Patents

Literature

110 results about "Dianhydrohexitol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

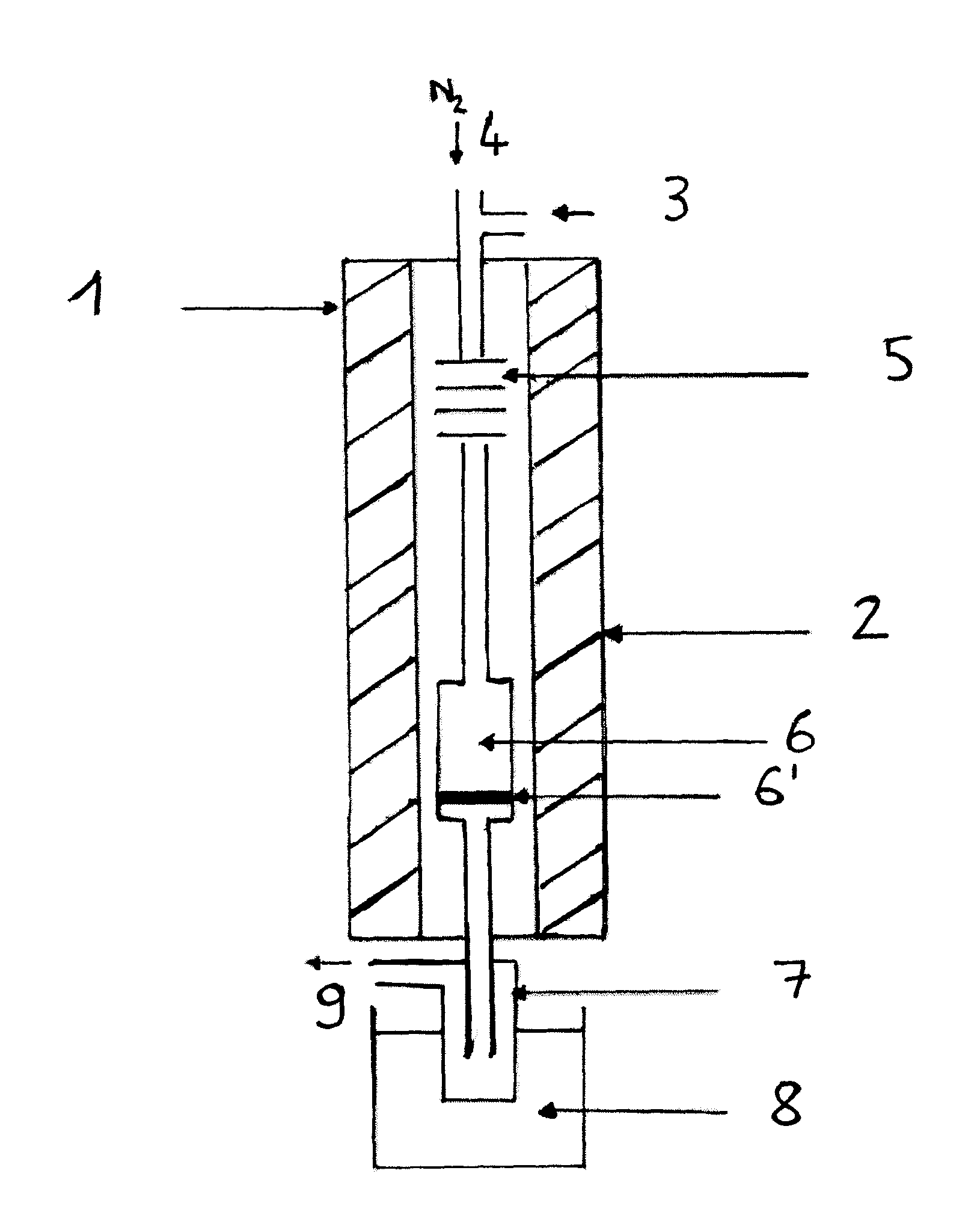

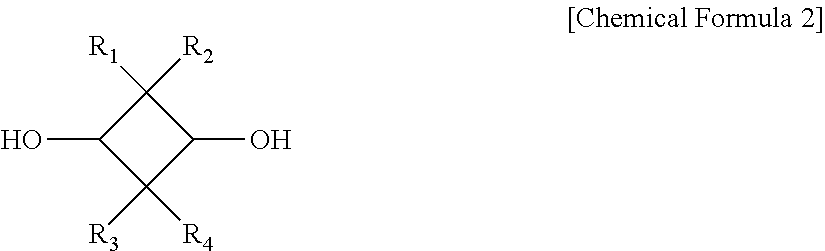

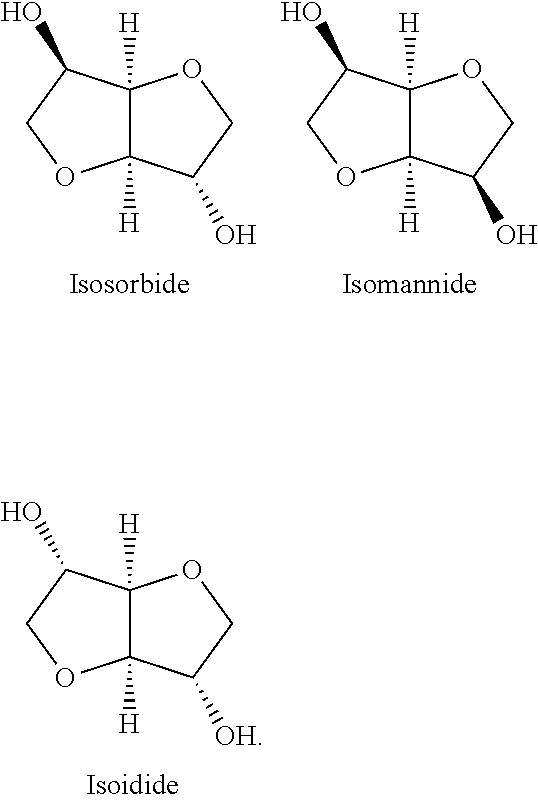

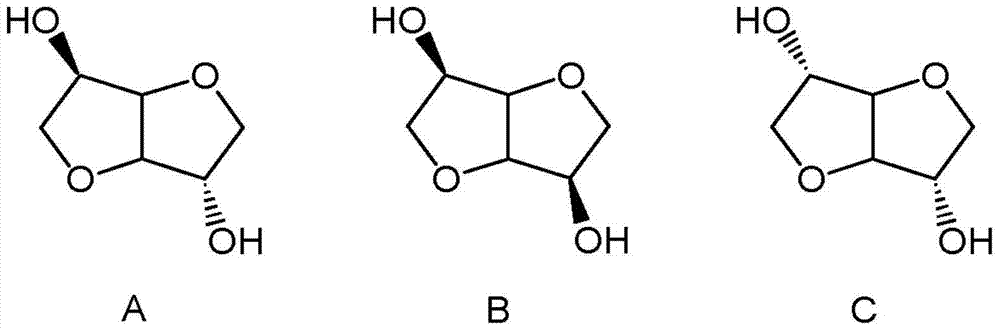

Dianhydrohexitols are heterocyclic compounds that are obtained by double dehydration of hexitols such as mannitol and sorbitol. Among these diols the 1,4- and 3,6-dianhydrohexitols are well known under the names isosorbide, isoidide and isomannide.

Two component solventless polyurethane laminating adhesives based on 1,4:3,6 dianhydrohexitols

InactiveUS20100136347A1Layered product treatmentPolyureas/polyurethane adhesivesMetallic foilDianhydrohexitol

A two component laminating adhesive is provided, wherein one component contains at least one isocyanate-functionalized compound and the other component contains one or more 1,4:3,6 dianhydrohexitols. A laminate may be formed by combining the two components to provide an adhesive and then using the adhesive to adhere one polymeric film or metallic foil to another polymeric film or metallic foil. The adhesive layer between the film and / or foil layers of the laminate is then cured. The adhesives exhibit faster green strength development and higher final bond strength as compared to conventional two component laminating adhesives not containing any 1,4:3,6 dianhydrohexitol as a coreactant.

Owner:SIMONS J BRANDON SIMONS +2

Impact-Resistant Polyurethane

ActiveUS20090171060A1Excellent thermo mechanical propertyGood chemical resistancePolyesterCyclohexanedimethanol

The present invention teaches a new process to produce novel, hard, optically clear, impact-resistant polyurethane polymers that are characterized by excellent thermo mechanical properties and chemical resistance, and the polymers made as a result of such a process.The polyurethanes are made by reactinga) a prepolymer made by reacting a polyisocyanate with a primary amine-terminated polyether with an amine functionality of about 2 and a molecular weight of >1000, and in which the free —NCO content of the resulting prepolymer is >18% by weight; withb) (i) a polyol having an average hydroxyl functionality greater than or equal to 2 and an average hydroxyl equivalent weight of from about 300 to about 1,000, and (ii) a curing agent that has isocyanate reactive groups, a functionality of 2 to 3 and a molecular weight of <400.More preferably the prepolymer is made by reacting a cycloaliphatic polyisocyanate with a primary amine-terminated polyether diamine of 2000 to about 2500 molecular weight, the polyol is either a polyester polyol triol with a molecular weight of between about 540 and 900, or a polyether glycol with a molecular weight of between about 650 and 2000, or a polyester polyol diol with a molecular weight of up to 2,000, and the curing agent is either dianhydrohexitol, an aromatic diamine, an aromatic ring containing diol or a cyclohexanedimethanol.

Owner:POLYPLEXX

Method for the treatment of a material other than the human body

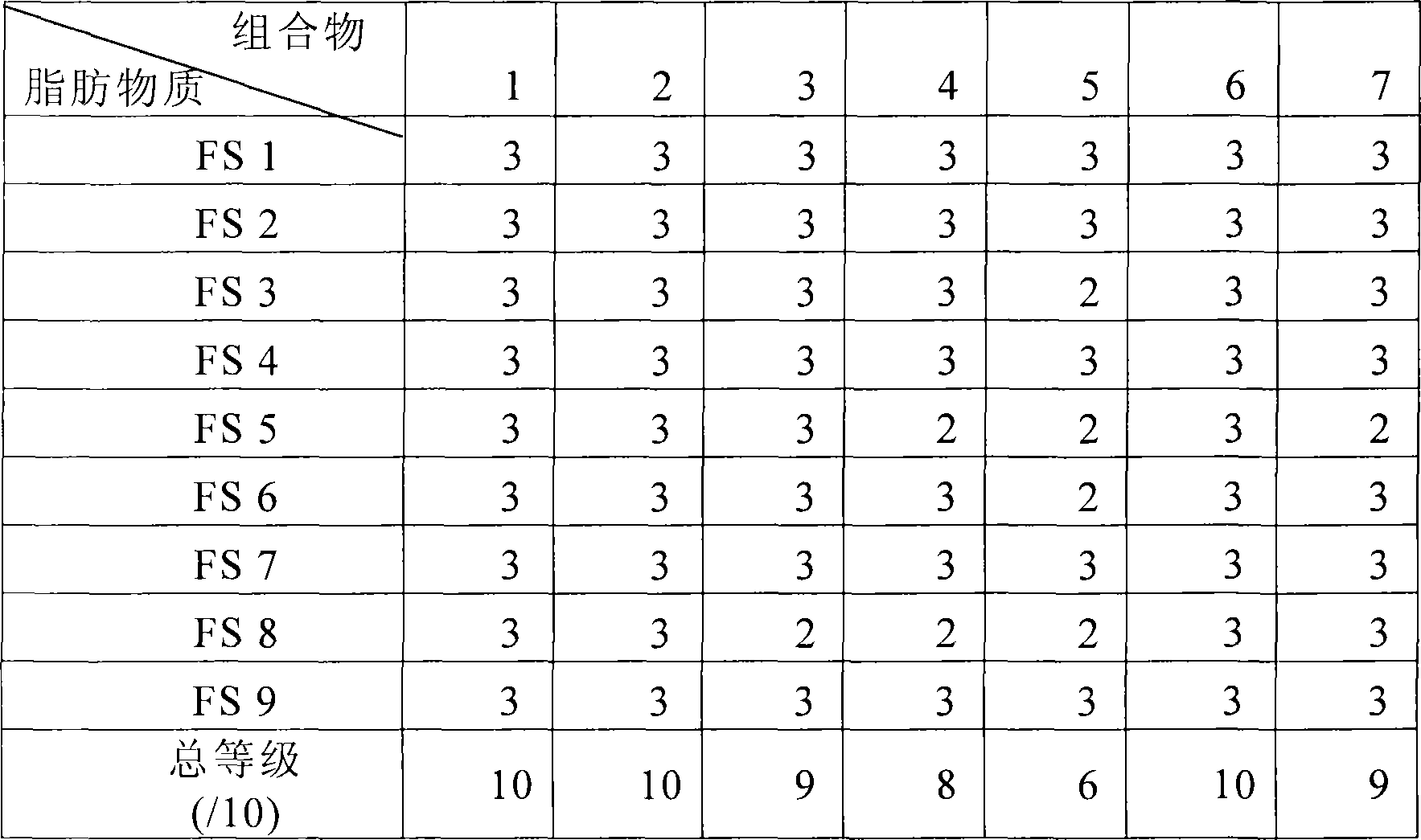

InactiveCN101175556ASame favorable characteristicsGood drying trendOrganic chemistryMixing methodsCompound aHuman body

The invention relates to a surface treatment method, in which a material other than the human body, which is selected from metallic materials and fibrous materials, is brought into contact with a composition comprising at least one dianhydrohexitol ether (compound A). The dianhydrohexitol ether can be associated with a compound B which is selected from among solubilising agents, acid agents and alkaline agents. The fibrous material to undergo surface treatment is chosen from the following materials in particular, namely: wood materials, vegetable materials, paper materials and textile materials.

