Patents

Literature

83 results about "Open fracture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

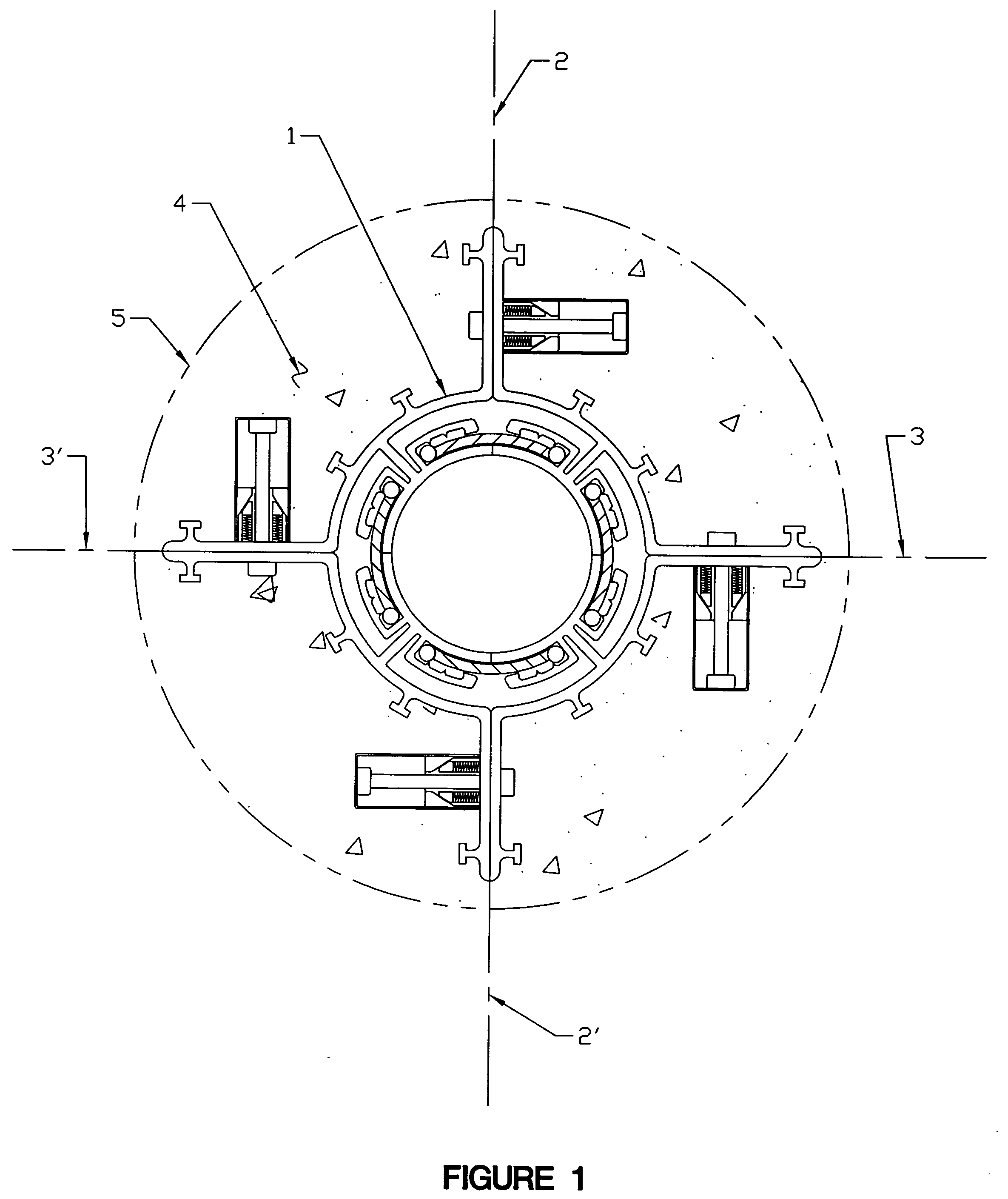

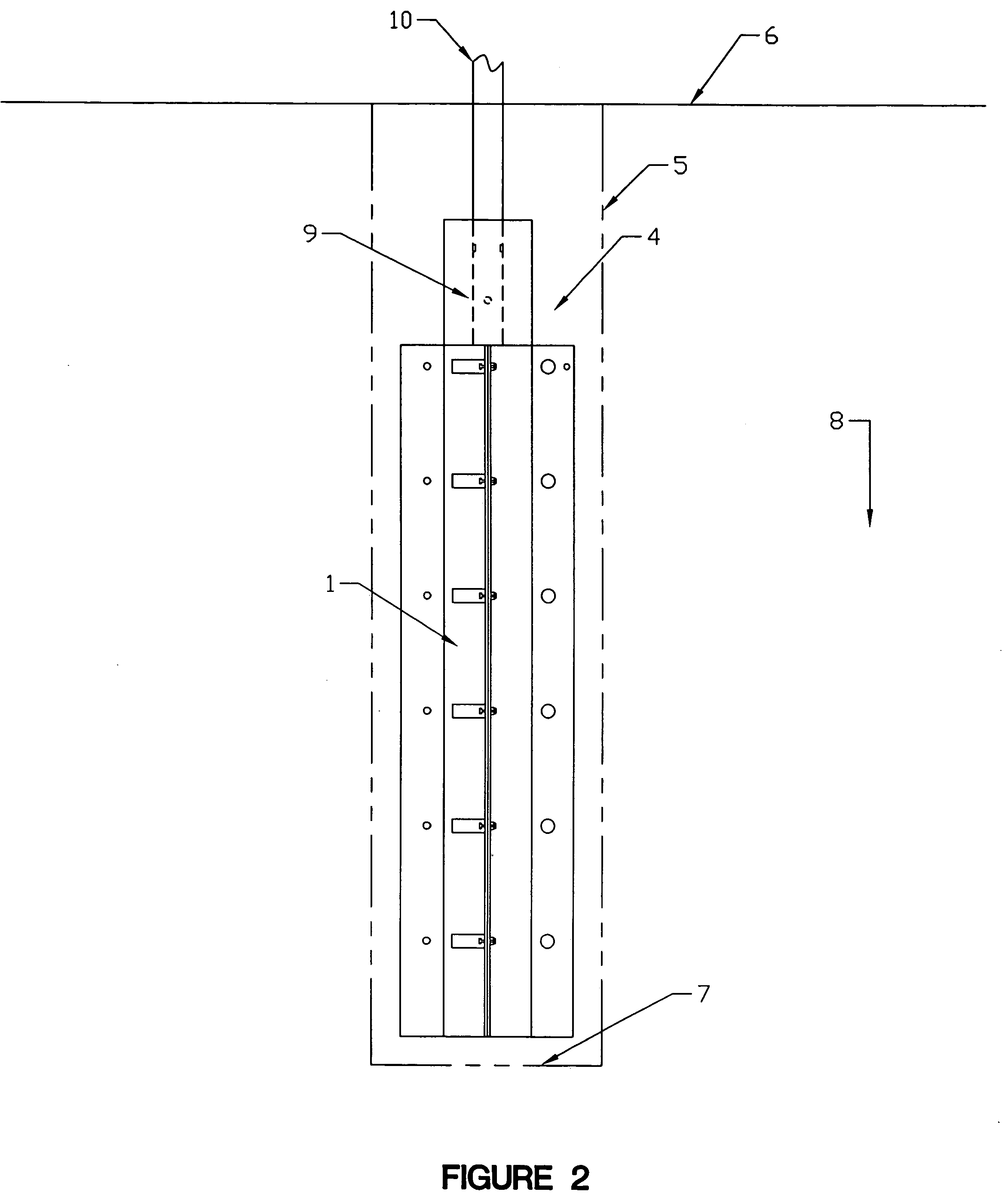

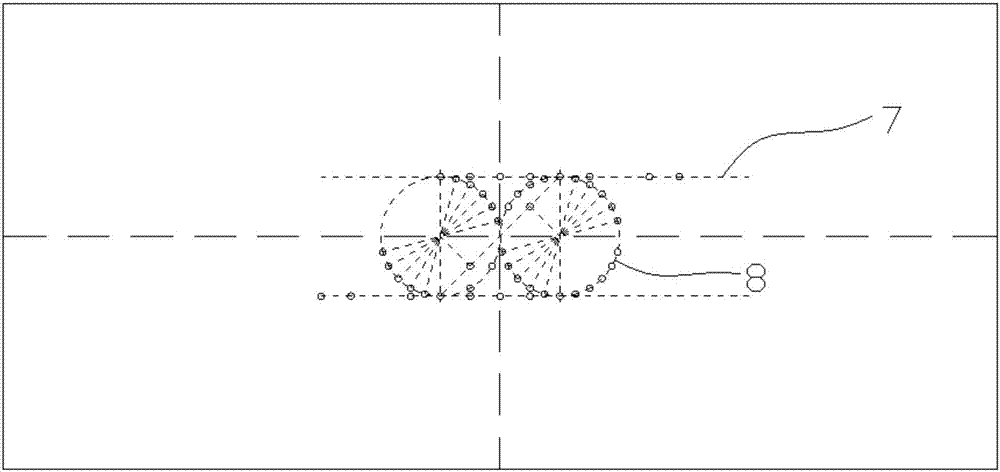

Multiple azimuth control of vertical hydraulic fractures in unconsolidated and weakly cemented sediments

InactiveUS6991037B2Increase pressureImprove stressDrilling rodsFluid removalFracturing fluidHydraulic fracturing

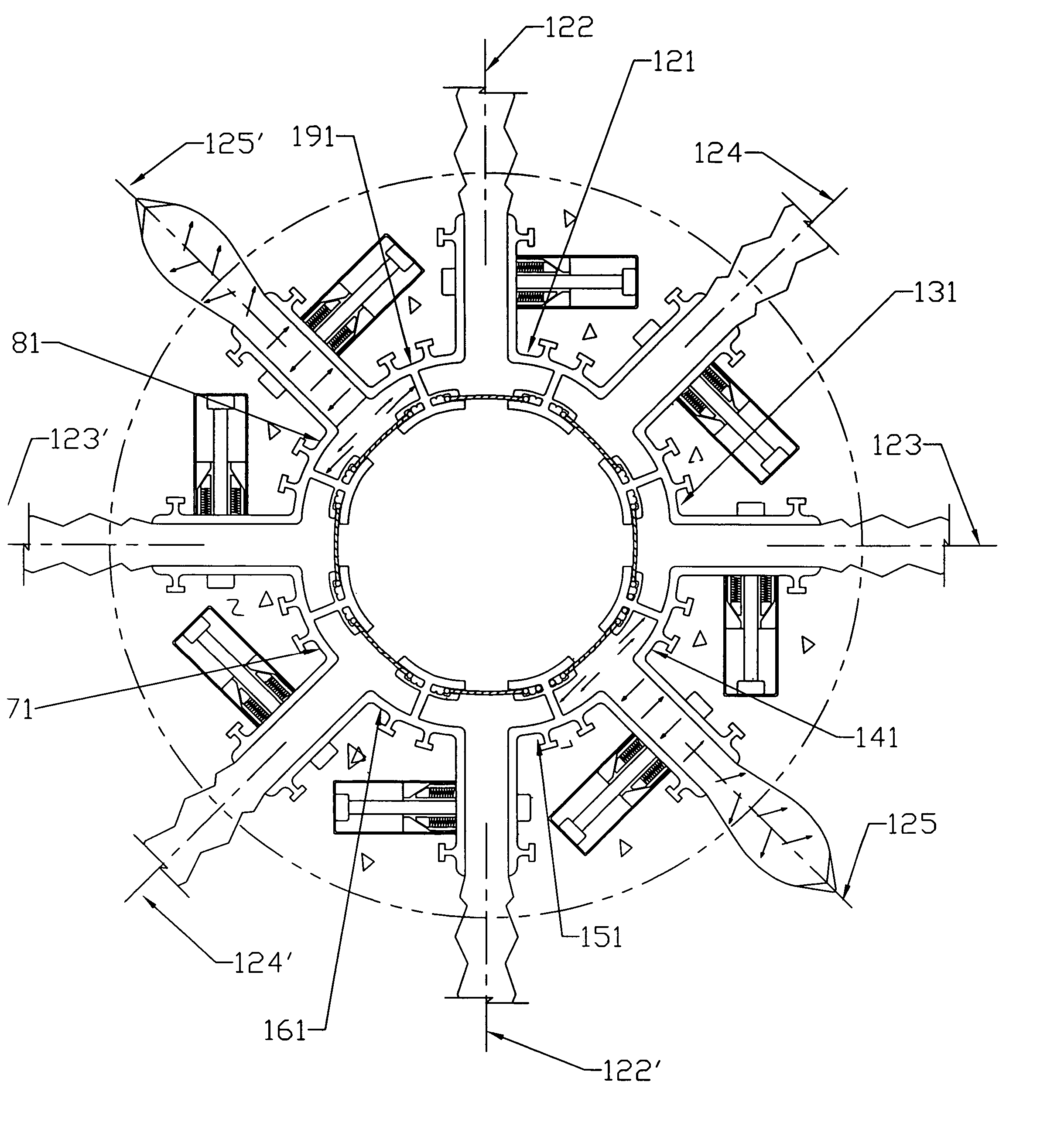

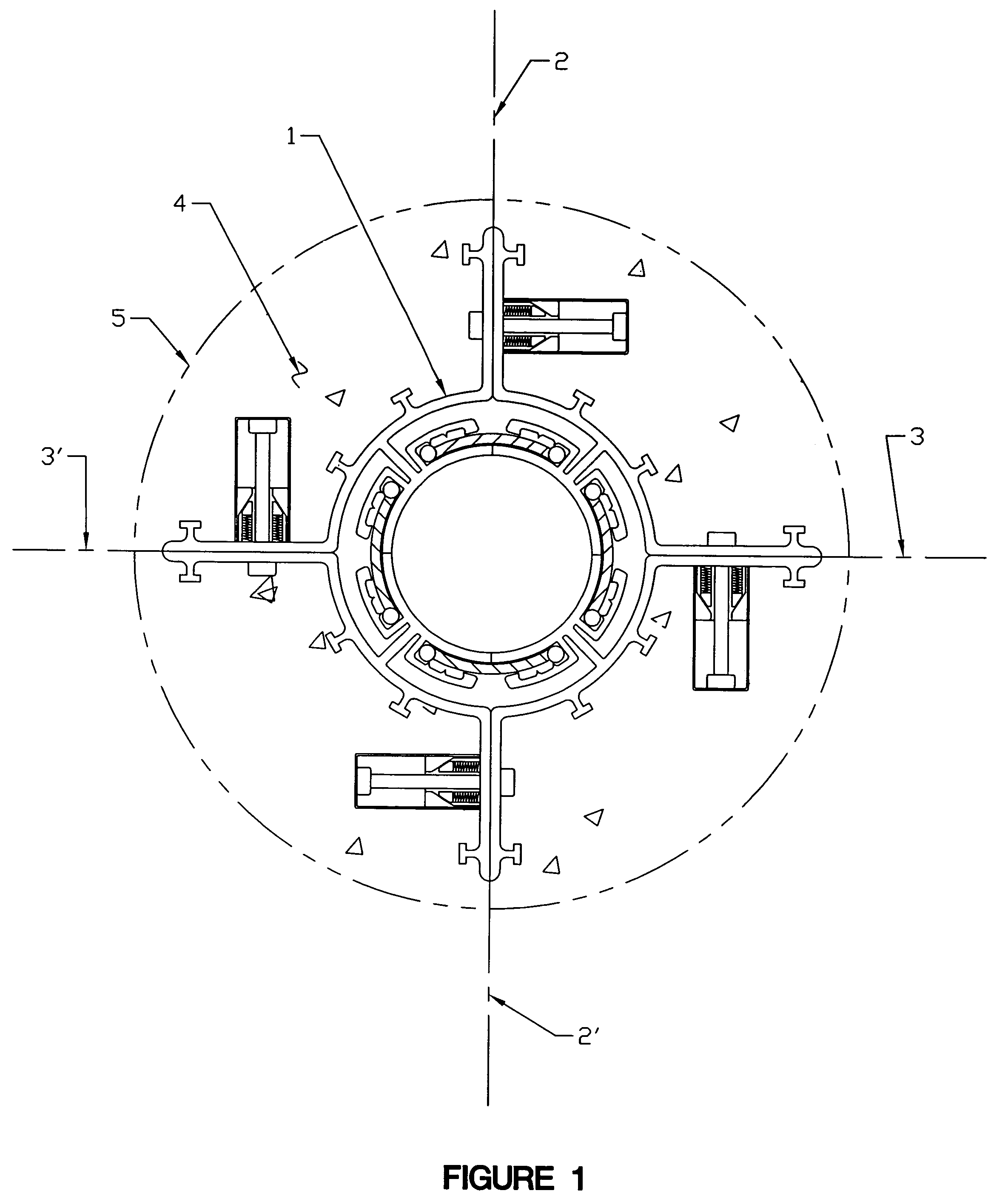

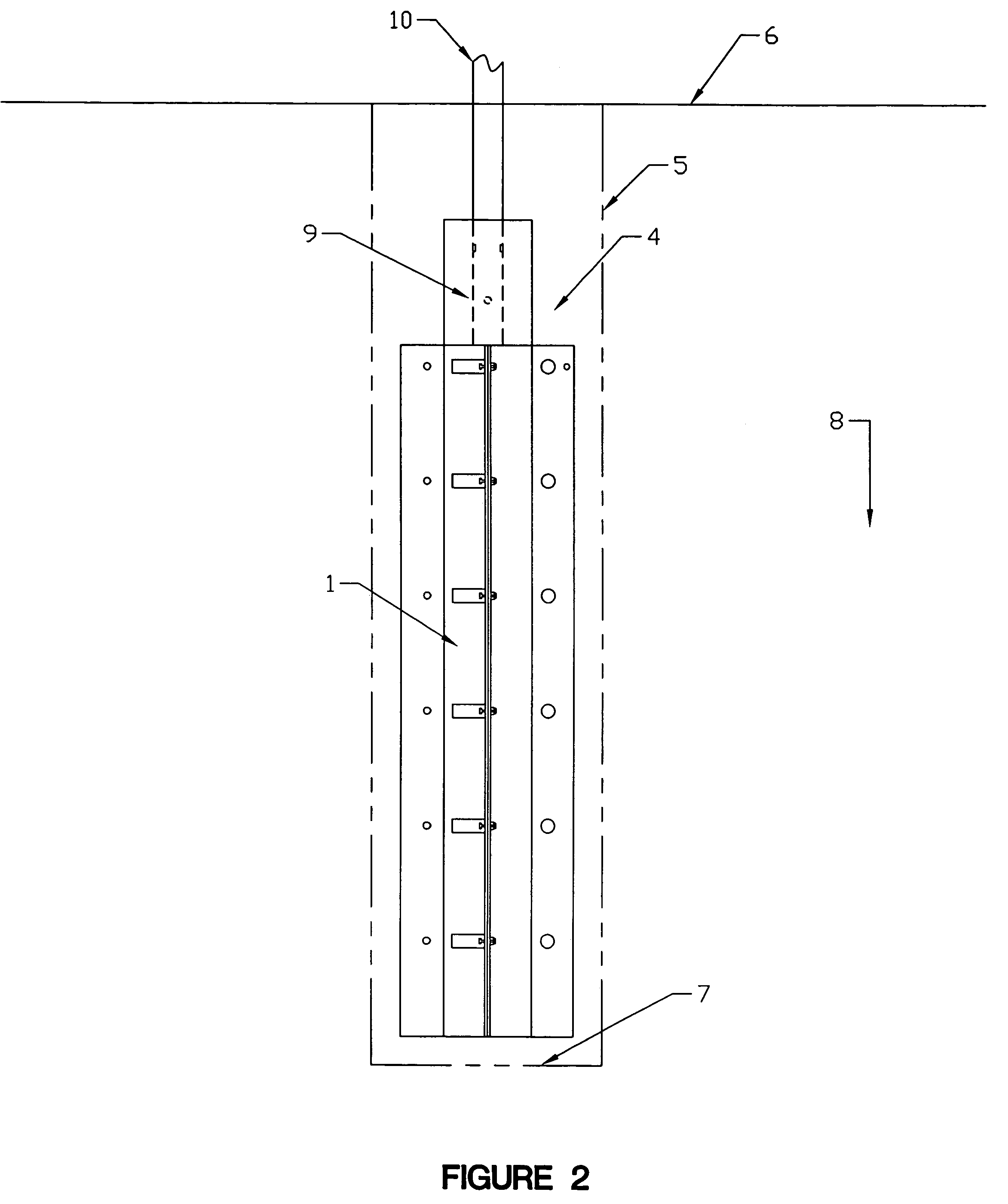

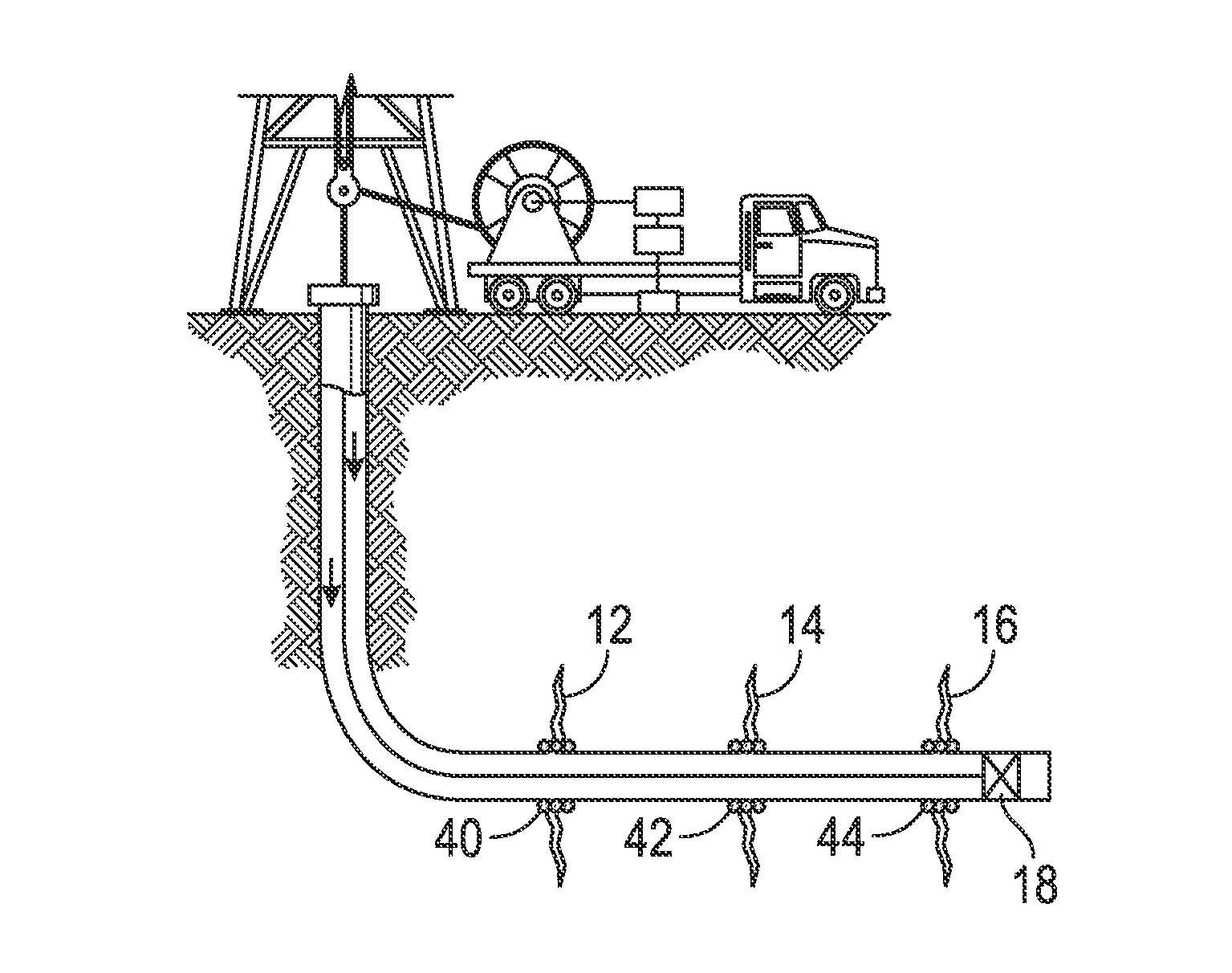

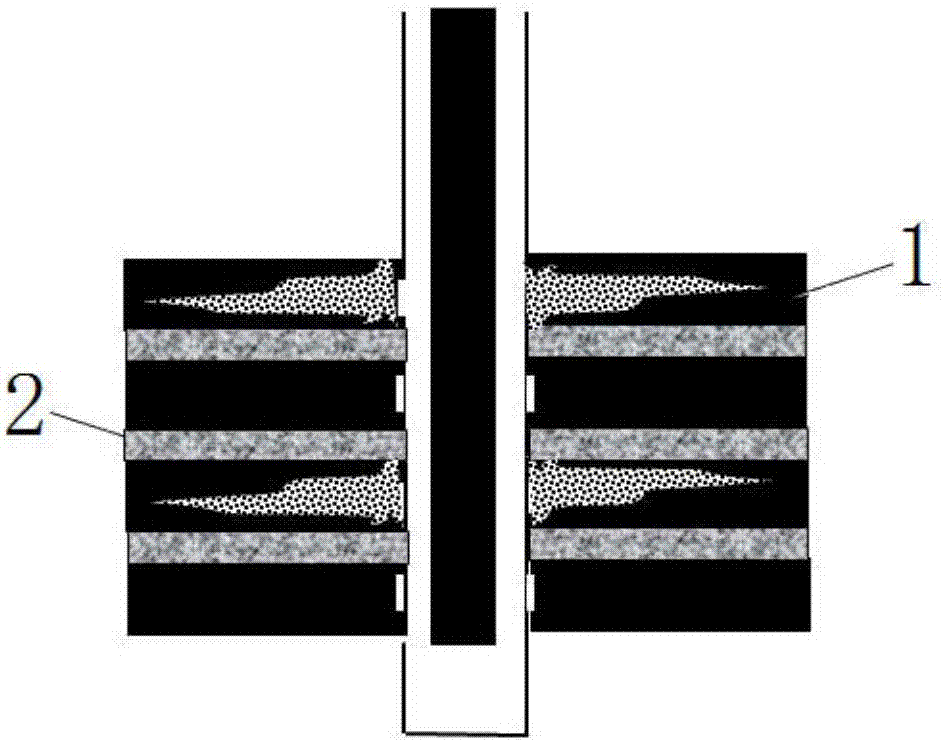

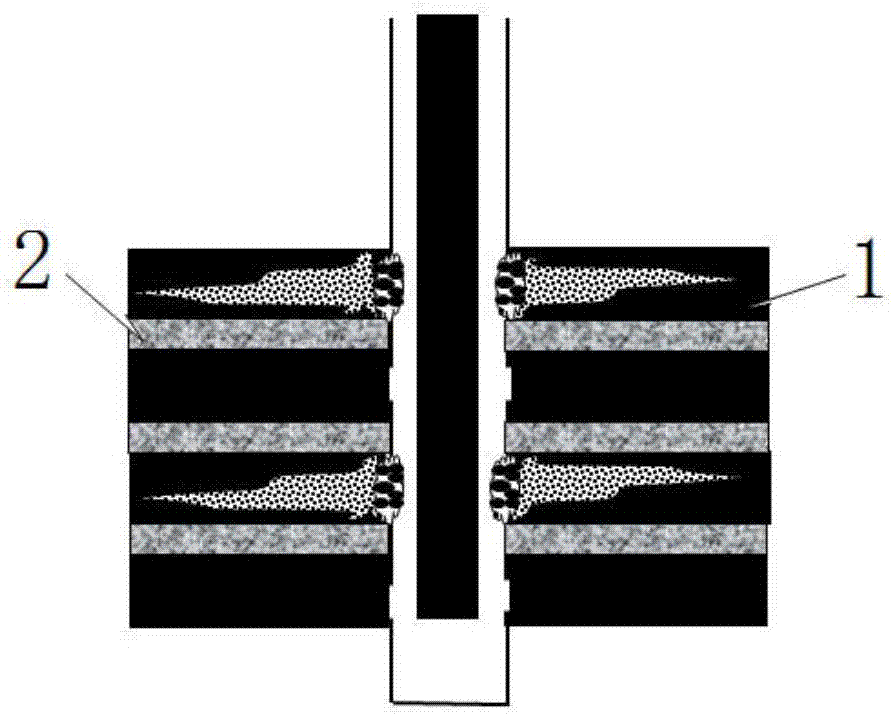

A method and apparatus for initiating multiple azimuth controlled vertical hydraulic fractures in unconsolidated and weakly cemented sediments from a single bore hole to control the fracture initiation and propagation of hydraulic fractures at differing azimuths, enabling greater yield and recovery of petroleum fluids from the formation. An injection casing with multiple fracture initiation sections is inserted and grouted into a bore hole. A fracture fluid carrying a proppant is injected into the injection casing and opens fracture initiation sections to dilate the formation in a direction orthogonal to the first fracture azimuth plane. Following completion of the first fracture injection, the fracture fluid is injected into the injection casing and opens a set of second and subsequent fracture initiation sections dilating the formation and initiating and propagating a second and subsequent vertical hydraulic fractures at different azimuths to the first and subsequent earlier installed fractures.

