Composite hydrogel for promoting bone repair and preparation method and application of composite hydrogel

A composite hydrogel and bone repair technology, applied in medical science, prosthesis, tissue regeneration, etc., can solve the problems of lack of elasticity and viscosity, hard hydrogel, poor colonization effect, etc., and achieve excellent adhesion performance, Promotes healing and is safe to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

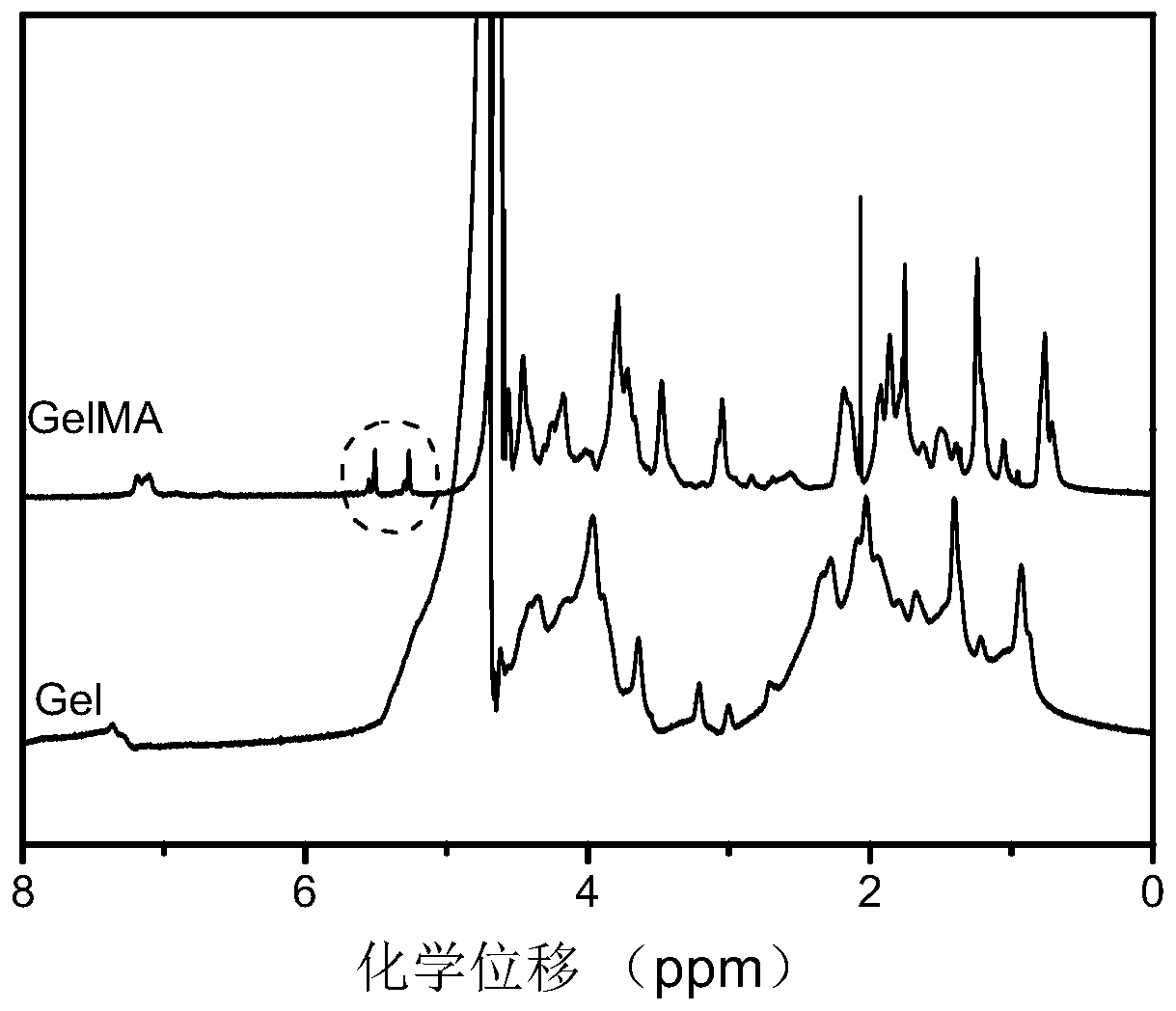

[0036] Preparation of methacrylic acid-modified gelatin (GelMA): Weigh 5 g of solid gelatin into 100 mL of pure water, stir and dissolve in a 60° C. water bath, and prepare a 5% w / v gelatin solution. Measure 3mL of methacrylic anhydride and dissolve it in 15mL of pure water to form a methacrylic anhydride solution. The methacrylic anhydride solution was slowly added dropwise to the gelatin solution, and stirred in a water bath at 60°C for 4 hours. After the reaction, the mixed solution was diluted to a solution containing 2.5% w / v gelatin, then dialyzed in pure water with a 8000-12000Da dialysis bag, and finally freeze-dried at -50°C to obtain GelMA.

