Patents

Literature

97 results about "Biodegradable polyurethane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

This feature allows polyurethane able to be modified in various ways to meet different clinical needs, biodegradable material included. Santerre et al. believed that biodegradable polyurethane could be an ideal drug carrier and this perspective was confirmed by Sivak et al. In 2008, Sivak et al.

Biodegradable polyurethanes and use thereof

InactiveUS20050013793A1Improve responseIncrease ratingsCell culture supports/coatingSkeletal/connective tissue cellsPolymer scienceDrug biological activity

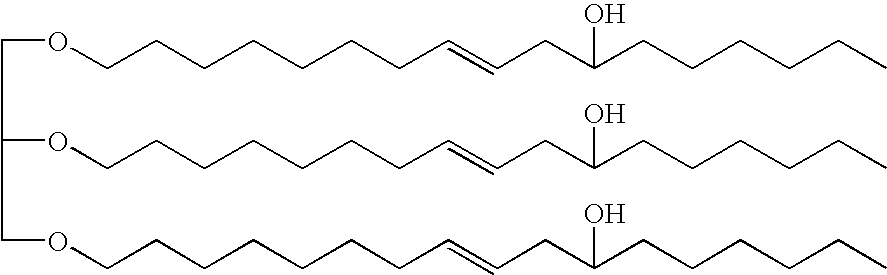

A biodegradable and biocompatible polyurethane composition synthesized by reacting isocyanate groups of at least one multifunctional isocyanate compound with at least one bioactive agent having at least one reactive group —X which is a hydroxyl group (—OH) or an amine group (—NH2). The polyurethane composition is biodegradable within a living organism to biocompatible degradation products including the bioactive agent. Preferably, the released bioactive agent affects at least one of biological activity or chemical activity in the host organism. A biodegradable polyurethane composition includes hard segments and soft segments. Each of the hard segments is preferably derived from a diurea diol or a diester diol and is preferably biodegradable into biomolecule degradation products or into biomolecule degradation products and a biocompatible diol. Another biodegradable polyurethane composition includes hard segments and soft segments. Each of the hard segments is derived from a diurethane diol and is biodegradable into biomolecule degradation products.