Owner:GEOSIERRA

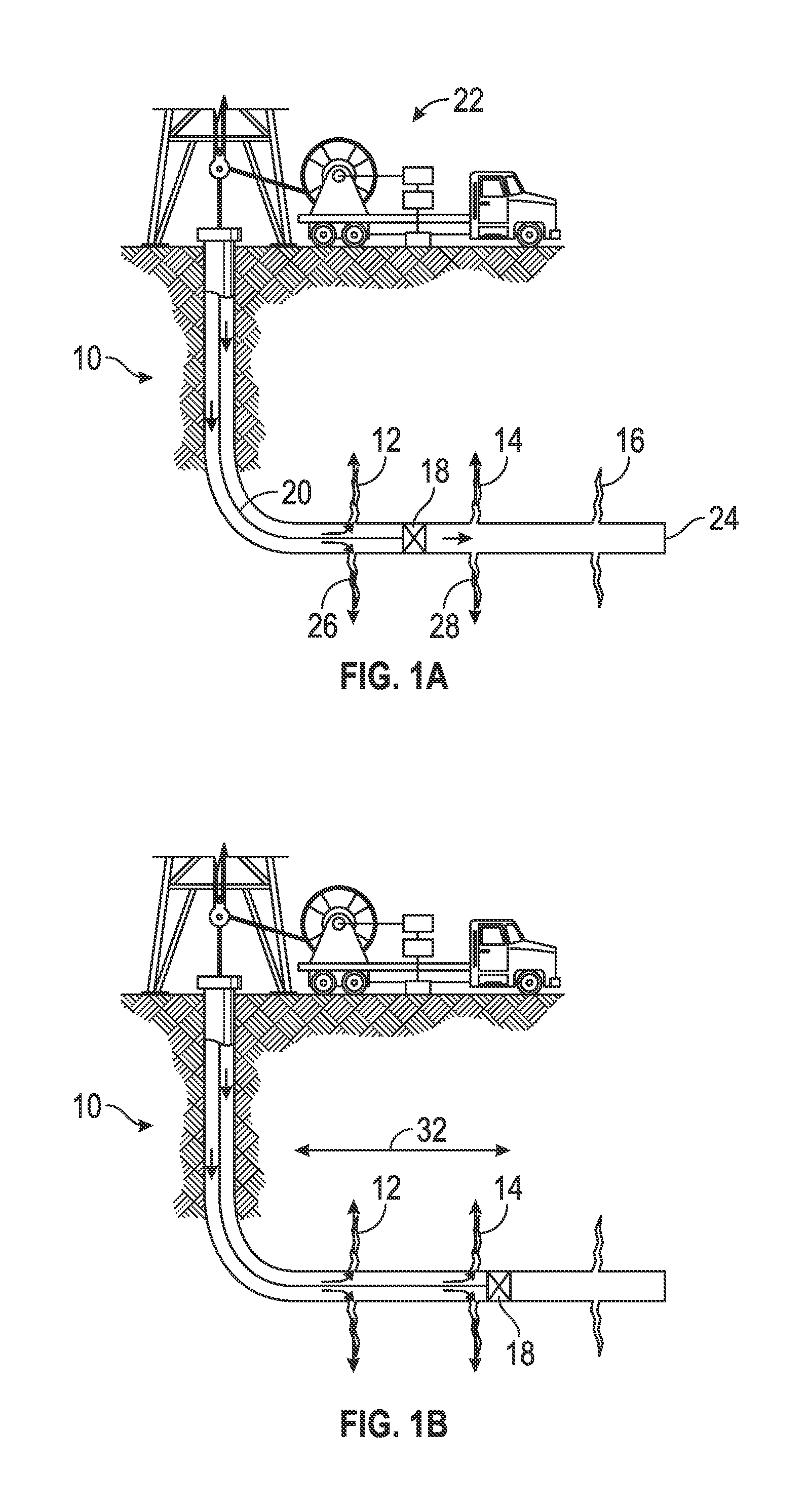

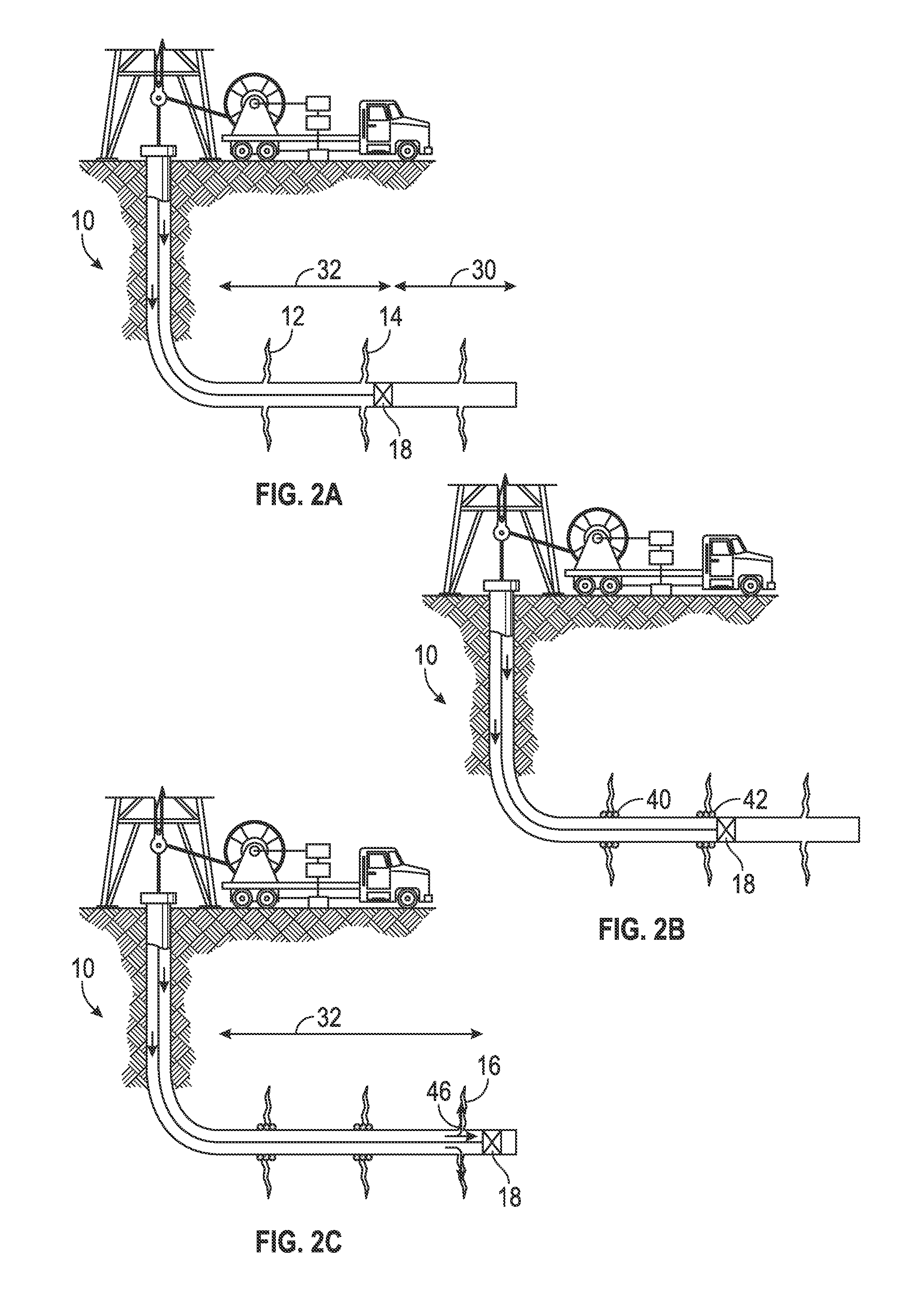

Well re-fracturing method

InactiveUS20160333680A1Diminishing rate of displacementReduce rateSurveyFluid removalOpen fracturePre-existing

A method of re-treating a well with pre-existing fractures which includes: displacing a tool in a well, leaking off motive fluid to an open fracture zone passed by the tool to diminish the rate of displacement, and locating the open fracture zone above the tool.

Owner:SCHLUMBERGER TECH CORP

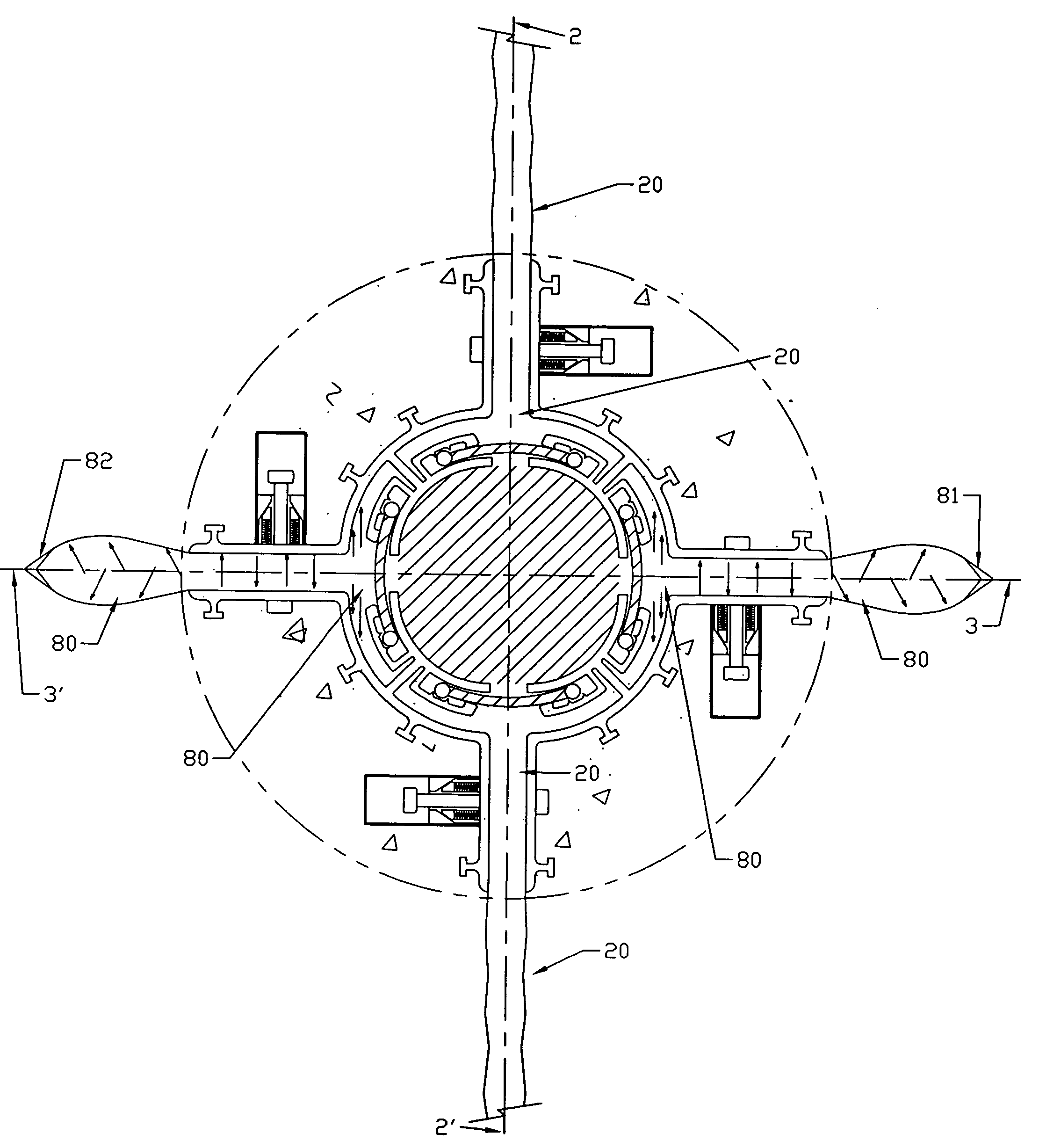

Multiple azimuth control of vertical hydraulic fractures in unconsolidated and weakly cemented sediments

InactiveUS20050145387A1Increased horizontal stressImprove stress conditionDrilling rodsFluid removalFracturing fluidOpen fracture

The invention is a method and apparatus for initiating multiple azimuth controlled vertical hydraulic fractures in unconsolidated and weakly cemented sediments from a single bore hole to control the fracture initiation and propagation of hydraulic fractures at differing azimuths. The multiple azimuth vertical fractures enable greater yield and increased recovery of petroleum fluids from the formation. An injection casing with multiple fracture initiation sections is inserted and grouted into a bore hole. A fracture fluid carrying a proppant is injected into the injection casing and opens fracture initiation sections to dilate the formation in a direction orthogonal to the first fracture azimuth plane. Following completion of the first fracture injection, the fracture fluid is injected into the injection casing and opens a set of second and subsequent fracture initiation sections dilating the formation and initiating and propagating a second and subsequent vertical hydraulic fractures at different azimuths to the first and subsequent earlier installed fractures. The injection casing initiation sections remains open after fracturing providing direct hydraulic connection between the production well bore, the permeable proppant filled fractures and the formation.

Owner:GEOSIERRA

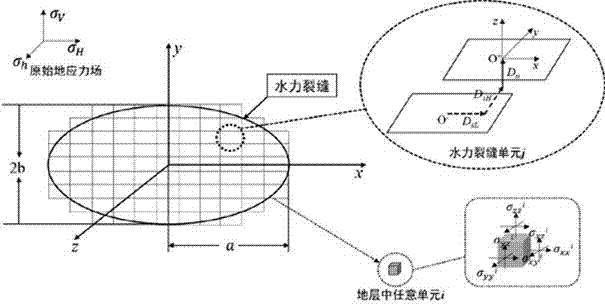

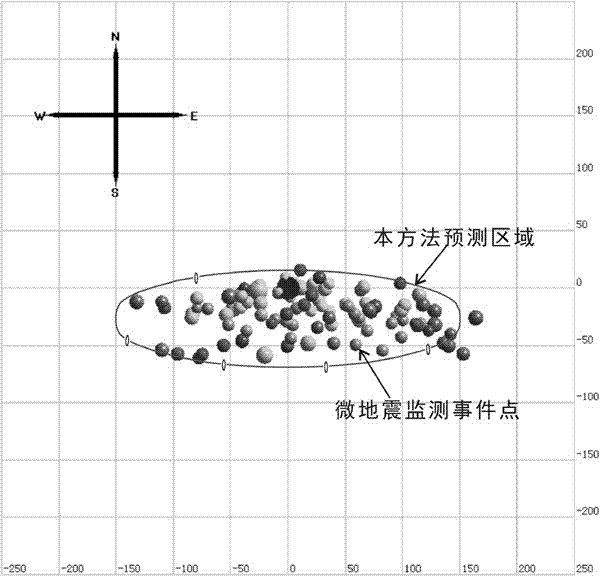

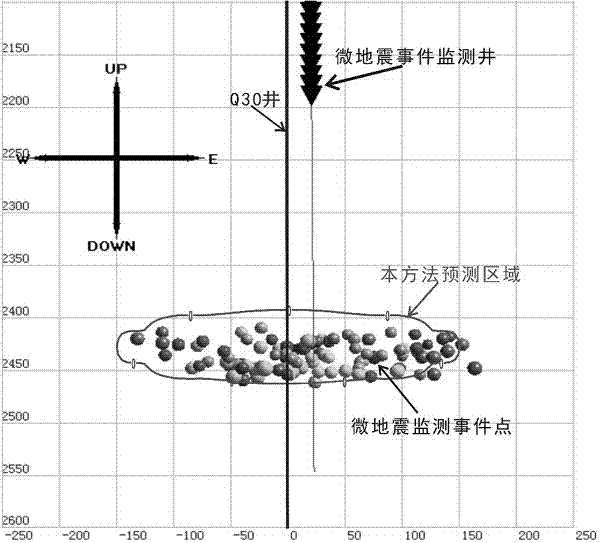

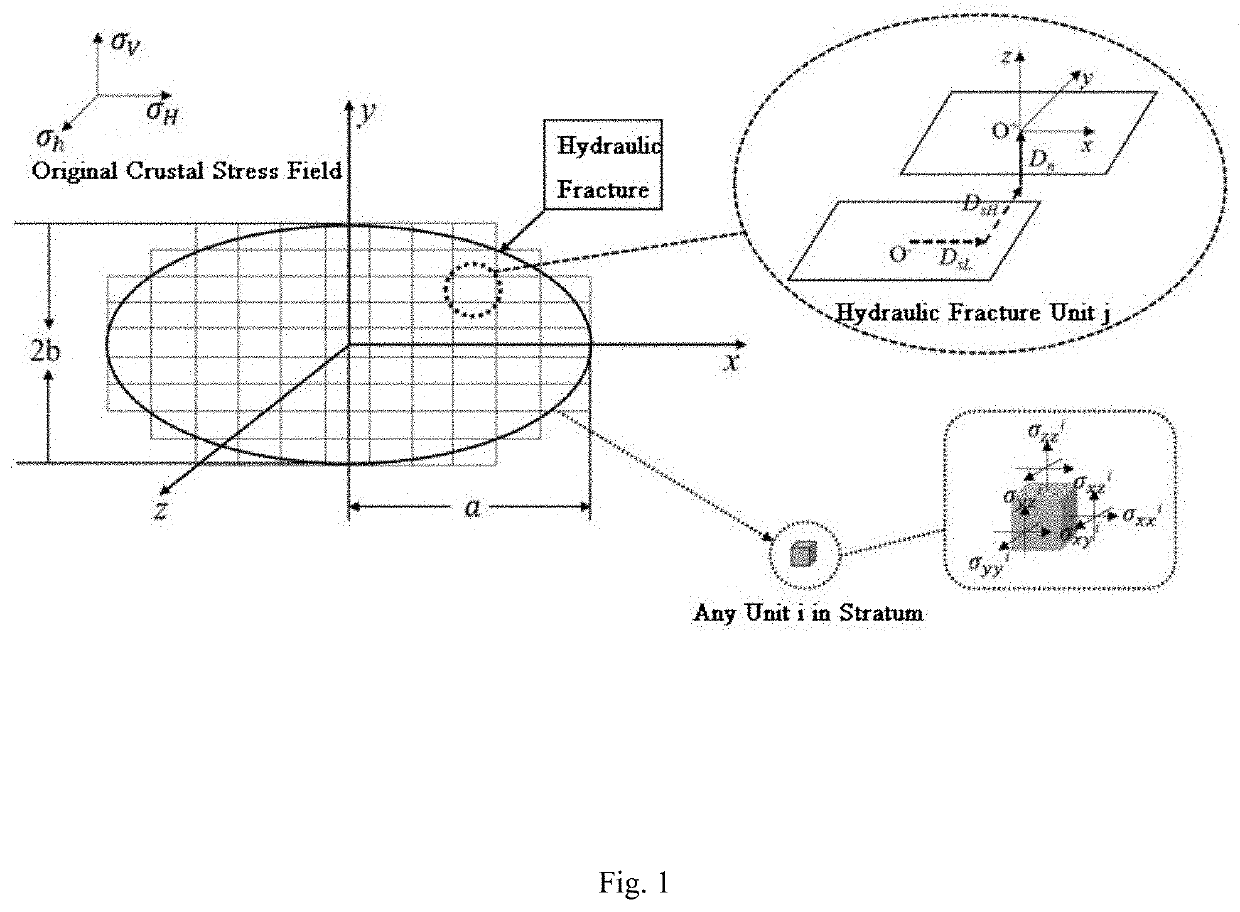

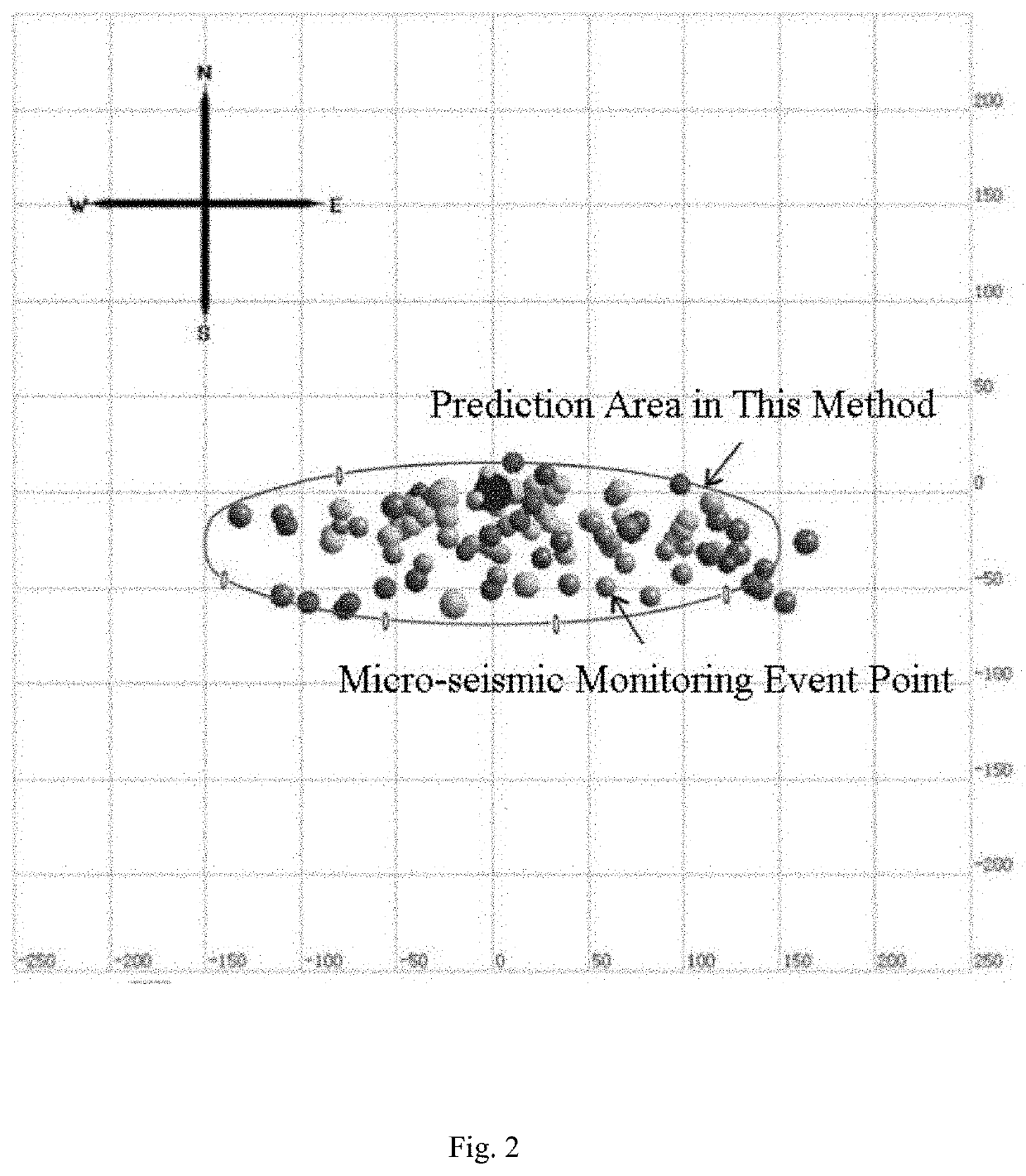

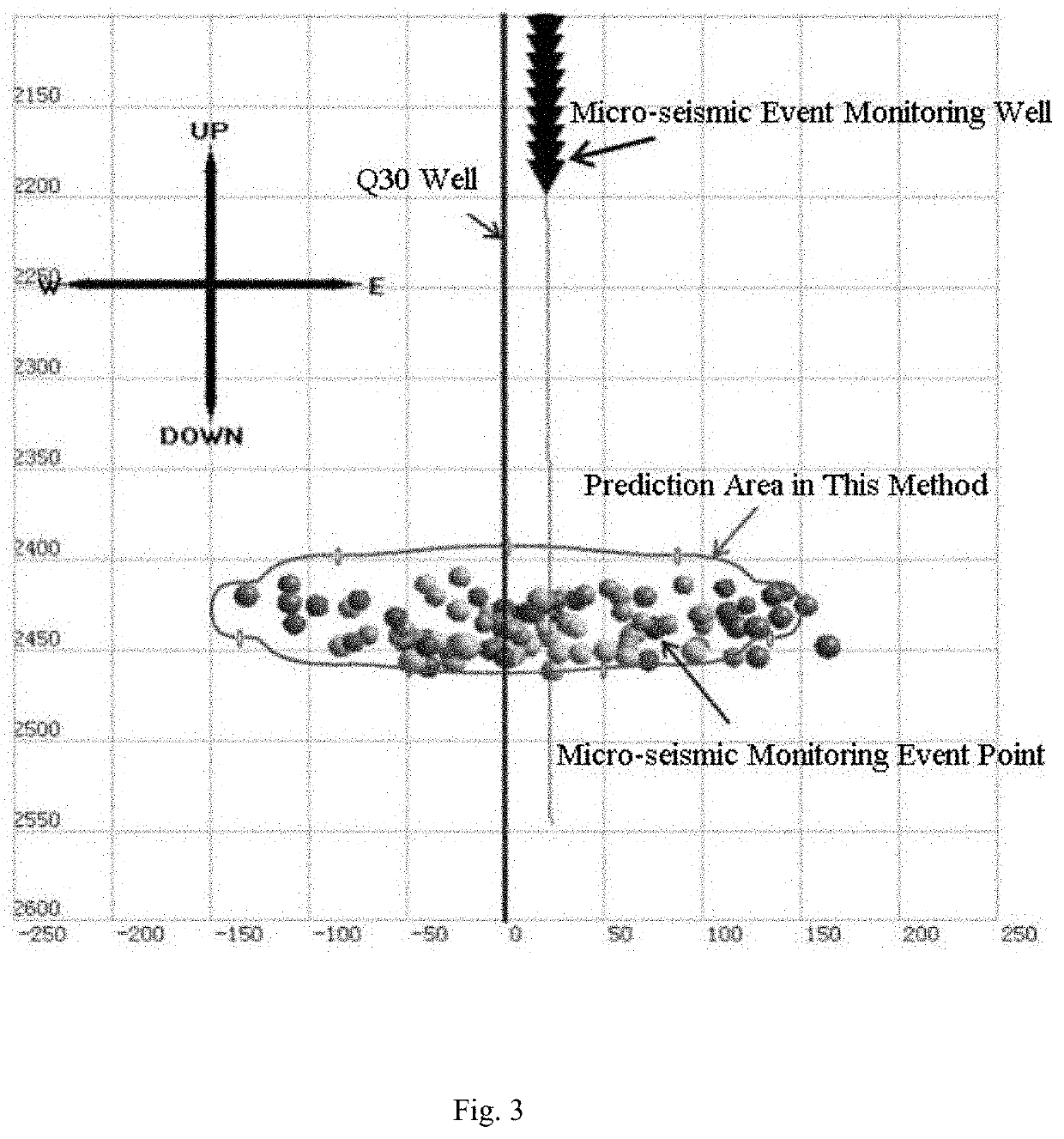

Method for predicting vertical well volume fractured reservoir reform volume of low permeable reservoir

The invention discloses a method for predicting vertical well volume fractured reservoir reform volume of low permeable reservoir. The method sequentially comprises the following steps: (1) calculating the induced stress produced by hydraulic fracture in a three-dimensional space; (2) calculating the formation pore pressure obtained after leak-off of fracturing fluid; (3) calculating the formation pore elastic stress obtained after the leak-off of the fracturing fluid; (4) overlapping the stress fields obtained in the step (1), (2) and (3) with an in-situ stress field to obtain a new crustal stress field, and calculating the magnitude and direction of three-way principal effective stress in the overlapped reservoir space; (5) calculating the open fracture determination coefficient M of a natural fracture in the reservoir space and the shear fracture region determination coefficient S of the natural fracture so as to predict the volume fractured reservoir reform volume. The method is used for predicting the reservoir reform volume after vertical well volume fracturing, is better in operability and accuracy, provides a favorable theoretical basis for effect evaluation and yield prediction after vertical well volume fracturing of the low permeable reservoir, and overcomes the defects of the prior art.