Embodiment 2

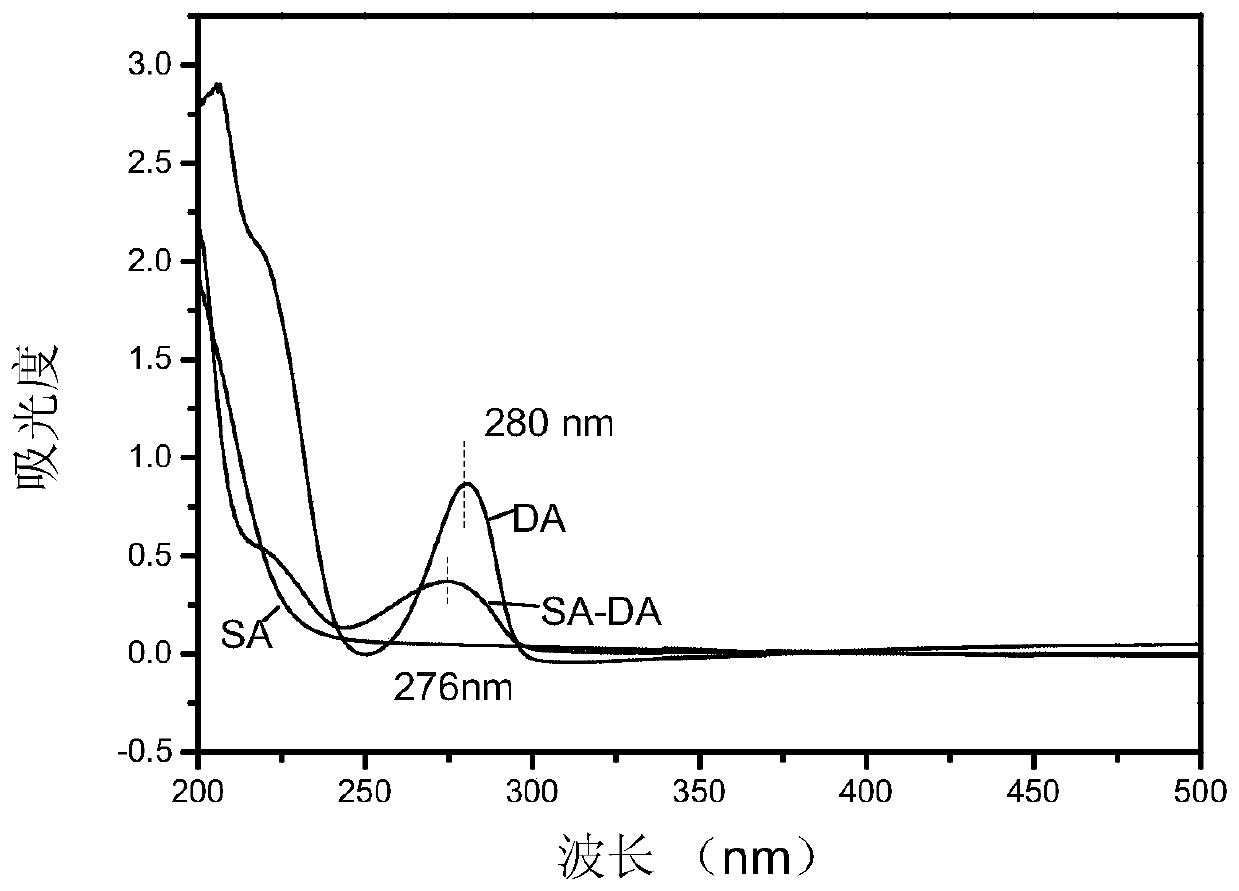

[0038] Preparation of dopamine-modified sodium alginate (SA-DA): 1 g of sodium alginate was weighed and dissolved in 100 mL of deionized water to prepare a 1% w / v sodium alginate solution. Weigh 1.0g of EDC and add it to the sodium alginate solution, adjust the pH to 5.5, activate for 15min, then add 1.5g of NHS, stir for 15min, quickly add 0.5g of dopamine hydrochloride, and then use 0.1mol / L of sodium hydroxide or Adjust the pH of the reaction system with hydrochloric acid solution and control the pH value between 5 and 6, react at room temperature under nitrogen protection for 12 hours, dialyze with hydrochloric acid solution with pH=5.5 for 1 day, and then dialyze with distilled water for 2 days (molecular weight cut-off: 8000~15000Da ), and finally freeze-dried at -50°C to obtain SA-DA.