Owner:CARNEGIE MELLON UNIV +1

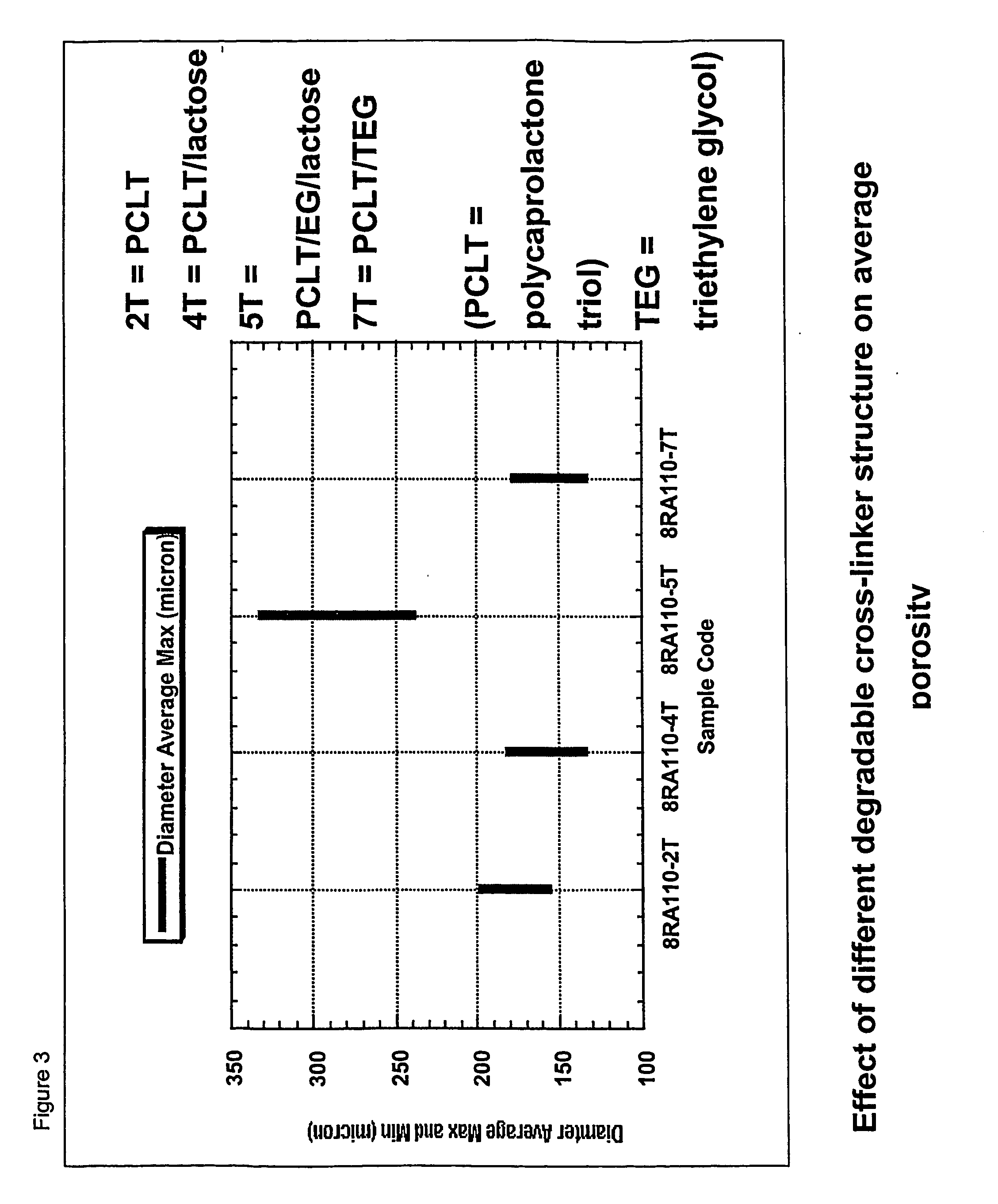