Owner:ROQUETTE FRERES SA

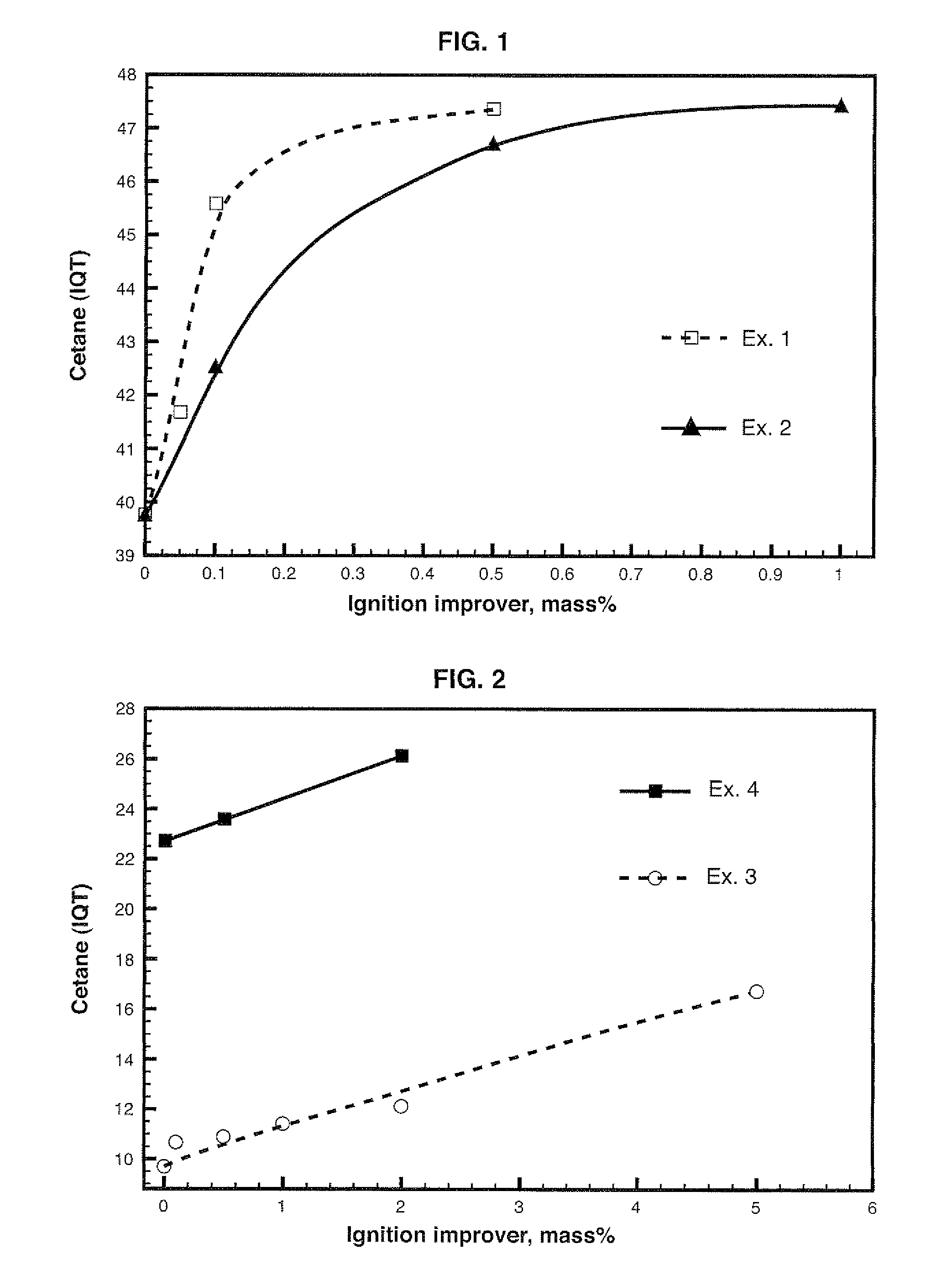

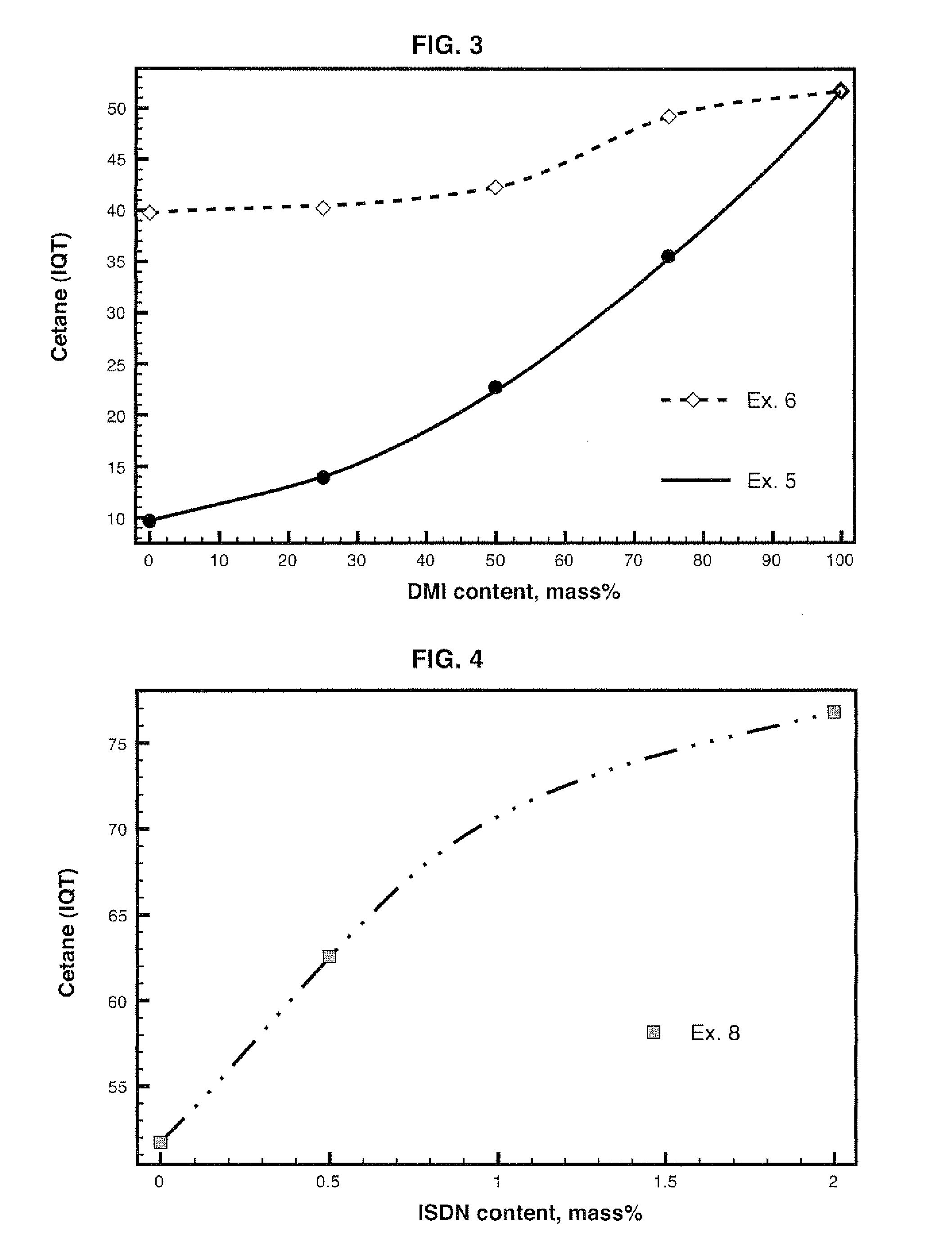

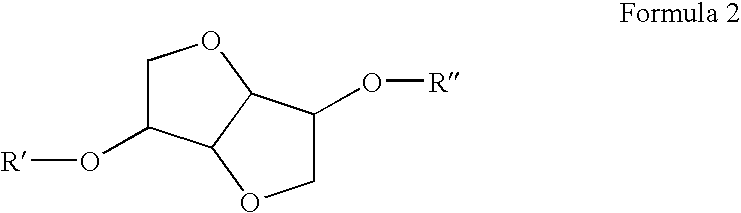

Diesel cycle fuel compositions containing dianhydrohexitols and related products

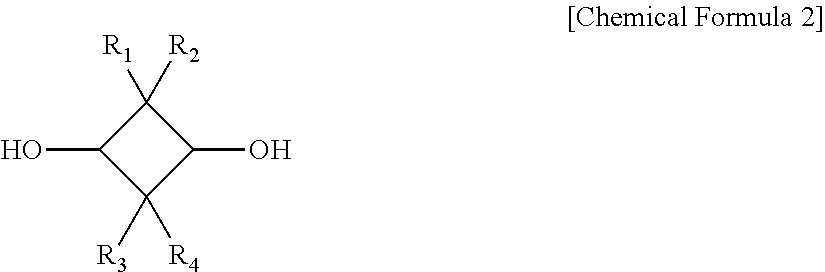

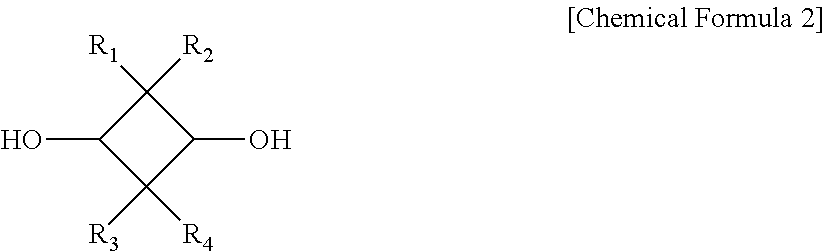

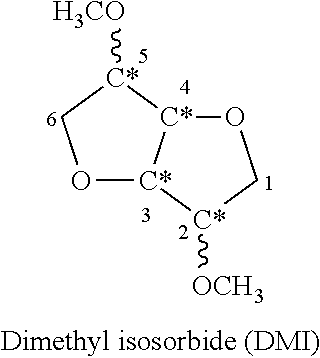

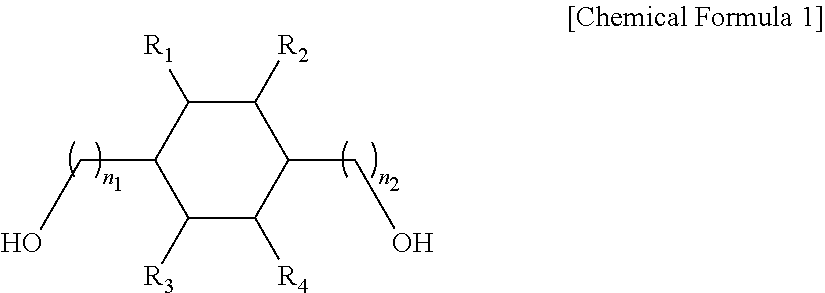

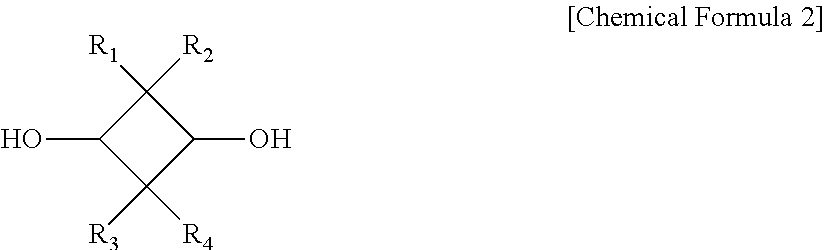

Diesel cycle fuel compositions are described containing at least one dianhydrohexitol compound according to the general formula 2 and / or itsderived hydrocarbyl ethers or nitric ethers compounds, where the R′ and R″ substituents are both H or one or both of R′ and R″ is alkyl, cycloalkyl or phenyl, or one or both are —NO2. A preferred fuel composition is that containing dimethyl isosorbide (DMI) added or not of isosorbide dinitrate (ISDN) as ignition improver. The dianhydrohexitols compounds form compositions with at least one of the components selected among petroleum-derived diesel fuel, biodiesel, ethanol and water. The mixture of DMI and ISDN has excellent cetane number (IQT). Still, the oxygenated nature of the dianhydrohexitols and related compounds of the fuel compositions inhibits soot formation upon burning of the said Diesel cycle fuel compositions.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

High-viscosity polyester with improved impact properties

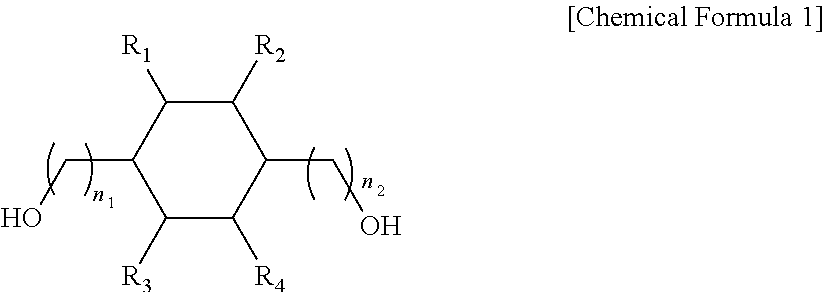

The invention relates to a thermoplastic polymer comprising at least one 1,4:3,6-dianhydrohexitol unit (A), at least one alicyclic diol unit (B) other than the 1,4:3,6-dianhydrohexitol units (A) and at least one high-viscosity terephthalic acid unit (C).