Owner:SOUTHWEST PETROLEUM UNIV

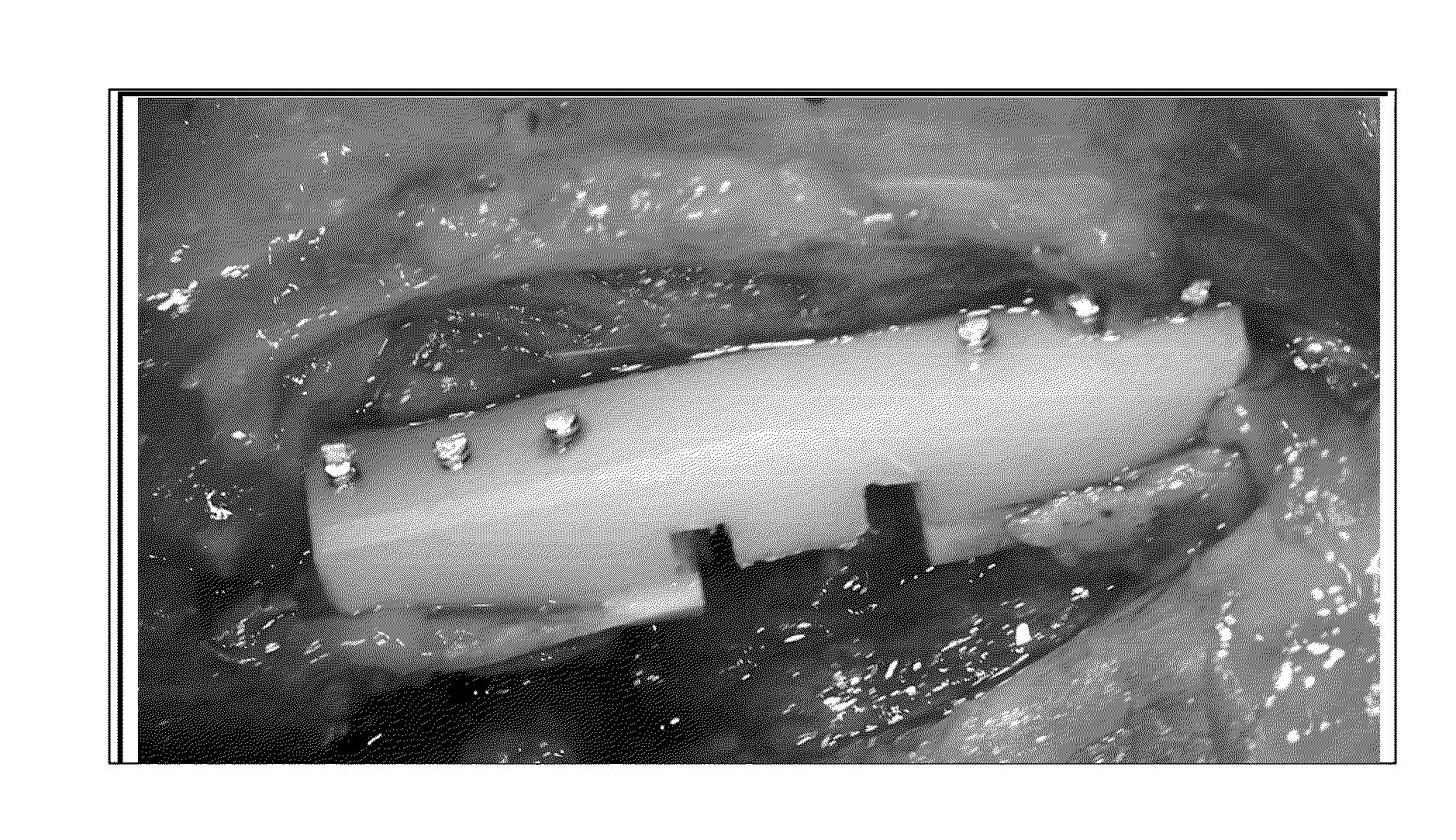

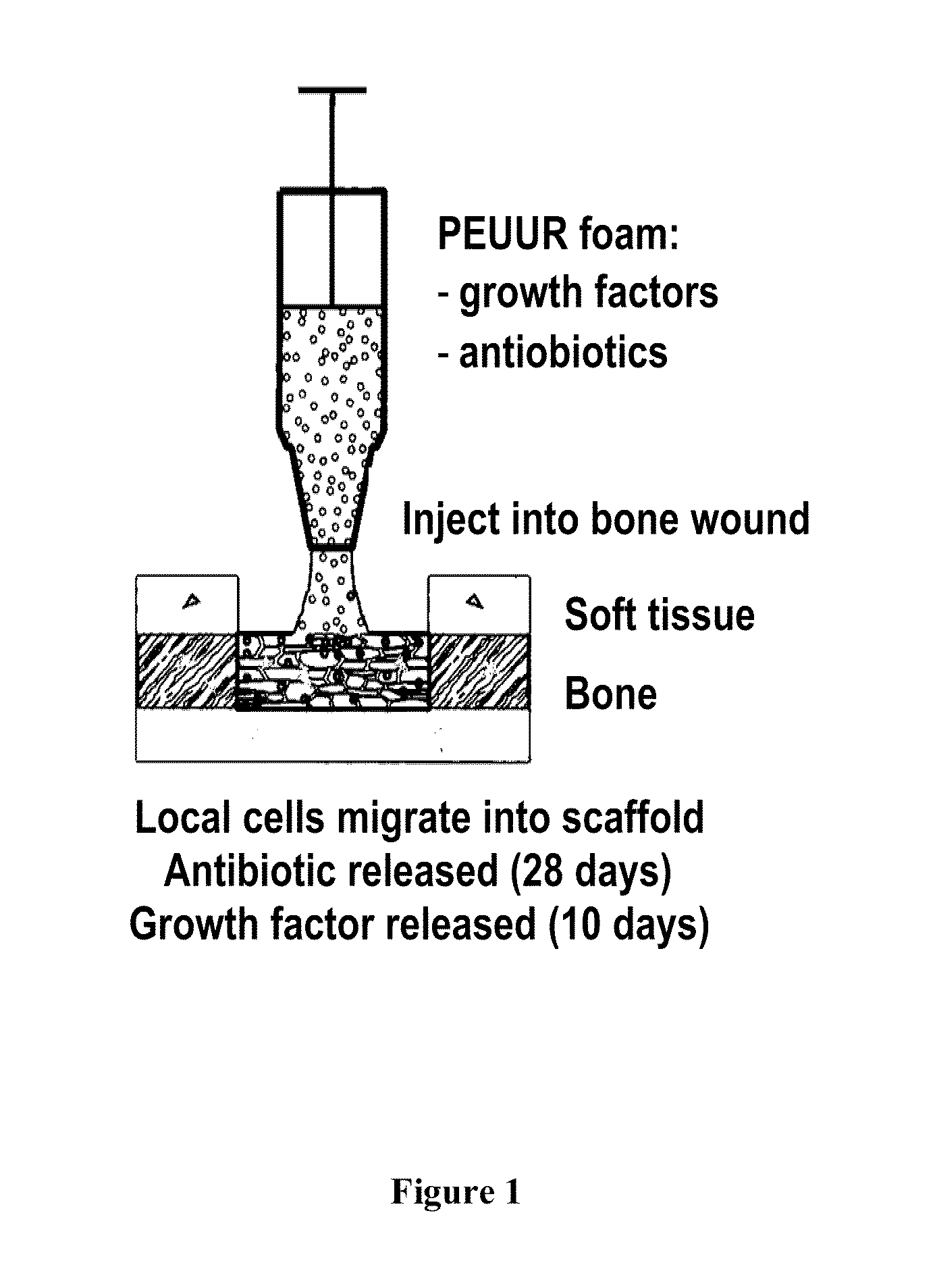

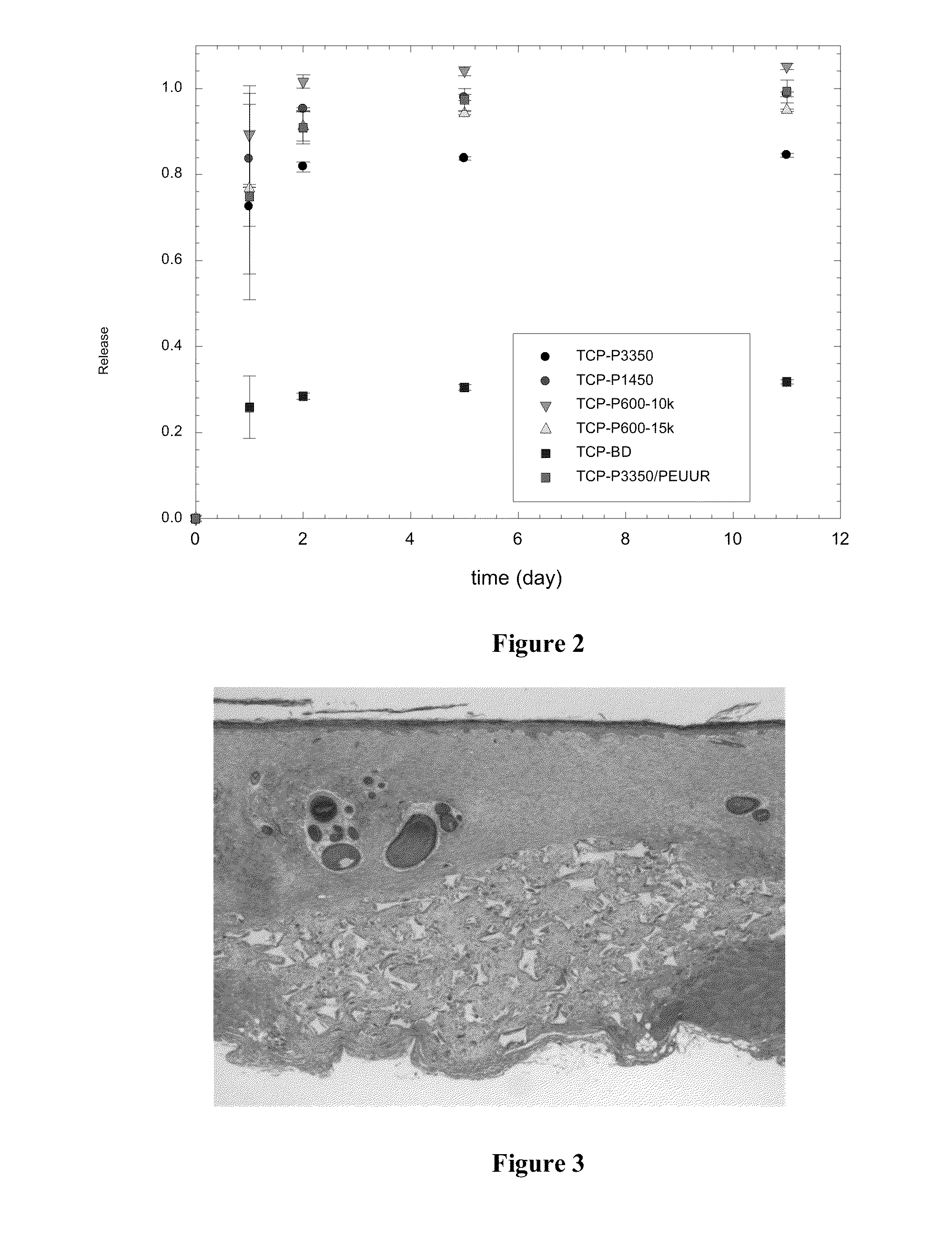

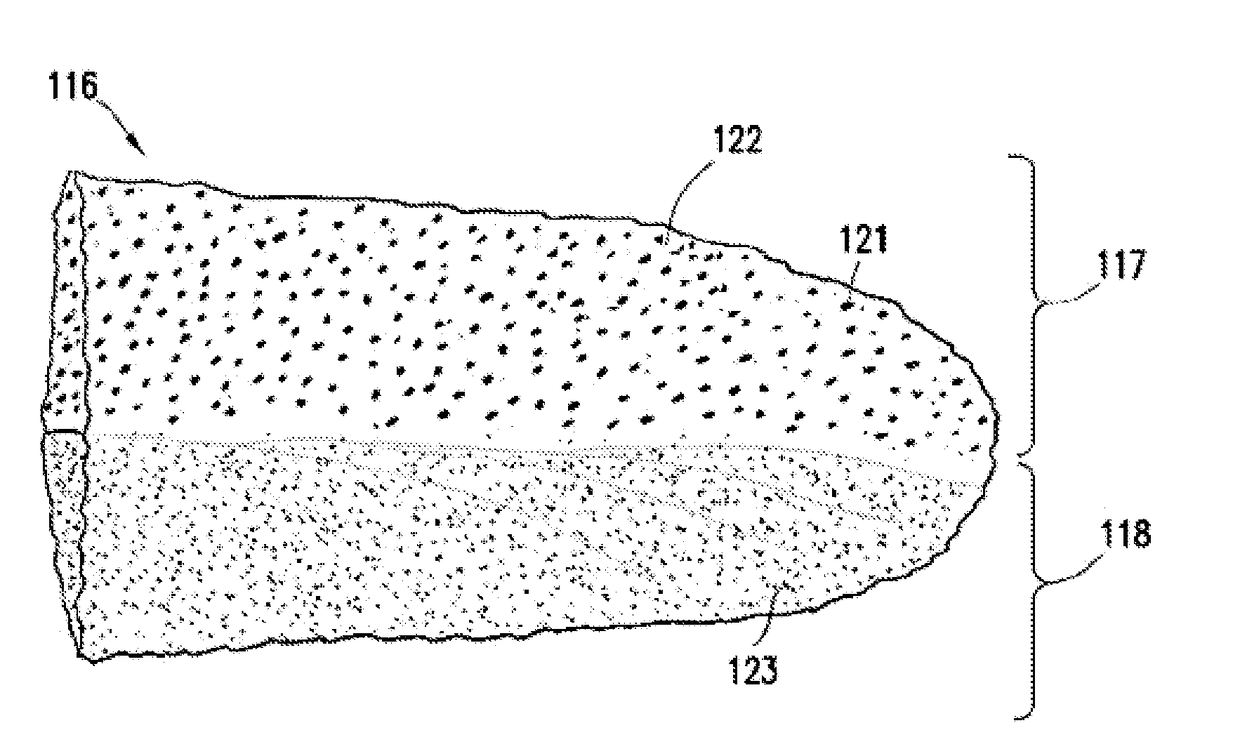

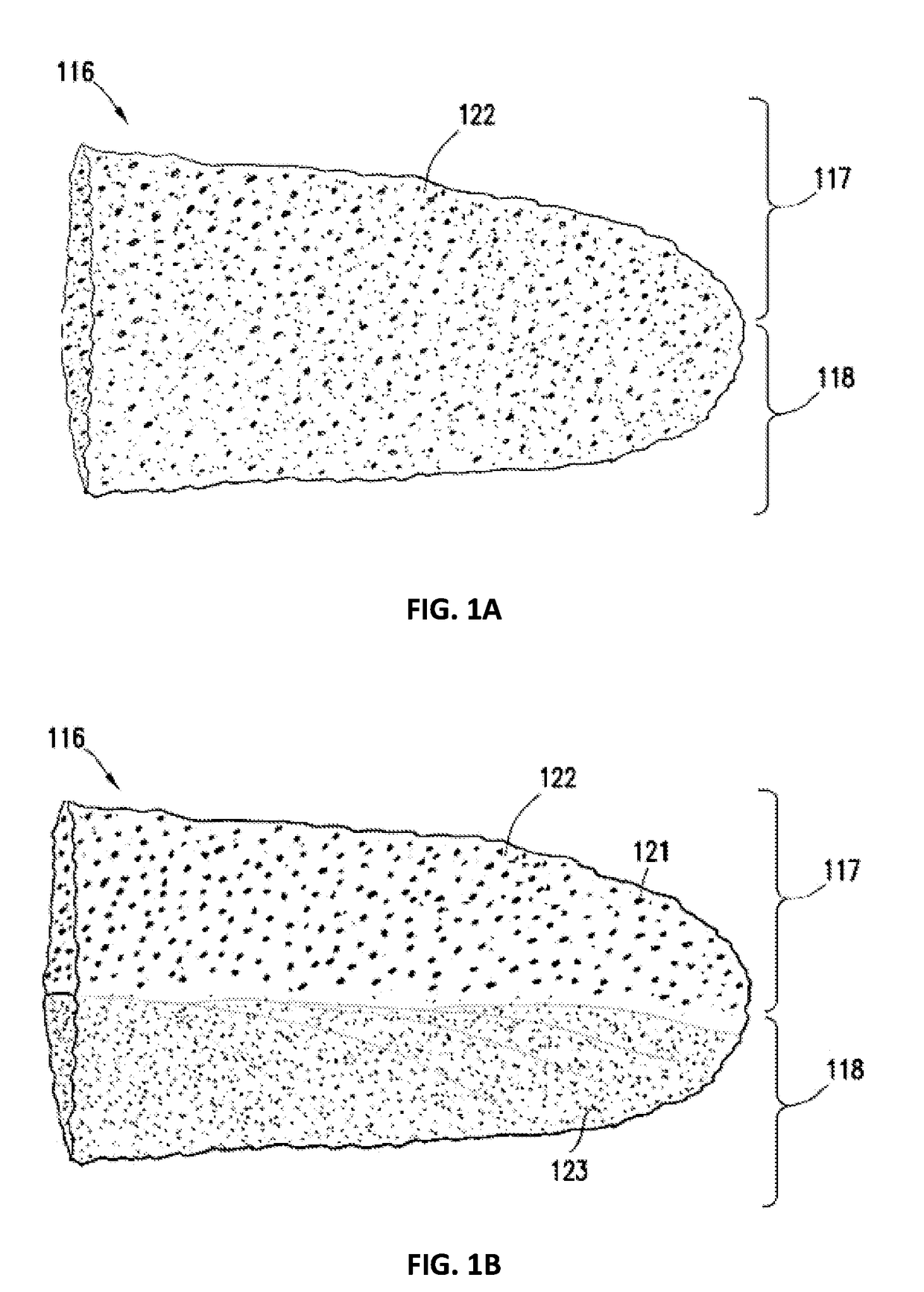

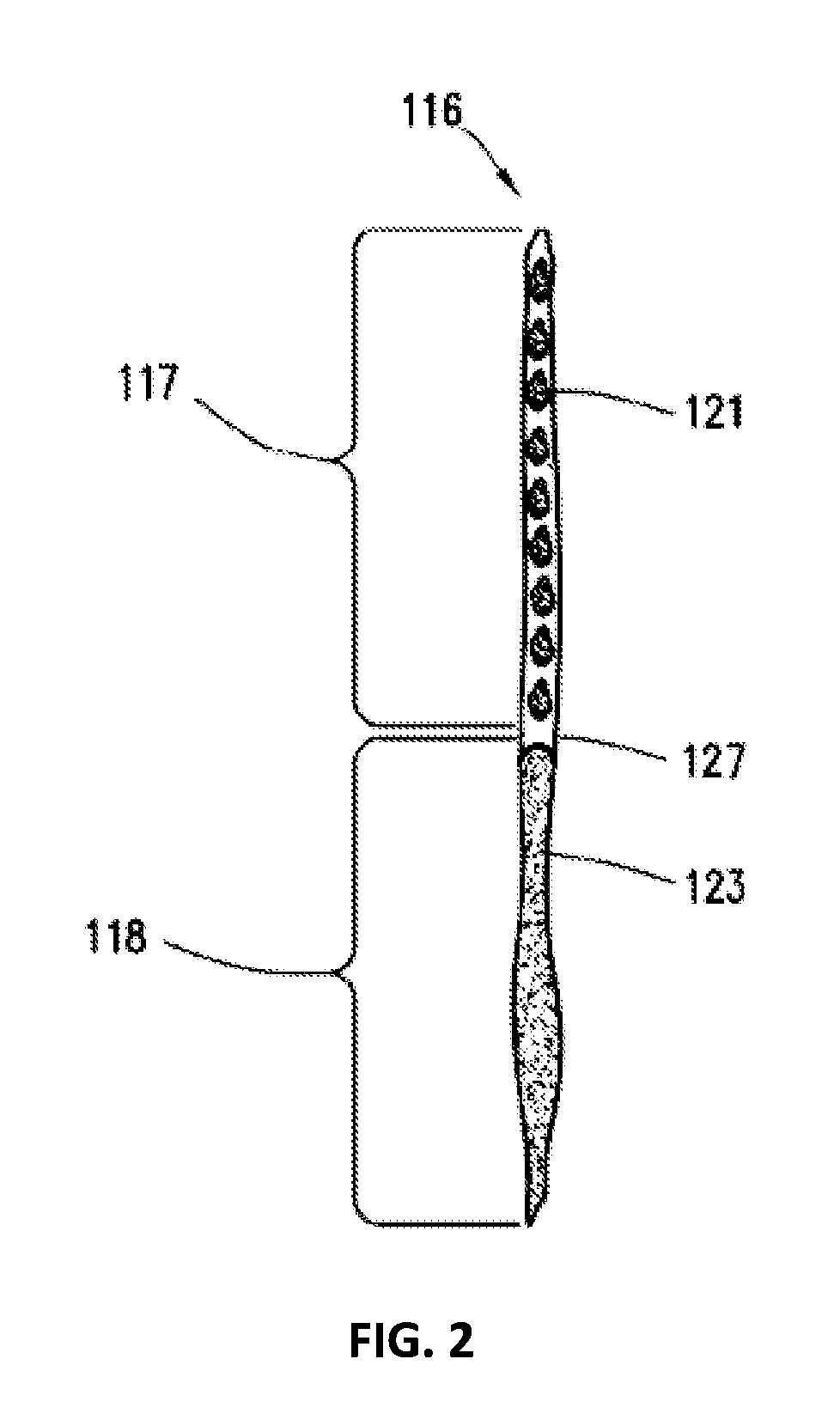

Injectable dual delivery allograph bone/polymer composite for treatment of open fractures

InactiveUS20110236501A1Shorten healing timeHealing is often complicatedBiocidePeptide/protein ingredientsPolyesterPorosity

A biodegradable polyurethane scaffold, comprising at least one polyisocyante, polyisocyanate prepolymer, or both, at least one polyester polyol, at least one catalyst, wherein the density of said scaffold is from about 50 to about 250 kg m-3 and the porosity of the scaffold is greater than about 70 (vol %) and at least 50% of the pores are interconnected with another pore, and wherein the scaffold incorporates at least one biologically active component in powder form.

