Laser radar composite view window and preparation process thereof

A technology of laser radar and preparation process, which is applied in the field of composite optical windows, can solve the problems of difficult long-term use of radar protection windows, insufficient surface strength, and easy breakage, so as to improve the transmission of infrared and visible light, improve mechanical strength and toughness, The effect of surface hardness and scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

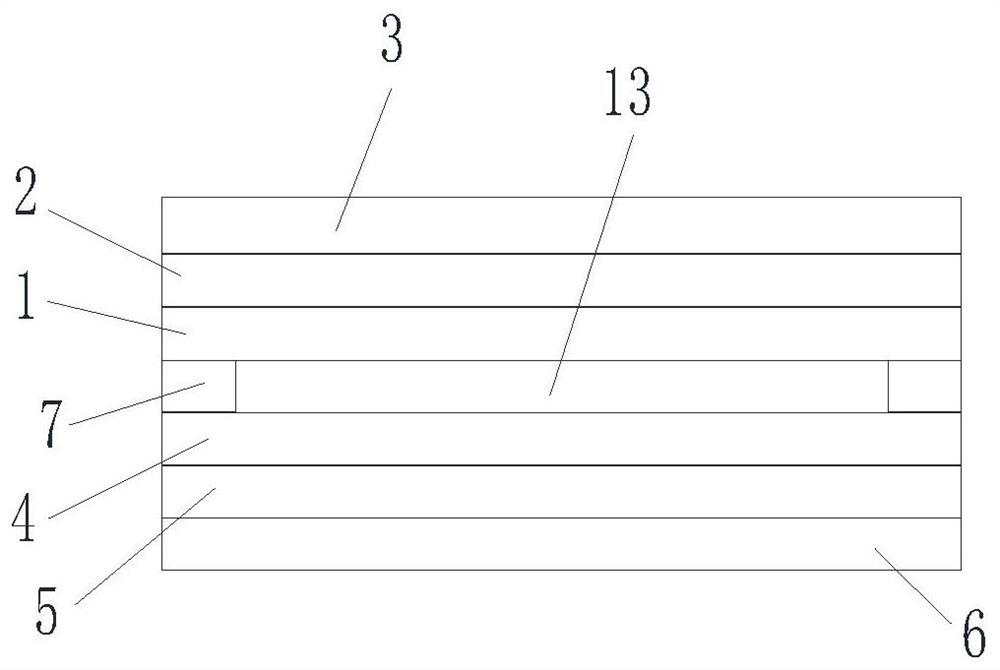

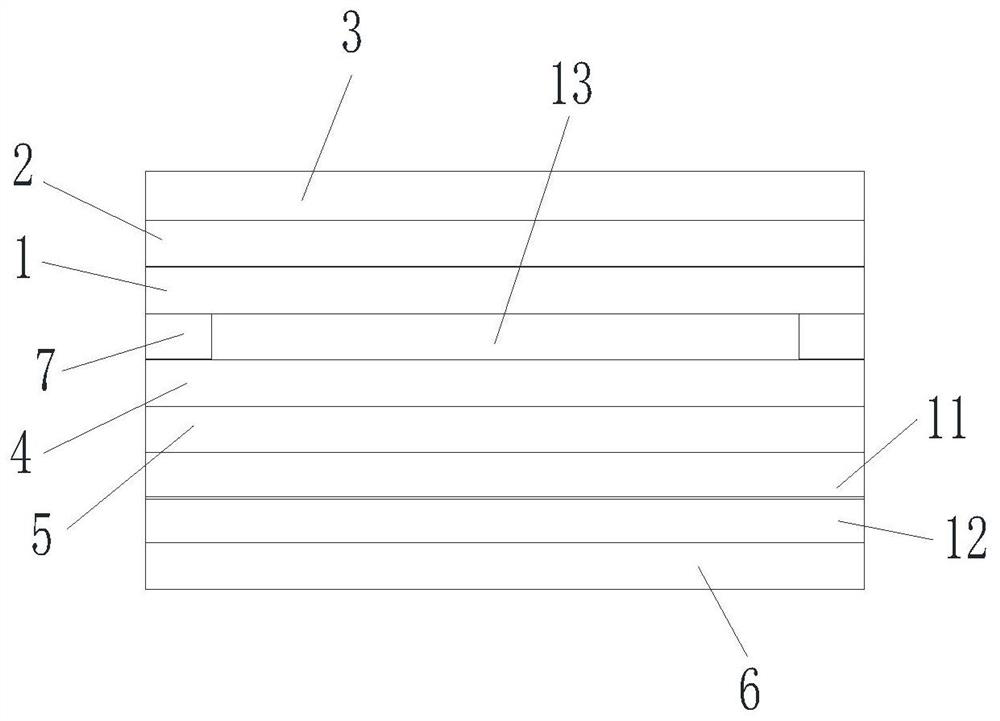

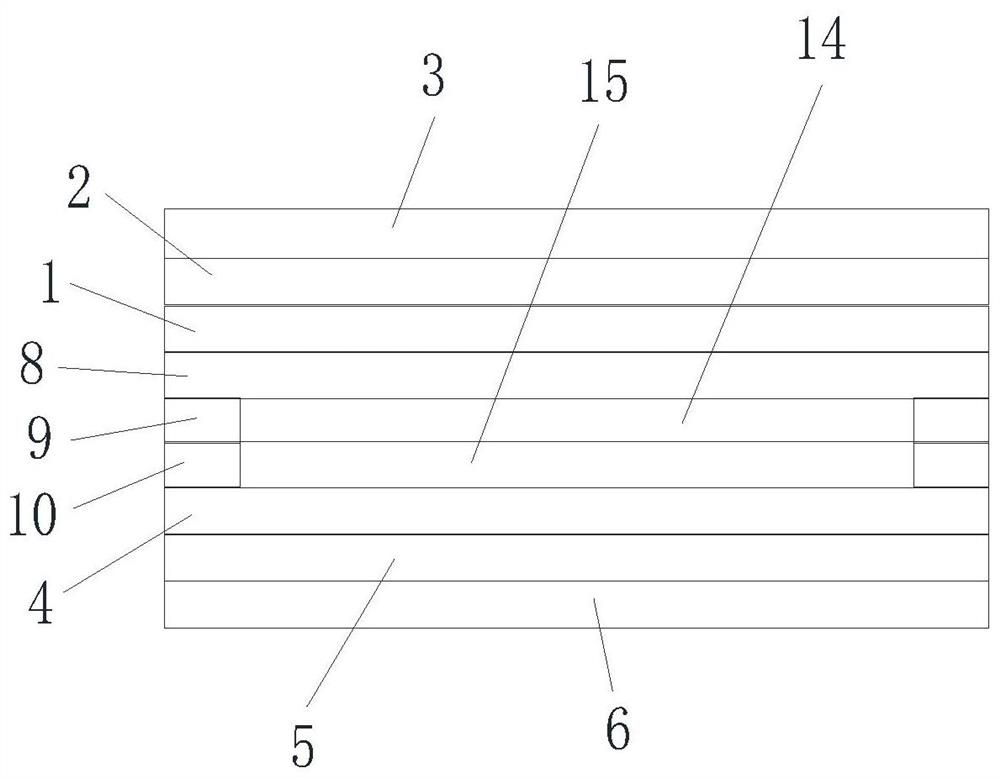

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

[0033] see Figure 1 to Figure 4 As shown, the present invention provides an embodiment: a lidar composite window, including a first optical glass 1, and the outer surface of the first optical glass 1 is provided with a first AR visible light infrared anti-reflection film 2 from the inside to the outside and the AF super-hydrophobic film 3, the inner surface of the first optical glass 1 is sequentially provided with a heating element, a first optical glue 4, a plastic 5 and a second AR visible infrared anti-reflection film 6 from the inside to the outside. Through the effect of composite lamination, the first AR visible light infrared anti-reflection film 2 and the second AR visible light infrared anti-reflection film 6 can be passed through. At the same time, infrared plastics are used to absorb visible light, so that the lidar protective window does not reflect light...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com