Owner:ROQUETTE FRERES SA

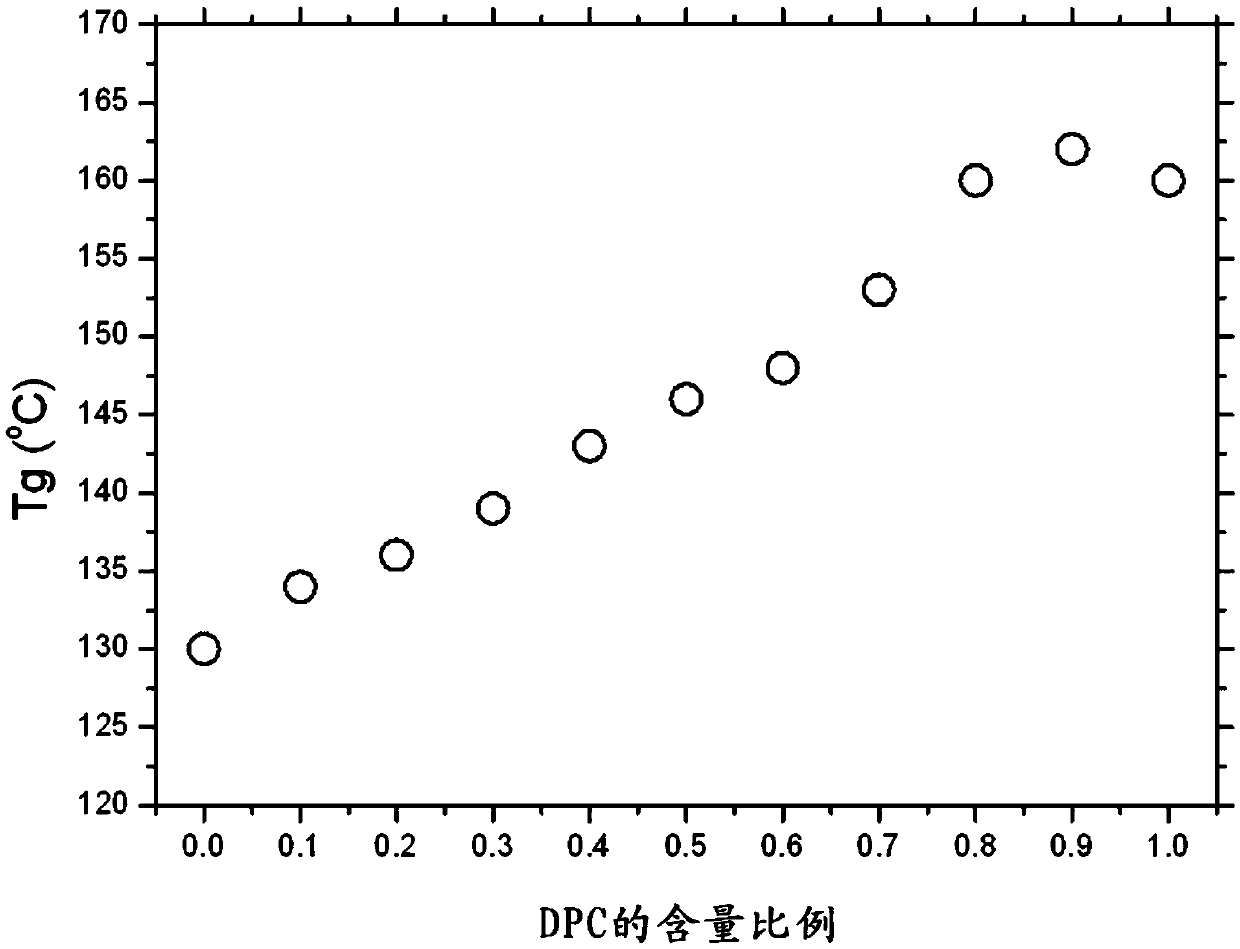

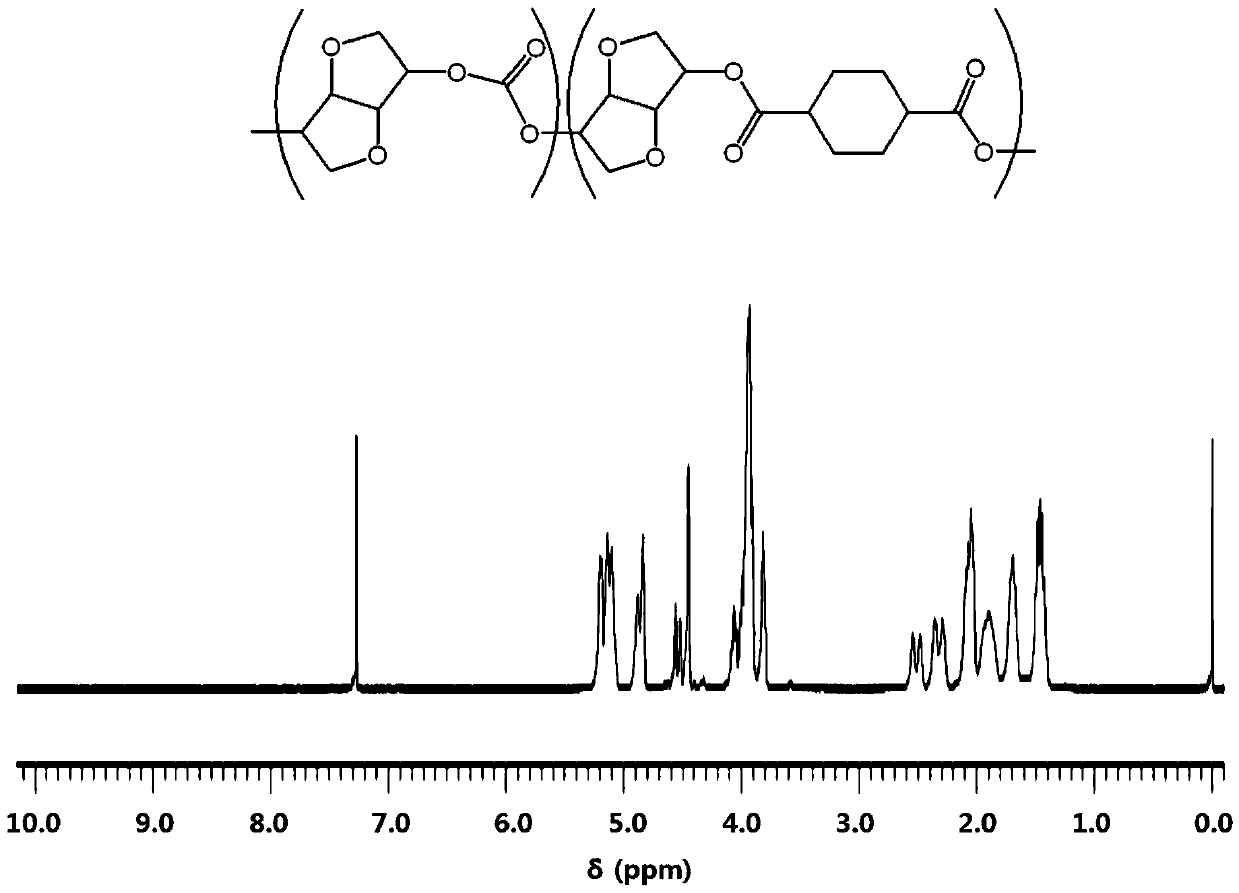

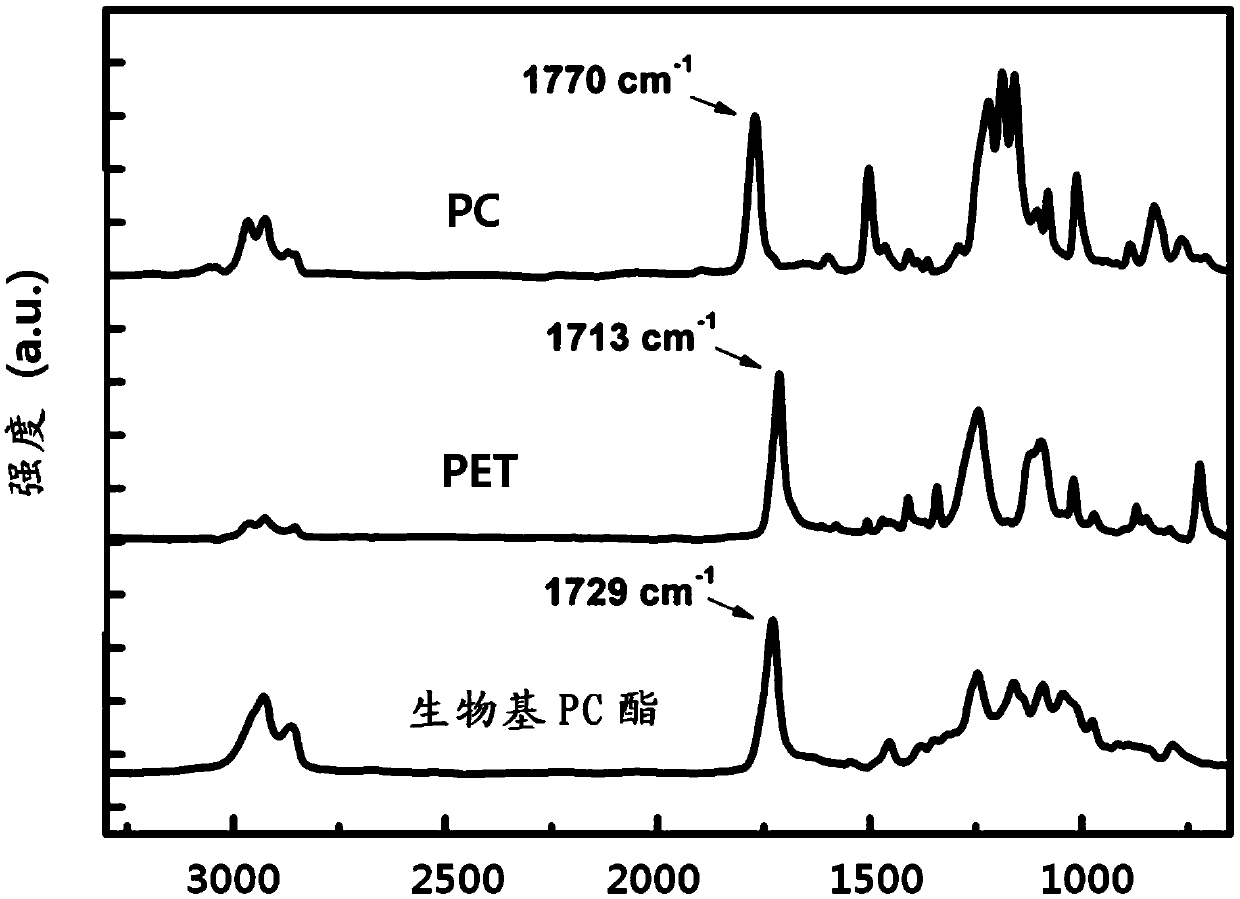

Highly heat-resistant and highly transparent polycarbonate ester, and preparation method therefor

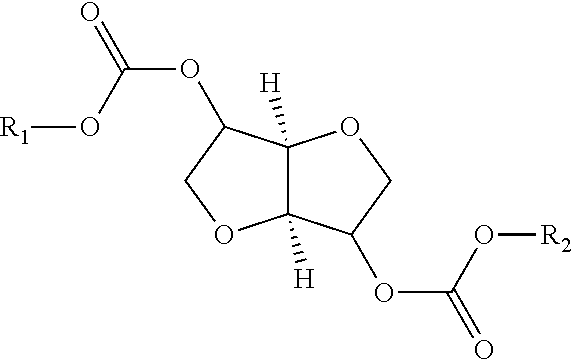

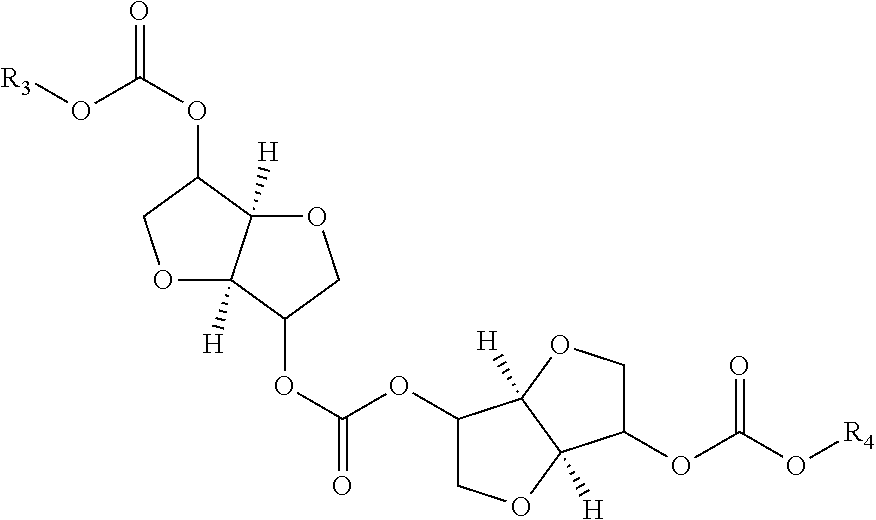

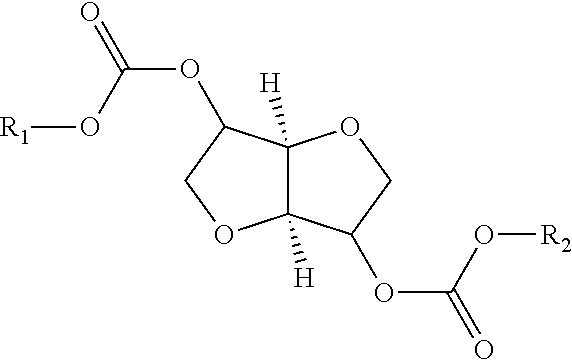

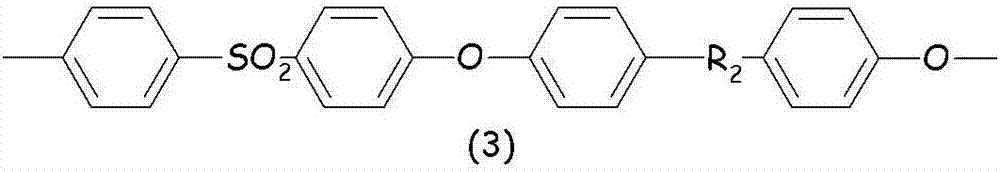

The present invention relates to: a bio-based polycarbonate ester comprising: (i) repeat unit 1 obtained from a condensation reaction of 1,4:3,6-dianhydrohexitol and carbonate; and (ii) repeat unit 2 obtained from a condensation reaction of 1,4:3,6-dianhydrohexitol and 1,4-cyclohexanedicarboxylate; and a preparation method for the bio-based polycarbonate ester, comprising the steps of: (1) preparing a compound represented by formula 3 through a trans-esterification or esterification reaction of a compound represented by formula 2 and phenol; and (2) preparing a compound comprising a repeat unit represented by formula 1 through a polycarbonate melt polycondensation reaction of the compound represented by formula 3 prepared in step (1), a compound represented by formula 4, and 1,4:3,6-dianhydrohexitol. The bio-based polycarbonate ester, according to the present invention, is capable of controlling advantages and disadvantages of physical properties obtained from each repeat unit, and has high thermal resistance and high transparency, and thus is capable of being effectively used for various uses.

Owner:SK CHEM CO LTD

Method for preparing dianhydrohexitol diester compositions

