Biobased dianhydride monomer, biobased polyimide resin and preparation method thereof

A technology of polyimide resin and bio-based dianhydride is applied in the field of polyimide resin to achieve the effect of good application prospect, good heat resistance and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

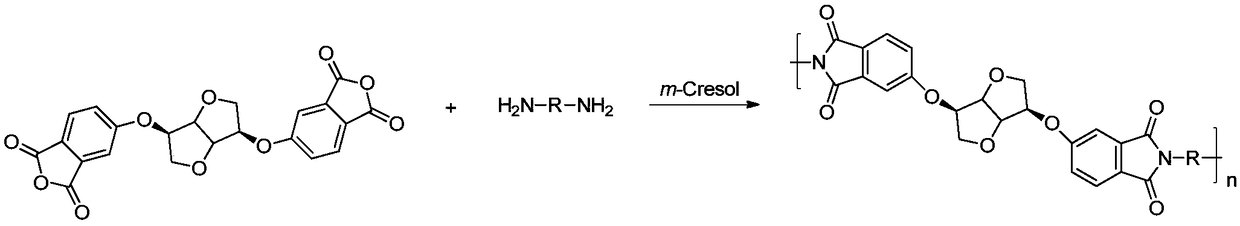

[0076] The present invention also provides a preparation method of polyimide resin, said polyimide resin is prepared by 1,4:3,6-dianhydrohexitol-dianhydride monomer and diamine monomer through high-temperature solution Prepared by one or more of polycondensation method, thermal imidization method and chemical imidization method;

[0077] The diamine monomers include aromatic dianhydride monomers and / or aliphatic dianhydride monomers.

[0078] The present invention has no special restrictions on the definition and naming of the 1,4:3,6-dianhydrohexitol-dianhydride monomer, and the definition and naming of such compounds well known to those skilled in the art will suffice. Personnel can correctly and uniquely understand its meaning based on common sense. The 1,4:3,6-dianhydrohexitol-dianhydride monomer of the present invention is preferably a semi-aromatic dianhydride monomer, specifically including one of the bio-based dianhydride monomers described in the above technical solu...

Embodiment 1

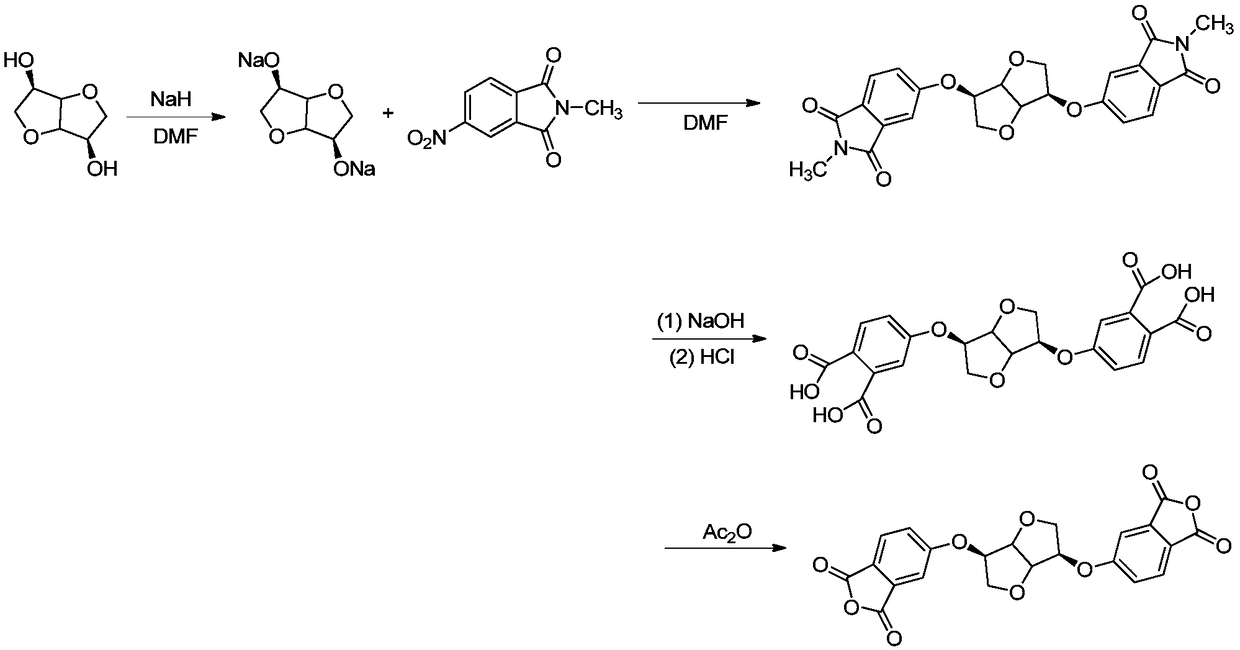

[0152] In this embodiment, mannitol is taken as an example for the preparation of the dianhydride monomer for illustration.

