Deep ultraviolet single-mode polarization maintaining optical fiber manufacturing device and method

A polarization-maintaining fiber and manufacturing device technology, which can be applied to polarization fibers, clad fibers, manufacturing tools, etc., can solve the problems of reducing the effect of de-lightening and darkening, and achieve the advantages of improving the transmission capacity of ultraviolet light, optimizing the production efficiency, and reducing the cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to facilitate those of ordinary skill in the art to understand and implement the present invention, the present invention will be described in further detail below in conjunction with the examples. It should be understood that the implementation examples described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

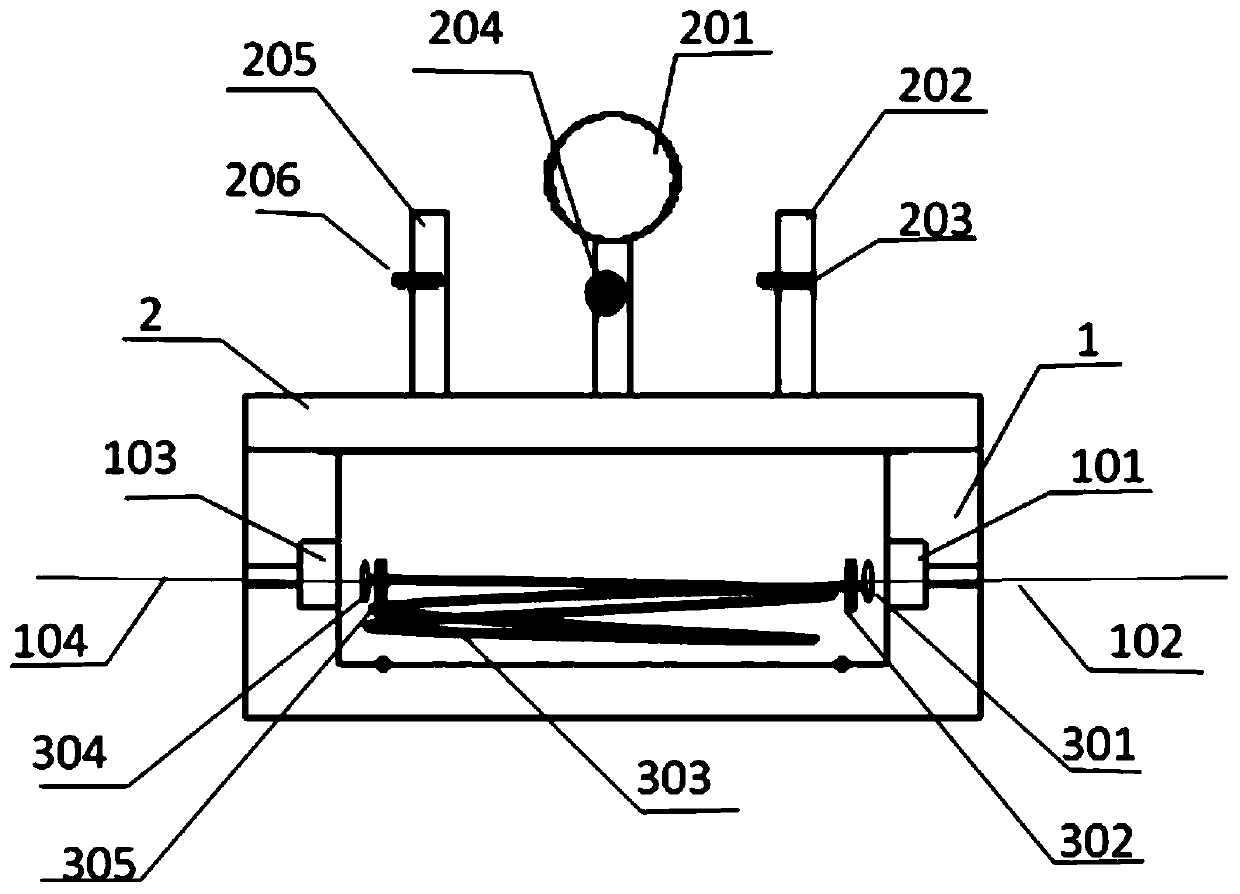

[0030] A method and device for manufacturing a deep ultraviolet single-mode polarization-maintaining optical fiber. Including an autoclave, the autoclave includes an autoclave main cavity 1 and an autoclave cover plate 2, and the opposite sides of the autoclave main cavity 1 are respectively provided with a laser input port 102 and a laser output port 104, and the input port quartz glass window 101 and The output port quartz glass window 103 is respectively installed in the inner side of the laser input port 102 and the laser output port 104 of the autoclave main chamber body 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com