Owner:VANDERBILT UNIV

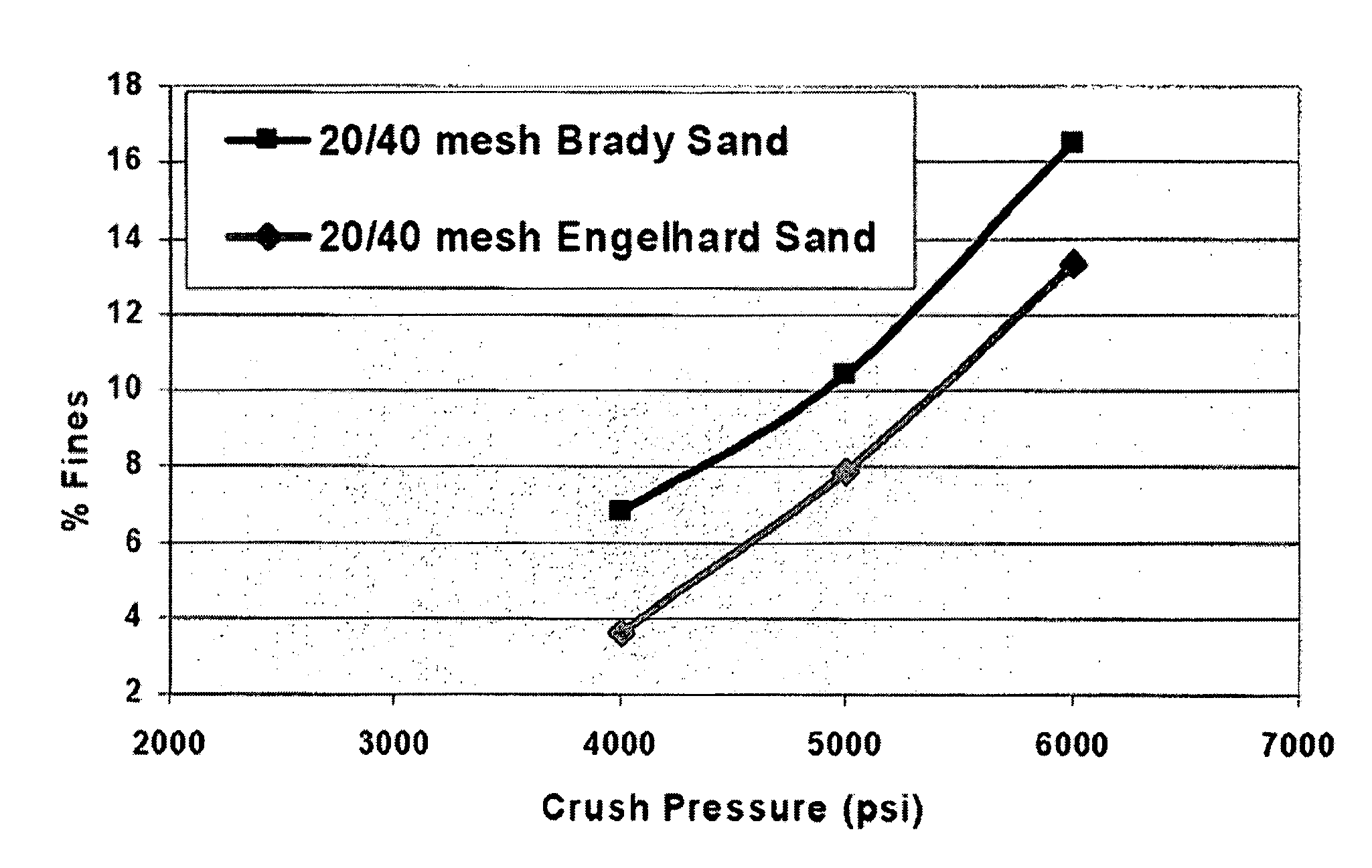

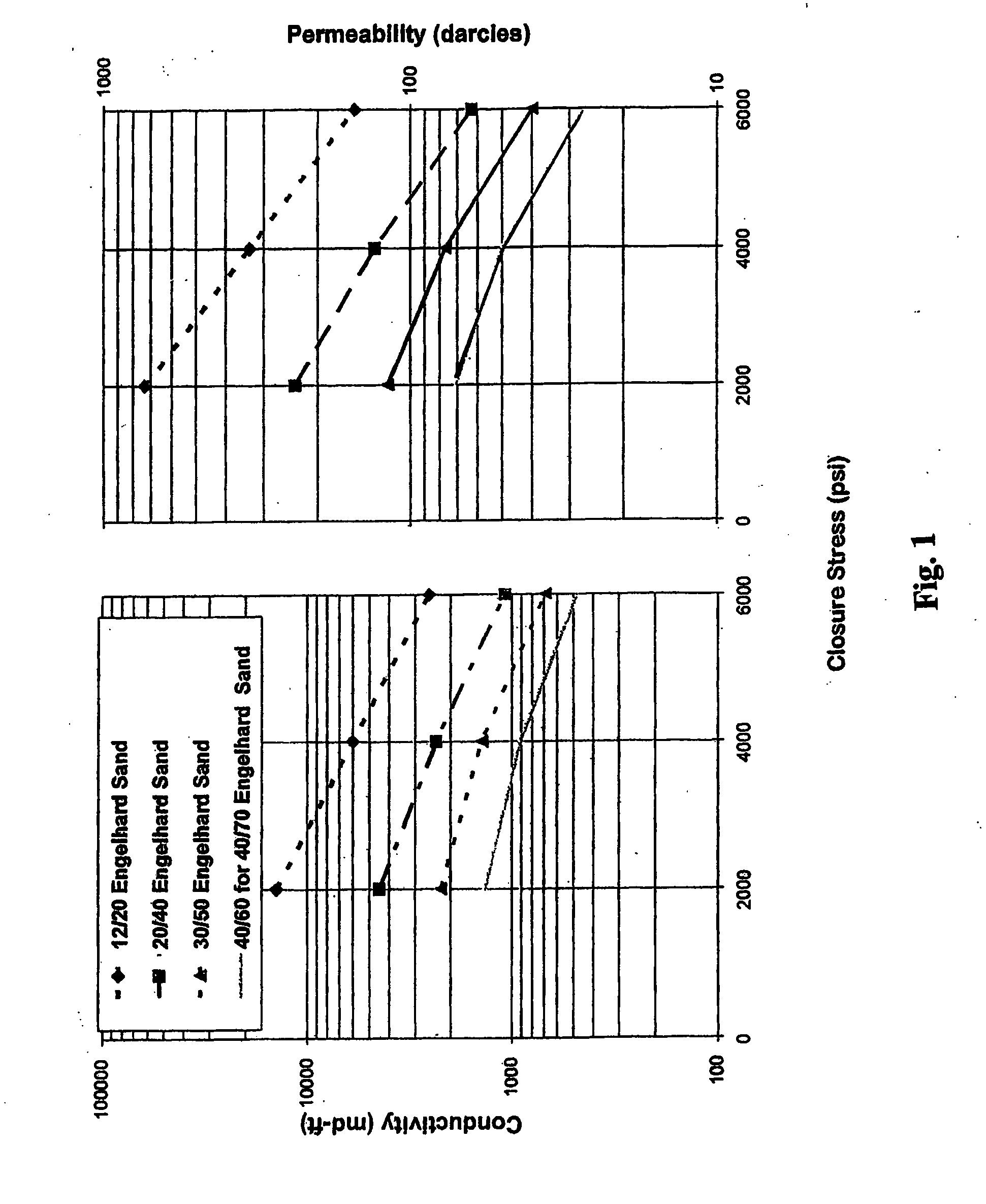

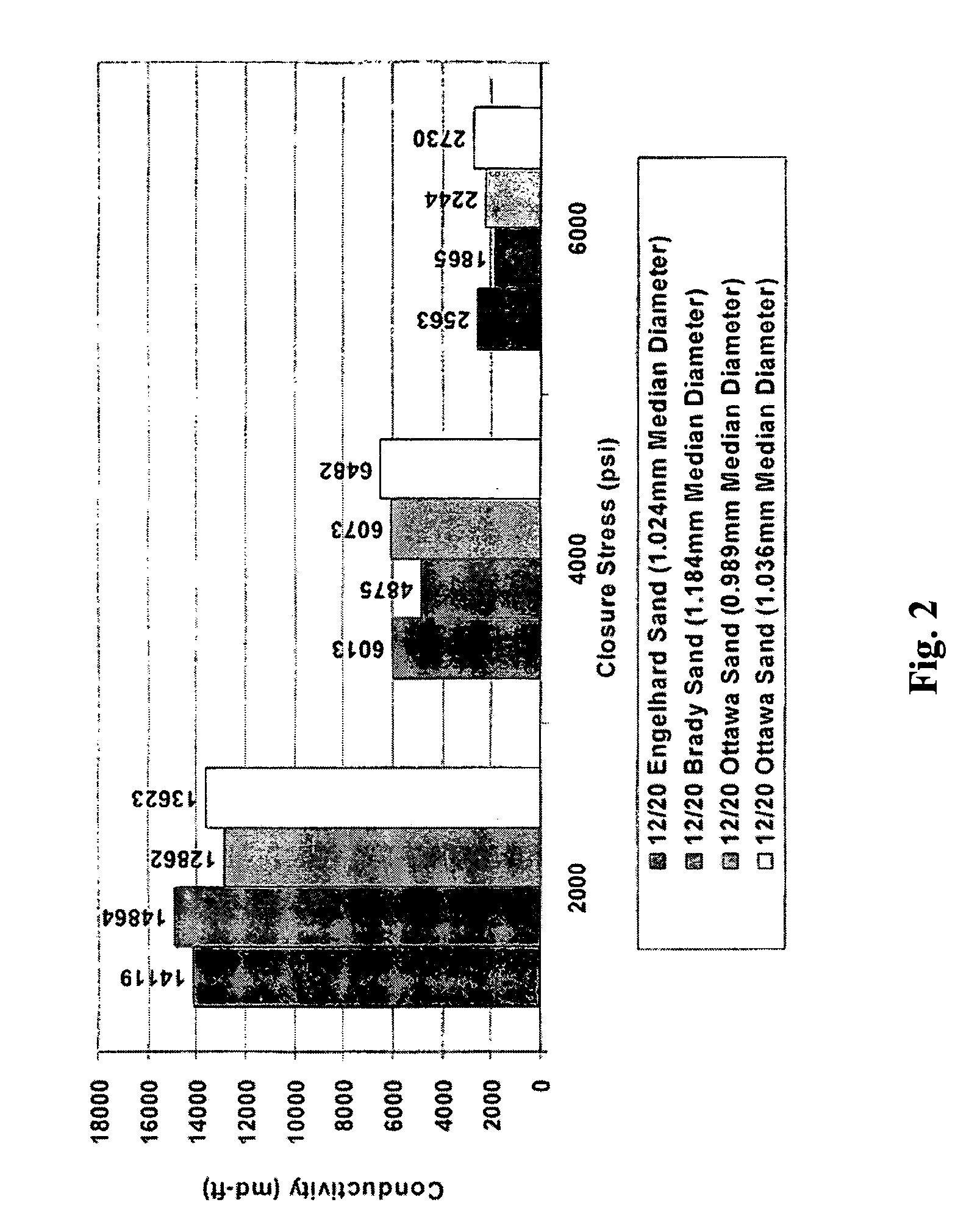

Hydraulic fracturing proppants and methods of use

Hydraulic fracturing proppants for use in propping fractures in subterranean well bores comprising sand particles and methods for their manufacture are described. According to one or more embodiments, the proppants exhibit a narrow particle size distribution, crush resistance, sphericity, roundness and turbidity. Methods for propping open fractures during a hydraulic fracturing operation are also described.

Owner:ENGELHARD CORP

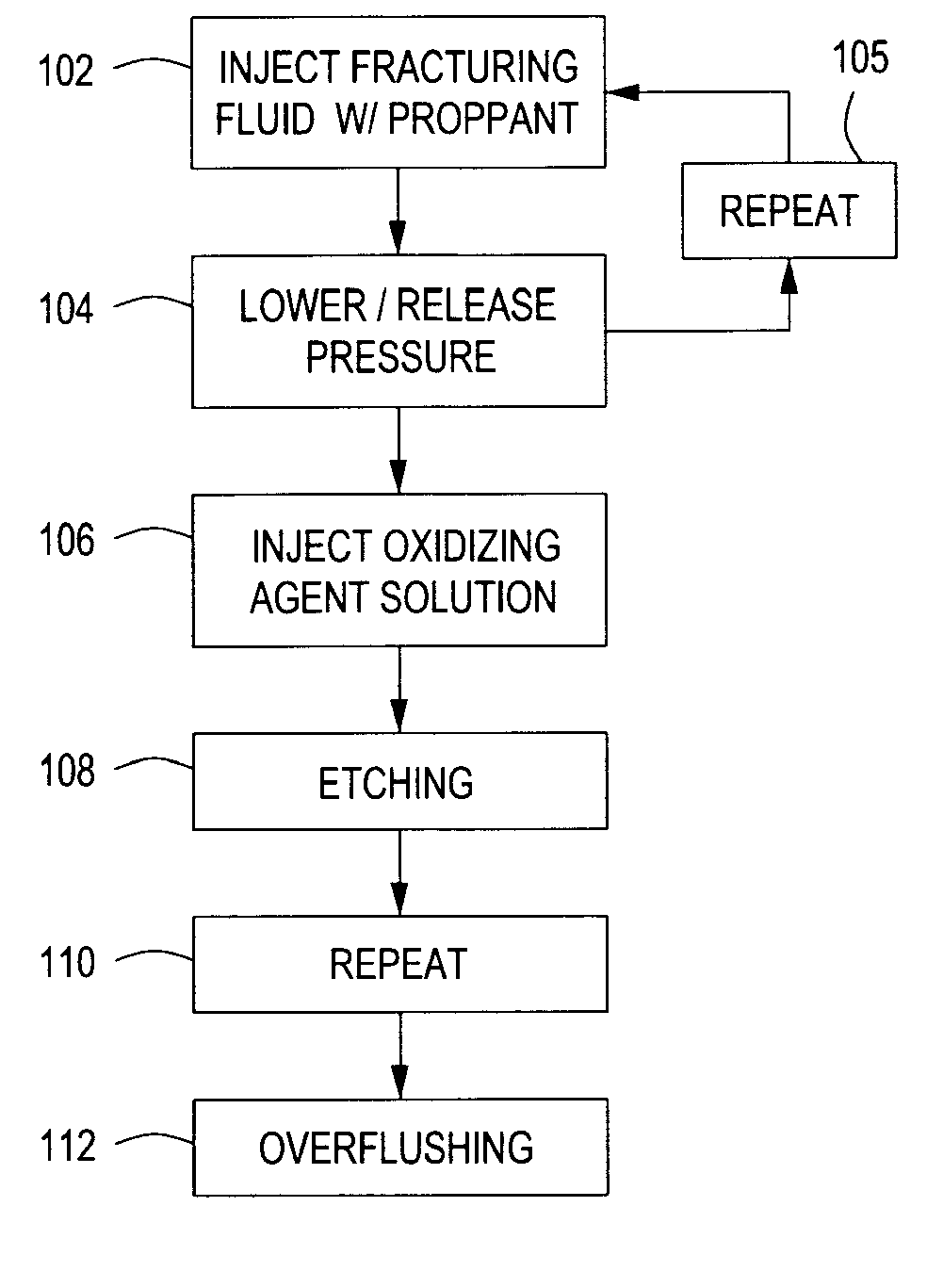

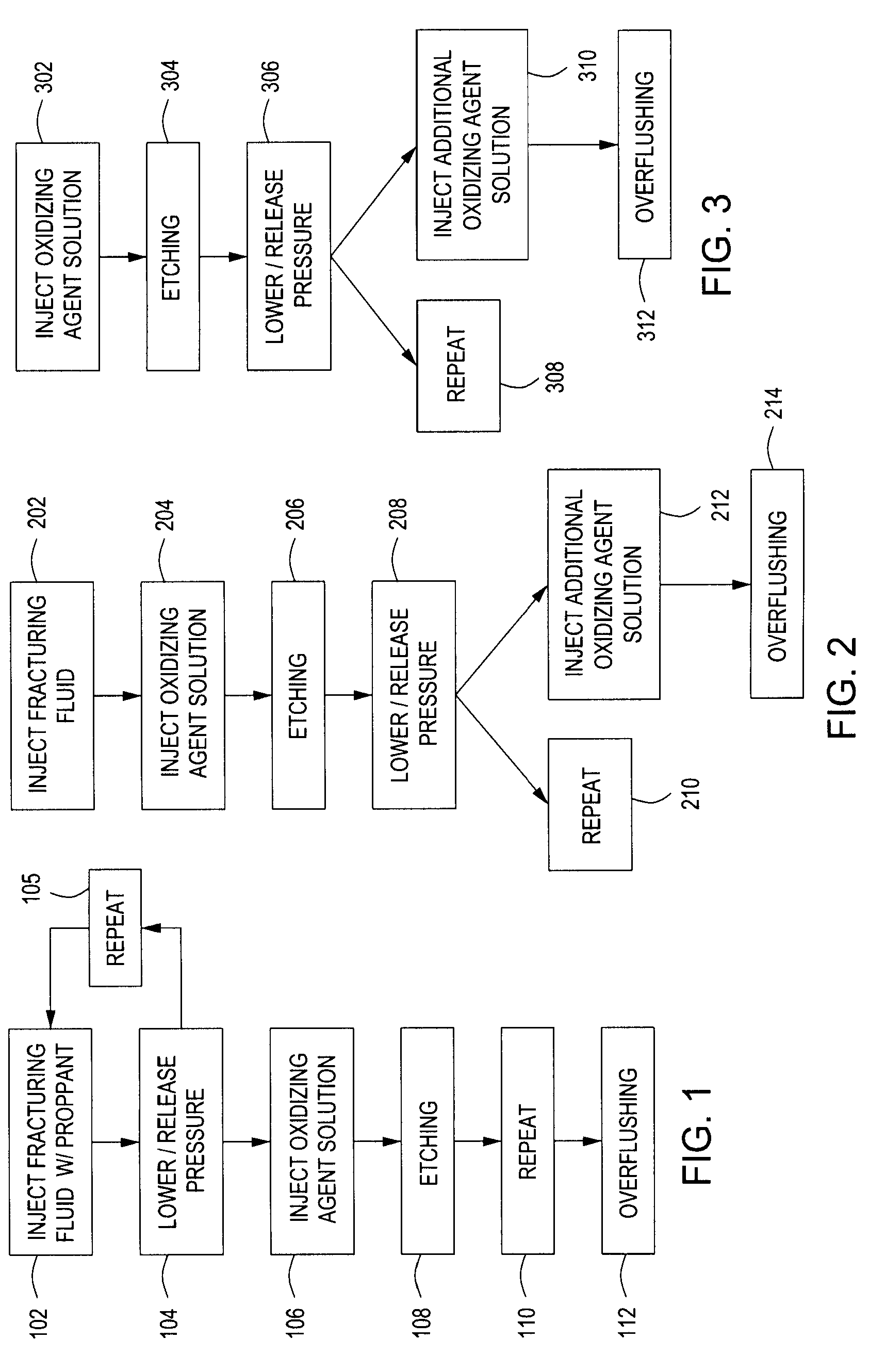

Hydraulic fracturing of subterranean formations

InactiveUS7770647B2Improve conductivityUniform widthFluid removalFracturing fluidHydraulic fracturing

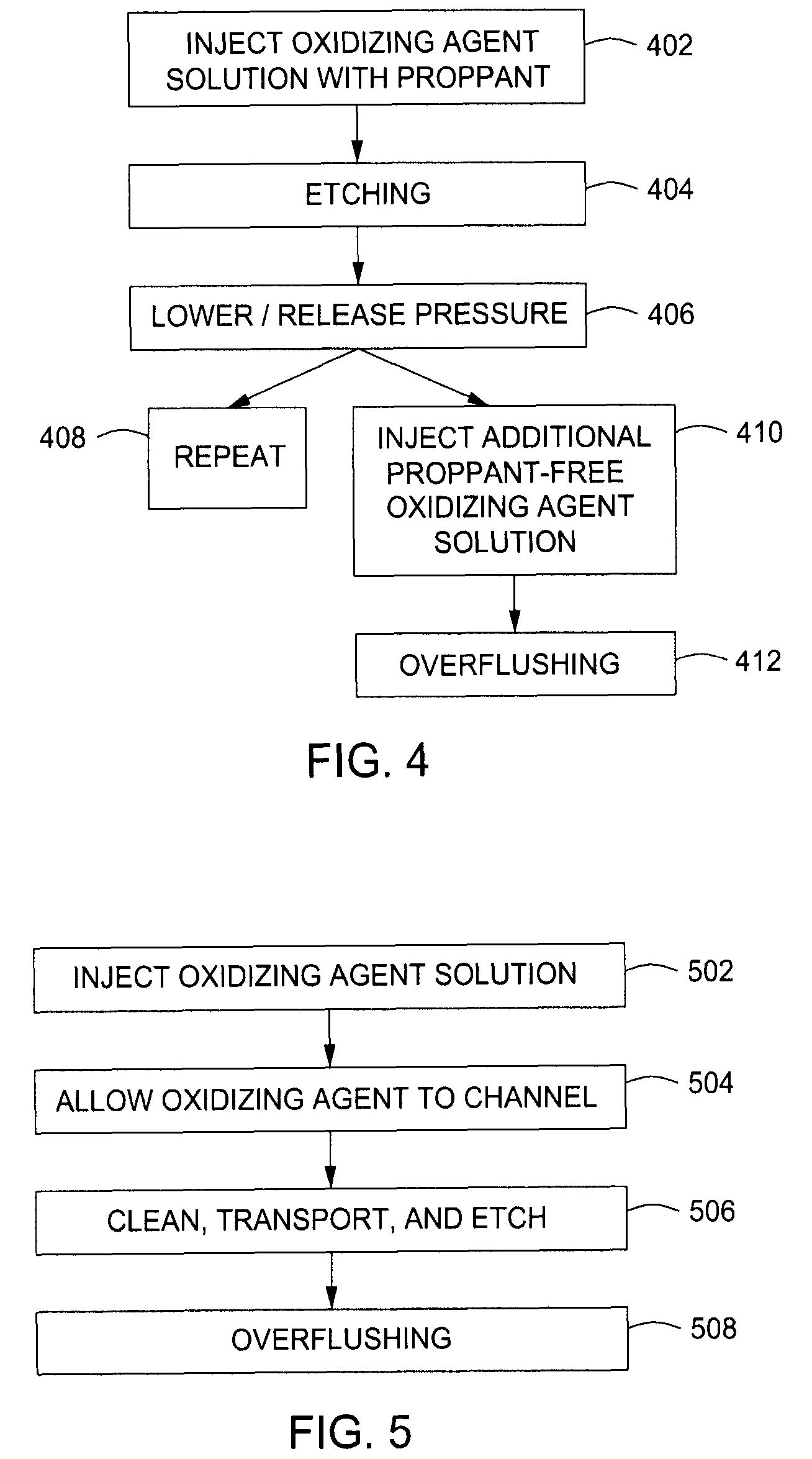

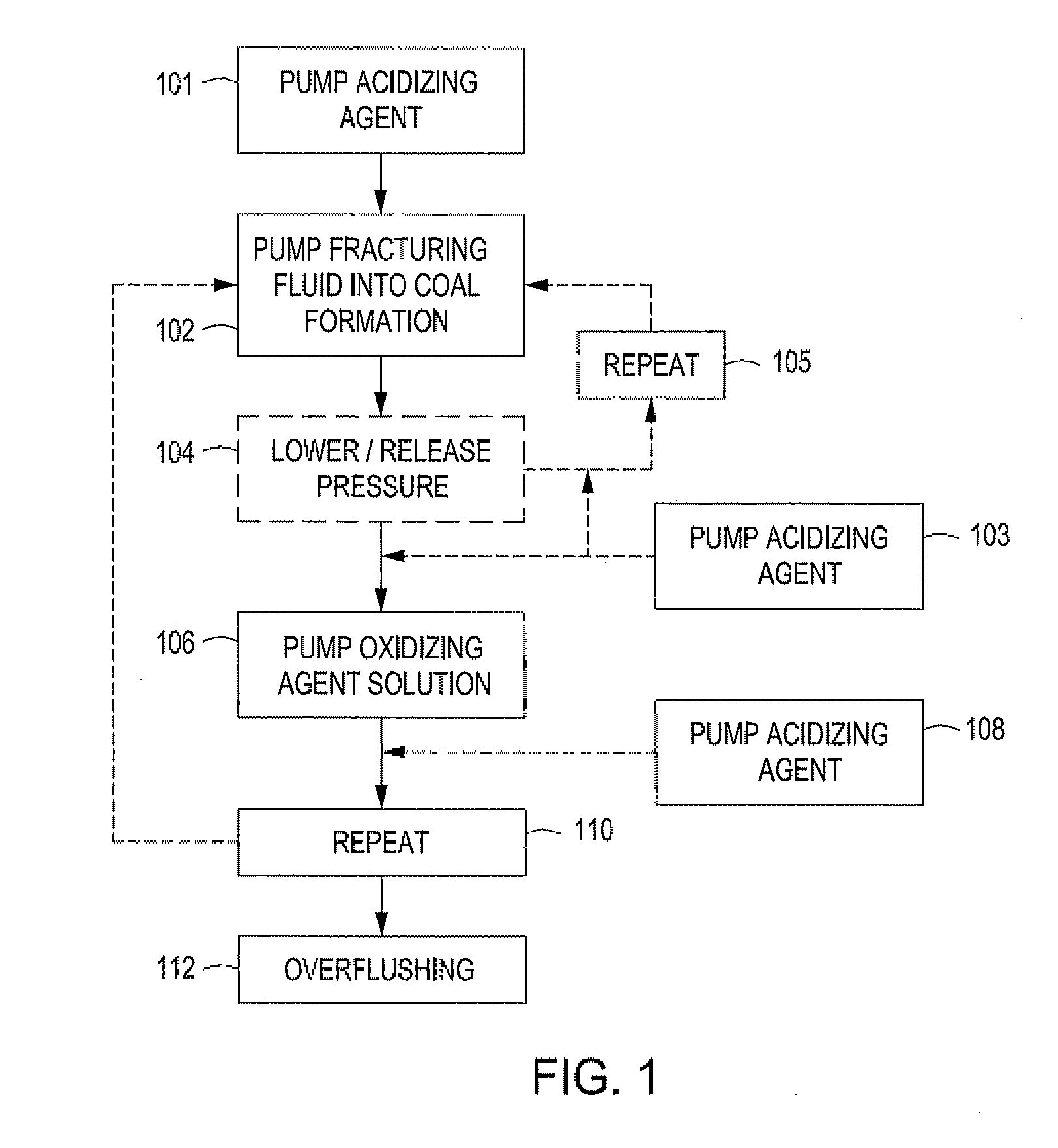

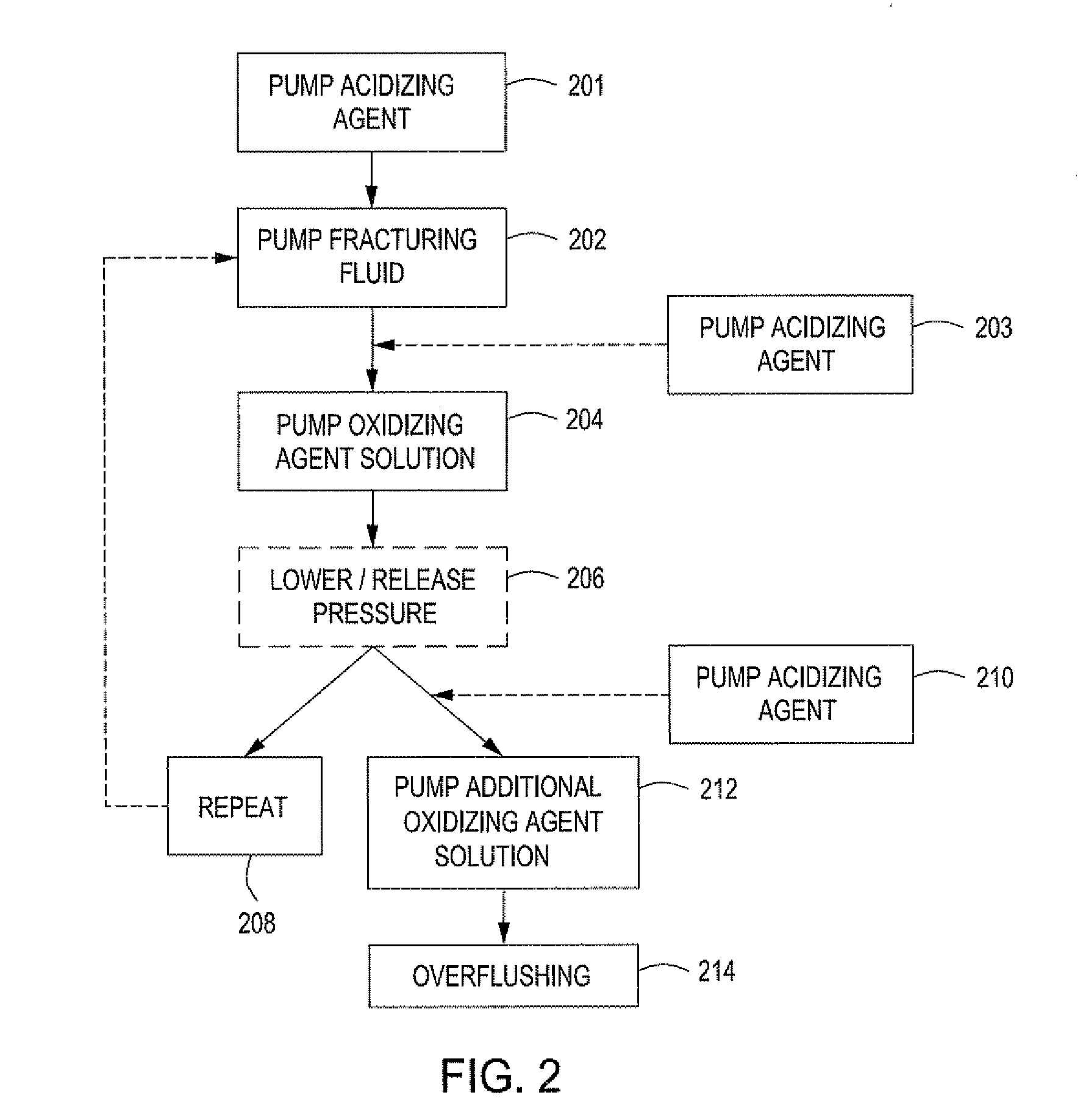

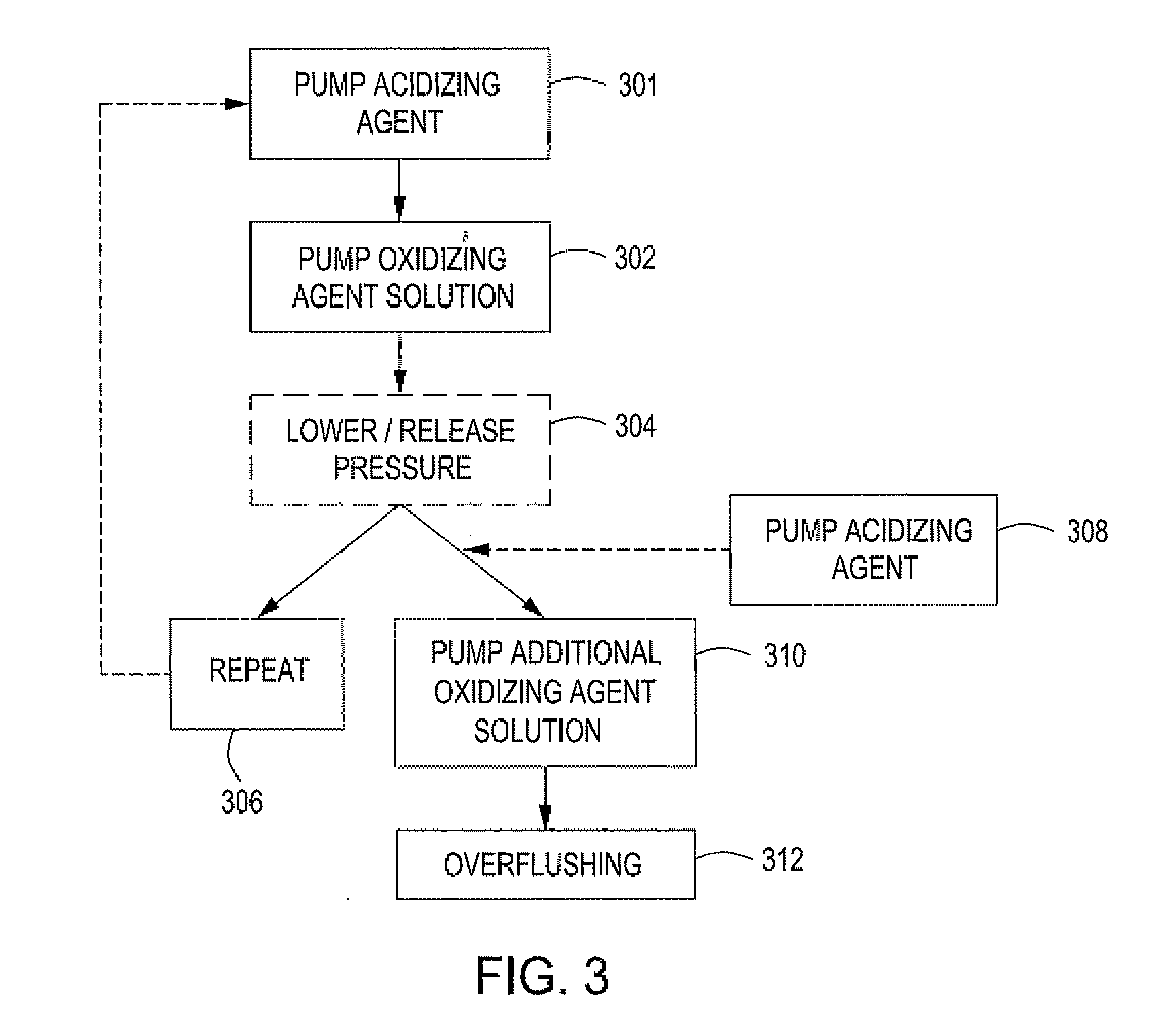

Methods of hydraulically fracturing subterranean coal seams and formations resulting in improved permeability to stimulate Coalbed Methane. In one method, the coal seam is fractured using a proppant-containing fracturing fluid in alternating stages with an aqueous base solution that etches the fracture faces of the coal thereby creating channels for fluid flow. In another method, the coal seam is fractured using a fracturing fluid without propping agents in alternating stages with an aqueous base solution that is pumped at a pressure sufficient to maintain the fractures in an open position thereby etching the fracture faces to create channels for fluid flow. In yet another embodiment, a base solution is injected into the formation at a pressure sufficient to create fractures therein and simultaneously etch the faces of the open fractures to thereby form channels in the faces for increased fluid flow.