[0153] 1,4:3,6-Didehydro-2,5-dioxy-(3,4-dibenzoic acid)- D - Preparation of mannitol-dianhydride

[0154] The preparation of the monomer is divided into three steps. The specific description is as follows:

[0155] In the first step, 1,4:3,6-dianhydro-2,5-dioxy-(4,4'-imide)- D - Mannitol. Its reaction steps are as follows:

[0156] Under a nitrogen atmosphere, add 12g (60%) of sodium hydride to a three-necked flask equipped with magnetic stirring, then add 100mL of N,N-dimethylformamide, stir at room temperature for a period of time, then add 14.6g of isomannose sugar alcohol. After stirring at room temperature for 2 h, the temperature was raised to 100° C. and the treatment was continued for 10 h. After cooling to room temperature, 45.4 g of 4-nitromonoimine and 50 mL of N,N-dimethylformamide were added. Raise the temperature to 110°C for 20h. ...

Embodiment 2

[0164] In this embodiment, the structure of bio-based polyimide is shown in the following formula:

[0165]

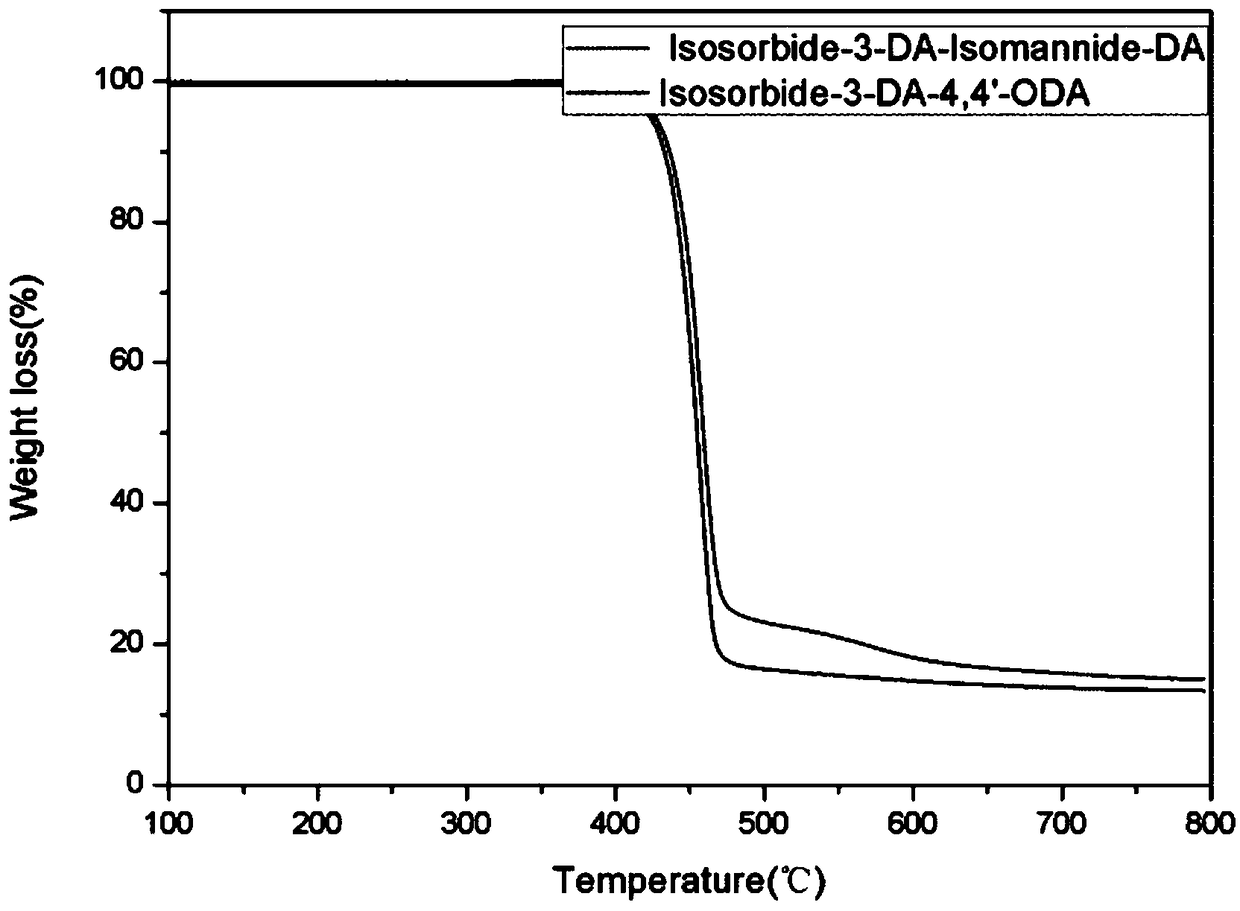

[0166] In a polymerization bottle equipped with mechanical stirring and nitrogen protection, add 0.8767g 1,4:3,6-dianhydro-2,5-dioxy-(3,4-dibenzoic acid)- D -Mannitol-dianhydride and equivalent 4,4'-diaminodiphenyl ether, then add 7.99g of m-cresol, raise the temperature to 80°C and stir for 4h, then raise the temperature to 200°C for 20h. After the reaction, the temperature was lowered to 100° C., and the solution was poured into ethanol to obtain a white fibrous solid. Soxhlet extraction was performed with ethanol. After extraction, dry at 100°C under vacuum.

[0167] The obtained polyimide was formulated with m-cresol into a solution with a solid content of 15%, and spread on a clean glass plate by the scraping method. The glass plate was then placed in an oven at 80°C overnight. Then, the temperature was programmed according to the following steps: 100°C / 2h,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com