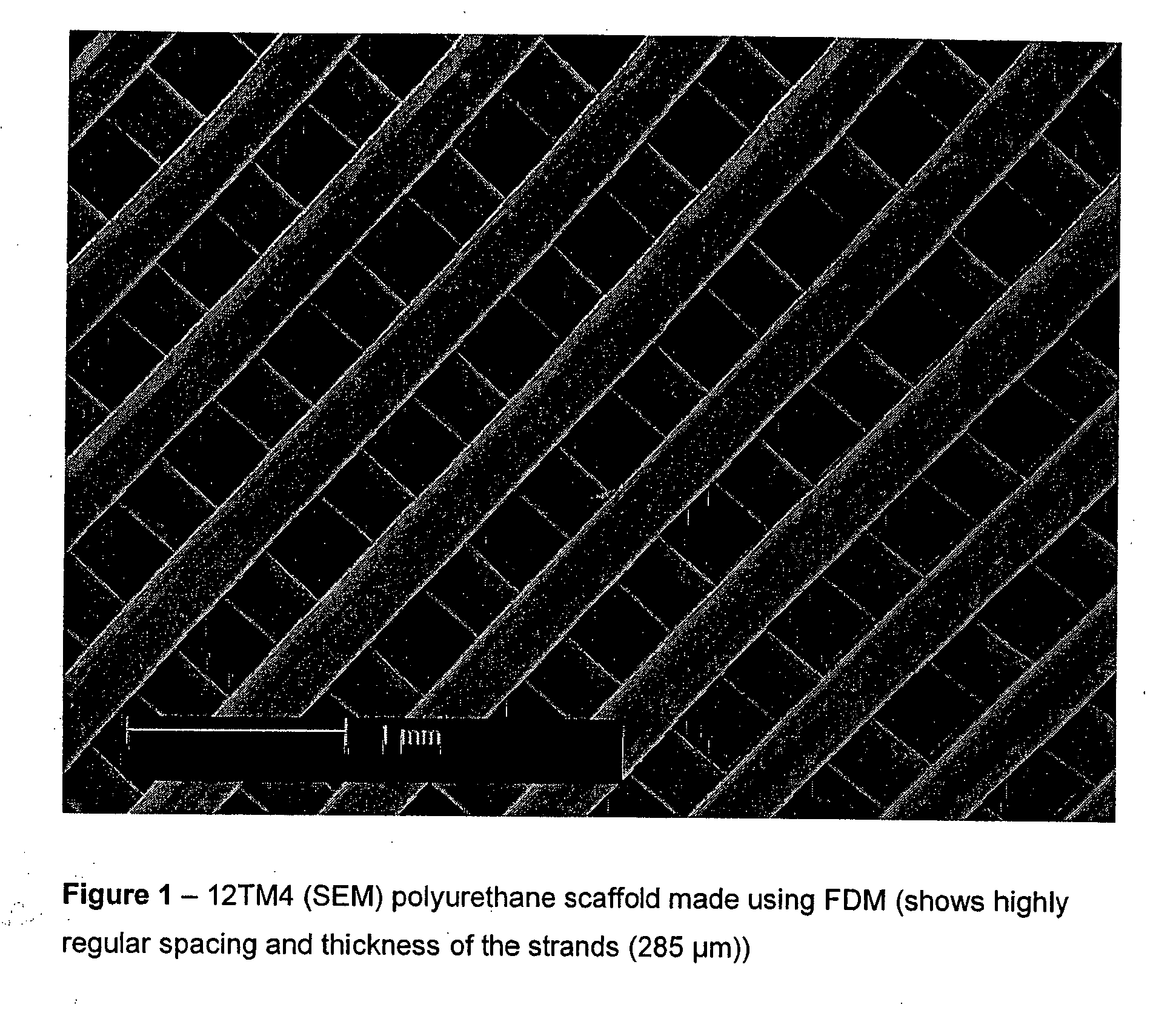

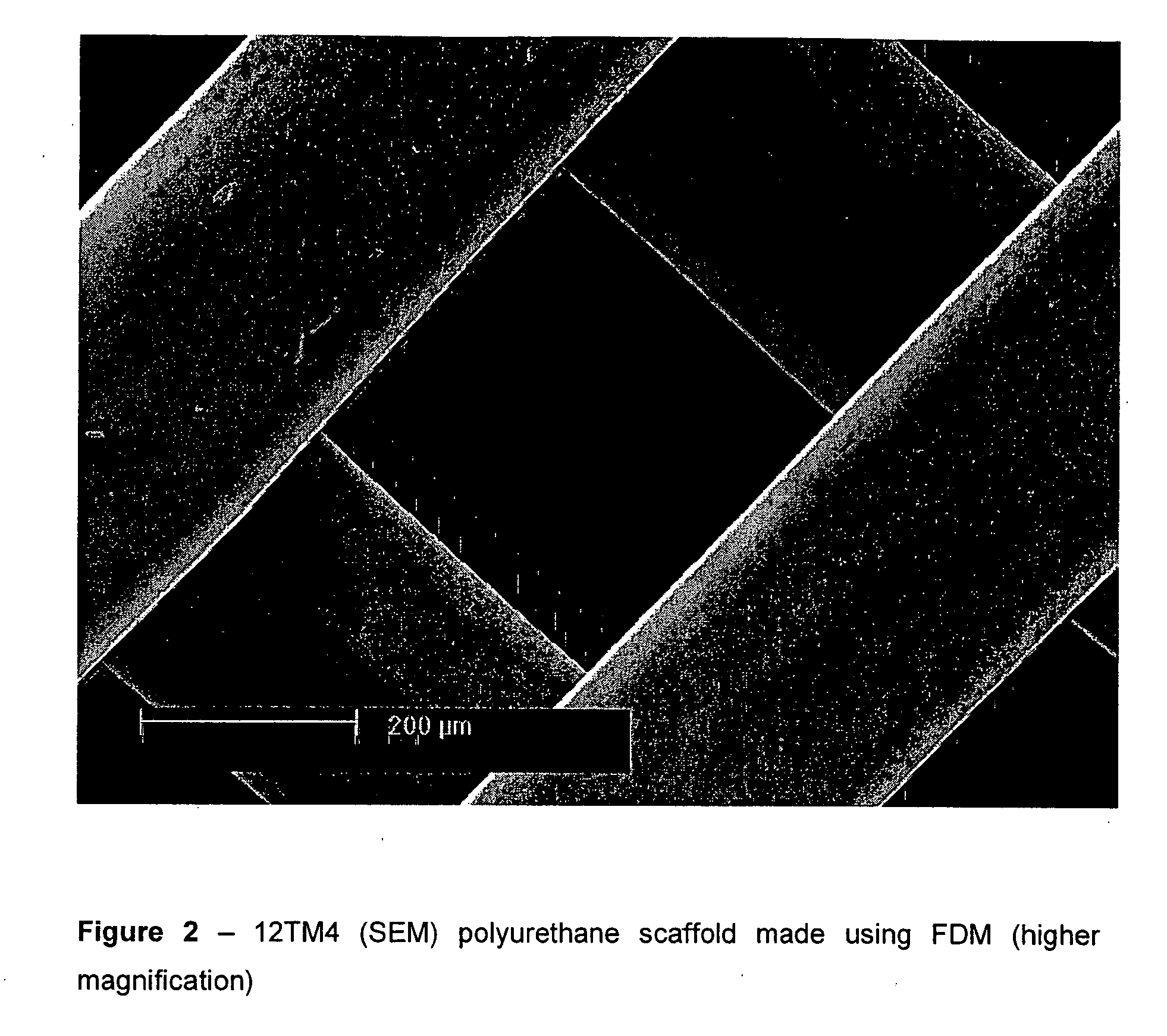