The invention concerns a method for preparing a dianhydrohexitol diester composition, characterized in that it comprises a step which consists in esterifying a dianhydrohexitol composition with a carboxylic acid in the presence of an acid catalyst and hypophosphorous acid. Preferably, the hypophosphorous acid is introduced in an amount ranging between 0.05 and 2 wt. % of dianhydrohexitol, and in a hypophosphorous acid / acid catalyst weight ratio less than 1 / 1. Said method enables novel dianhydrohexitol diester compositions, for example isosorbide diesters, isomannide and / or isoidide richer in diester(s) and / or less coloured, useful in numerous industrial applications, in particular in plastic compositions, to be obtained.

Owner:ROQUETTE FRERES SA

Polymer resin composition having excellent impact resistance or heat resistance

ActiveUS20150368460A1Improve heat resistanceImprove impact resistanceCarboxylic acidTerephthalic acid

A polymer resin composition capable of providing a synthetic resin showing physical properties of improved heat resistance or impact resistance is provided, in which the polymer resin composition includes a polyester tetrapolymer containing a residue of a dicarboxylic acid component containing terephthalic acid and a residue of a diol component containing dianhydrohexitol, and one or more terpolymers selected from the group consisting of an unsaturated nitrile-diene-based rubber-aromatic vinyl graft terpolymer, an alkyl methacrylate-diene-based rubber-aromatic vinyl graft terpolymer, and an alkyl methacrylate-silicone / alkyl acrylate graft terpolymer.

