Polyester resin and toner including same

一种聚酯树脂、调色剂的技术,应用在聚酯树脂以及包含所述聚酯树脂的调色剂领域,能够解决劣化聚酯树脂透明度、低活性等问题,达到低成本、高图像亮度、宽定影温度范围的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

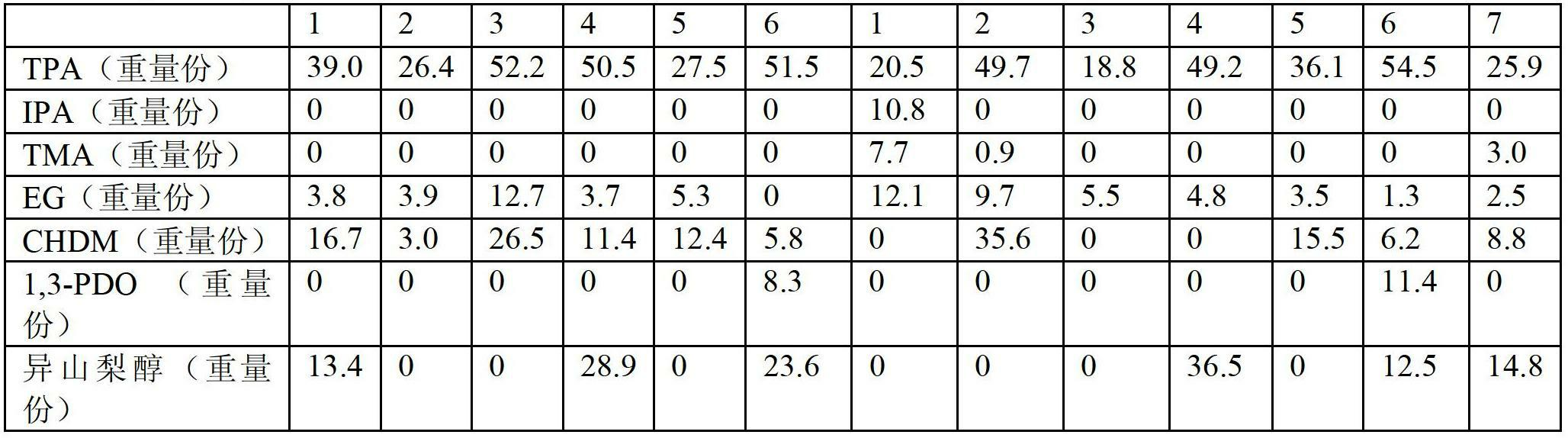

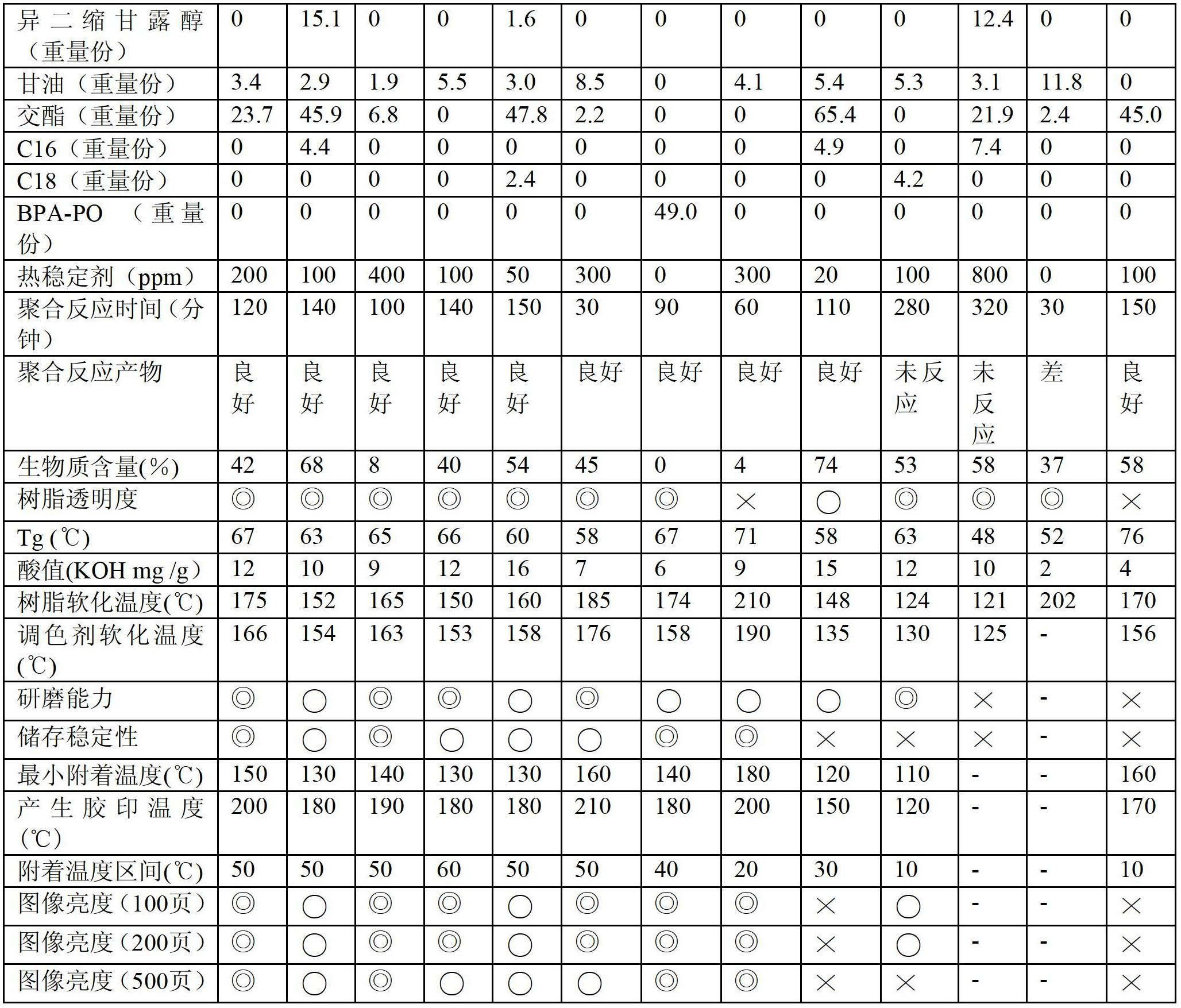

[0070] Hereinafter, the present invention will be described in more detail with reference to the following Examples and Comparative Examples. These examples are used to illustrate the present invention in detail, not to limit the scope of the present invention. The performance evaluation methods used in the following Examples and Comparative Examples are as follows.

[0071] (1) Polymerization reaction product: When the polymerization reaction is carried out under the same polycondensation conditions, in the case where the reaction product cannot leave the reactor, that is, due to a rapid increase in viscosity, its gel, is defined as "poor"; In the case where the polymerization reaction time exceeded 300 minutes due to too slow polymerization reaction speed, it was defined as "unreacted", and in the case where the polymerization reaction was a normal reaction, it was defined as "good".

[0072] (2) Biomass content (%): Use a 600Mhz nuclear magnetic resonance (NMR) spectromete...

Embodiment 1-6 and comparative example 1-6

[0111] A. Preparation of polyester resin

[0112] To a 2l reactor equipped with a stirrer and a condenser, add reactants having the components and contents given in Table 1 below (ratio of acid component to alcohol component, G / A=1.2~1.5), and Add 100ppm (based on the total amount of polyester resin) of TiO 2 / SiO 2 Co-precipitates act as catalysts. Afterwards, the reactor was slowly heated to 250° C., and the by-product water was removed from the reactor while the esterification reaction was carried out.

[0113] After the water was completely discharged outside the reactor, the reactants were transferred to a polycondensation reactor equipped with a stirrer, a condenser, and a vacuum system. A heat stabilizer (trimethyl phosphate) was added, the reaction temperature was increased to 250°C, the reaction pressure was lowered to 50 mmHg for 30 minutes, then excess diol was vented while the reaction was run under low vacuum.

[0114] Thereafter, the reaction pressure was slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com