Owner:ACT OPERATING

Hydraulic fracturing of subterranean formations

InactiveUS20100282471A1Improved methane extractionReduce pressureFluid removalFracturing fluidHydraulic fracturing

Methods of hydraulically fracturing subterranean coal seams and formations resulting in improved permeability to stimulate Coalbed Methane. In one method, the coal seam is fractured using a proppant-containing fracturing fluid in alternating stages with an aqueous base solution that etches the fracture faces of the coal thereby creating channels for fluid flow. In another method, the coal seam is fractured using a fracturing fluid without propping agents in alternating stages with an aqueous oxidizing solution that is pumped at a pressure sufficient to maintain the fractures in an open position thereby etching the fracture faces to create channels for fluid flow. In yet another embodiment, the aqueous oxidizing agent solution is pumped into the formation at a pressure sufficient to create fractures therein and simultaneously etch the faces of the open fractures to thereby form channels in the faces for increased fluid flow.

Owner:ACT OPERATING

Polyacrylate-grafted modified gelatin-adhesive and preparation method thereof

ActiveCN107383290AShorten the timeImprove photopolymerization efficiencySurgical adhesivesCross-linkMethacrylate

The invention relates to polyacrylate-grafted modified gelatin-adhesive and a preparation method thereof. An embedded material which is formed by co-mixing and ultrasonic promoted dissolution of water-soluble polymer containing beta-cyclodextrin and camphorquinone is taken as a photoinitiator; glycerol is taken as a medium to provide more active hydroxyl free radicals; methacrylic acid modified grafted gelatin, acrylate monomer and a cross-linking agent polyethyleneglycol dimethacrylate promote the adhesive to form hydrogel under illumination of blue light with wavelength of 420-480 nm and light intensity of 1200-2000 mw / cm<2>, so that the curing and adhering effect is achieved. The adhesive provided by the invention has the characteristics of being high in photopolymerization efficiency, good in adhesion performance, non-toxic to human body, and the like, can be widely applied to sealing and bleeding-stopping of various acute open wounds, adhering and sealing of operative incisions or holes, and recovering, adhering and fixing of non-open fracture.

Owner:CHENGDU MEDART MEDICAL SCI CO LTD

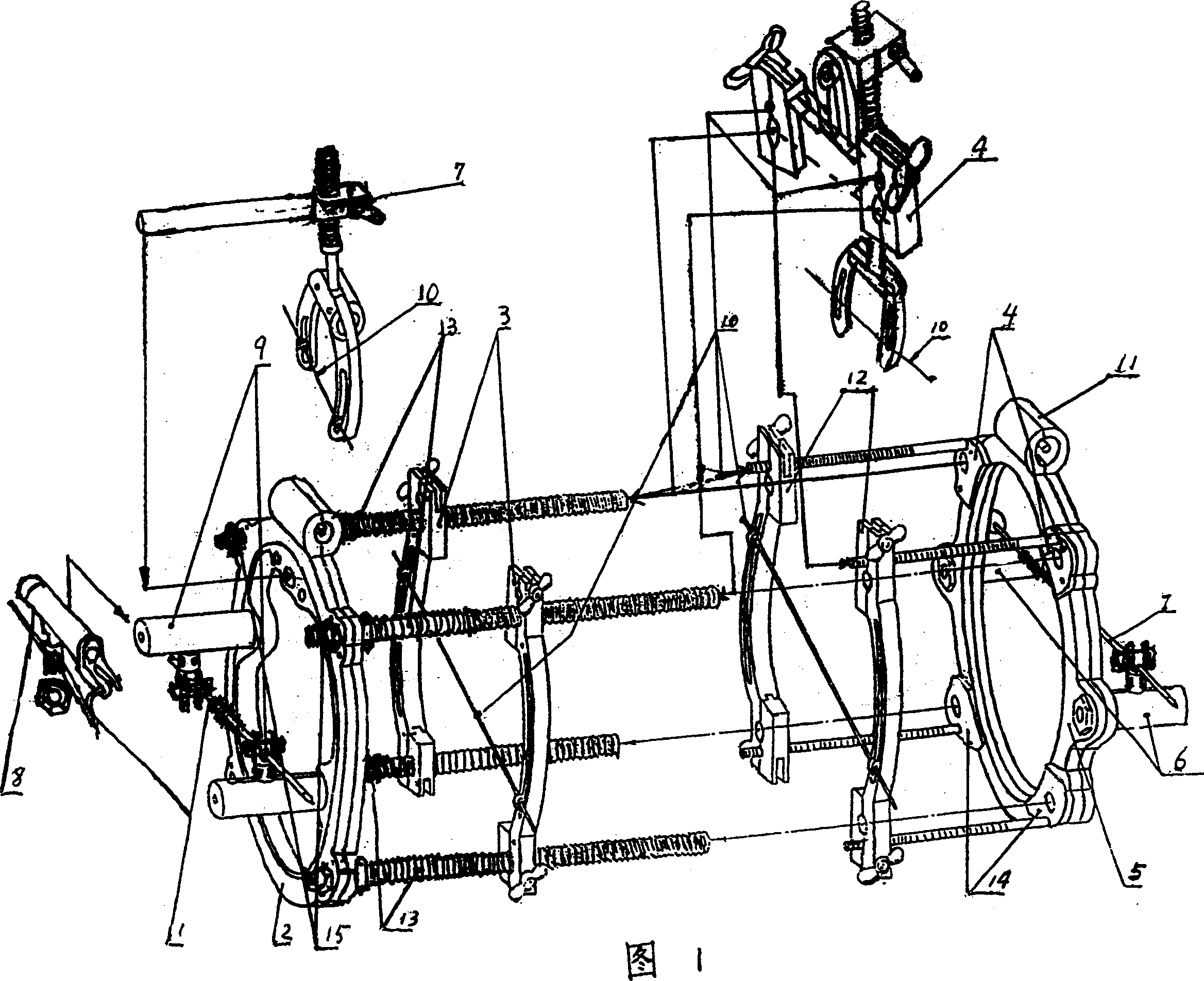

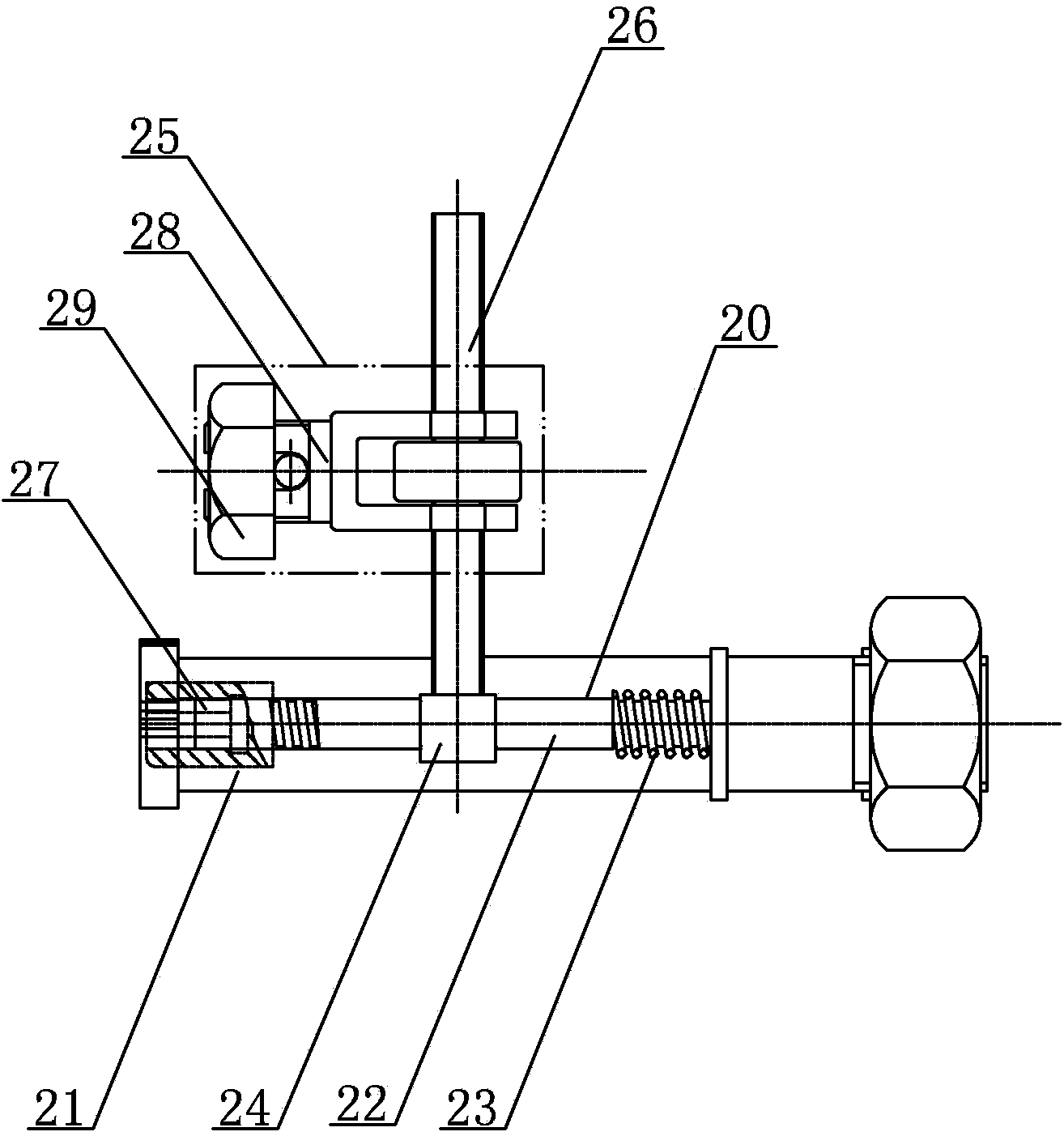

Computer-controlled fracture shaping, repairing and outer fixing system

InactiveCN1389182ASave resourcesGuaranteed firmnessSpecial data processing applicationsOsteosynthesis devicesExternal fixatorRemote control

The computer controlled reduction external fixation system comprises: computer combined equipment is respectively connected with X-ray machine, sensor and two gearboxes, said gearboxes are connected with correspondent soft shaft and manual push-button function display lamp, and the reduction external fixator is respectively connected with sensor and two soft shafts. Said system can utilzie comptuer operation to implement 3-D 6-freedom accurate reduction of fracture in remote control mode. Its reduction process is high in automation, can implement optico-mechanico-electric integration, and can raise reduction accuracy and speed and shorten union period. It is applicable to open fracture, closed fracture and comminuted fracture.

Owner:哈尔滨首创骨科微创医疗设备有限公司

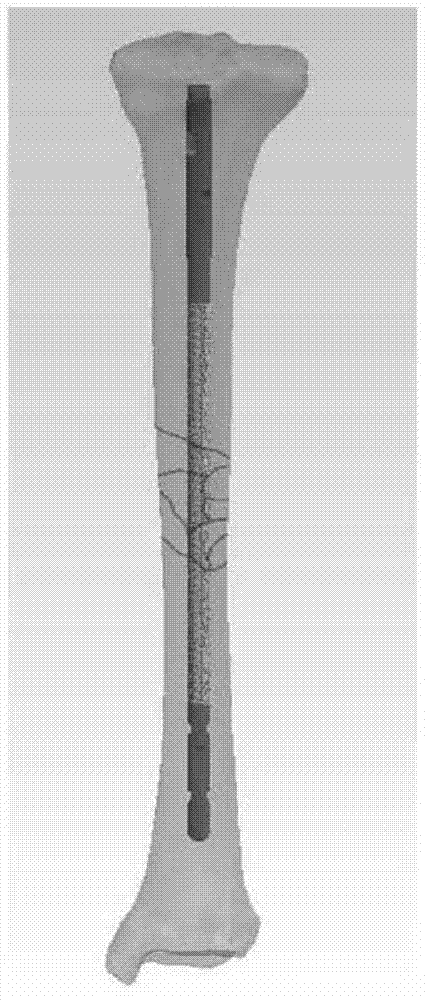

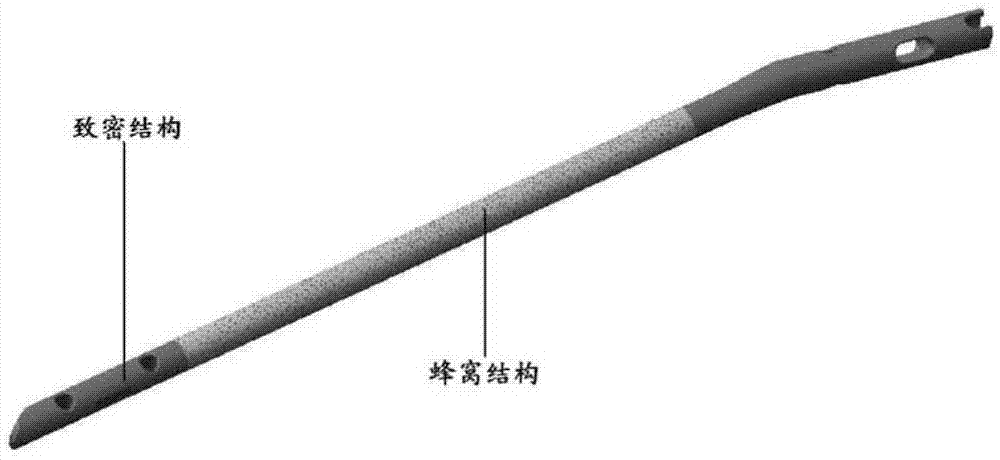

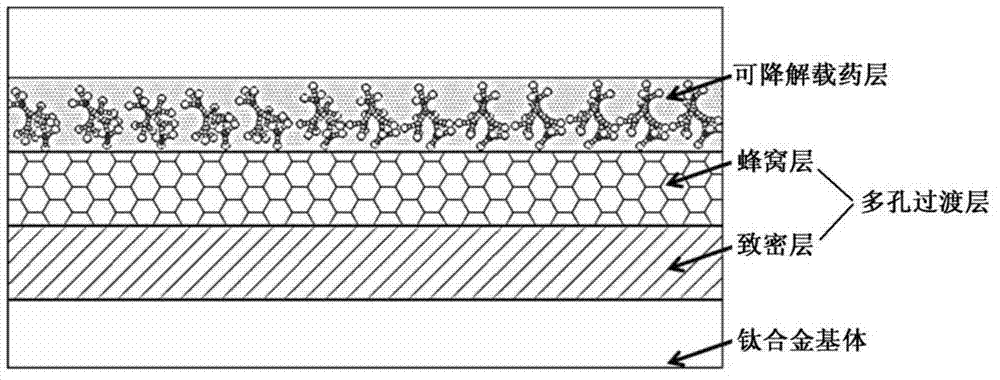

Intramedullary nail having multifunctional coating and preparation method

The invention relates to the medical instrument field, especially relates to the orthopaedics titanium alloy internal fixation field. The invention provides an intramedullary nail having a multifunctional coating and a preparation method. The intramedullary nail comprises a multifunctional composite medicament coating slow release system, and the slow release system comprises a porous transition layer and a degradable coating containing the medicament. The intramedullary nail integrates the functions of preventing, treating infection and internal fixation as one, and is mainly used for treating adaptation diseases such as open fracture and osteomyelitis, and has the effect for degrading and slowly releasing the medicines.

Owner:SUZHOU MINIMALLY INVASIVE SPINAL TRAUMA MEDICAL TECH CO LTD

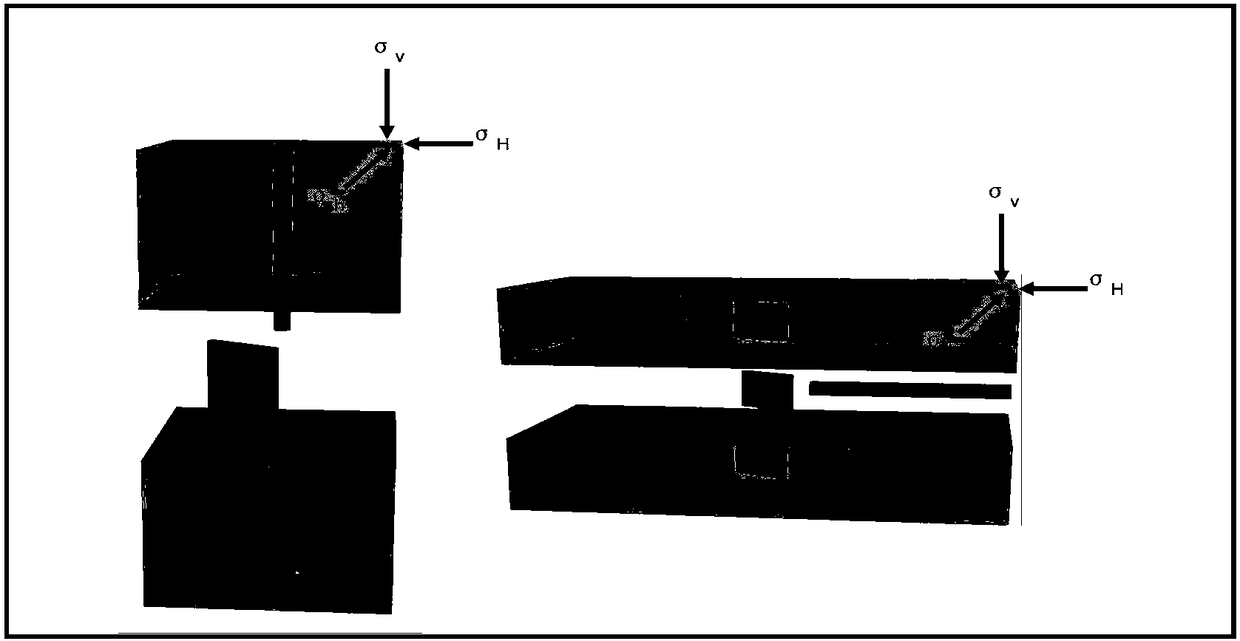

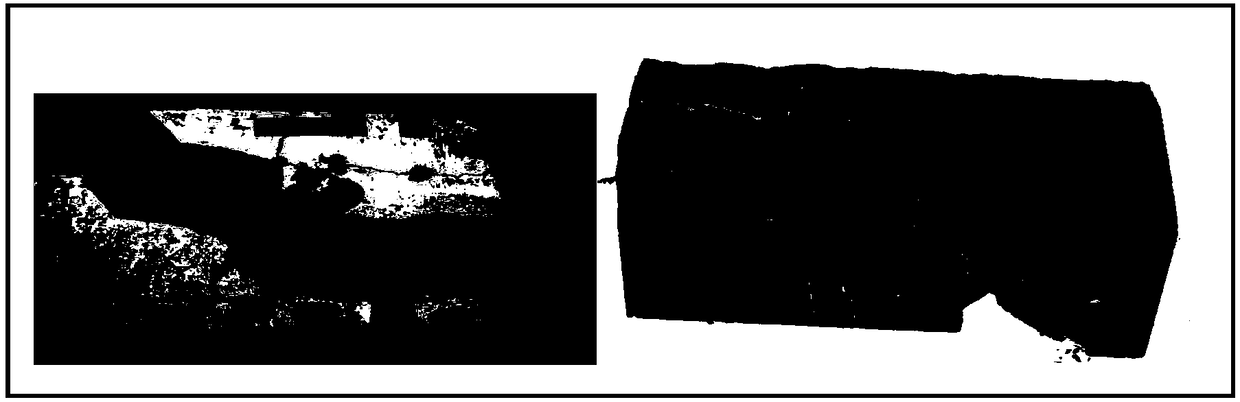

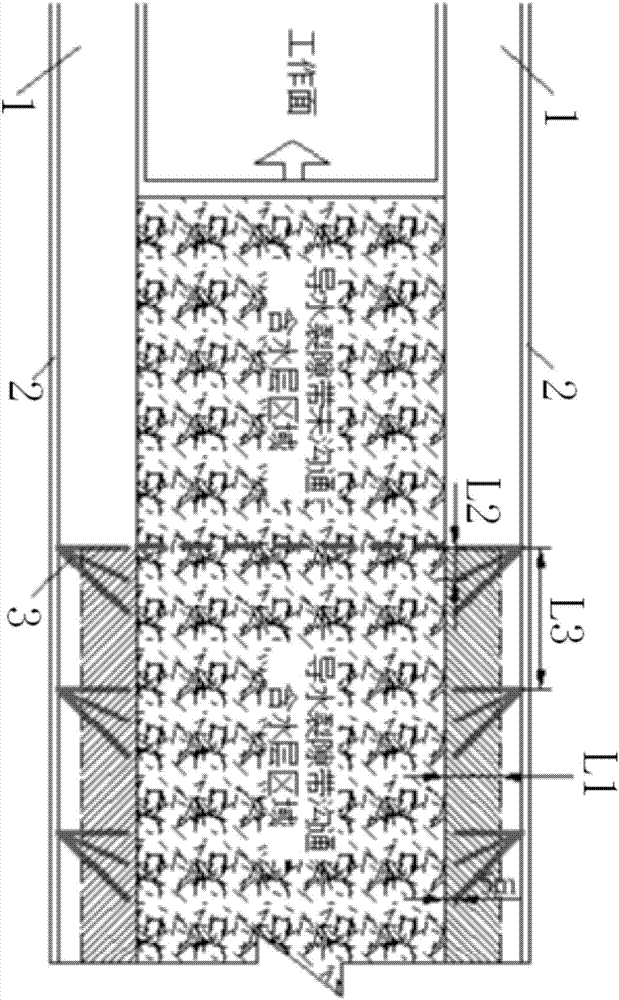

Physical model test method for extension rules of natural cracks and artificial cracks

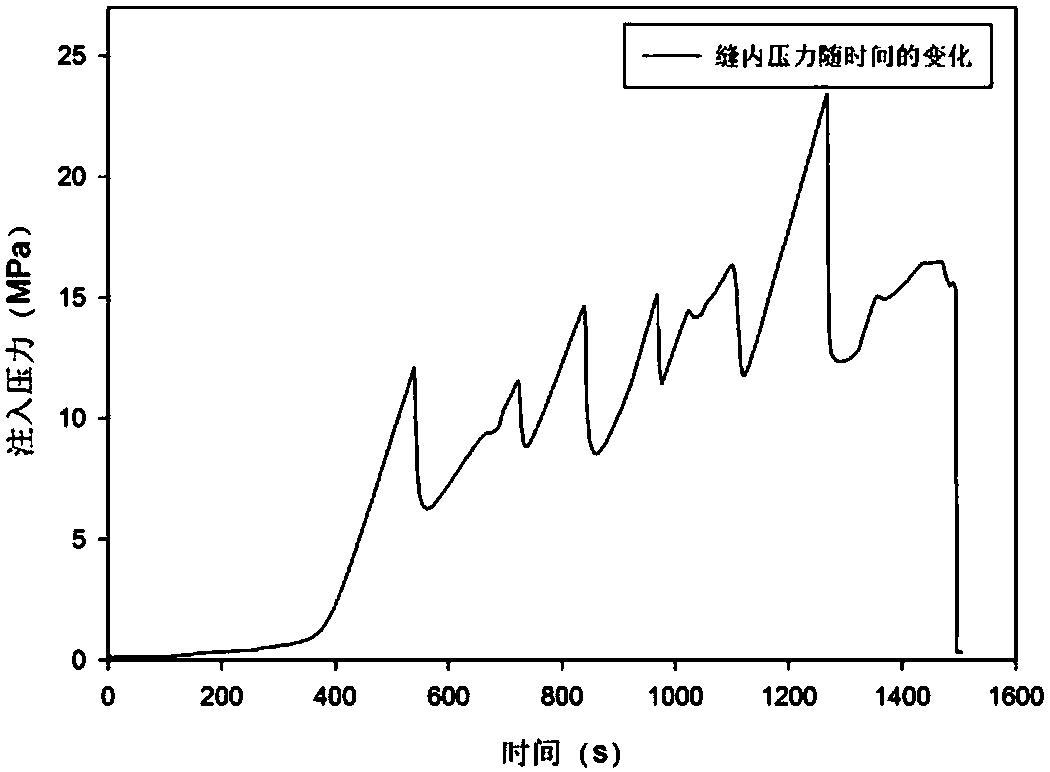

ActiveCN108386176AReflect the actual stress situationImprove the development effectFluid removalRock corePhysical model

The invention belongs to the technical field of yield increase of oil-gas wells and particularly relates to a physical model test method for extension rules of natural cracks and artificial cracks. The method comprises the following steps: acquiring three-dimensional terrestrial stress and rock mechanics parameters of a real geological rock core under stratum conditions; establishing a physical model of a real reservoir interlayer in a simulated mode, and prefabricating natural cracks in the physical model; loading confining pressure on the physical model according to the three-dimensional terrestrial stress parameters, performing a hydraulic fracture test on the physical model, and acquiring data until the model fractures; sectioning and scanning the fractured model; and performing quantitative analysis on the crack morphology of the model, and researching the influence of the natural cracks on the extension rules of the artificial cracks. The method provided by the invention solvesthe problems that an existing model is a homogeneous model, only one crack is prefabricated in the model, and the crack problems of quantity, positions, sizes and the like of the natural cracks are not considered. The method provided by the invention can master the major factors of the natural cracks on the extension influence of the artificial cracks, provides a theoretical basis for reservoir reformation, and greatly improves the development effect of the oil reservoir.

Owner:PETROCHINA CO LTD

Combined type multifunctional physiological bone pressurization external fixation support

The invention provides a combined type multifunctinal physiological bone pressurization external fixation support, and belongs to the technical field of bone treatment equipment. The problems that a bone pressurizer conducts bone pressurization on the bone broken end blindly, a fracture is not healed frequently, the size of the bone pressurizer is large, the bone pressurizer is fixed outside the limb and is not convenient to carry, and inconvenience is brought to the post-operation life are solved. The combined type multifunctinal physiological bone pressurization external fixation support comprises a physiological bone pressurizer which is installed on a carbon fiber rod, a bone nail fixation clamp is further installed on the carbon fiber rod, the tail of a bone nail is installed on the fixation clamp, the physiological bone pressurizer is adjusted to drive the carbon fiber rod to move to the bone broken end, the carbon fiber rod drives the bone nail fixation clamp on the carbon fiber rod, the fixation clamp drives the bone nail, the bone nail drives the fracture section, and the physiological bone pressurization is completed. The combined type multifunctinal physiological bone pressurization external fixation support is small in size, light in weight, flexible and safe in physiological bone pressurization of the broken end and easy to operate, the cure rate is increased, and bone infection brought by open fracture treatment is avoided.

Owner:HARBIN MEDICAL UNIVERSITY

Forming conductive arch channels in subterranean formation fractures

ActiveUS20180051203A1Promote formationFacilitating formationFluid removalDrilling compositionTreatment intervalOpen fracture

Methods including introducing a pad fluid into a subterranean formation to create or enhance an open fracture at a first treatment interval therein; introducing a treatment fluid into the fracture, wherein the treatment fluid comprises a second base fluid, crushable-proppant particulates (CPPs), and buoyant-proppant particulates (BPPs), and wherein a first specific gravity of the CPPs is at least about 0.3 greater than a second specific gravity of the BPPs; placing the CPPs and the BPPs in the fracture, wherein the CPPs settle to a bottom portion of the fracture and the BPPs neutrally suspend in the treatment fluid in a top portion of the fracture; and reducing the hydraulic pressure, thereby permitting the fracture to close, wherein the CPPs form a crushed-proppant pack in the bottom portion of the fracture and the BPPs form a proppant pack in the top portion of the fracture, thereby forming an arch channel therebetween.