Owner:SK CHEM CO LTD

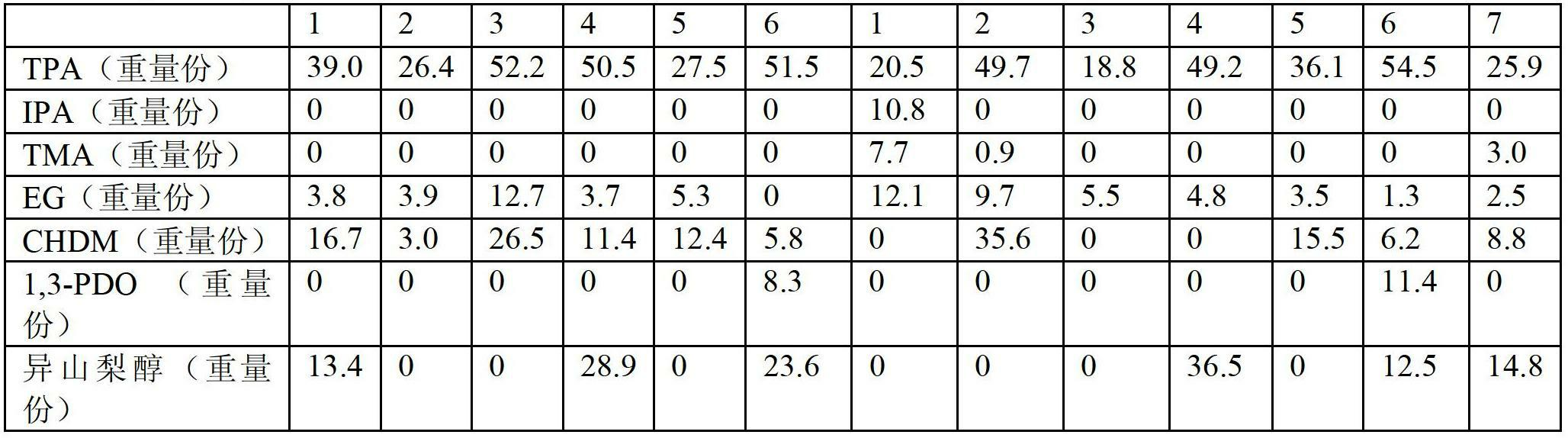

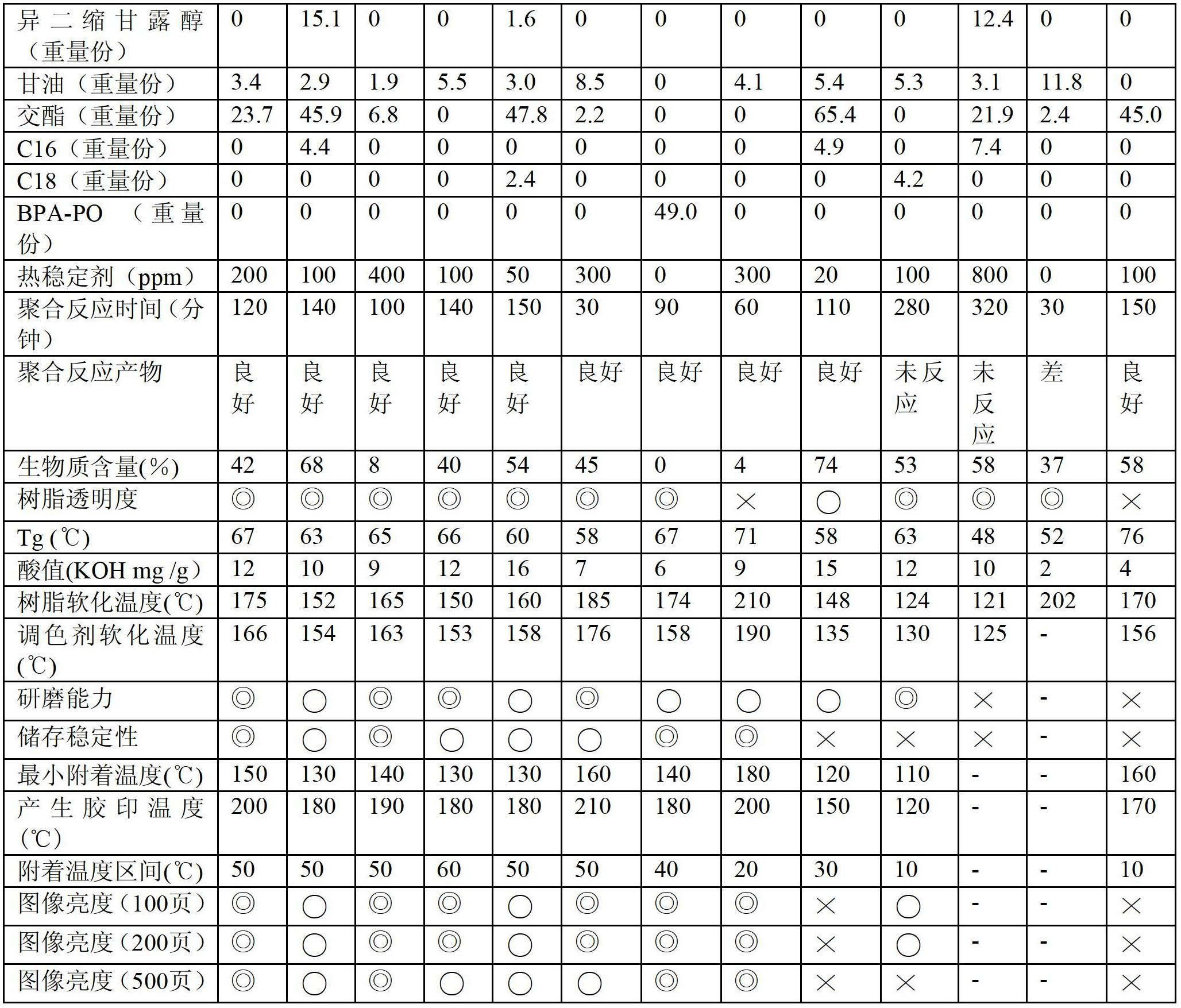

Polyester resin and toner including same

ActiveUS20120276479A1Good storage stabilityWide fusing temperature rangeDevelopersLactidePolyester resin

Owner:SK CHEM CO LTD

Polymer resin composition having excellent chemical resistance

InactiveUS20160137834A1Good chemical resistanceImprove heat resistanceCarboxylic acidTerephthalic acid

The present invention relates to a polymer resin composition that is capable of providing an environmentally friendly biomass-containing synthetic resin having improved chemical resistance. The present invention provides a polymer resin composition including: a polyester copolymer including a residue of a dicarboxylic acid component containing terephthalic acid, and a residue of a diol component including dianhydrohexitol; and one or more copolymers selected from the group consisting of an unsaturated nitrile-diene-based rubber-aromatic vinyl graft copolymer, an alkyl methacrylate-diene-based rubber-aromatic vinyl graft copolymer, and an alkyl methacrylate-silicone / alkyl acrylate graft copolymer, and which has a tensile strength loss defined in the following Equation 1 ranging from 0.5 to 30%.Tensile Strength Loss (%)=[(Tensile Strength before Test−Tensile Strength after Test) / Tensile Strength before Test]×100 [Equation 1]

Owner:SK CHEM CO LTD

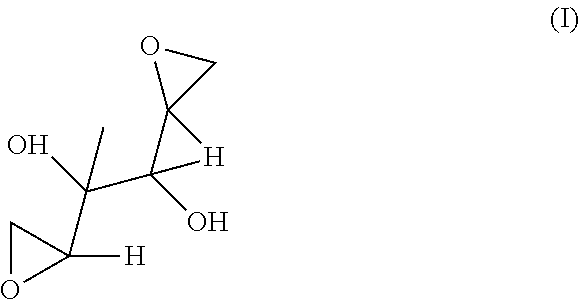

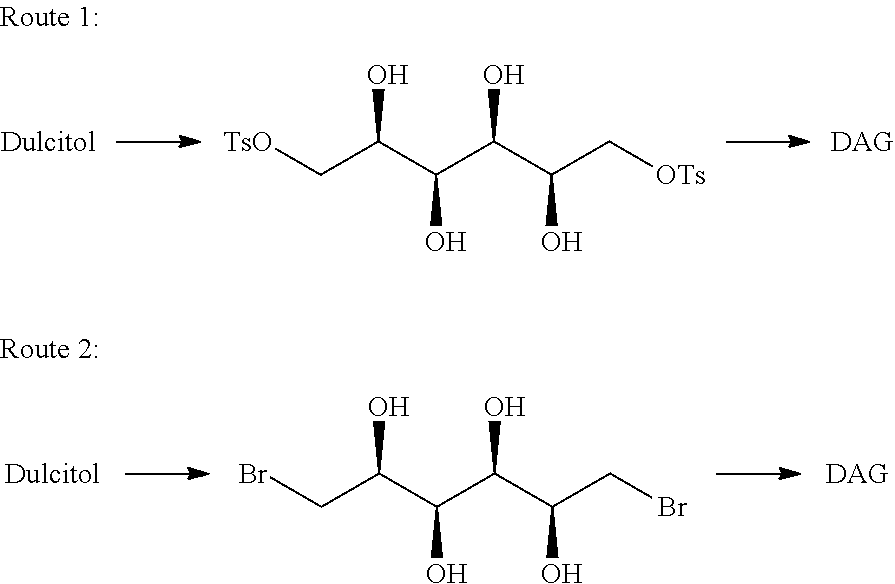

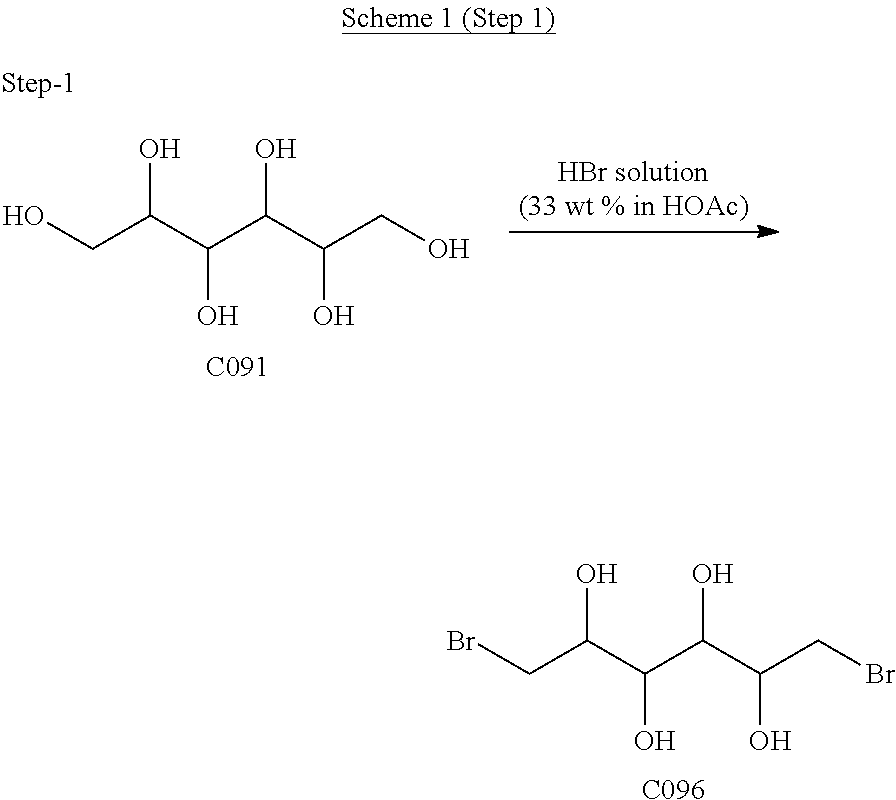

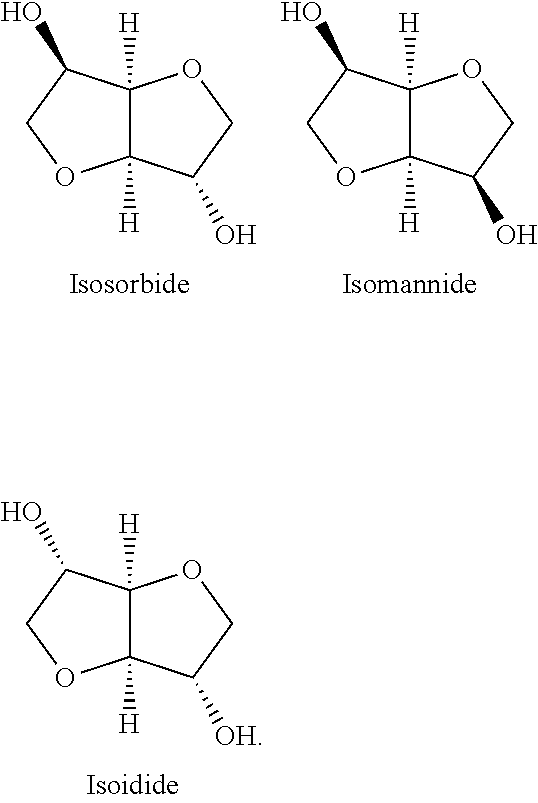

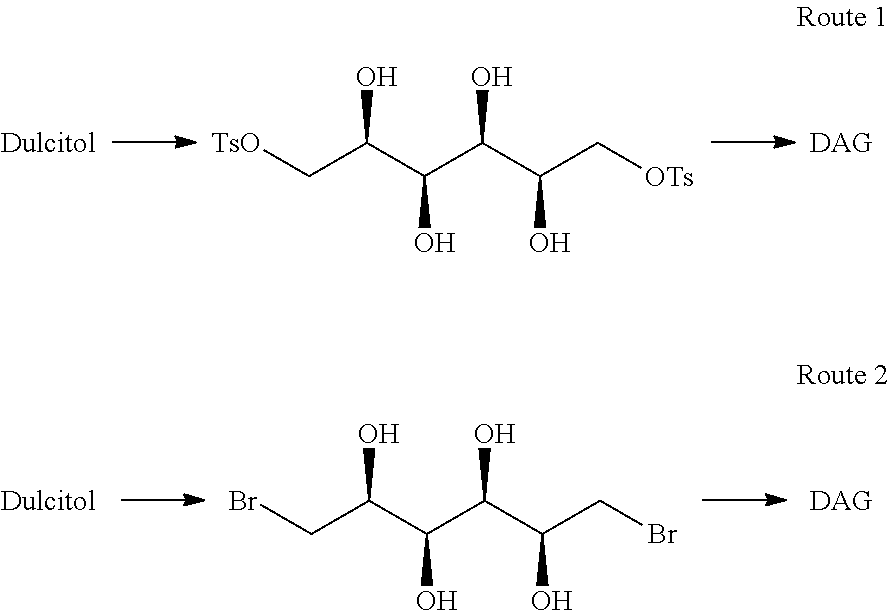

Method of synthesis of substituted hexitols such as dianhydrogalactitol

The present invention provides an efficient method of synthesizing and purifying dianhydrohexitols such as dianhydrogalactitol. In general, as applied to dianhydrogalactitol, the method comprises: (1) reacting dulcitol with a concentrated solution of hydrobromic acid at a temperature of about 80° C. to produce dibromogalactitol; (2) reacting the dibromogalactitol with potassium carbonate in t-butanol to produce dianhydrogalactitol; and (3) purifying the dianhydrogalactitol using a slurry of ethyl ether to produce purified dianhydrogalactitol. Another method produces dianhydrogalactitol from dulcitol; this method comprises: (1) reacting dulcitol with a reactant to convert the 1,6-hydroxy groups of dulcitol to an effective leaving group to generate an intermediate; and (2) reacting the intermediate with an inorganic weak base to produce dianhydrogalactitol through an intramolecular SN2 reaction. Other methods for the synthesis of dianhydrogalactitol from dulcitol are described.

