Resin lens with high impact resistance

A resin lens, high impact resistance technology, used in optics, instruments, optical components, etc., can solve the problems of low impact resistance, low Abbe number, poor impact strength, etc., to achieve improved impact resistance, high refraction rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

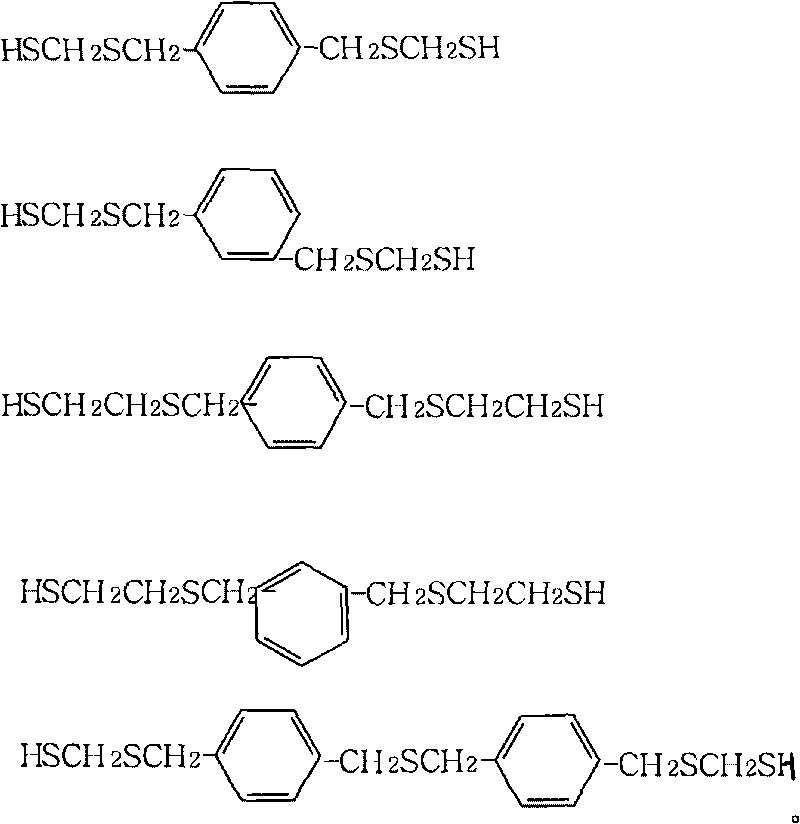

Method used

Image

Examples

example 1

[0026] Example 1, drop into isophorone diisocyanate 55.7g (0.25mol) and dibutyl tin dichloride 0.2g in a 250ml four-neck flask equipped with a thermometer, condenser, nitrogen inlet and stirrer, under nitrogen protection Heating to 50°C; adding 96.2g (0.5mol) of dimercaptomethylthioethane dropwise for 1 hour, and then aging at 60°C for 2 hours to obtain 152.1g of mercapto-terminated polythiourethanes The solution of the prepolymer; its refractive index n D 25 1.5753, viscosity η 25 80CP.

example 2

[0027] Example 2, drop into 55.7g (0.25mol) of isophorone diisocyanate (0.25mol) and 0.25g of dibutyl tin dichloride in a 250ml four-necked flask equipped with a thermometer, condenser, nitrogen inlet and stirrer, under nitrogen protection Heating to 50°C; adding 50.1 g (0.4 mol) of dimercaptoethylthiomethane dropwise for 1 hour, and then aging at 60°C for 2 hours to obtain 106.05 g of mercapto-terminated polythiourethane precursors Polymer solution; its refractive index n D 25 1.5690, viscosity η 25 55CP.

example 3

[0028] Example 3, 222.3g (1.0mol) of isophorone diisocyanate (IPDI) and 209.8g (0.8mol) of dicyclohexylmethane diisocyanate were fully stirred for 1 hour under nitrogen protection to obtain 432.1g of polyisocyanate-containing compounds The solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com