Darkening bleaching device and method based on fiber laser darkening maintenance

A technology of fiber lasers and lasers, applied in lasers, laser components, phonon exciters, etc., can solve problems such as inability to improve and darkening cannot be adjusted, achieve high stability and adaptability, slow down the darkening process, and ensure The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

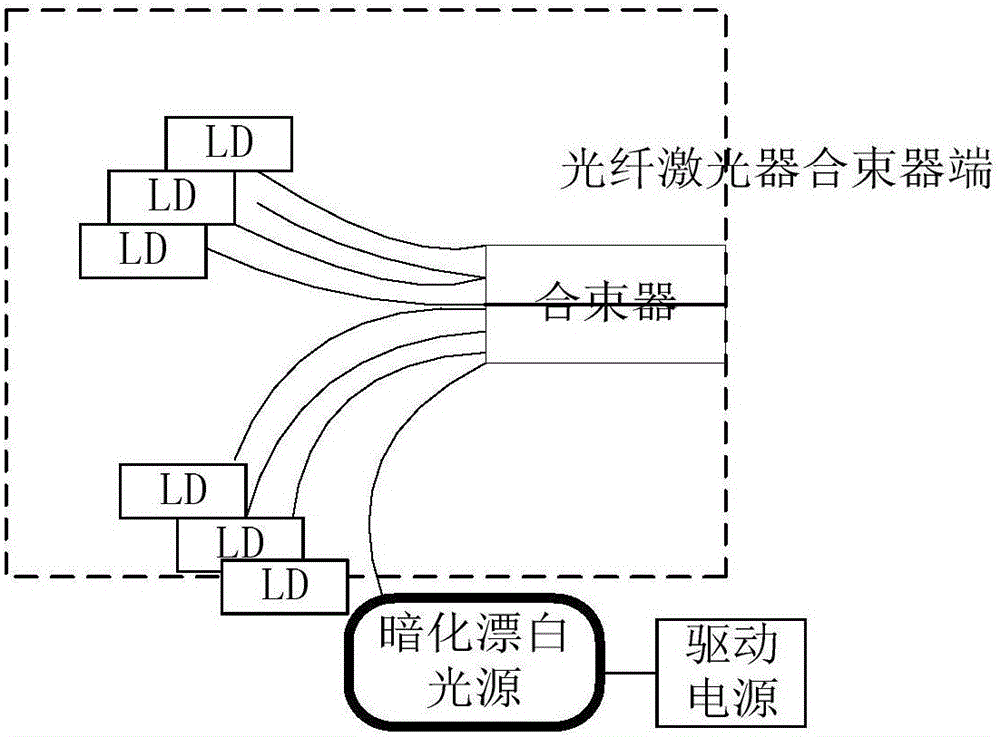

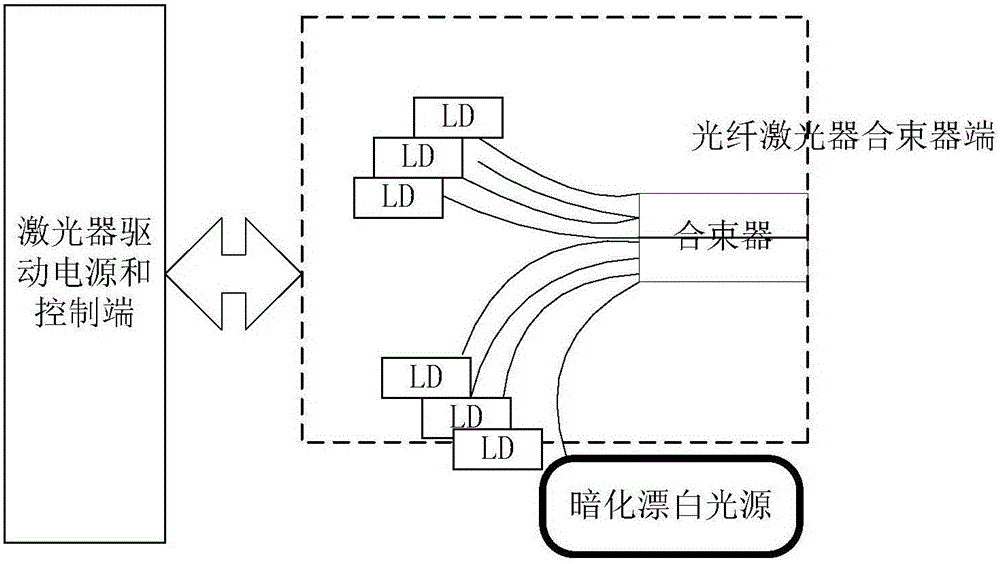

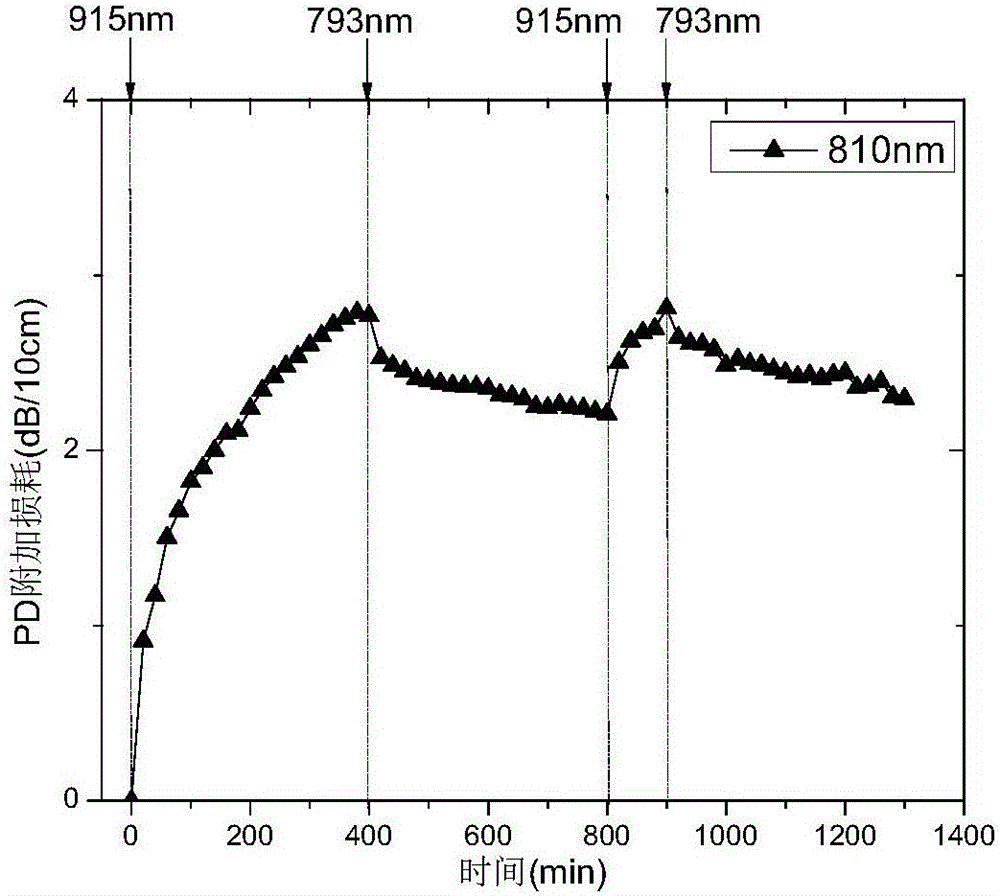

Method used

Image

Examples

example 1

[0032] The instructions for using the darkening and bleaching device of the present invention to carry out laser photon darkening and bleaching are as follows;

[0033] When the 30w ytterbium-doped laser works for 300 hours, when the pump light (915nm or 975nm pump source) is turned off, turn on the driving power of the darkened bleaching light source, adjust the input power, and use the center wavelength at 793nm to darken the bleaching light source The output power is 5 watts and it can work continuously for 12 hours. Turn off the driving power of the darkened bleaching light source, and use it again in accordance with the requirements for the use of ytterbium-doped fiber lasers. After working for 300 hours, the power of the 30w ytterbium-doped fiber laser dropped to 29w. After darkening and bleaching using the darkening and bleaching device of the present invention, the power is restored to 29.7 watts, and the recovery degree of darkening and bleaching reaches 70%. When t...

example 2

[0035] The instructions for using the darkening and bleaching device of the present invention to carry out laser photon darkening and bleaching are as follows;

[0036] When the 100w ytterbium-doped laser is pumped for 150 hours, when the pump light (15nm or 975nm pump source) is turned off, turn on the driving power of the darkened bleaching light source, adjust the input power, and use the center wavelength at 808nm to darken the bleaching light source The output power is 12 watts and it can work continuously for 12 hours. Turn off the driving power of the darkened bleaching light source, and use it again in accordance with the requirements for the use of ytterbium-doped fiber lasers. The recovery rate of the power loss caused by the darkening of the ytterbium-doped fiber laser before and after darkening and bleaching by adding the darkening and bleaching device of the present invention is 68%. After the fiber laser works for 300 hours, the above steps are repeated to final...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com