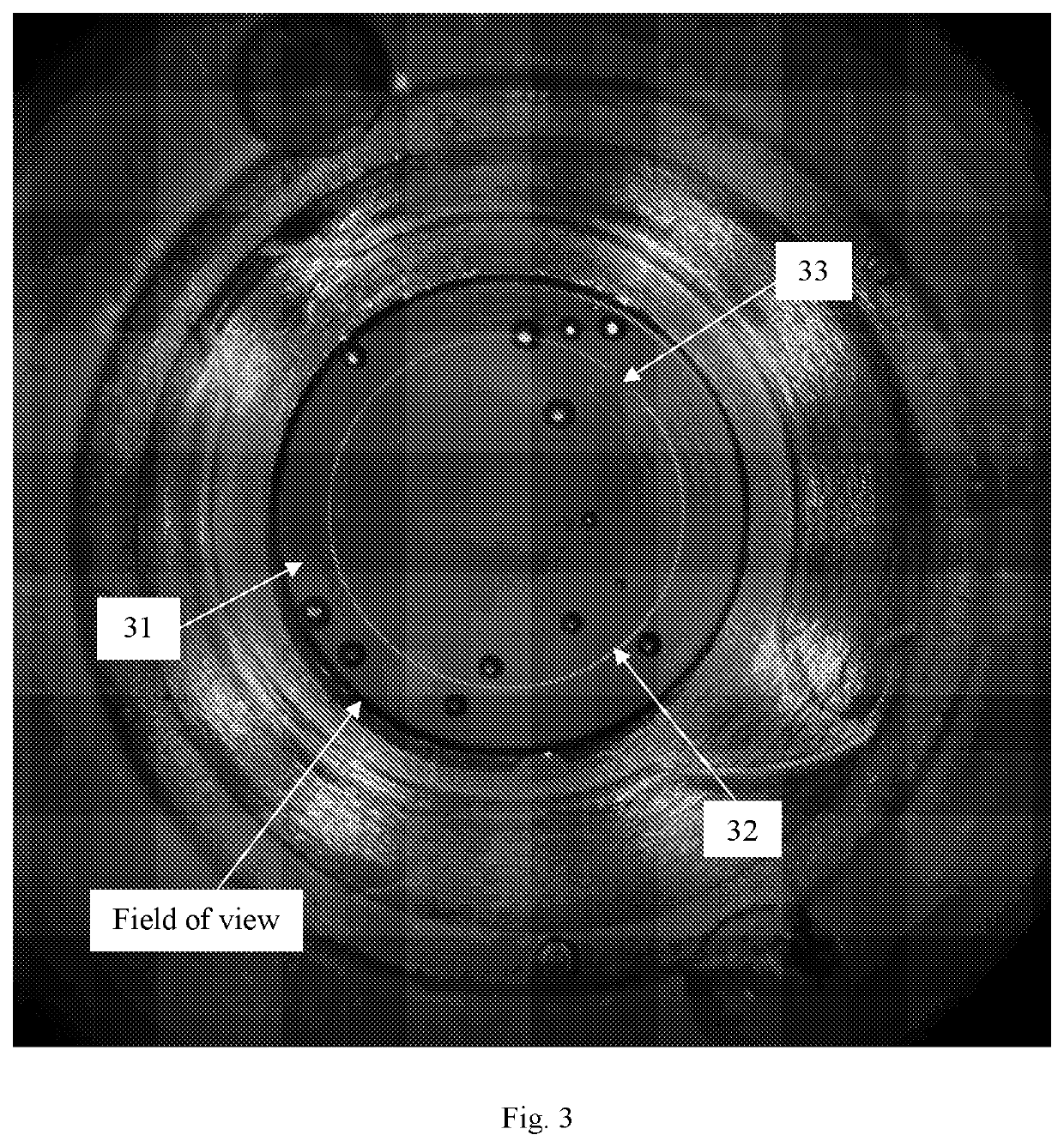

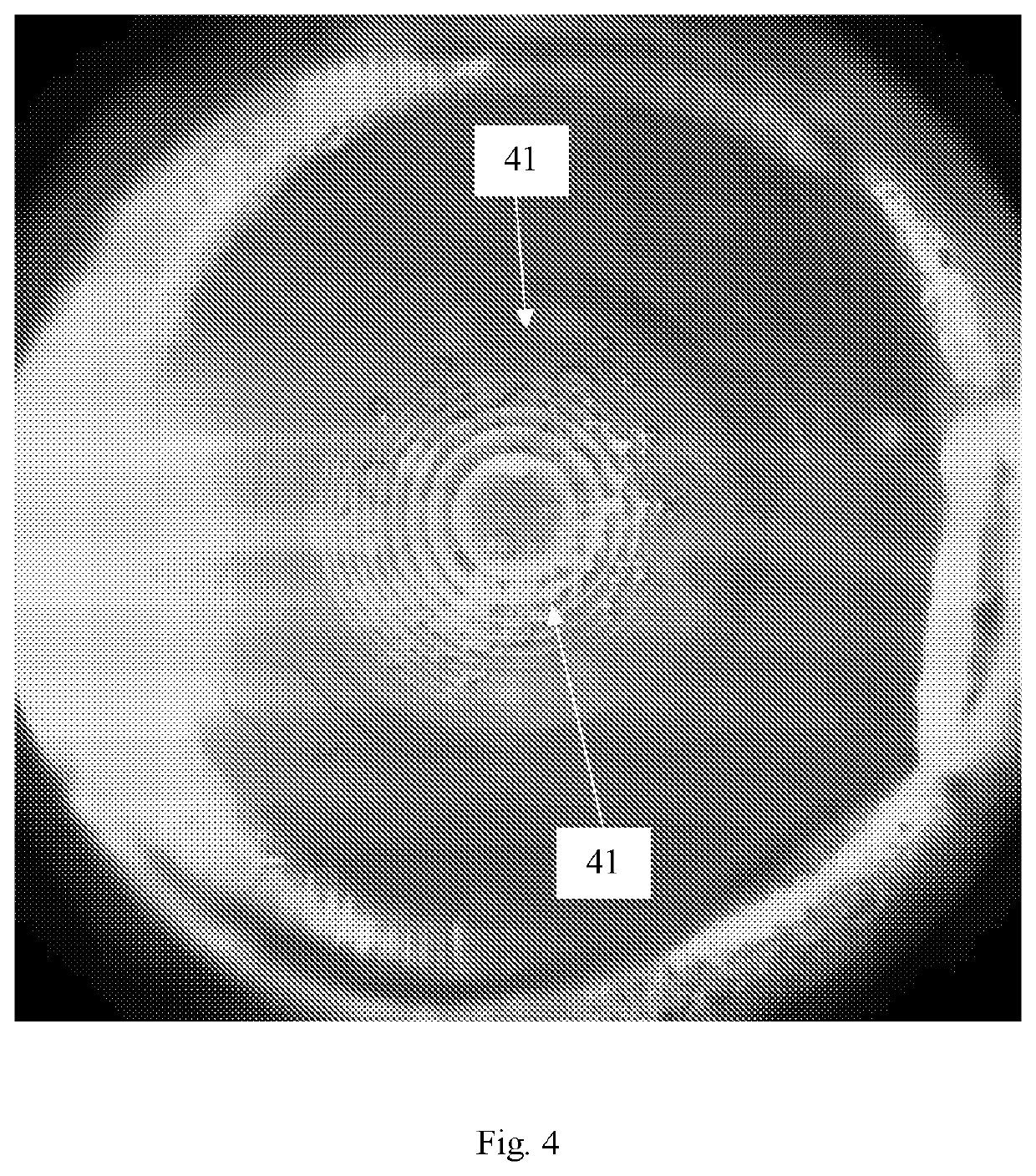

Process monitoring and control during laser-based refractive index modification of intraocular lenses in patients

Methods and related apparatus for real-time process monitoring during laser-based refractive index modification of an intraocular lens. During in situ laser treatment of the IOL to modify the refractive index of the IOL material, a signal from the IOL is measured to determine the processing effect of the refractive index modification, and based on the determination, to adjust the laser system parameters to achieve intended processing result. The signal measured from the IOL may be a fluorescent signal induced by the treatment laser, a fluorescent signal induced by an external illumination source, a temporary photodarkening effect, a color change, or a refractive index change directly measured by phase stabilized OCT.

Owner:AMO DEVMENT

Optically active glass and optical fiber with reduced photodarkening and method for reducing photodarkening

InactiveUS8055115B2Reduced photodarkening propertyReduce impactGlass/slag layered productsYarnOptical propertySilicon dioxide

An optically active glass and an optical fiber comprising such glass, having reduced photodarkening properties are provided. The optically active glass is mainly composed of silica representing from about 50 to 98 mol % of the glass. It also includes at least one active ion, such as a rear-earth ion, which induces a photodarkening effect in optical properties of the glass. Moreover, the glass includes an effective amount of phosphorus oxide providing the photodarkening reducing effect, preferably in an amount of from about 1 to 30 mol %. A method for reducing a photodarkening effect in optical properties of an optically active glass including the step of introducing phosphorus oxide to the glass is also provided.

Owner:CORACTIVE HIGH TECH

A darkening bleaching device and method based on fiber laser darkening maintenance

ActiveCN104993369BImprove stabilityImprove adaptabilityActive medium shape and constructionBleachOptoelectronics

The invention discloses a photon darkening bleaching device to solve the current situation of lack of intervention in the photon darkening phenomenon in the operation process of the ytterbium-doped fiber laser. The invention includes a darkening bleaching light source and a driving power source thereof. The present invention adds a darkening and bleaching device inside the ytterbium-doped fiber laser, so the main structure of the fiber laser is not changed and has high applicability. The device of the invention is especially suitable for periodically bleaching the darkening of the fiber laser during work, which promotes the stability of the power of the fiber laser during use, slows down the photon darkening process of the laser, and improves the service life of the laser.