Owner:HALLIBURTON ENERGY SERVICES INC

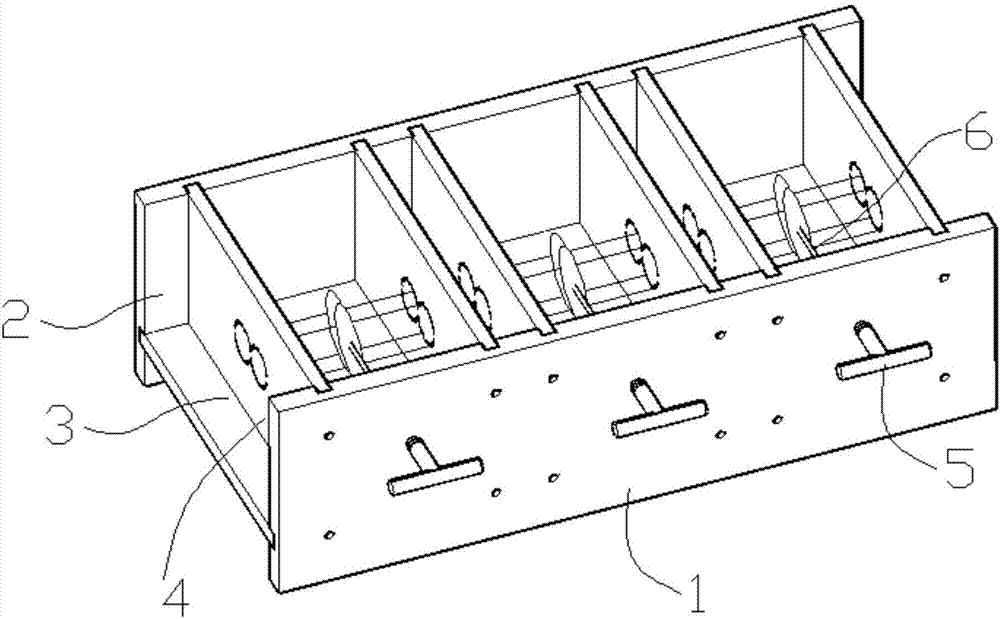

Manufacture device and method of hydrological coupling test three-dimensional fracture rock sample

ActiveCN106989968AAchieve positioningCrack localization achievedPreparing sample for investigationPolyesterGeomorphology

The invention relates to a manufacture device and method of a hydrological coupling test three-dimensional fracture rock sample; the manufacture method comprises a three-dimensional fracture precision positioning sample mold and a high-pressure injection fracture preforming device; the three-dimensional fracture precision positioning sample mold comprises side plate I, side plate II, a bottom plate and positioning porous plates and can provide precision positioning for multiple three-dimensional fractures and forming of a sample. The high-pressure injection fracture preforming device comprises polyester film boxes, cotton threads, rubber water pipes, mandrels and manual screws, and can preform high-pressure injection three-dimensional fractures and form an injection passage. By combining annularly distributed holes and transversely distributed holes, the positioning porous plates are used to allow precision positioning for the angle, spacing and spatial positions of the multiple three-dimensional fractures; the small-diameter rubber water pipes and mandrels to preform hydraulic passages in the sample and communicate the open fractures, high-pressure injection of water is achieved for the open fractures. The manufacture device and method are simple in structure, convenient to operate and good positioning precision and are widely applicable to the hydraulic coupling test for three-dimensional fracture rock materials.

Owner:SHANDONG UNIV

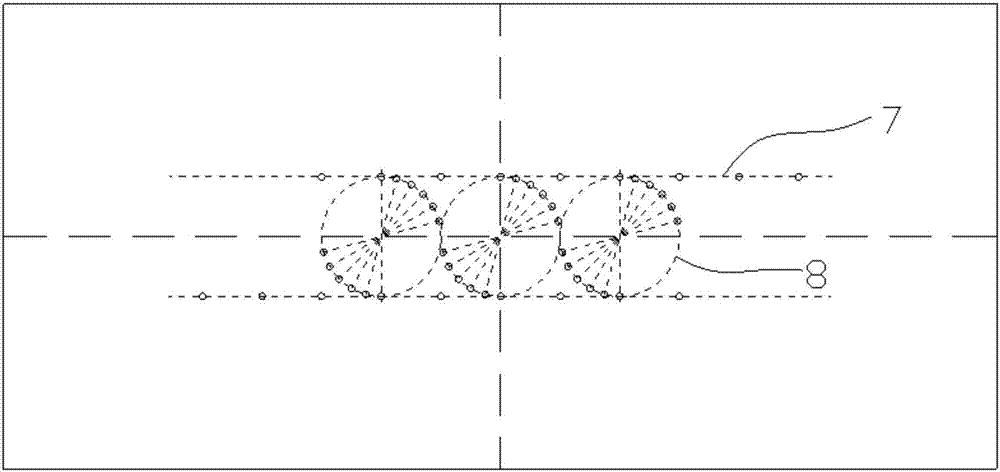

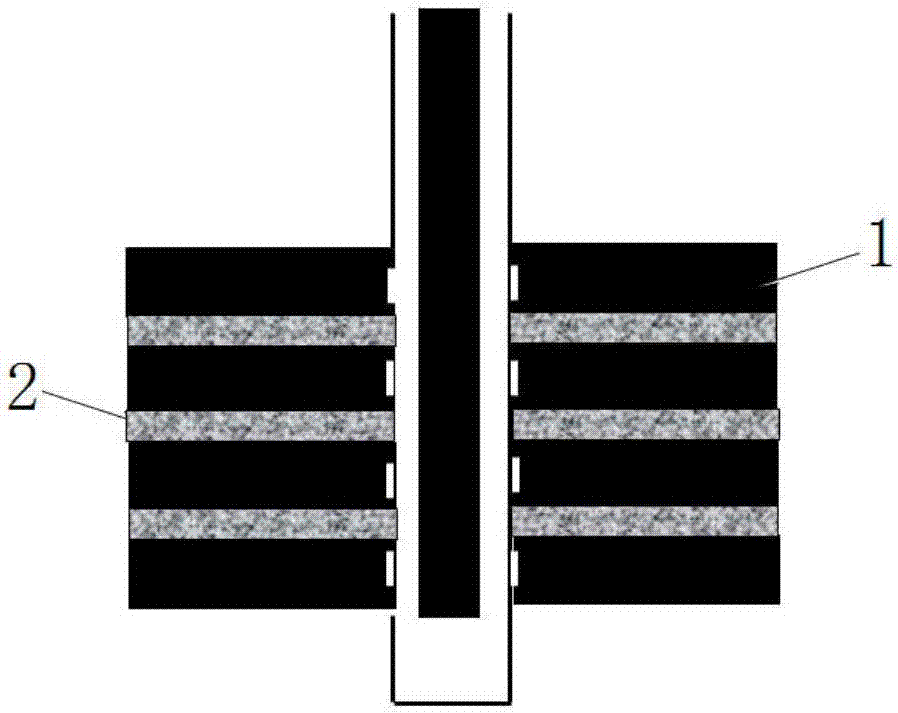

Orthopaedic metal implant loaded with slow release antibiotic and preparation method thereof

The invention discloses an orthopaedic metal implant loaded with slow release antibiotic, composed of a matrix (1) and slow release antibiotic layer (2) covered on the matrix; wherein the matrix (1) is titanium alloy, or stainless steel or cobalt molybdenum alloy, and the slow release antibiotic layer (2) is a PDLLA coating combined with antibiotic. The preparation method includes pretreatment ofthe matrix (1), confection of antibiotic solution and sedimentation of the coating. The orthopaedic metal implant loaded with slow release antibiotic of the invention improves anti infection capacity,ensures continuity of implanted bone and repaired bone in period I after debridement or focus clearing of bone defect caused by open fracture and other reasons and also can prevent tubercle germ infection. PDLLA can be well absorbed by organism. Slow-release antibiotic can maintain release for a period of time, thus antibiotic effective concentration in local part can be maintained for a long time, and side effect of whole body medicine application is avoided while infection is effectively prevented and treated at the local part.

Owner:THE THIRD AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIV OF PLA

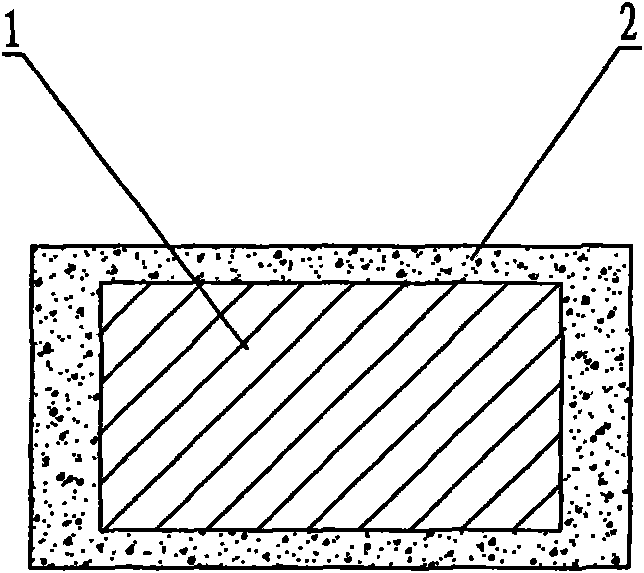

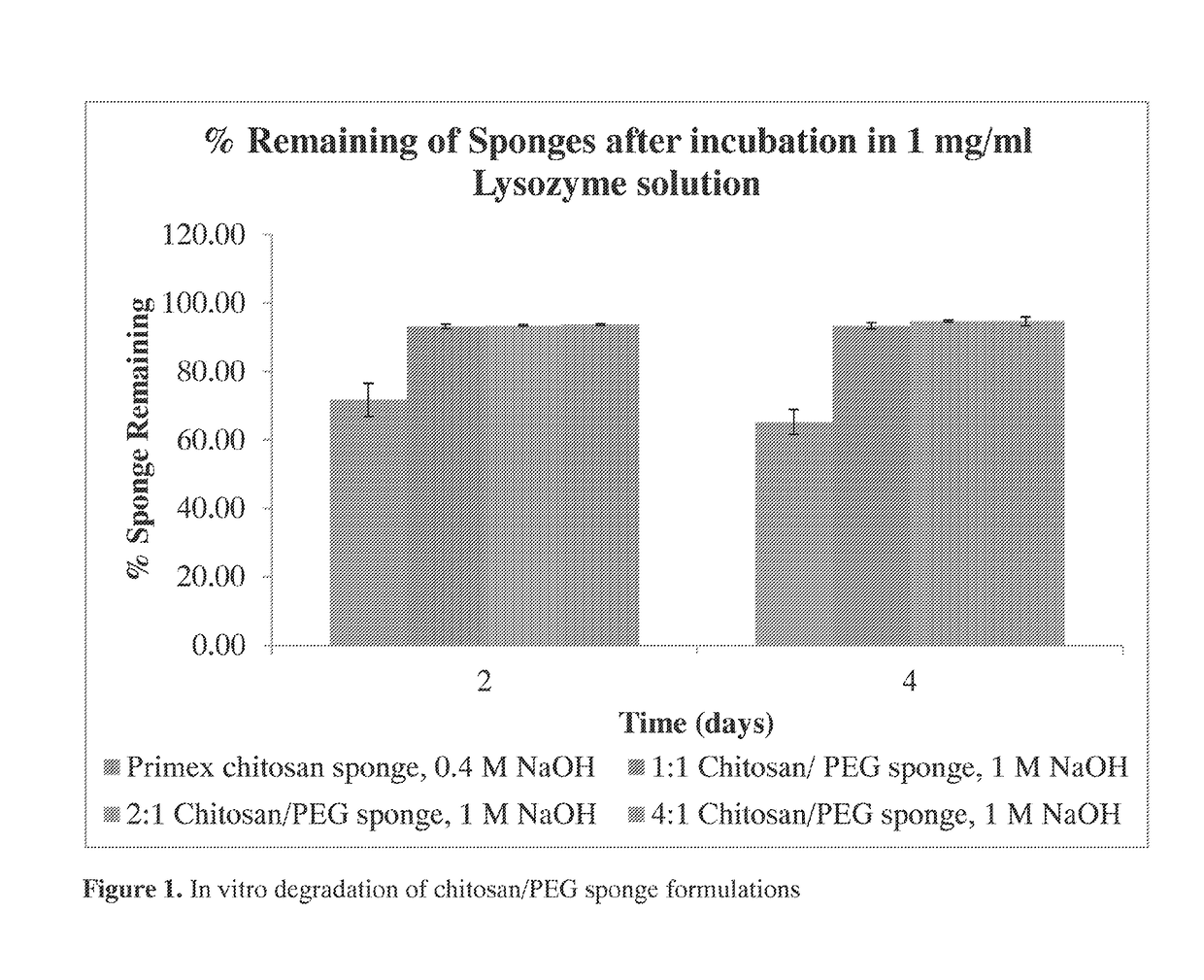

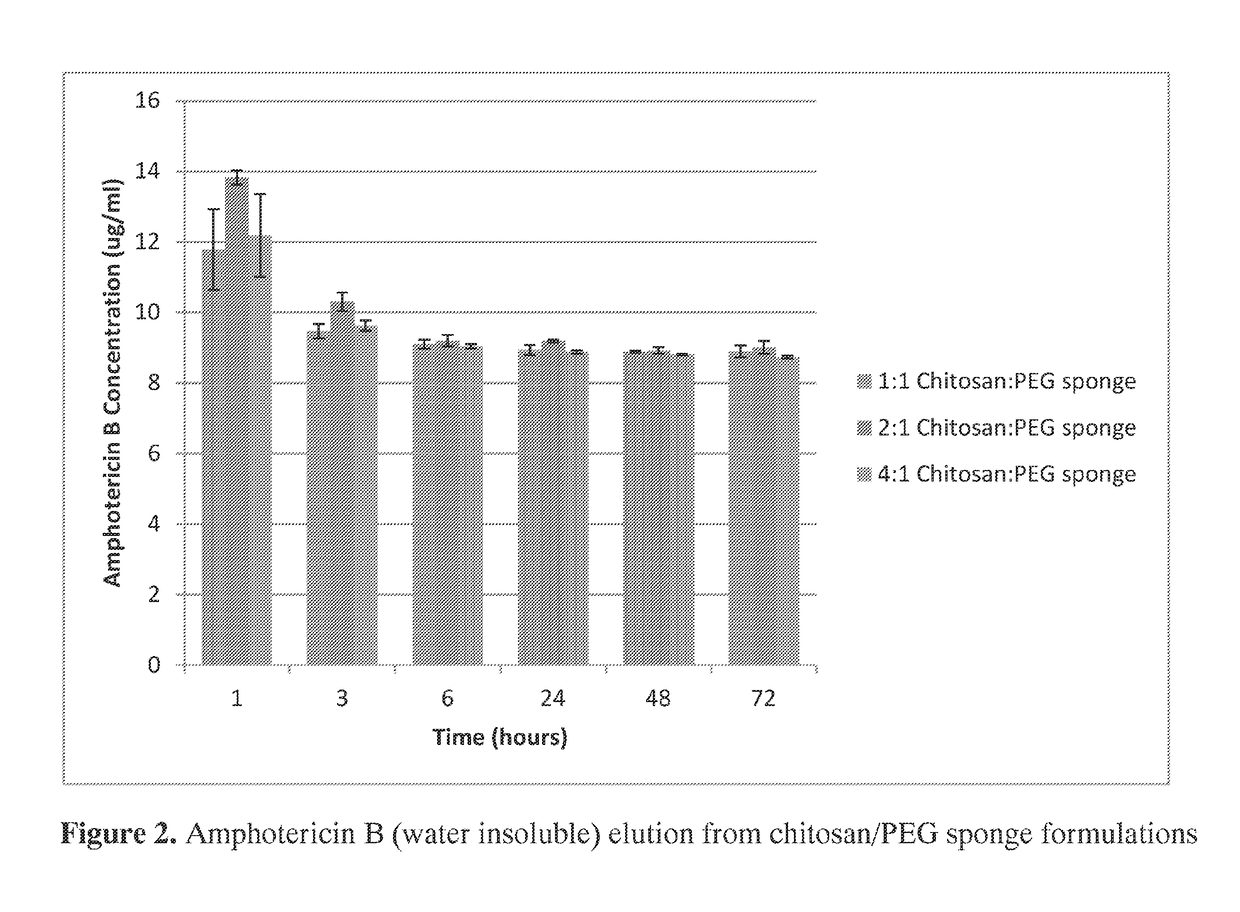

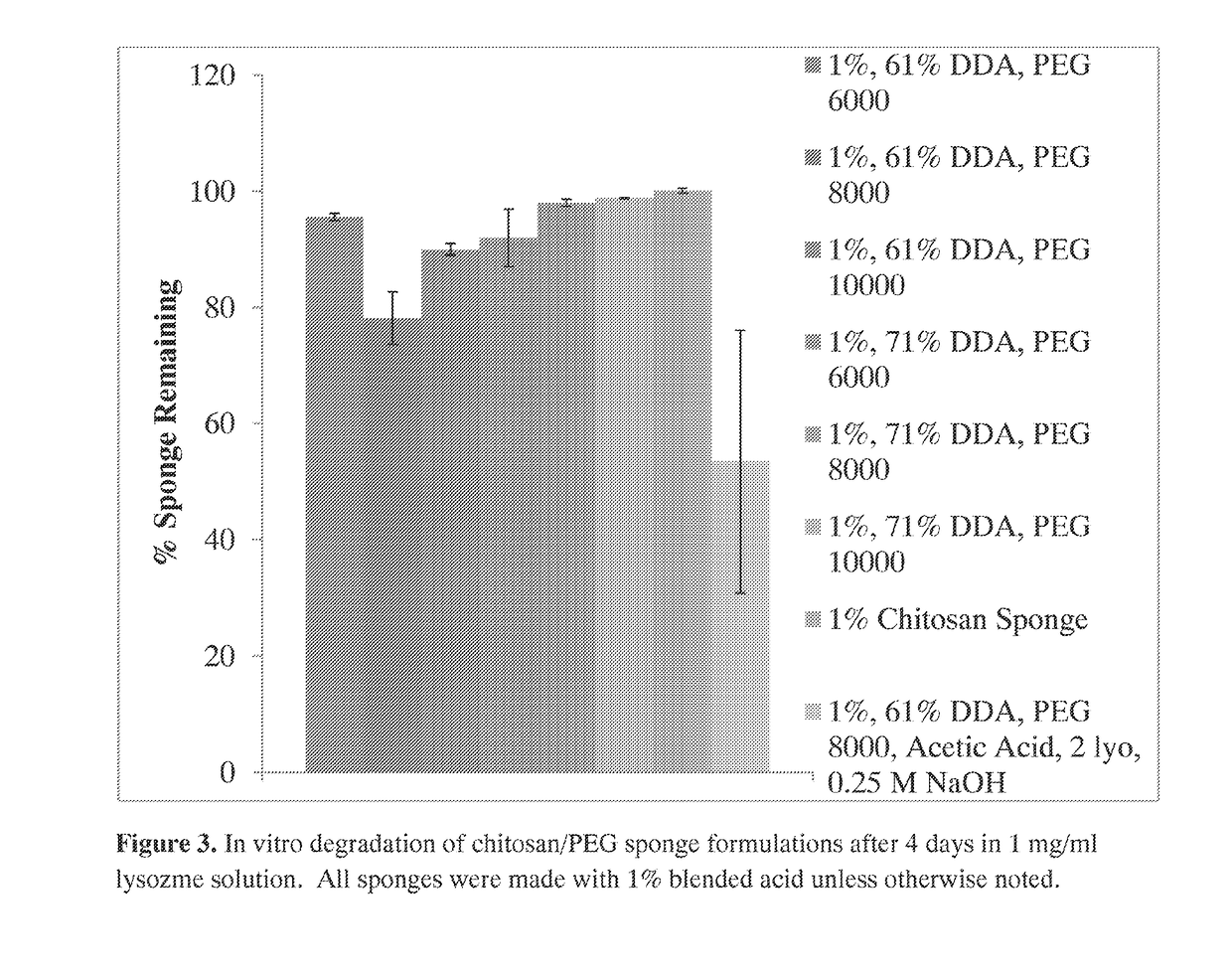

Compositions and methods for delivering an agent to a wound

ActiveUS20120149659A1Reduce probabilityReduced survivalAntibacterial agentsBiocidePoint of careClinical settings

