Treatment method for improving crystallinity and optical transmittance of mercurous halide single crystal

A technology for single and processing methods of mercury halide, which is applied in the field of processing to improve the crystallinity and optical transmittance of mercury halide single crystals, and can solve the problem of not being able to solve the darkening characteristics of mercury halide or restore the performance of darkened crystals, device preparation and application adverse effects, low crystal quality, etc., to achieve the effect of crystallinity and optical transmittance improvement, optical transmittance recovery, and low temperature requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The processing method for improving the crystallinity and optical transmittance of mercury bromide single crystal, the steps are as follows:

[0034] (1) Mercury bromide crystal treatment

[0035] Use SYJ-150 low-speed diamond cutting machine to Ф35×40mm 3 Mercury bromide crystal is cut to get 5×5×2mm 3 mercurous bromide chips. Use sandpaper with a roughness of 7000 mesh to roughly polish the cut wafers to remove cutting scratches, and then use Al with a particle size of 0.5 μm 2 o 3 Polish the wafer finely with the ethanol suspension of polishing powder, and rinse the wafer surface with ethanol after polishing.

[0036] (2) Post-annealing treatment

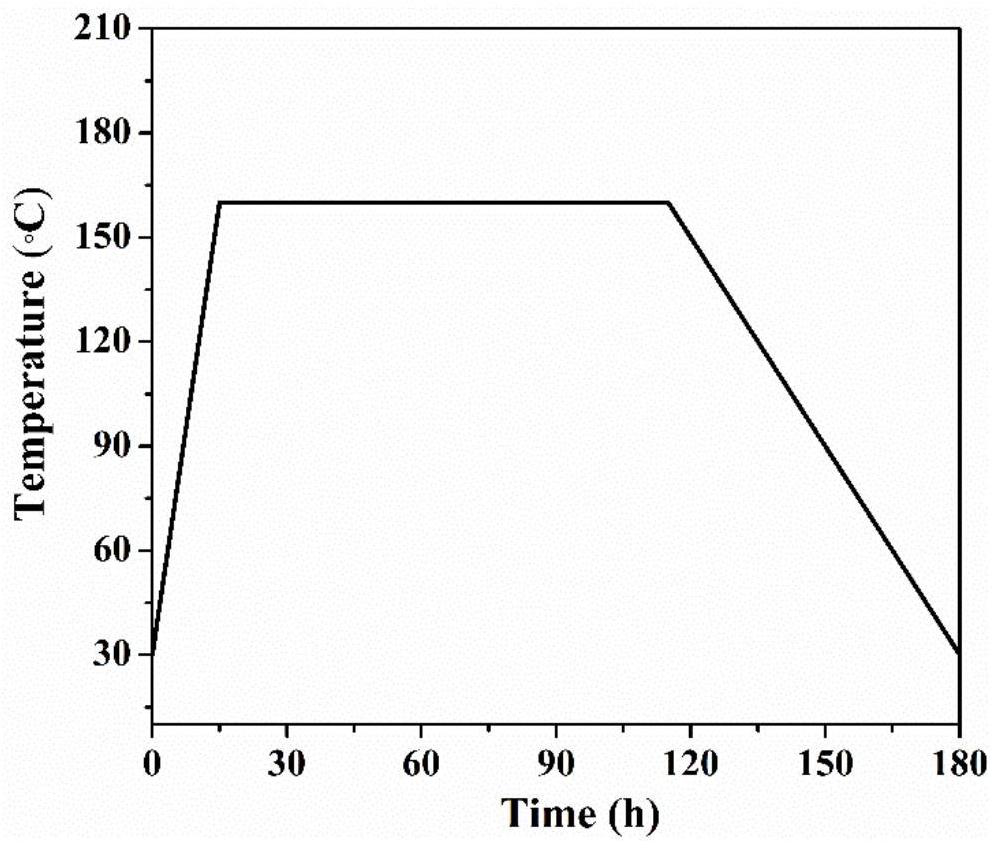

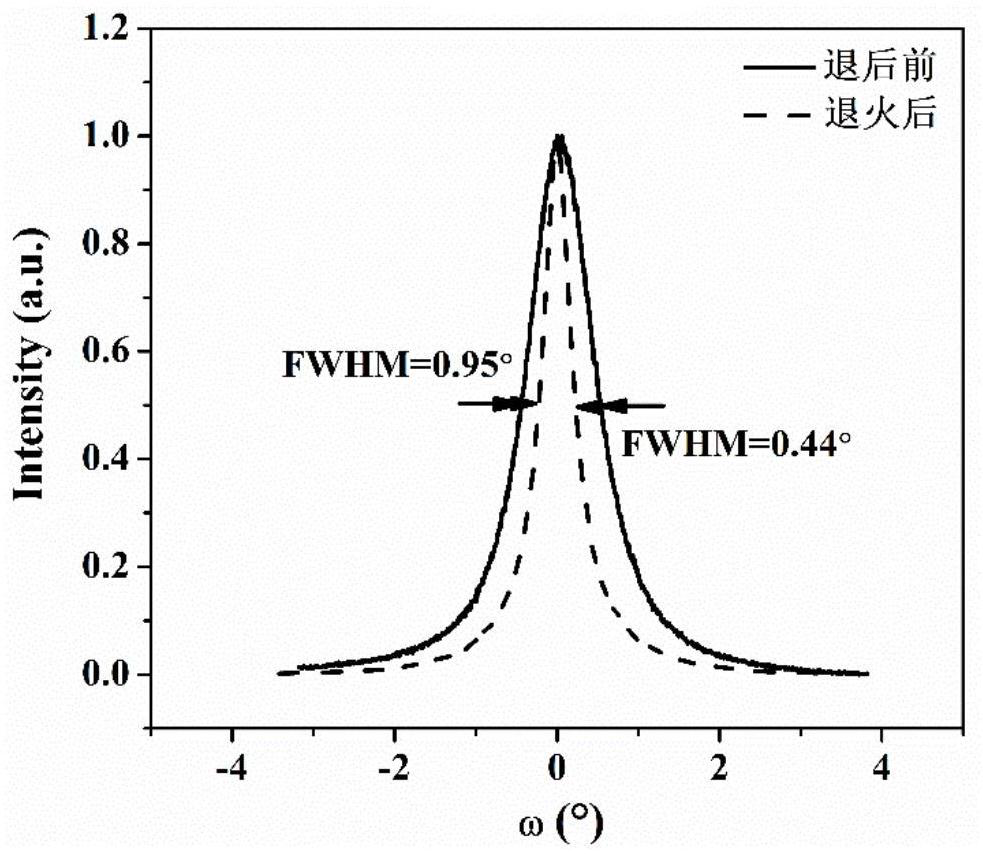

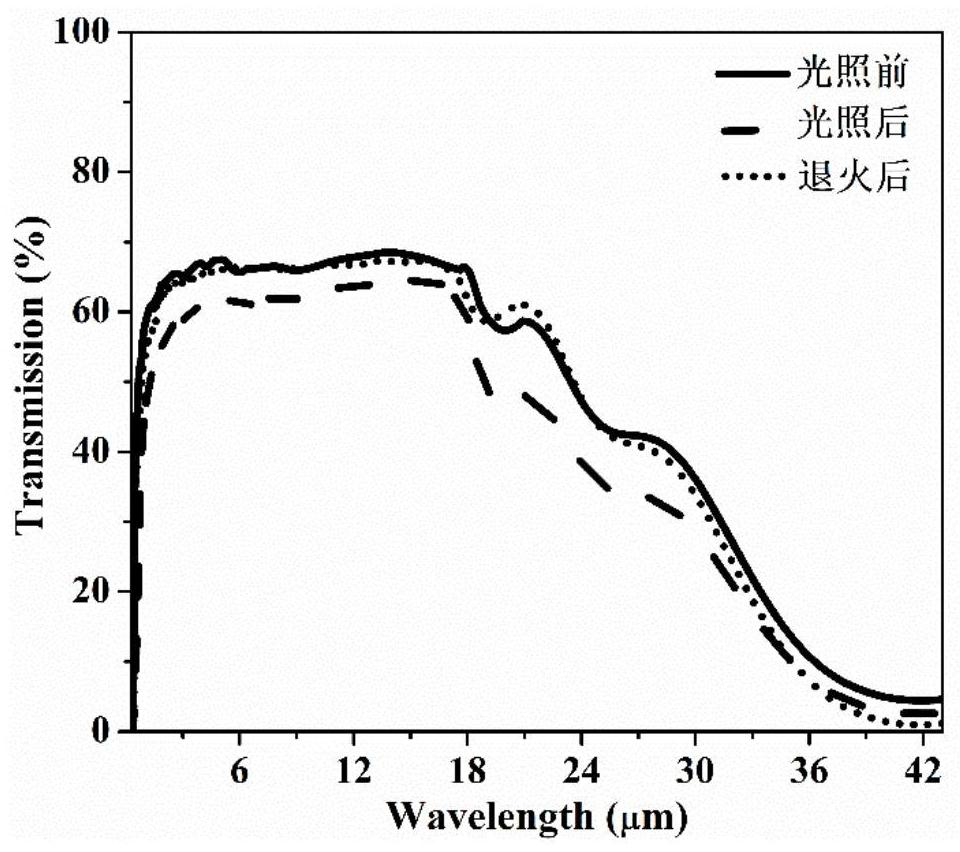

[0037] Place the double-sided polished mercury bromide wafer in the pretreated high-purity quartz crucible, and wait for the vacuum degree in the quartz crucible to drop to 10 -4 Below Pa, sinter and seal the quartz crucible and place it in a multi-temperature zone vacuum annealing furnace for post-annealing treatmen...

Embodiment 2

[0042] With the processing method described in embodiment 1, the difference is:

[0043] Replace the single crystal of mercurous bromide with the crystal of mercurous chloride.

Embodiment 3

[0045] With the processing method described in embodiment 1, the difference is:

[0046] Replace mercurous bromide single crystals with mercurous iodide crystals.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com