Owner:HUAZHONG UNIV OF SCI & TECH

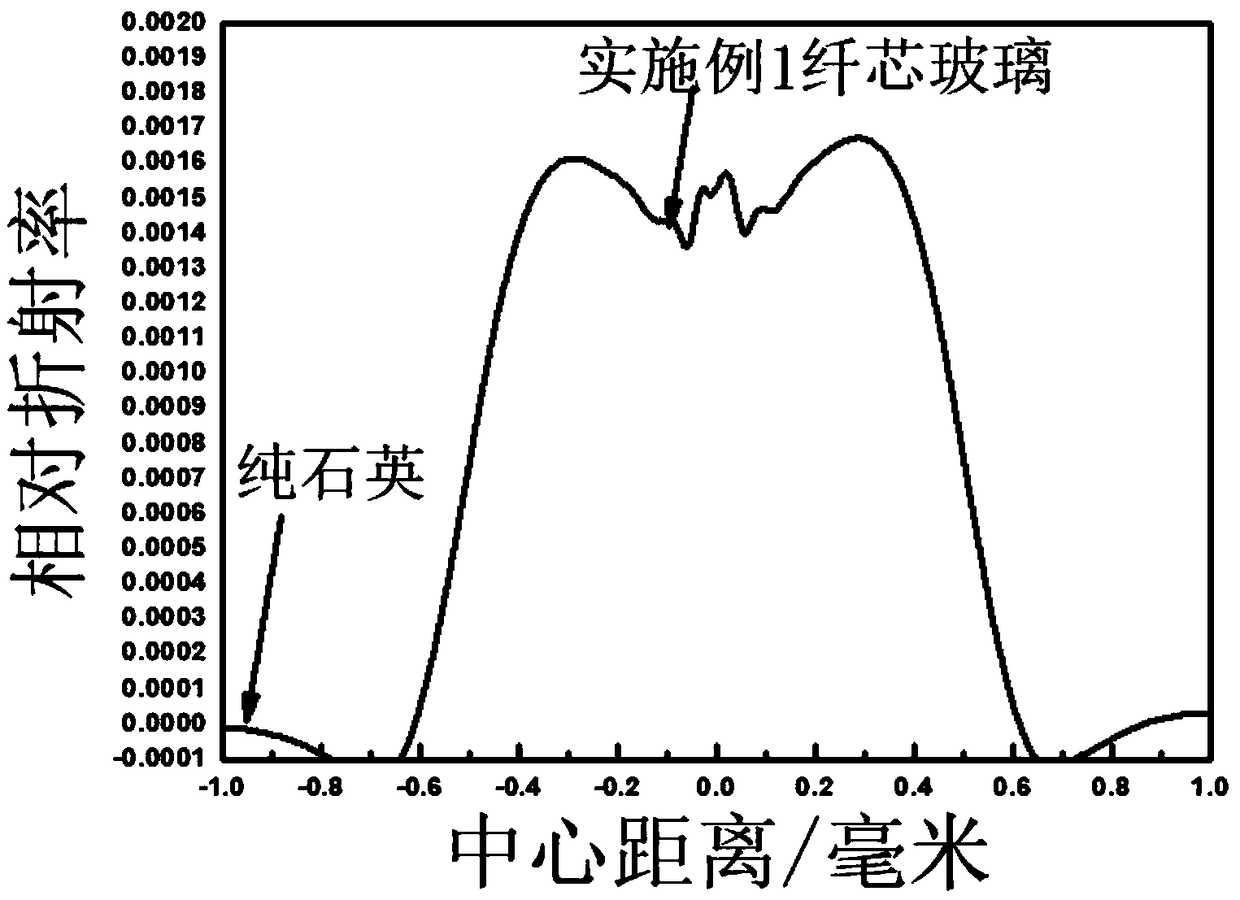

A kind of anti-photodarkening ytterbium-doped silica fiber and its preparation method

The invention relates to an anti-photodarkening ytterbium-doped silica fiber and a preparation method thereof. Specifically, the present invention provides an anti-photodarkening ytterbium-doped silica optical fiber, the glass of the optical fiber core rod at least includes Yb 2 o 3 、Al 2 o 3 ,P 2 o 5 , SiO 2 , where Yb 2 o 3 、Al 2 o 3 ,P 2 o 5 The proportions in the whole substance are: Yb 2 o 3 : 0.05~0.3mol%, Al 2 o 3 : 1~3mol%, P 2 o 5 : 1 to 5 mol%. The invention also provides a preparation method of an anti-photodarkening ytterbium-doped silica fiber. The present invention combines the sol-gel method and the improved chemical vapor deposition method, respectively utilizes its molecular-level doping uniformity and low-loss preparation advantages, effectively doping ytterbium ions, aluminum ions and phosphorus ions into the quartz matrix, effectively solving the problem of It solves the problems of high fiber loss, photodarkening due to clusters and other reasons, and the depression of the refractive index center.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com