Owner:DEL MAR PHARMA

Polyester resin and toner including same

Disclosed is a toner for use in an electronic photograph-duplicating process or in an electrostatic printing process, and a polyester resin included in the toner as a binder. The polyester resin comprises lactic acids (D or L-lactic acids) or lactides (D or L-lactides) which are derivative compounds thereof, and dianhydrohexitols which are bio-derived sugar derivatives.

Owner:SK CHEM CO LTD

Impact-resistant polyurethane

The present invention teaches a new process to produce novel, hard, optically clear, impact-resistant polyurethane polymers that are characterized by excellent thermo mechanical properties and chemical resistance, and the polymers made as a result of such a process. The polyurethanes are made by reacting a) a prepolymer made by reacting a polyisocyanate with a primary amine-terminated polyether with an amine functionality of about 2 and a molecular weight of >1000, and in which the free —NCO content of the resulting prepolymer is >18% by weight; with b) (i) a polyol having an average hydroxyl functionality greater than or equal to 2 and an average hydroxyl equivalent weight of from about 300 to about 1,000, and (ii) a curing agent that has isocyanate reactive groups, a functionality of 2 to 3 and a molecular weight of <400. More preferably the prepolymer is made by reacting a cycloaliphatic polyisocyanate with a primary amine-terminated polyether diamine of 2000 to about 2500 molecular weight, the polyol is either a polyester polyol triol with a molecular weight of between about 540 and 900, or a polyether glycol with a molecular weight of between about 650 and 2000, or a polyester polyol diol with a molecular weight of up to 2,000, and the curing agent is either dianhydrohexitol, an aromatic diamine, an aromatic ring containing diol or a cyclohexanedimethanol.

Owner:POLYPLEXX

Method for preparing dialkyloxydianhyrohexitol by etherification of dianhydrohexitol using a light alcohol, in the presence of an acidic catalyst

ActiveUS9321783B2Improved and simple and economical processEasy to industrializeOrganic chemistryDimethyl isosorbideMethyl group

Owner:CENT NAT DE LA RECHERCHE SCI +1

Impact-Resistant Polyurethane

InactiveUS20090171059A1Excellent thermo mechanical propertyGood chemical resistancePolyesterEquivalent weight

The present invention teaches a new process to produce novel, hard, optically clear, impact-resistant polyurethane polymers that are characterized by excellent thermo mechanical properties and chemical resistance, and the polymers made as a result of such a process.The polyurethanes are made by reactinga) a prepolymer made by reacting a polyisocyanate with a primary amine-terminated polyether with an amine functionality of about 2 and a molecular weight of >1000, and in which the free —NCO content of the resulting prepolymer is >18% by weight; withb) (i) a polyol having an average hydroxyl functionality greater than 2 and an average hydroxyl equivalent weight of from about 400 to about 1,000, and (ii) a curing agent that has isocyanate reactive groups, a functionality of 2 to 3 and a molecular weight of <400.More preferably the prepolymer is made by reacting a cycloaliphatic polyisocyanate with a primary amine terminated polyether diamine of 2000 to 4000 molecular weight, the polyol is either a polyester polyol triol with a molecular weight of between about 540 and 900, or a polyether glycol with a molecular weight of between about 650 and 2000, and the curing agent is either dianhydrohexitol, an aromatic diamine, or a cyclohexanedimethanol.

Owner:GERKIN RICHARD M +1

2, 5-furandicarboxylic acid-based polyesters

The invention is directed to a polyester comprising 5-furandicarboxylic acid moieties (A); ethylene glycol moieties (B); 1,4:3,6-dianhydrohexitol moieties (C); alicyclic diol moieties other than the 1,4:3,6-dianhydrohexitol moieties (D); wherein the molar ratio (B) / [(B)+(C)+(D)] is greater than 0.2. The invention aloes relates to a process of preparing the polyester and to its use.

Owner:FURANIX TECH BV +1

Method for producing a polyester containing at least one 1,4:3,6-dianhydrohexitol unit with improved colouring

ActiveUS20170335055A1Polycondensation time is very substantially reducedReduce colorPolyesterDianhydrohexitol

The invention concerns a method for producing a polyester containing at least one 1,4:3,6-dianhydrohexitol unit comprising:·a step of introducing, into a reactor, monomers comprising at least one monomer (A) that is a diacid or a diester and at least one monomer (B) that is a 1,4:3,6-dianhydrohexitol;·a step of introducing, into the reactor, a catalytic system comprising either a catalyst comprising the element germanium and a catalyst comprising the element aluminum, or a catalyst comprising the elements germanium and aluminum, or a mixture of said two catalysts;·a step of polymerising said monomers to form the polyester;·a step of recovering a polyester composition comprising the polyester and the catalytic system. The invention also concerns a polyester composition containing a catalytic system comprising either a catalyst comprising the element germanium and a catalyst comprising the element aluminum, or a catalyst comprising the elements germanium and aluminum, or a mixture of said two catalysts, and the use of same to reduce the colouring of the polyester.

Owner:ROQUETTE FRERES SA

Thermoplastic copolyesters comprising 1,4:3,6-dianhydrohexitol and various aromatic diacids

InactiveUS20180355101A1High glass transition temperatureLower glass transition temperatureOptical elementsFuranDicarboxylic acid

A thermoplastic polyester having: at least one 1,4:3,6-dianhydrohexitol unit; at least one alicyclic diol unit other than 1,4:3,6-dianhydrohexitol units; at least one carboxylic diacid unit selected from among furan-2,5-dicarboxylic acid, 2,6-naphthalic acid and isophthalic acid units, said polyester including at least 10% 1,4:3,6-dianhydrohexitol units and being free from ethylene glycol and terephthalic acid units. The invention also relates to the production method and use of same.

Owner:ROQUETTE FRERES SA

Method of synthesis of substituted hexitols such as dianhydrogalactitol

The present invention provides an efficient method of synthesizing and purifying dianhydrohexitols such as dianhydrogalactitol. In general, as applied to dianhydrogalactitol, the method comprises: (1) reacting dulcitol with a concentrated solution of hydrobromic acid at a temperature of about 80° C. to produce dibromogalactitol; (2) reacting the dibromogalactitol with potassium carbonate in t-butanol to produce dianhydrogalactitol; and (3) purifying the dianhydrogalactitol using a slurry of ethyl ether to produce purified dianhydrogalactitol.

Owner:DEL MAR PHARMA

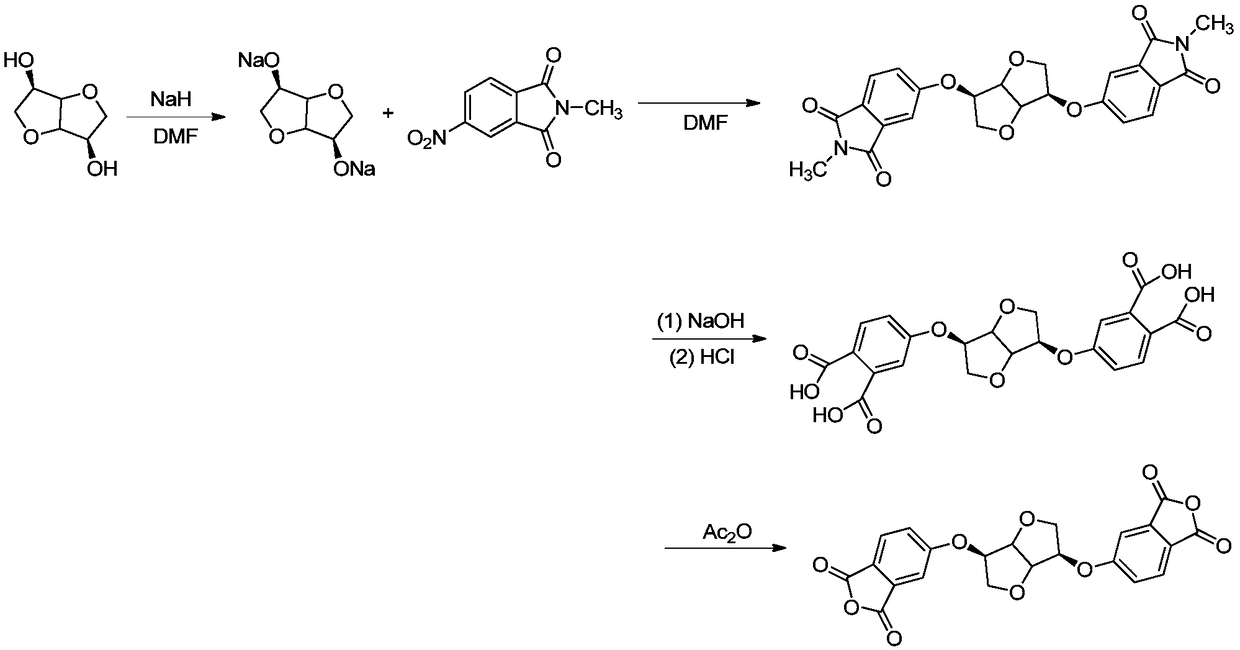

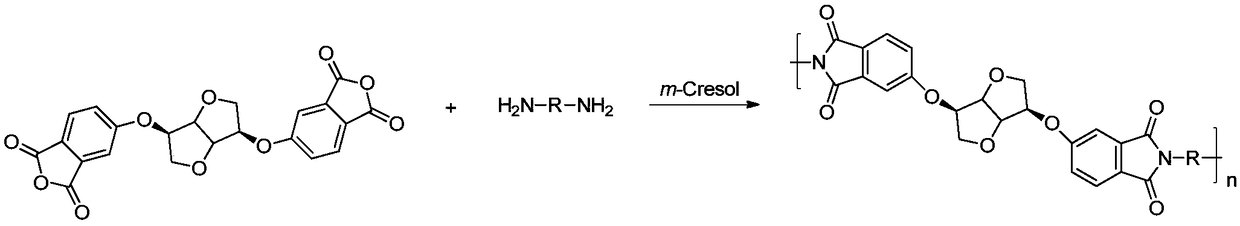

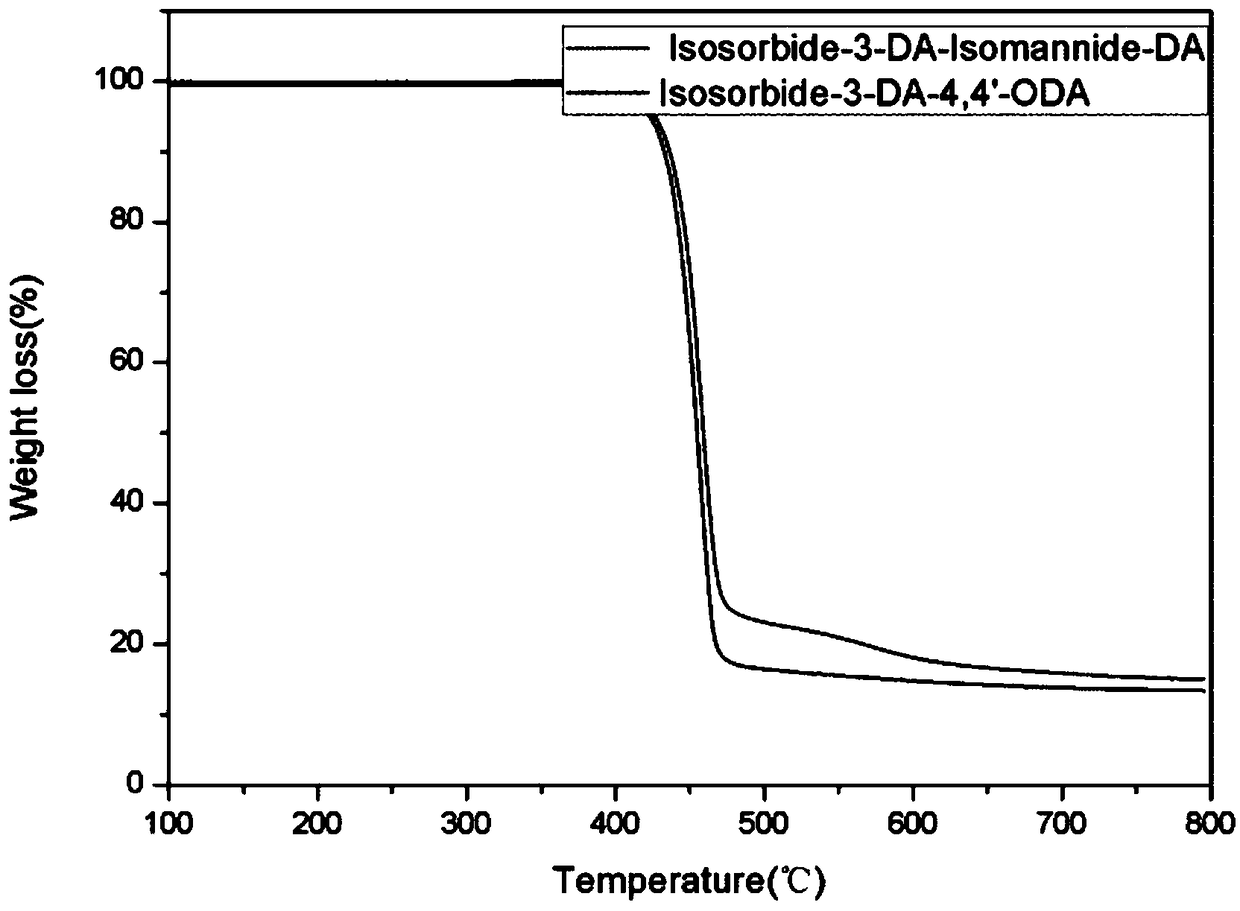

Biobased dianhydride monomer, biobased polyimide resin and preparation method thereof

