Amplifying optical fibre and production method

A production method and optical fiber technology, applied in cladding optical fiber, optics, lasers, etc., can solve the problems of reducing optical fiber core photo-darkening, not ensuring high concentration of rare earth ions, etc., maximizing amplification efficiency and avoiding photo-darkening The effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0051] Example 1: Production of optical fibers for pulsed lasers

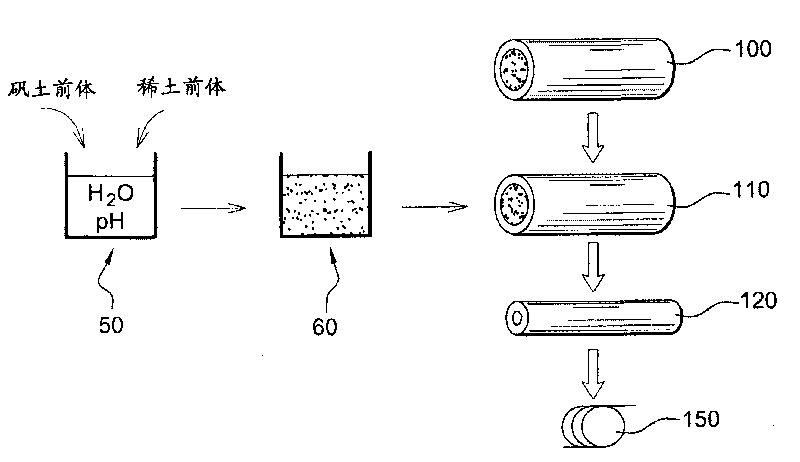

[0052] The chemical synthesis of nanoparticles of ytterbium doped alumina was performed. The size of the nanoparticles is about 5nm. Precursors of alumina and ytterbium salts co-precipitate in aqueous solution at controlled pH (final pH 4). The molar ratio of the precursors of alumina salt and ytterbium salt is about 20 in order to ensure good dispersion of ytterbium ions in the alumina matrix. It is thus possible to guarantee a minimum distance between the two ytterbium ions in each nanoparticle so as not to form clusters.

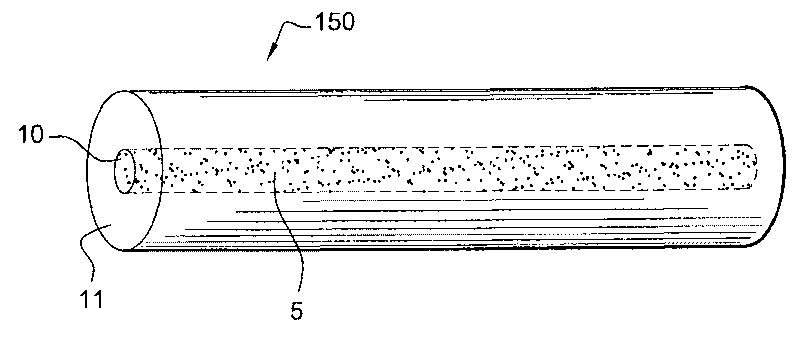

[0053] Take about 8·10 17 NPs / cm 3 Aqueous solutions of these nanoparticles were prepared. This solution was then used to impregnate the porous silica rod core by MCVD operation. A heat treatment at a temperature above 1000° C. is applied for at least 1 hour before the clearing step of the core in order to strengthen the nanoparticle structure in the core. The primary preform is t...

example 2

[0055] Example 2: Production of optical fibers for compact amplifiers

[0056] A chemical synthesis of nanoparticles of erbium-doped alumina was performed. The size of the nanoparticles is about 10 nm. Precursors of alumina and erbium salts were co-precipitated in aqueous solution at controlled pH (final pH 9). The molar ratio of the precursors of alumina salt and erbium salt is about 200 in order to ensure good dispersion of erbium ions in the alumina matrix and a high concentration of aluminum close to each erbium ion to broaden the Er gain band. A minimum distance between two erbium ions can be guaranteed in each nanoparticle to avoid cluster formation.

[0057] Take about 2·10 17 NPs / cm 3 Aqueous solutions of these nanoparticles were prepared. This solution was then used to impregnate the porous silica rod core by MCVD operation. Before the clearing stage of the core, a heat treatment at a temperature above 1000° C. is applied for at least 1 hour in order to streng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com