Transparent ceramic and preparation method thereof

A transparent ceramic and powder technology, applied in the field of transparent ceramics and its preparation, can solve the problems of material thermal conductivity loss, aggravated thermal effect of laser system and pump light darkening effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

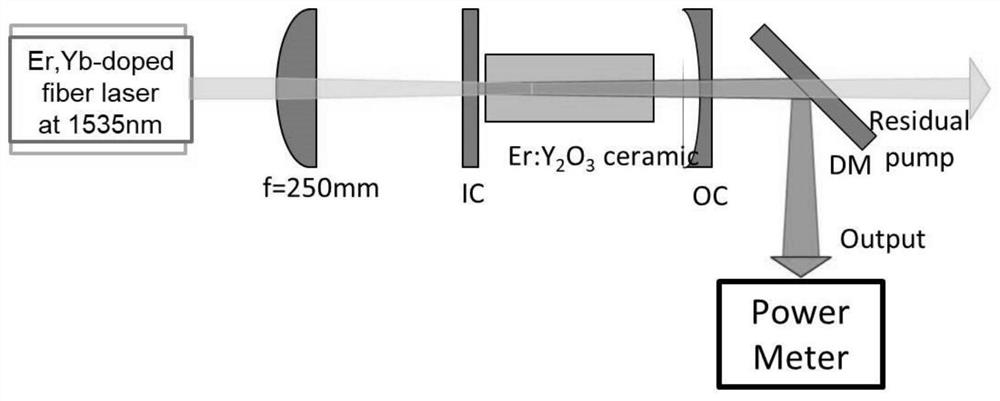

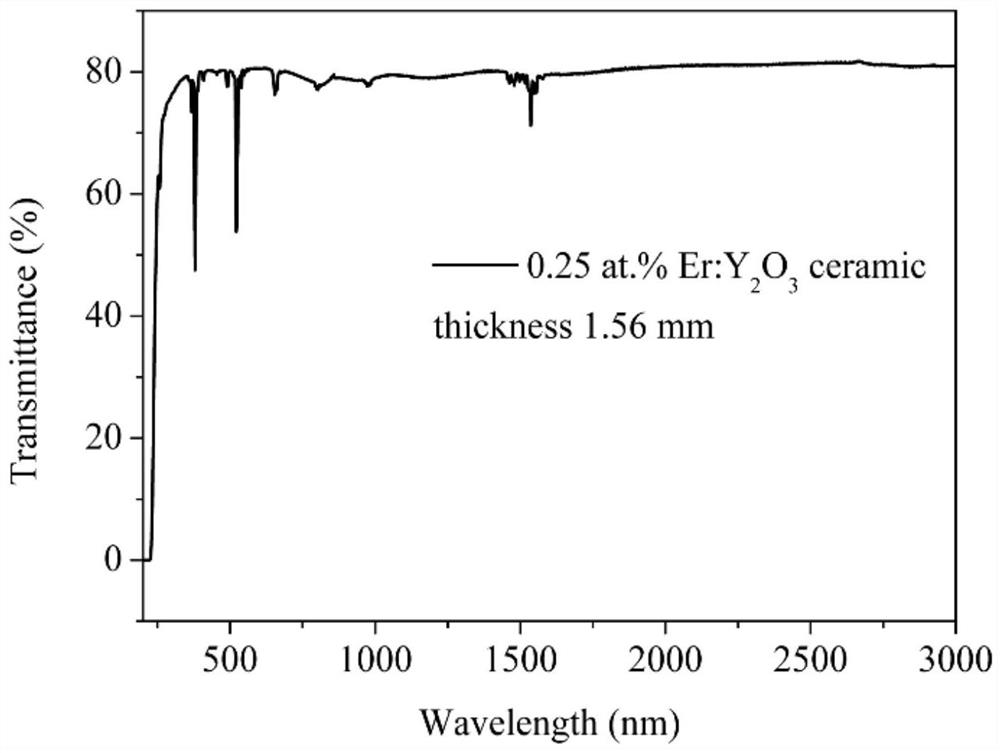

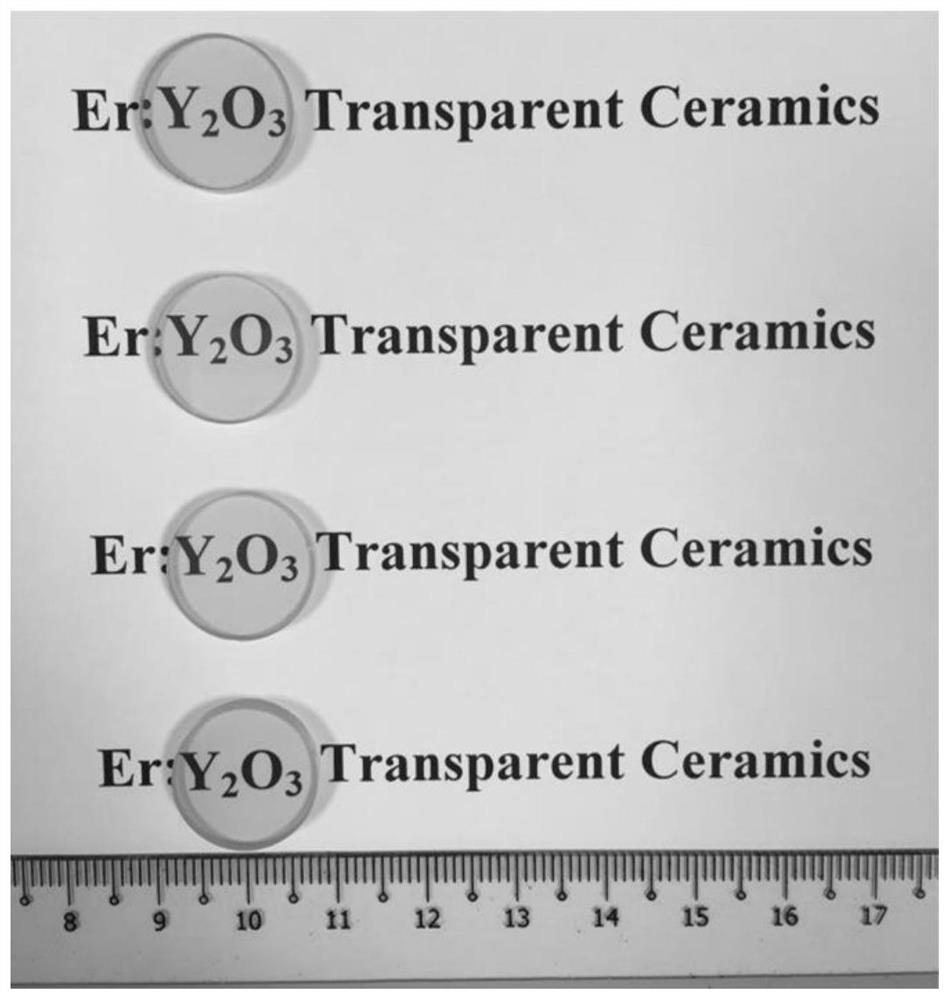

[0037] Such as Figure 1 to Figure 4 Shown, a kind of preparation method of transparent ceramics is characterized in that, comprises:

[0038] Step A, put Y 2 o 3 and Er-containing dopants according to the chemical formula (Er x Y 1-x ) 2 o 3 Weigh and mix to obtain mixed powder, wherein, 0.0005≤x≤0.005, and successively undergo ball milling, drying, grinding, sieving and calcining to obtain Er:Y 2 o 3 Powder;

[0039] When Er 3+ When the ion concentration is higher than 0.5 at.%, there will be a more obvious up-conversion phenomenon, and the up-conversion is not conducive to the generation of 1.6 μm laser. Therefore, the optimal situation is according to the chemical formula (Er x Y 1-x ) 2 o 3 (0.0005≤x≤0.005) Weigh the raw materials.

[0040] Preparation of Er in step A: Y 2 o 3 The powder steps include:

[0041] The weighed high-purity Y 2 o 3and Er-containing dopants are placed in a ball mill and absolute ethanol is added to obtain a slurry with a powde...

Embodiment 1

[0061] Use commercial high-purity Y 2 o 3 and Er 2 o 3 powder as raw material. According to the chemical formula (Er 0.0025 Y 0.9975 ) 2 o 3 The raw material is weighed, wherein the yttrium oxide is 80g. After adding 100 mL of absolute ethanol and 500 g of zirconia balls, ball milling was carried out. The rotational speed of the ball mill was 140 rpm, and the ball milling time was 10 h. After the materials are mixed evenly, put them into an oven at 50°C to dry for about 48 hours, then grind them and sieve them, and finally calcinate them in a muffle furnace for 3 hours at a calcination temperature of 800°C to obtain Er:Y 2 o 3 Powder.

[0062] Er:Y 2 o 3 The powder is first unidirectionally pressed under a pressure of 5MPa. In order to further increase the density, the green body is subjected to cold isostatic pressing under 200MPa to obtain Er:Y 2 o 3 Ceramic bisque.

[0063] The green body was sintered at 1500°C for 5 hours in a flowing oxygen atmosphere, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com