InactiveCN108841004ANovel structureImprove heat resistanceOrganic chemistryDianhydrohexitolPolyimide

The invention provides a biobased dianhydride monomer adopting a structure shown as formulae I-IV. The invention further provides biobased polyimide resin adopting a structure shown as formula 1, wherein n is 1-10000 and R1 is one or more of structures shown as formulae 2-7. The biobased dianhydride monomer provided by the invention, namely a 1,4:3,6-dianhydrohexitol-dianhydride monomer, has certain rigidity, and when the biobased dianhydride monomer is applied to synthesis of the polyimide resin, the obtained polyimide resin adopting a novel structure has the advantages of good heat resistance and toughness and the like. Moreover, the polyimide resin is white, and a film is light yellow and transparent and has certain optical activity. A polyimide material prepared by the preparation method provided by the invention can meet requirements in certain fields such as the field of electronic components, and can also be applied to the field of the conventional plastic, films and fiber and the like.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

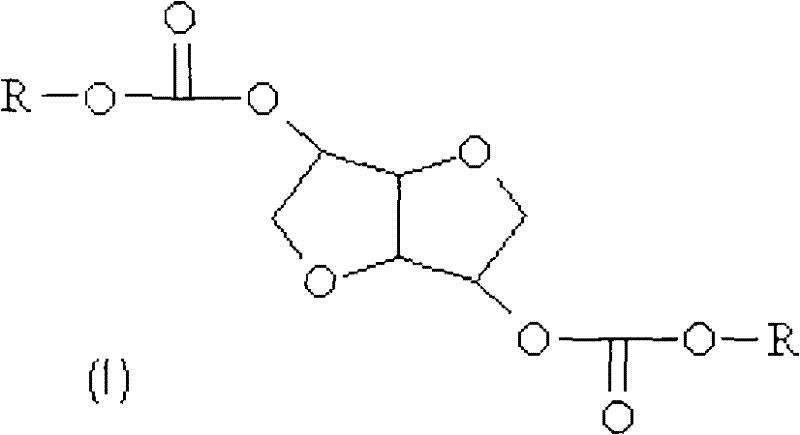

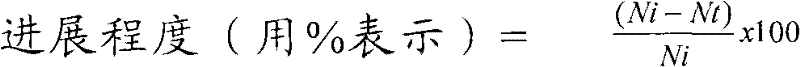

Method for preparing a dialkyl carbonate of dianhydrohexitol

The present invention relates to a method for preparing dialkyl carbonates of dianhydrohexitol, said method including the following steps: (a) preparing an initial reaction mixture containing at least one dianhydrohexitol, at least two mole equivalents of a dialkyl carbonate of formula and a transesterification catalyst; (b) heating the reaction mixture to a temperature greater than or equal to the boiling temperature of the formed alcohol, or of the azeotrope thereof, in a reaction chamber preferably provided with a rectification column comprising a sufficient number of theoretical distillation plates to separate the resulting alcohol from the reaction mixture. The invention also relates to certain dialkyl carbonates of dianhydrohexitols produced by said method and to the use thereof for synthesising synthetic polymers.

Owner:ROQUETTE FRERES SA

Use of a material based on a thermoplastic polymer having a high content of antioxidants for packaging dianhydrohexitols

The present invention relates to the use of a packaging material based on a thermoplastic polymer for packaging a dianhydrohexitol, the packaging material comprising at least one thermoplastic polymer layer containing at least 0.1% by weight of at least one antioxidant (layer (A)), said layer (A) either being directly in contact with the dianhydrohexitol or being separated from the latter by a thermoplastic polymer layer (layer (B)) having a thickness at most equal to 150 [mu]m, and the thermoplastic polymer of the layer (A) and / or of the layer (B) being chosen independently from polyethylene, polypropylene, ethylene / polypropylene copolymers and blends of the latter.

Owner:ROQUETTE FRERES SA

High heat resistant polymer resin composition having excellent chemical resistane

Provided is a polymer resin composition capable of providing an environmentally friendly biomass-containing synthetic resin which exhibits improved chemical resistance. Provided is a high heat resistant polymer resin composition having excellent chemical resistance, the composition including a polyester copolymer containing a residue of a dicarboxylic acid component containing terephthalic acid and a residue of a diol component containing dianhydrohexitol; one or more copolymers selected from the group consisting of an unsaturated nitrile-diene-based rubber-aromatic vinyl graft copolymer, an alkylmethacrylate-diene-based rubber-aromatic vinyl graft copolymer, and an alkylmethacrylate-silicone / alkylacrylate graft copolymer; and polytrimethylene terephthalate, and having 0.5 to 20% of percent loss in tensile strength, which is represented by the following Equation 1:Percent loss in tensile strength (%)=[(tensile strength before test−tensile strength after test) / tensile strength before test]×100 [Equation 1]

Owner:SK CHEM CO LTD

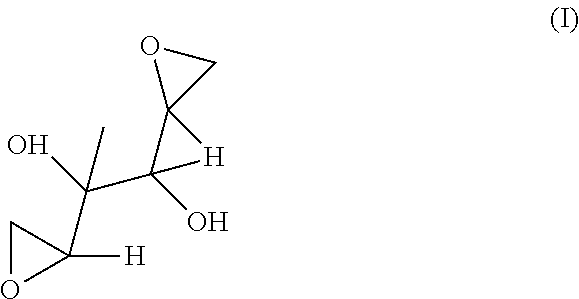

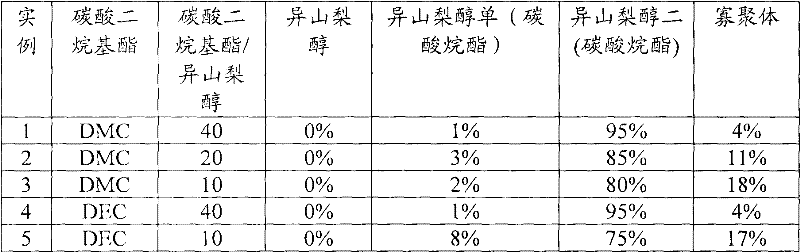

Process for manufacturing polycarbonate from dianhydrohexitol dialkylcarbonate

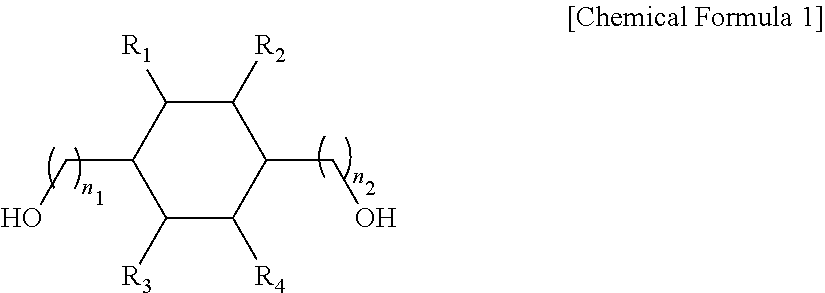

A process for manufacturing a polycarbonate, having a glass transition temperature greater than or equal to 50° C., includes: ▪ a step (1) of introducing into a reactor a monomer of formula (I) and R1 and R2 being identical or different alkyl groups; ▪ a step (2) of introducing into the reactor at least one cyclic diol or a mixture of diols (B) including at least 20 mol % of cyclic diols; ▪ a subsequent step (3) of polycondensation via transesterification of the mixture of monomers including the monomers (A) and (B); ▪ a step (4) of recovering the polycarbonate formed during step (3).

Owner:ROQUETTE FRERES SA

Method for preparing dialkyloxydianhyrohexitol by etherification of dianhydrohexitol using a light alcohol, in the presence of an acidic catalyst

ActiveUS20150203507A1Reduce usageImproved and simple and economical processOrganic chemistryDimethyl isosorbideMethyl group