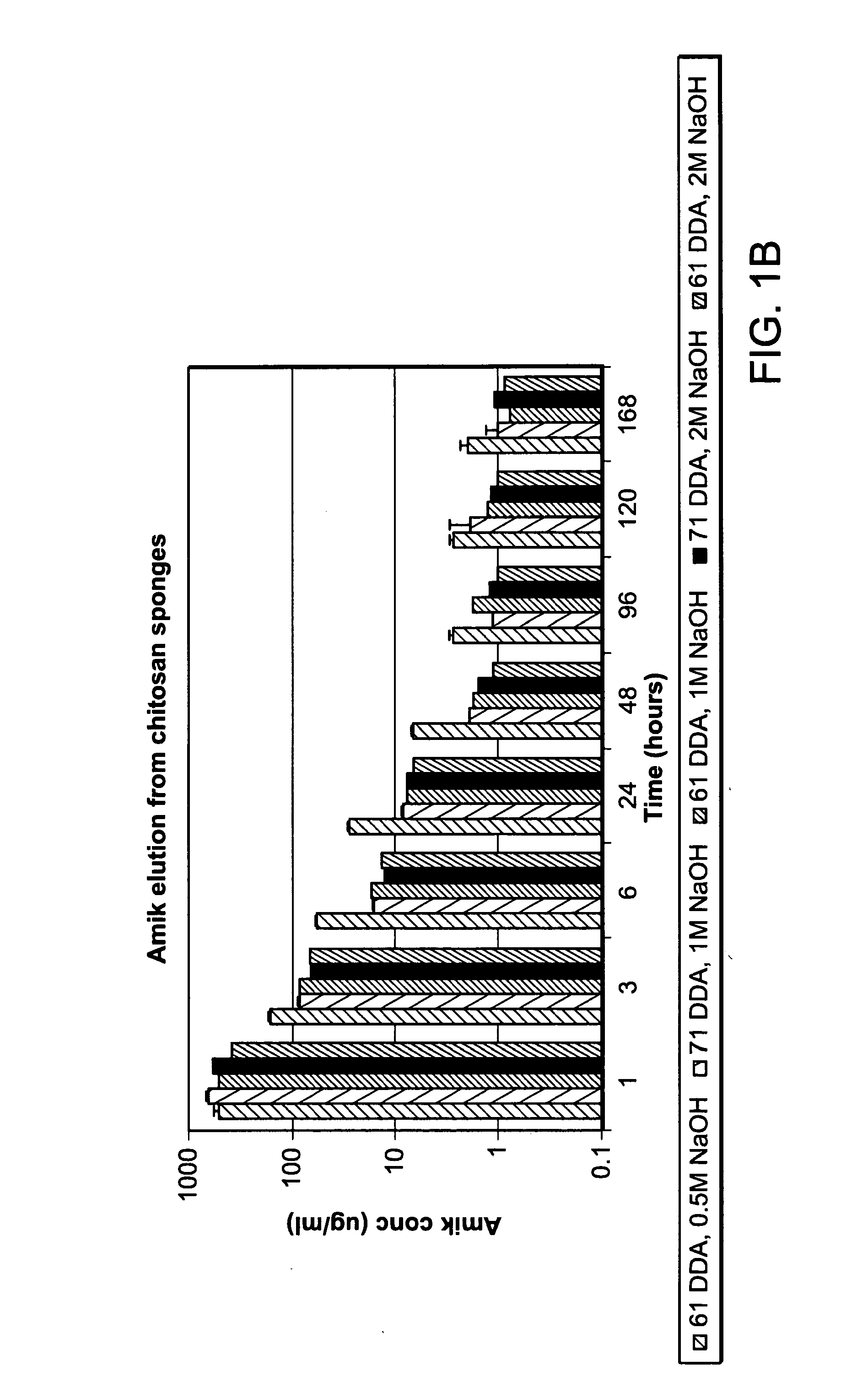

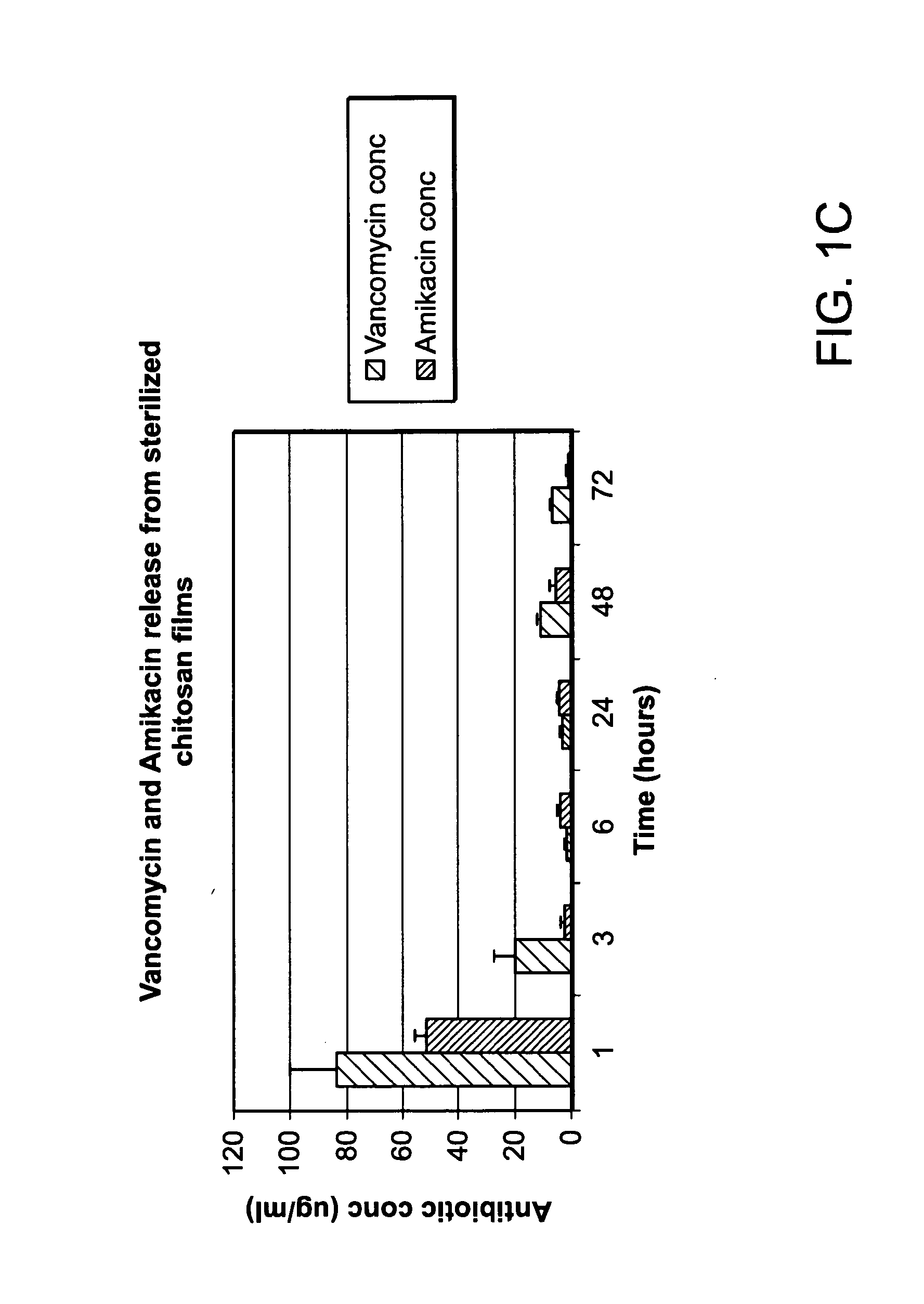

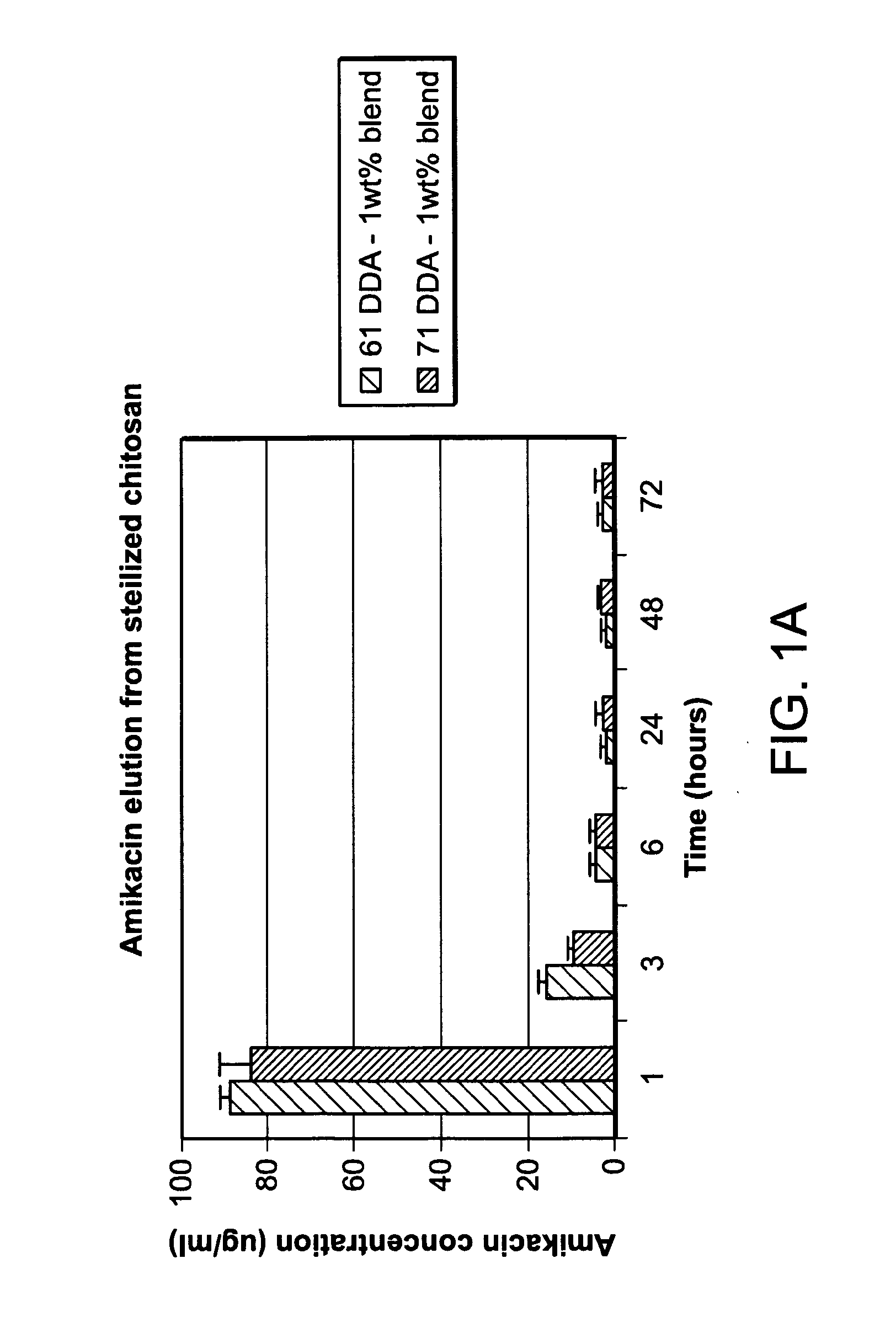

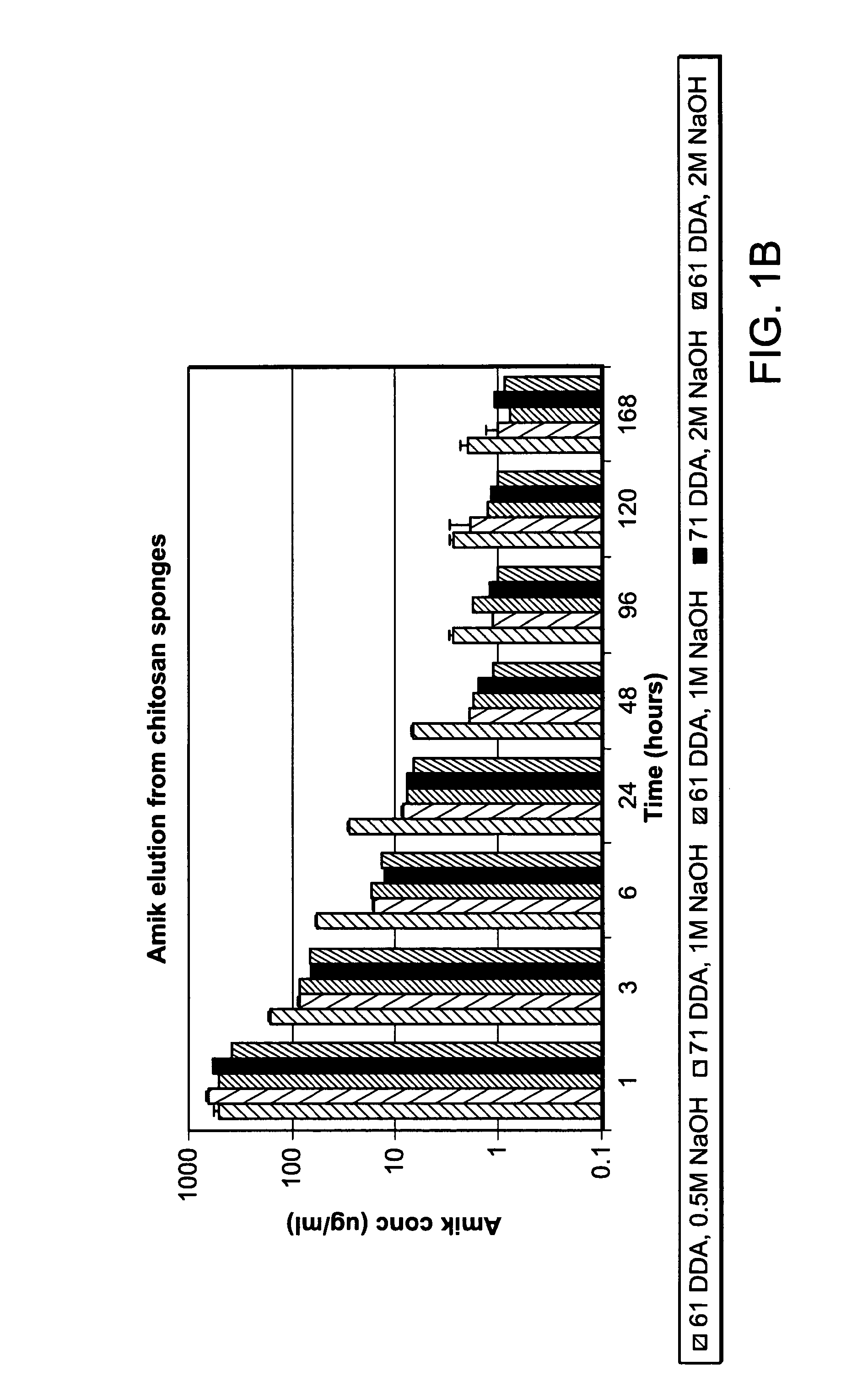

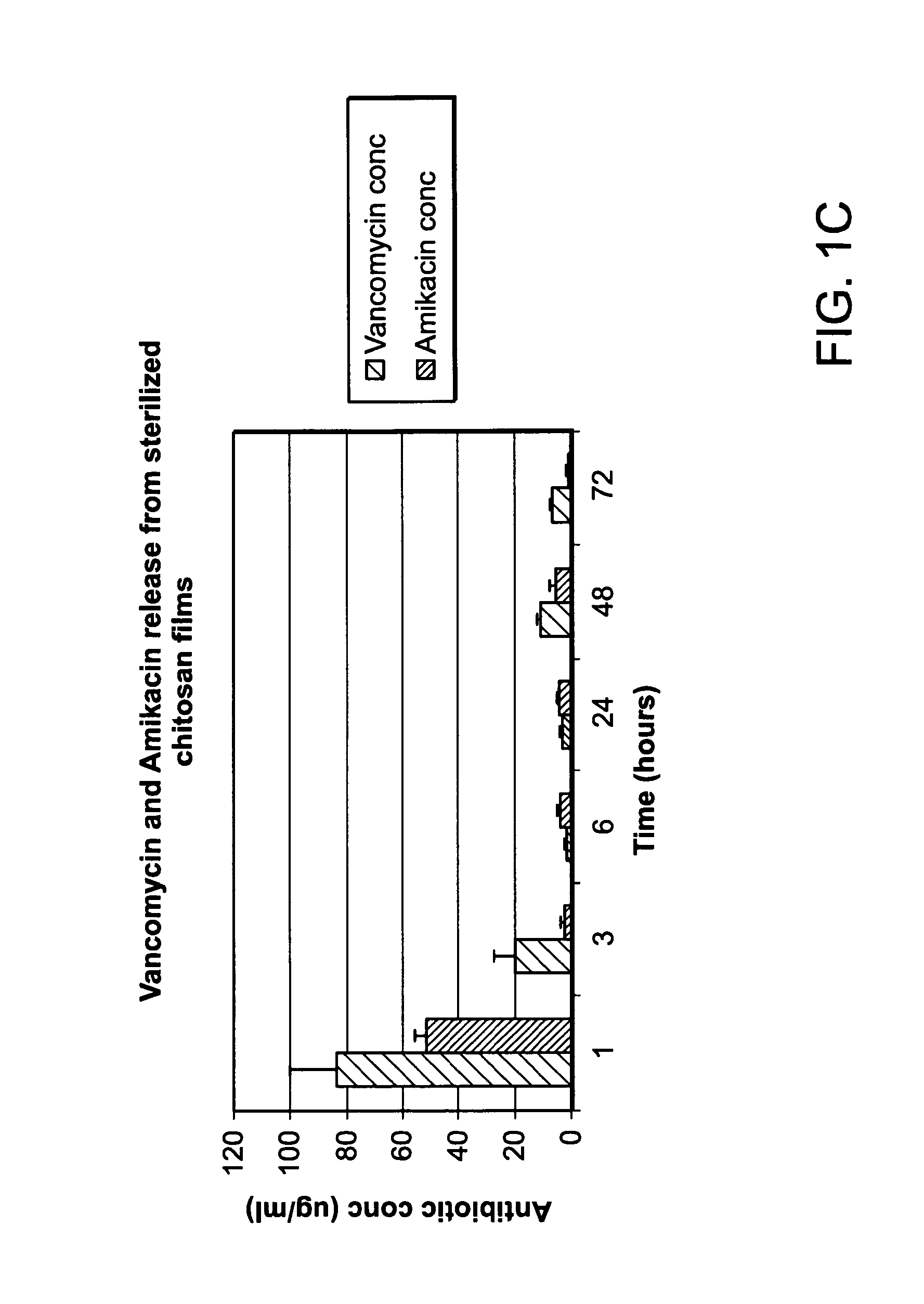

The invention provides compositions featuring chitosan and methods for using such compositions for the local delivery of biologically active agents to an open fracture, complex wound or other site of infection. Advantageously, the degradation and drug elution profiles of the chitosan compositions can be tailored to the needs of particular patients at the point of care (e.g., in a surgical suite, clinic, physician's office, or other clinical setting).

Owner:UNIVERSITY OF MEMPHIS RESEARCH FOUNDATION

Compositions and methods for delivering an agent to a wound

ActiveUS8993540B2Reduced survivalReduce proliferationAntibacterial agentsOrganic active ingredientsPoint of careClinical settings

The invention provides compositions featuring chitosan and methods for using such compositions for the local delivery of biologically active agents to an open fracture, complex wound or other site of infection. Advantageously, the degradation and drug elution profiles of the chitosan compositions can be tailored to the needs of particular patients at the point of care (e.g., in a surgical suite, clinic, physician's office, or other clinical setting).

Owner:UNIVERSITY OF MEMPHIS RESEARCH FOUNDATION

Medicine for treatment of skin ulcer

InactiveCN103830478ASafe and effective treatmentGood treatment effectHeavy metal active ingredientsHydroxy compound active ingredientsDiseaseCinnabar

The present invention relates to a medicine for treatment of skin ulcer. The medicine comprises, by weight, 5-15 parts of selaginella tamariscina, 3-8 parts of borneol, 10-20 of rheum officinale; 5-15 parts of litharge; 5-15 parts of catechu; 10-20 parts of crude fossil fragments; 10-20 parts of Chinese angelica; 3-8 parts of cinnabar; 5-15 parts of frankincense; 3-8 parts of dragon's blood; 4-12 parts of lithospermum; 6-14 parts of Chinese magnoliavine; and 10-16 parts of calamine. Traditional Chinese medicines of the invention are formulated by clinical combination for several times, The medicine has effects of invigorating blood circulation and dispelling slough, relieving pain and promoting regeneration, engendering flesh, astringing sore and solidifying skin, nourishing blood, moistening skin and dispelling turgescence. The medicine is based on systemic treatment, treats both principal and secondary aspect of disease after being used. Proved by hundreds of clinical experiments, the medicine has obvious effects for severe and lingering ulcer, complex wound (such as cutting, stamping contusion, open fracture, and the like), bedsore, lower limb ulcer, and the like. The effective rate achieves 92%. The medicine has high cure rate.

Owner:马翠霞

Method for predicting reservoir reform volume after vertical well volume fracturing of low-permeability oil/gas reservoir

The invention provides a method for predicting a reservoir reform volume after vertical well volume fracturing of a low-permeability oil / gas reservoir. The method sequentially includes the following steps: (1) calculating an induced stress produced by a hydraulic fracture in a three-dimensional space; (2) calculating a stratum pore pressure obtained after leak-off of fracturing fluid; (3) calculating a stratum pore elastic stress obtained after the leak-off of the fracturing fluid; (4) overlapping the stress fields obtained in the step (1), (2) and (3) with an original crustal stress field to obtain a new crustal stress field, and calculating the magnitude and direction of the overlapped three-direction effective principal stress in the reservoir space; (5) calculating an open fracturing determination coefficient M of a natural fracture in the reservoir space and a shear fracturing area determination coefficient S of the natural fracture.

Owner:SOUTHWEST PETROLEUM UNIV

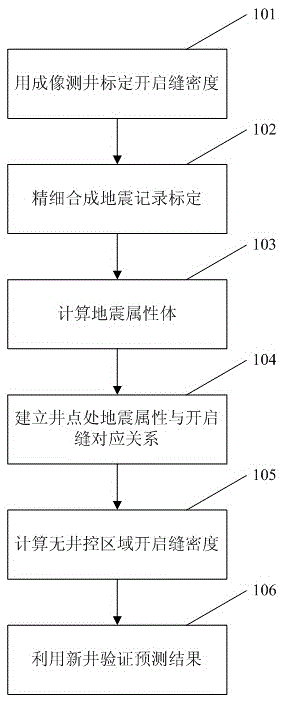

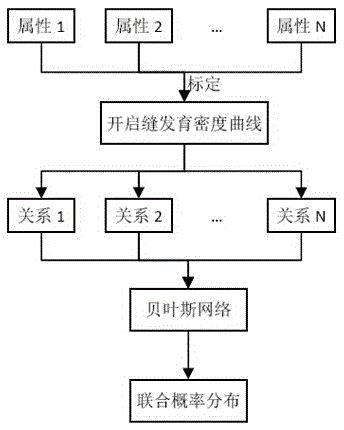

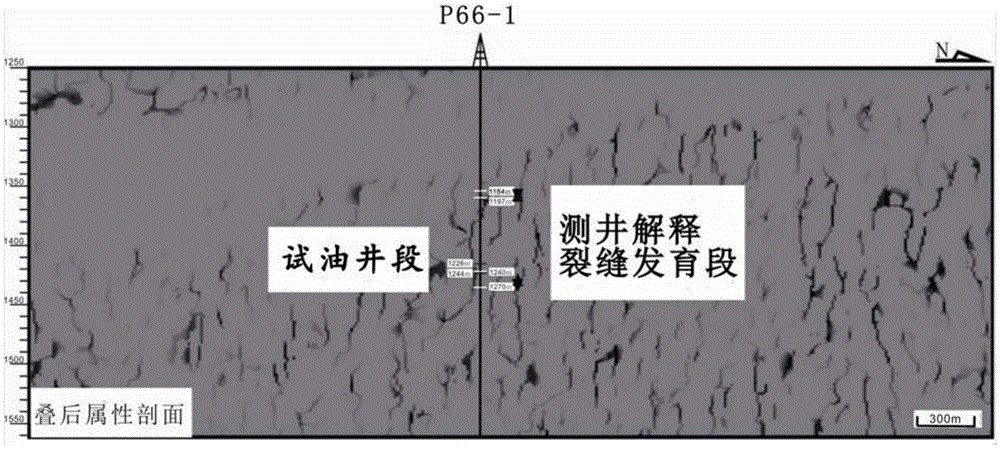

Igneous rock open-fracture earthquake prediction method

PendingCN106772570ASmall amount of calculationAccurate predictionSeismic signal processingCount densityEarthquake prediction

The invention provides an igneous rock open-fracture earthquake prediction method. The method comprises steps of step 1, through analysis of the FMI imaging logging, counting density of open fractures of a depth segment; step 2, carrying out refined synthesis earthquake recording calibration; step 3, by analyzing response features of the fractures on the earthquake recording, using post-stack earthquake data to extract earthquake attribute bodies; step 4, establishing a corresponding relation between the density of the open fractures and the earthquake attributes and using well point data to calibrate the earthquake attributes; step 5, by using the corresponding relation on well points, calculating distribution of density of the open fractures in a non-well control region, and establishing a fracture skeleton module; and step 6, carrying out open fracture density calibration on a new well and carrying out verification and correction on the prediction precision. According to the invention, the information included by the post-stack earthquake data can be fully used for analyzing earthquake response caused by open fracture development zones, and precisely predicting the open fracture development zones.

Owner:CHINA PETROLEUM & CHEM CORP +1

Temporary blocking and deflection fracturing method of in-layer artificial fracture in coalbed gas well

The invention relates to a temporary blocking and deflection fracturing method of an in-layer artificial fracture in a coalbed gas well. According to the temporary blocking and deflection fracturing method, a fracture blocking agent with the high strength is used to enter an opened fracture along with adding of fracturing fluid to form bridge blinding, net pressure of the fracture is improved, fluid is subjected to deflection in a stratum to form fractures in different directions or enable fractured sand to be uniformly distributed in the fracture, so that a new fluid flowing channel is openedin a reservoir, wider communication of an oil and gas reservoir is achieved, and oil and gas production is increased.

Owner:北京泰坦通源天然气资源技术有限公司 +1

Fracturing method for realizing effective partial pressure of dense heterogeneous reservoir stratum

ActiveCN107420081ASolve underutilized issuesOvercoming Inability to Retrofit AdequatelyFluid removalFiberFracturing fluid

A fracturing method for realizing the effective partial pressure of a dense heterogeneous reservoir stratum includes the steps of cutting to an artificial well bottom through a gauge cutter, conducting a pressure test on a shaft after well flushing till the test is qualified, selecting the point with the best physical property of the stratum as a perforation section or spot, conducting heat power perforation or heat power sandblast perforation, putting in a fracture drill tool to conduct first-grade fracturing construction, implementing general fracturing through fracturing liquid, replacing with sand-carrying fluid to enter the stratum, closing a well till a fracturing seam is closed, adding degradable fiber and a water-soluble temporarily plugging agent for blocking a fractured layer section, starting second-grade fracturing construction, repeatedly executing the steps of adding the degradable fiber and the water-soluble temporarily plugging agent and conducting fracturing construction according to the perforation hole number till all perforation sections are sufficiently refitted, and finally conducting well closing, well opening for gushing, production volume finding and well completing. Through the combination of multi-section fixed point perforation and the fiber and the water-soluble temporarily plugging agent, the opened fracturing seam is selectively blocked, an unused stratus is forced to be fractured and a new seam is created, and the aim of effective fracturing and sufficient refitting of all oil reservoirs can be achieved.

Owner:PETROCHINA CO LTD

Orally taken and externally applied traditional Chinese bone setting medicine

InactiveCN101934011APromote circulationShorten the period of hematoma formationPowder deliveryHeavy metal active ingredientsCinnabarRhizome

The invention relates to an orally taken and externally applied traditional Chinese bone setting medicine, which is characterized by comprising the following components in ratio: 1-3% of Chinese angelica, 1-3% of cassia twigs, 1-4% of pseudo-ginseng, 4-8% of dragon's blood, 1-4% of catechu, 1-3% of deoiled frankincense, 1-3% of deoiled myrrh, 0.5-2% of saffron, 1-4% of drynaria rhizome, 1-4% of ground beeltle, 0.5-2% of cinnabar, 2-5% of native copper and 55-85% of brown sugar. A preparation process comprises the following steps of: weighing all medicine components according to the formulation quantity, grinding all medicine components except brown sugar into fine powder, adding the brown sugar and uniformly mixing. The use method comprises the following steps of: treating and fixing the fracture, if the skin is broken, debriding and disinfecting the wound, applying the bone setting medicine, wrapping with gauze, and orally taking the bone setting medicine. The bone setting medicine overcomes the defects of the traditional medicines for treating fractures and is applicable to the treatment of closed and open fractures.

Owner:刘思波

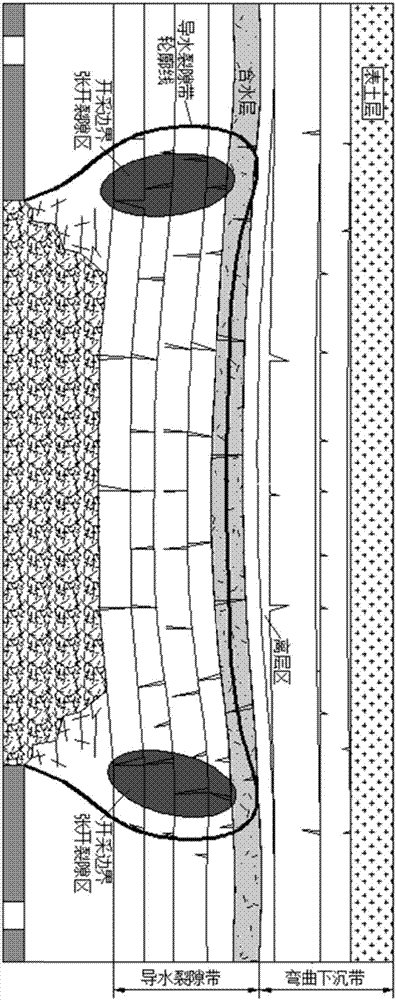

Water disaster prevention and treatment method for promoting fracture closing through explosion loosening of boundary coal pillars/bodies

ActiveCN107227959APromote break gyrationReduced water conductivityMining devicesTunnelsGrowth heightGeomorphology

The invention discloses a water disaster prevention and treatment method for promoting fracture closing through explosion loosening of boundary coal pillars / bodies. On the basis of the growth characteristics of the mining covered rock water-flowing fracture zone height under the specific mining condition, by collecting surface drilling columnar data of coal mining zones, positions of key strata in covered rock are determined by adopting a key stratum position discrimination method, then, on the basis of a covered rock water-flowing fracture zone height prediction method, each zone water-flowing fracture zone growth height and distribution zones, communicated with water-bearing strata, of water-flowing fracture zones are determined, finally, boundary coal pillar / body construction blasting drilling is performed in the goaf direction in a roadway nearby the zone, communicated with the water-baring strata, of the water-flowing fracture zone, and explosion loosening is performed so as to promote a covered rock stratum to be subjected to advanced fracturing; accordingly, original boundary open fractures are closed step by step, the fracture opening degree is decreased, and the water-flowing capacity is lowered.

Owner:CHINA UNIV OF MINING & TECH

PRP loaded slow release antibiotic-mesenchymal stem cell gel system and preparation method thereof

InactiveCN106362213ASolving the technical challenges of healingTechnical Difficulties in Promoting HealingTissue regenerationProsthesisMuscle tissueAntibiotic Y

The invention discloses a PRP loaded slow release antibiotic-mesenchymal stem cell gel system and a preparation method thereof. Thrombin and calcium ions are added into PRP, an irregular micro three-dimensional grid structure of 50-200 micrometers is formed, and bacterium-sensitive antibiotics and stem cells are loaded on the grid structure. The PRP loaded slow release antibiotic-mesenchymal stem cell gel system and the preparation method thereof have the advantages that open fractures, bone and joint infection, skin, subcutaneous tissue and muscular tissue infection, four limb and spine implant related infection and artificial joint prosthesis peripheral infection are obviously prevented and treated, and the related infection occurrence rate is reduced. The technology releases the antibiotics within a certain time from inside to outside, bacteria around an implant are directly killed, formation of a bacterial biofilm is restrained or damaged, and the technical purpose that coalescence of bone joints and soft tissue is promoted while the antibiotics are slowly released in the body is achieved.

Owner:THE THIRD AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIV OF PLA

Quick bone-setting powder

InactiveCN102000234AThe application effect is magicalSignificant effectAnthropod material medical ingredientsSkeletal disorderX-rayExternal cause

The invention discloses quick bone-setting powder. The powder consists of the following medicinal materials in part by mass: 10 to 15 parts of dragon's blood, 30 to 50 parts of crab, 20 to 30 parts of nux vomica, 20 to 30 parts of gynura divaricata, 30 to 40 parts of torricellia angulata, 15 to 20 parts of scopolia acutangula, 25 to 30 parts of actinodaphne obivata, 30 to 35 parts of earthworm, 20 to 30 parts of clerodendron serra tum, 20 to 30 parts of tamala bark or leaf and 20 to 30 parts of vicia hirsuta; and 20 to 30 parts of bitter orange is added into the medicinal materials or not. The quick bone-setting powder is already applied in clinic, has magical effect and obvious curative effect, and can be used for quickly setting open fracture and broken fracture. The quick bone-setting powder can relieve the pain of a patient in short time, and can quickly recover the limb function. Aligned with the fracture patient in a line, the bone is set under X-ray, and the healing rate reaches over 95 percent. Generally, after the quick bone-setting powder is externally applied for 3 to 4 times, the patient can be healed. The quick bone-setting powder is suitable for the patients of fracture caused by various external reasons.

Owner:龚定军

Compositions and methods for delivering an agent to a wound

InactiveUS20170258967A1Reduce probabilityIncrease or decrease weightSuture equipmentsOrganic active ingredientsPoint of careClinical settings

The invention provides compositions featuring chitosan and polyethylene glycol and methods for using such compositions for the local delivery of biologically active agents to an open fracture, complex wound or other site of infection. Advantageously, the chitosan-PEG compositions can be loaded with one or more antimicrobial agents, including hydrophobic agents, and can be tailored to the needs of particular patients at the point of care (e.g., in a surgical suite, clinic, physician's office, or other clinical setting).