Embodiment 3

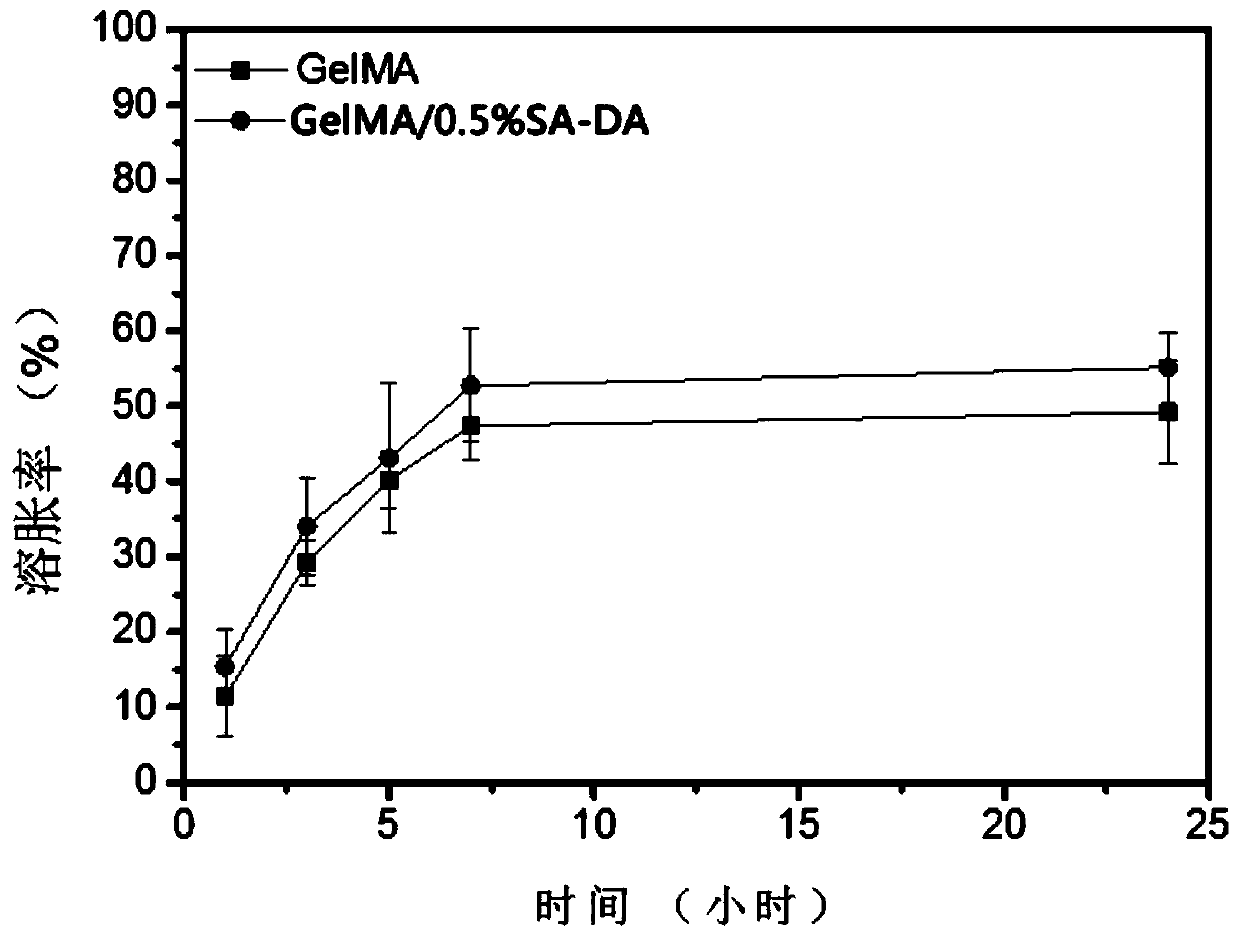

[0040] Preparation of GelMA hydrogel: the GelMA prepared in Example 1 was dissolved in PBS solution to prepare a GelMA solution with a concentration of 10% w / v. Put 0.2 mL of the above GelMA solution in a 48-well cell plate, add 0.1% w / v photoinitiator LAP, stir well, and irradiate with ultraviolet light for 1 min to obtain GelMA hydrogel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com