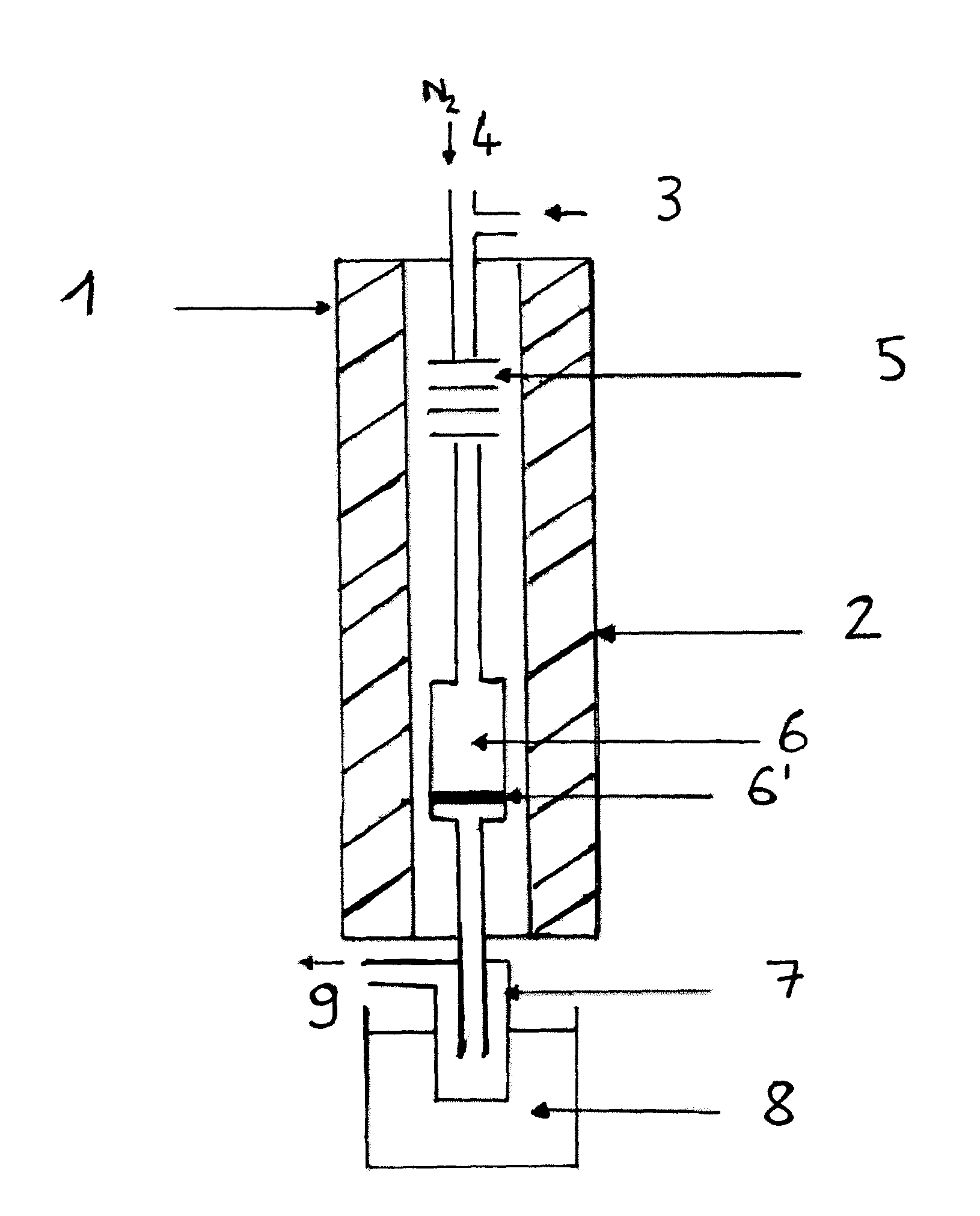

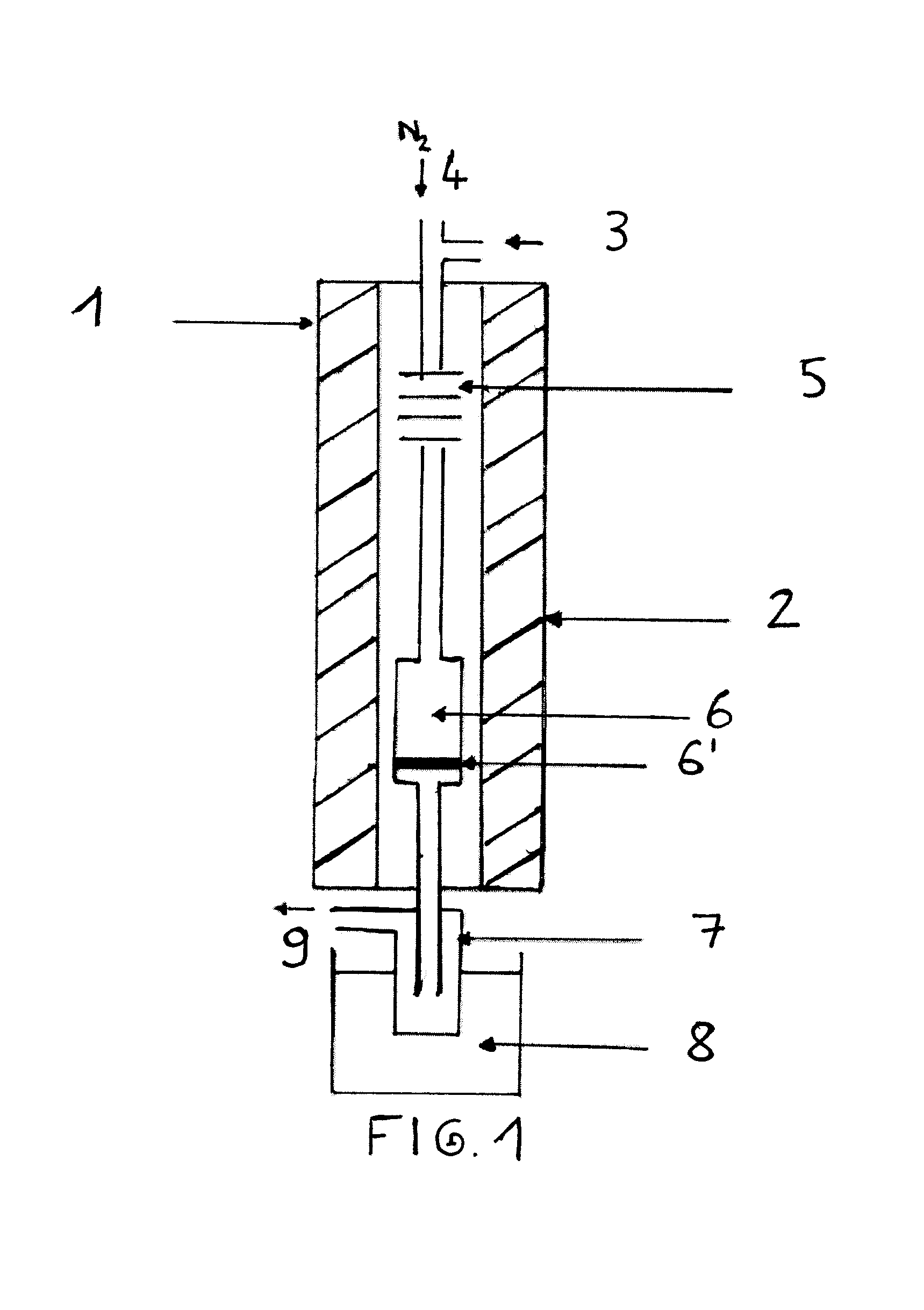

A method for preparing a dialkyloxydianhyrohexitol (dimethylisosorbide) composition by etherification of dianhydrohexitol (isosorbide). The aim is to achieve a “clean” method that avoids the use of a methylation agent such as dimethyl sulfate or methyl chloride, which generates stoechiometric quantities of salts, or expensive dialkyl-carbonates, wherein only one of the two methyl groups participates in the preparation of mixed isosorbide ethers. The method involves using at least one O-alkylation agent and a catalyst including an acid or an acid salt, preferably a catalyst having Lewis or BrØnsted acid properties. A device for carrying out the method wherein the device includes a vaporization oven and a reaction oven is also described.

Owner:CENT NAT DE LA RECHERCHE SCI +1

Method for producing vinyl ester urethane resins based on dianhydrohexitol compounds and use thereof

The invention relates to a method for producing vinyl ester urethane resins, in which a dianhydrohexitol-compound is reacted with a diisocyanate in the presence of a monomeric radically co-polymerizable compound as a solvent and the product is reacted with a hydroxy-substituted (meth)acrylate. As a result, vinyl ester urethane resins based on dianhydrohexitol-compounds and also based on renewable raw materials can be obtained in a simple manner with high yields. Said resins are suitable as binding agents in chemical fixing engineering.

Owner:HILTI AG

Parts for automobiles, electrical/electronic devices, home appliances, office equipment, or daily necessities

ActiveUS20160137835A1Good chemical resistanceImprove heat resistanceCarboxylic acidTerephthalic acid

The present invention relates to parts for automobiles, electrical / electronic devices, home appliances, office equipment, or daily necessities, which are manufactured by using a polymer resin composition that is capable of providing an environmentally friendly biomass-containing synthetic resin having improved chemical resistance. The parts for automobiles, electrical / electronic devices, home appliances, office equipment, or daily necessities which are manufactured by using a polymer resin composition including: a polyester copolymer including a residue of a dicarboxylic acid component containing terephthalic acid, and a residue of a diol component containing dianhydrohexitol; and one or more copolymers selected from the group consisting of an unsaturated nitrile-diene-based rubber-aromatic vinyl graft copolymer, an alkyl methacrylate-diene-based rubber-aromatic vinyl graft copolymer, and an alkyl methacrylate-silicone / alkyl acrylate graft copolymer, and which has a tensile strength loss defined in the following Equation 1 ranging from 0.5 to 30%, can be provided.Tensile Strength Loss (%)=[(Tensile Strength before Test−Tensile Strength after Test) / Tensile Strength before Test]×100 [Equation 1]

Owner:SK CHEM CO LTD

Aromatic thermoplastic copolyesters comprising 1,4:3,6-dianhydrohexitol and various cyclic diols

InactiveUS20180362707A1High glass transition temperatureEasy to transformSynthetic resin layered productsOptical articlesCyclohexanedimethanolCopolyester

A thermoplastic polyester including: at least one 1,4:3,6-dianhydrohexitol unit (A); at least one cyclic diol unit (B) other than cyclohexanedimethanol units and 1,4:3,6-dianhydrohexitol units (A); and at least one aromatic carboxylic diacid unit (C), the polyester being free from ethylene glycol units. It also relates to the production method and use of same.

Owner:ROQUETTE FRERES SA

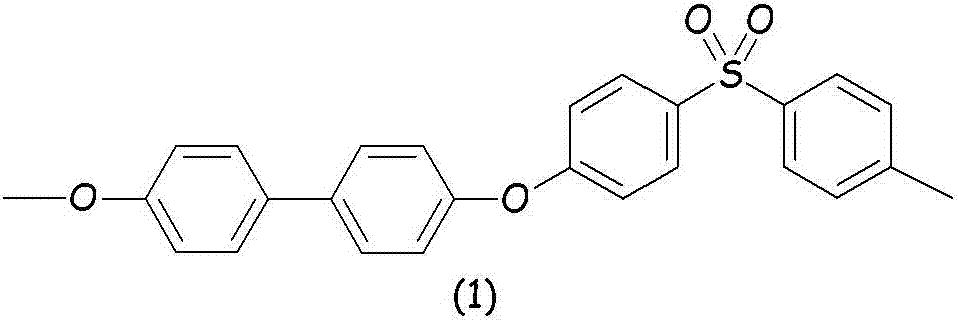

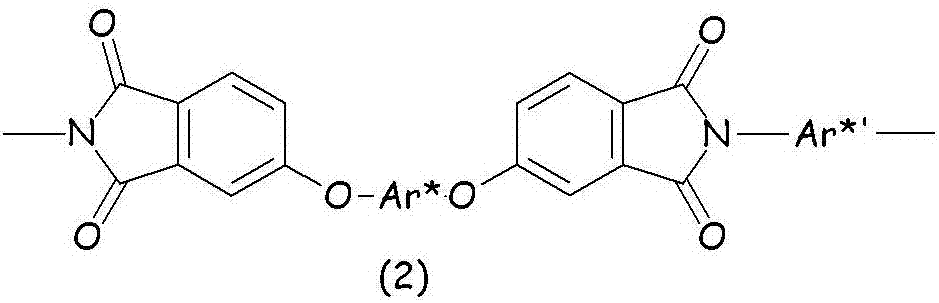

Polymer compositions based on a bio-sourced polyarylene ether ketone

A polymer composition [composition (C)] comprising: (a) a polyarylene ether ketone (PAEK-1) comprising recurring units deriving from the incorporation of 1,4:3,6-dianhydrohexitols; (b) a poly(biphenylether) sulfone (PPSU-1 ) comprising repeating units of formula (I) and / or (c) a polyetherimide (PEI-1) comprising repeating units of formula (II) wherein Ar* and Ar*' are as defined in the specification are herein disclosed. (PAEK-1) and (PPSU-1) and / or (PEI-1) are completely miscible and give rise to compositions that are transparent and possess high strength and stiffness and that are suitablefor the manufacture of a variety of shaped articles.

Owner:SOLVAY SPECIALTY POLYMERS USA LLC

Packaging method based on a semi-crystalline thermoplastic polyester

InactiveUS20190161259A1Maintain good propertiesImprove heat resistancePackagingThermoplasticPolymer science

Packaging method comprising the following steps: (a) providing a semi-crystalline thermoplastic polyester having at least one 1,4:3,6-dianhydrohexitol unit (A), at least one alicyclic diol unit (B) other than the 1,4:3,6-dianhydrohexitol units (A), and at least one terephthalic acid unit (C), wherein the molar ratio (A) / [(A)+(B)] is at least 0.05 and at most 0.30, said polyester being free of non-cyclic aliphatic diol units or comprising a molar amount of non-cyclic aliphatic diol units, relative to the totality of monomeric units in the polyester, of less than 5%, and with a reduced viscosity in solution (25° C.; phenol (50 wt. %): ortho-dichlorobenzene (50 wt. %); 5 g / L of polyester) greater than 50 mL / g; (b) preparing a heat-shrinkable film from the semi-crystalline thermoplastic polyester obtained in step (a); (c) covering a product with the heat-shrinkable film obtained in step (b); (d) applying a heat treatment to the packaged product.

Owner:ROQUETTE FRERES SA

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com