Owner:UNIVERSITY OF MEMPHIS RESEARCH FOUNDATION

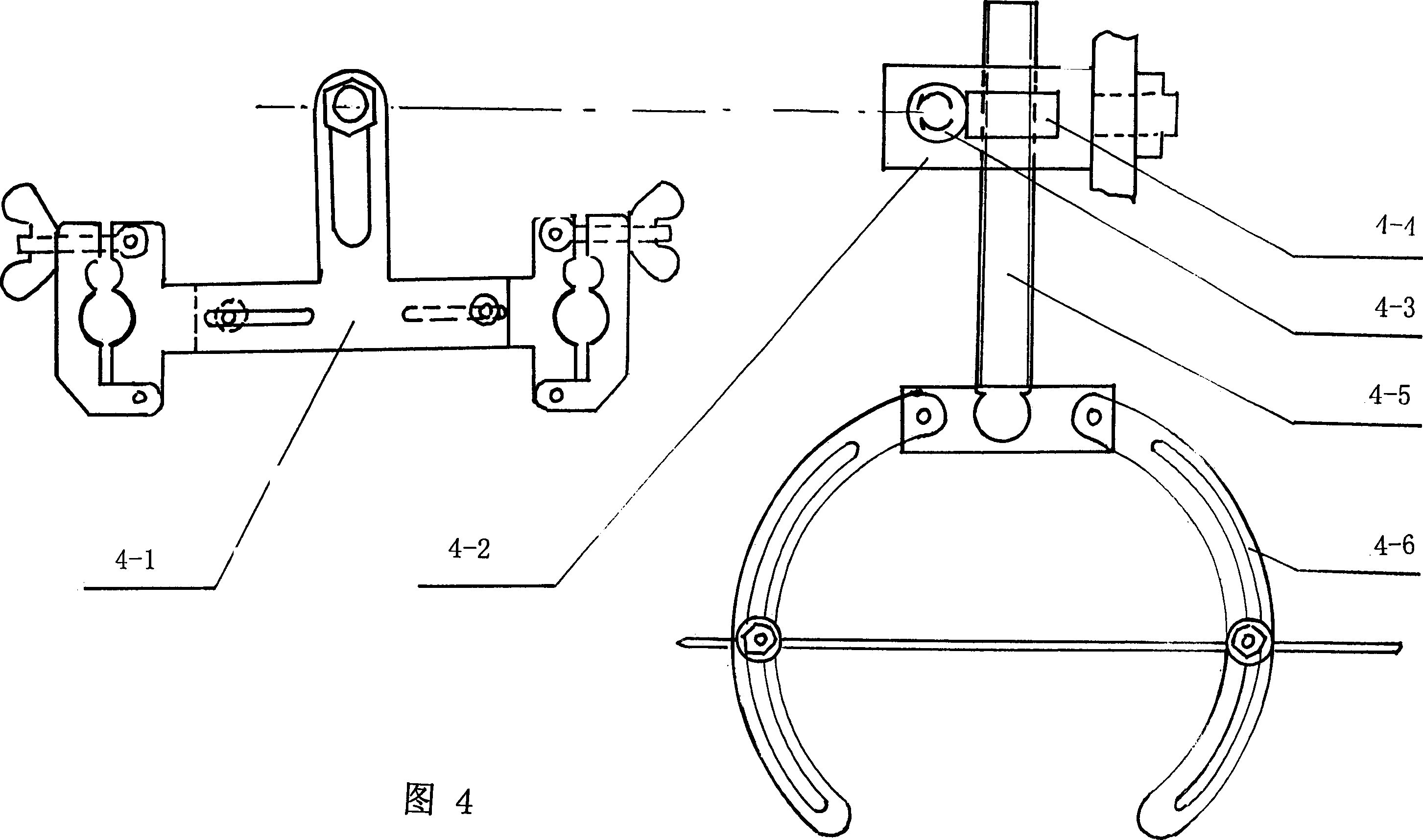

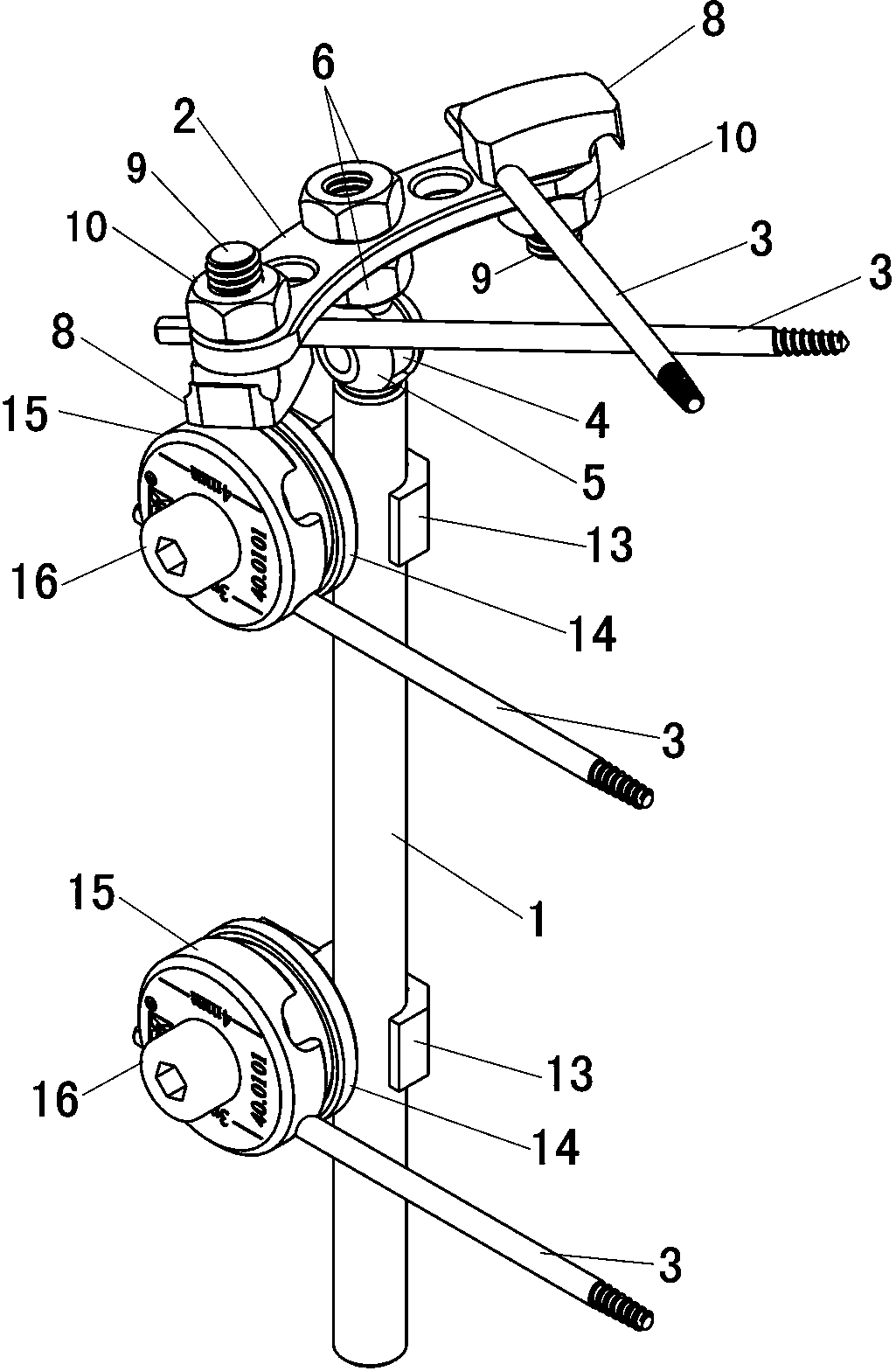

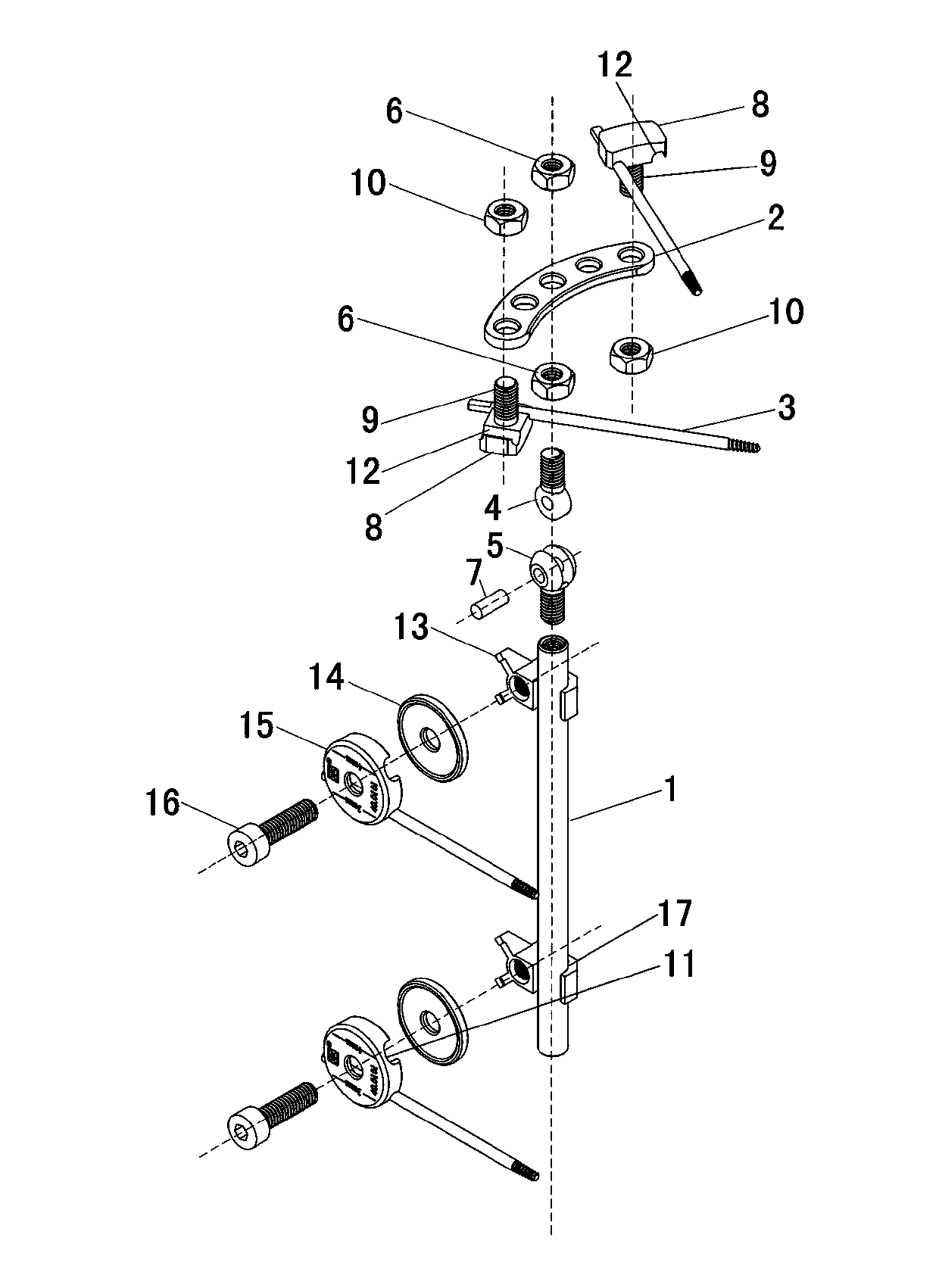

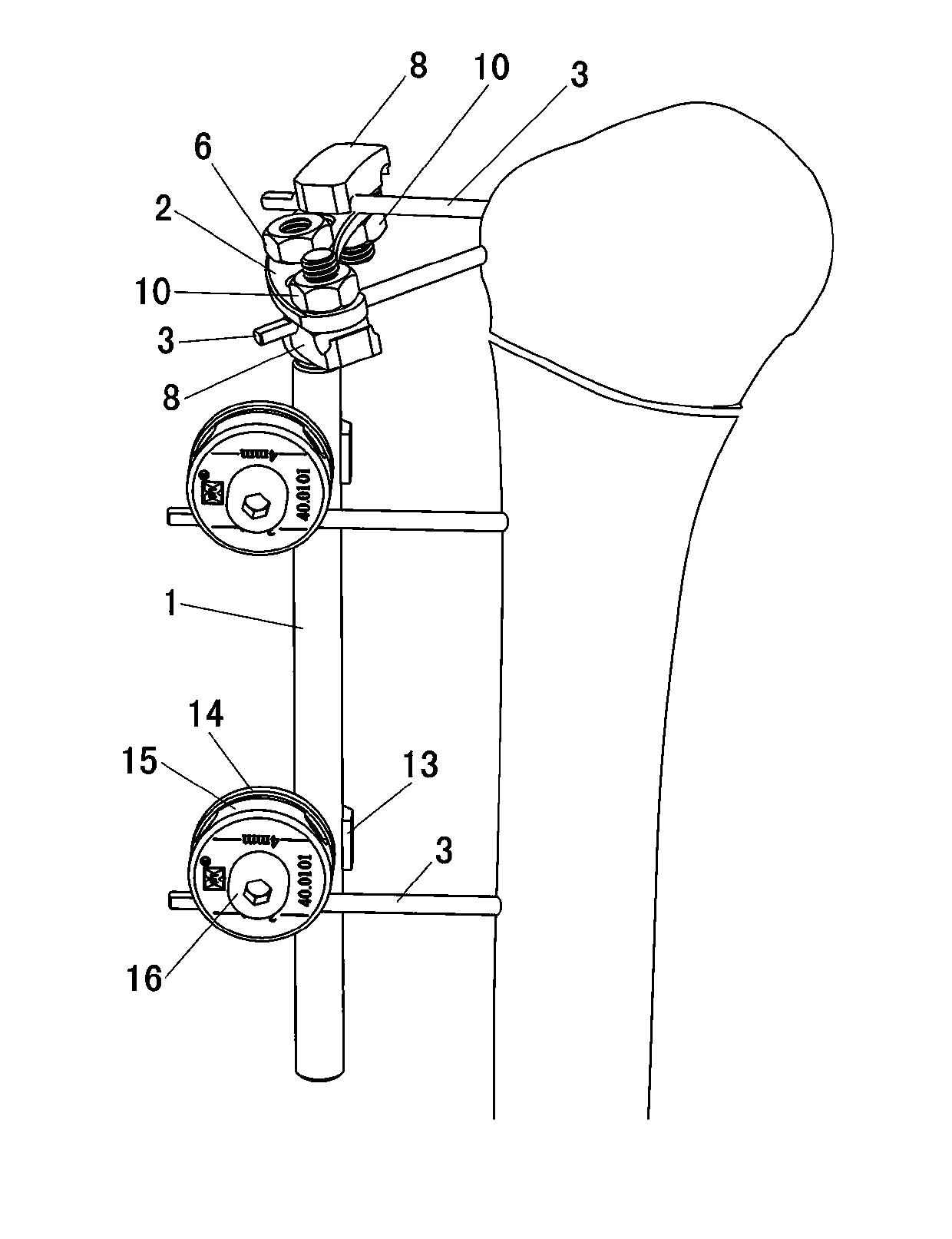

Proximal humerus T-shaped outer fixator

ActiveCN103417278AHigh activitySimple structureExternal osteosynthesisHumeral fractureExternal fixator

A proximal humerus T-shaped outer fixator is composed of an outer fixator frame body, a steel needle fixing clamp connected to the outer fixator frame body and a half needle clamped in the steel needle fixing clamp. The outer fixator frame body is composed of a vertical tubular connection rod, a horizontal arc multi-hole connection plate and a locking joint apparatus for connecting the arc multi-hole connection plate to the upper end of the tubular connection rod. The steel needle fixing clamp is composed of a steel needle fixing clamping A connected to the tubular connection rod and a steel needle fixing clamp B connected to the arc multi-hole connection plate. More than three holes are formed in the arc multi-hole connection plate, and the number of the holes is an odd number. The proximal humerus T-shaped outer fixator is simple in structure, stable in fixing, capable of facilitating movement of limbs, suitable for simple fracture and complex fracture in proximal humeral fracture, especially suitable for curing humerus surgical neck fracture, open fracture and infectious fracture and capable of quickly achieving restoration and fixation of the proximal humeral fracture.

Owner:JIANGSU GUANGJI MEDICAL TECH

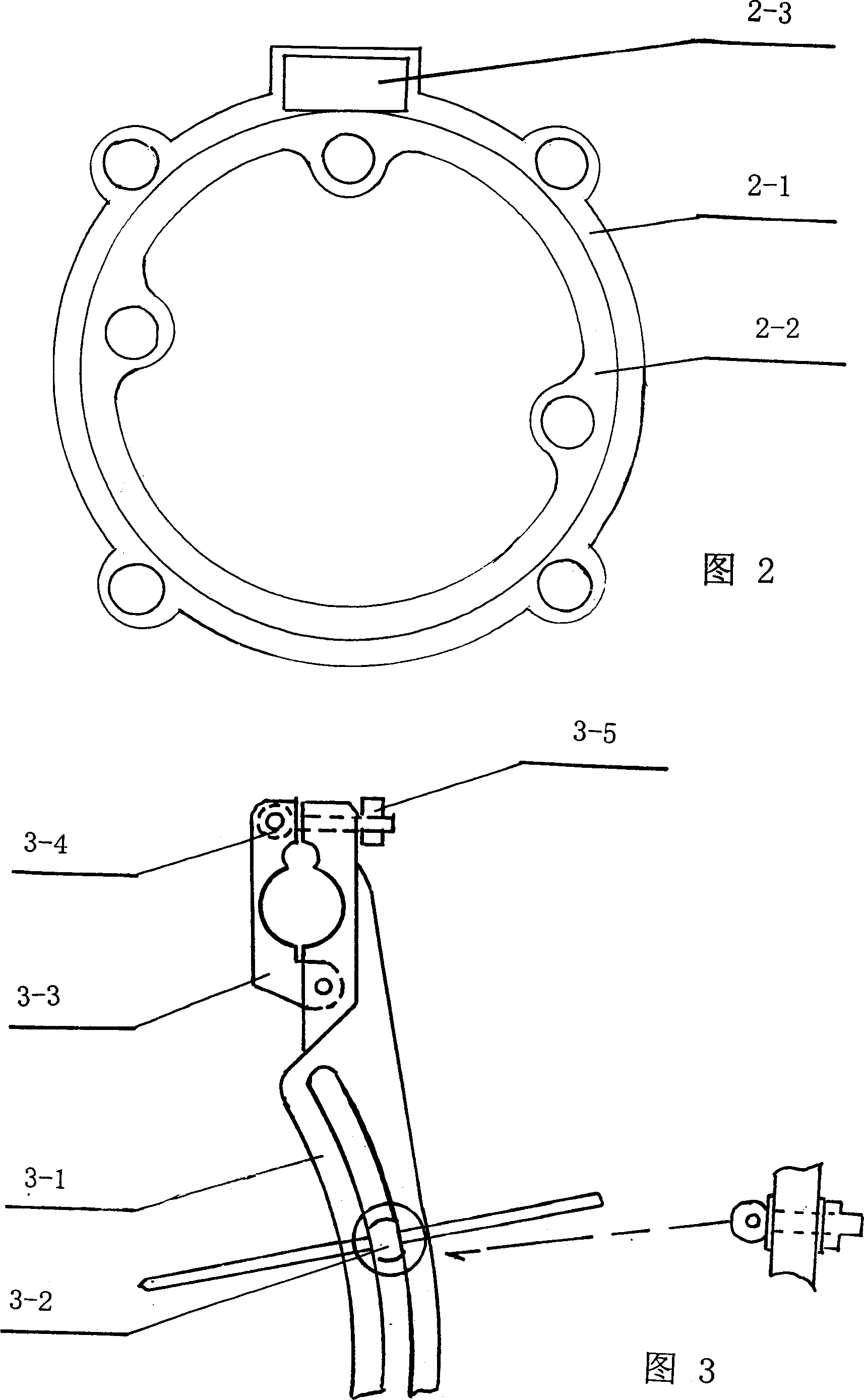

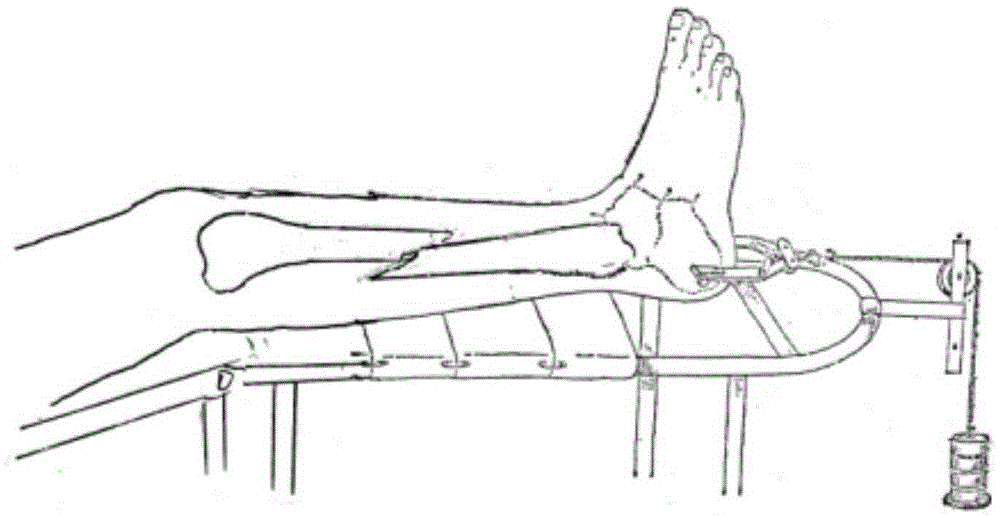

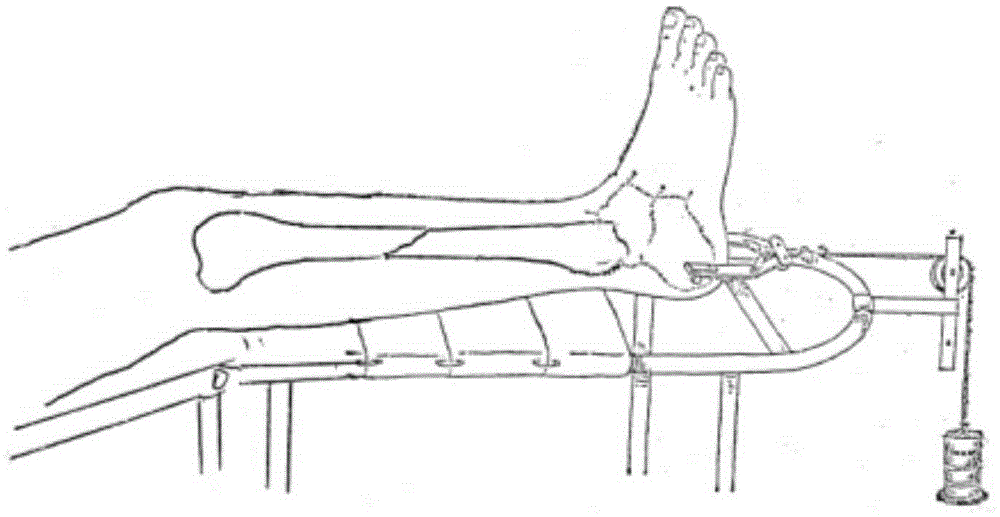

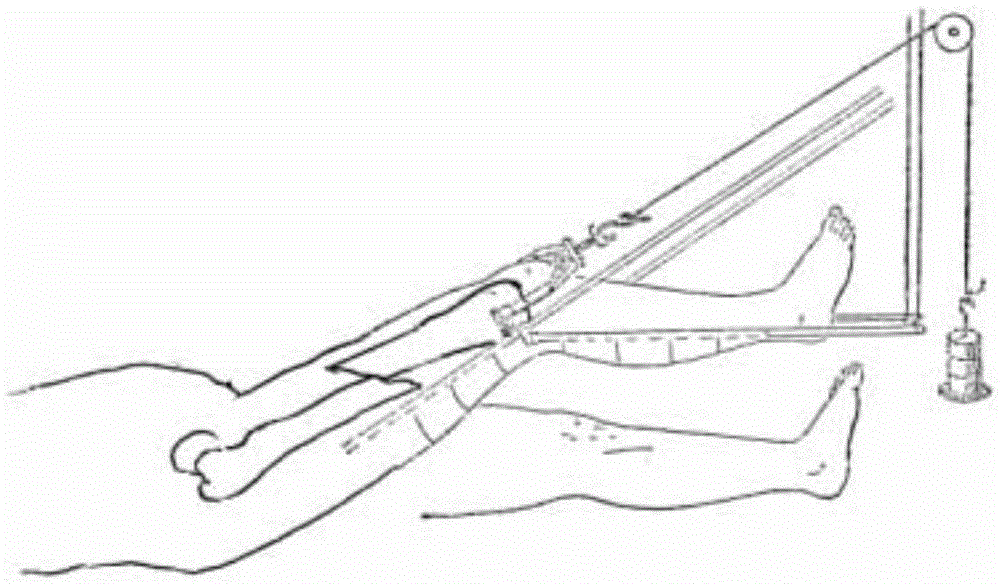

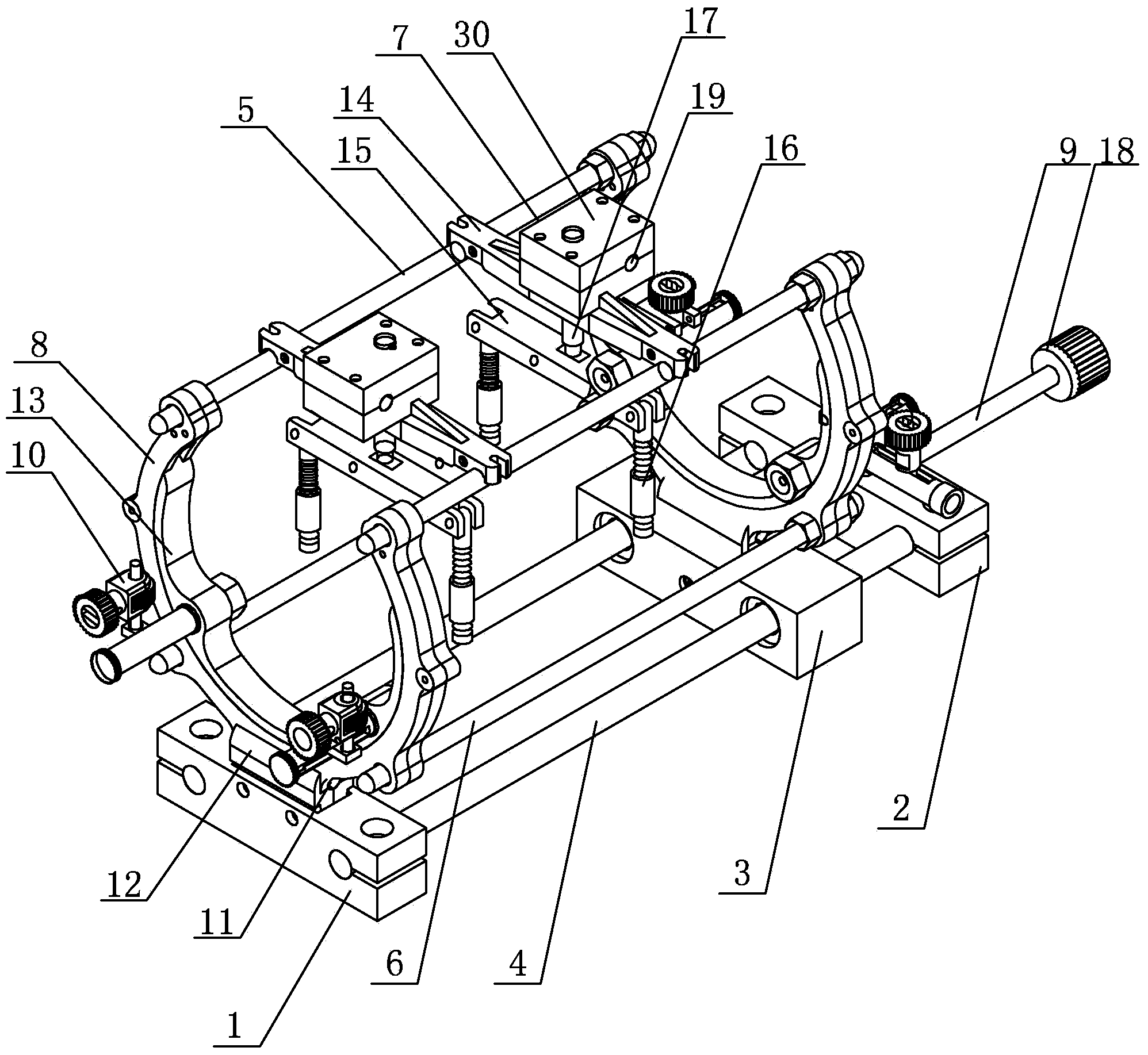

Limb long bone fracture semicircular reduction device

ActiveCN103393454AEasy to placePrecious recovery timeExternal osteosynthesisFracture reductionLONG BONE FRACTURE

The invention discloses a limb long bone fracture semicircular reduction device, and relates to a fracture reduction device. The reduction device aims at solving the problem that the existing close reduction fracture external fixing stand is inconvenient for traumatic fracture and open fracture. A first fixing slide block and a second fixing slide block of the reduction device are arranged from left to right sequentially; two slide rods are arranged between the first fixing slide block and the second fixing slide block; a movable slide block is slidingly arranged on the two slide rods and between the first fixing slide block and the second fixing slide block; two semicircular rotary rings are arranged on the first fixing slide block and the movable slide block respectively; two spicule angle adjustment seats are arranged on the outer side of each of the two semicircular rotary rings; two movable spicule lifting shifters are arranged on two upper slide rods; one end of a lower screw penetrates through the second fixing slide block to be connected with the movable slide block; and a rotary handle is suspended at the other end of the screw. The reduction device is used for fracture reduction.

Owner:博斯创想(上海)医疗科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com