Biodegradable polyurethane/urea compositions

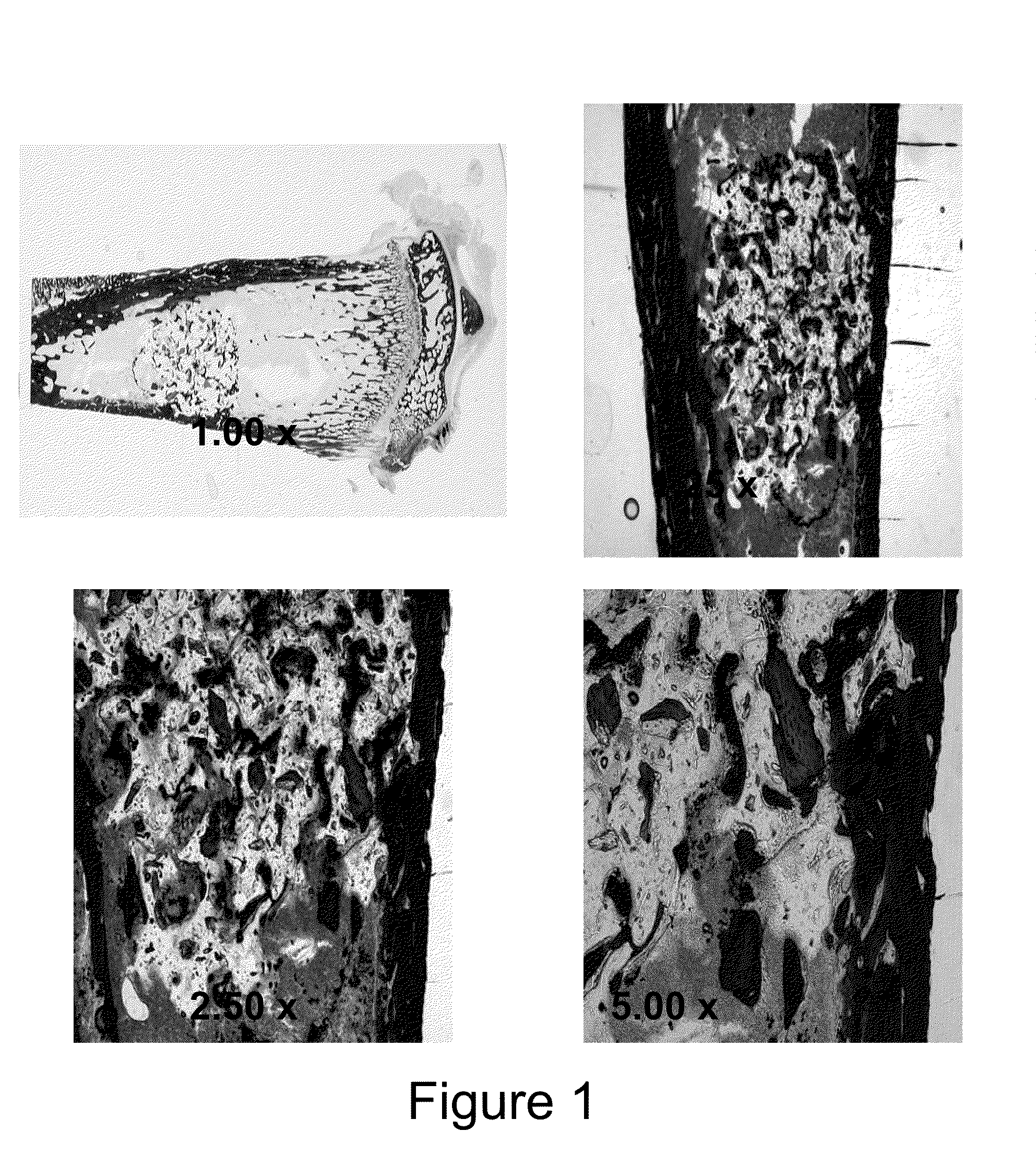

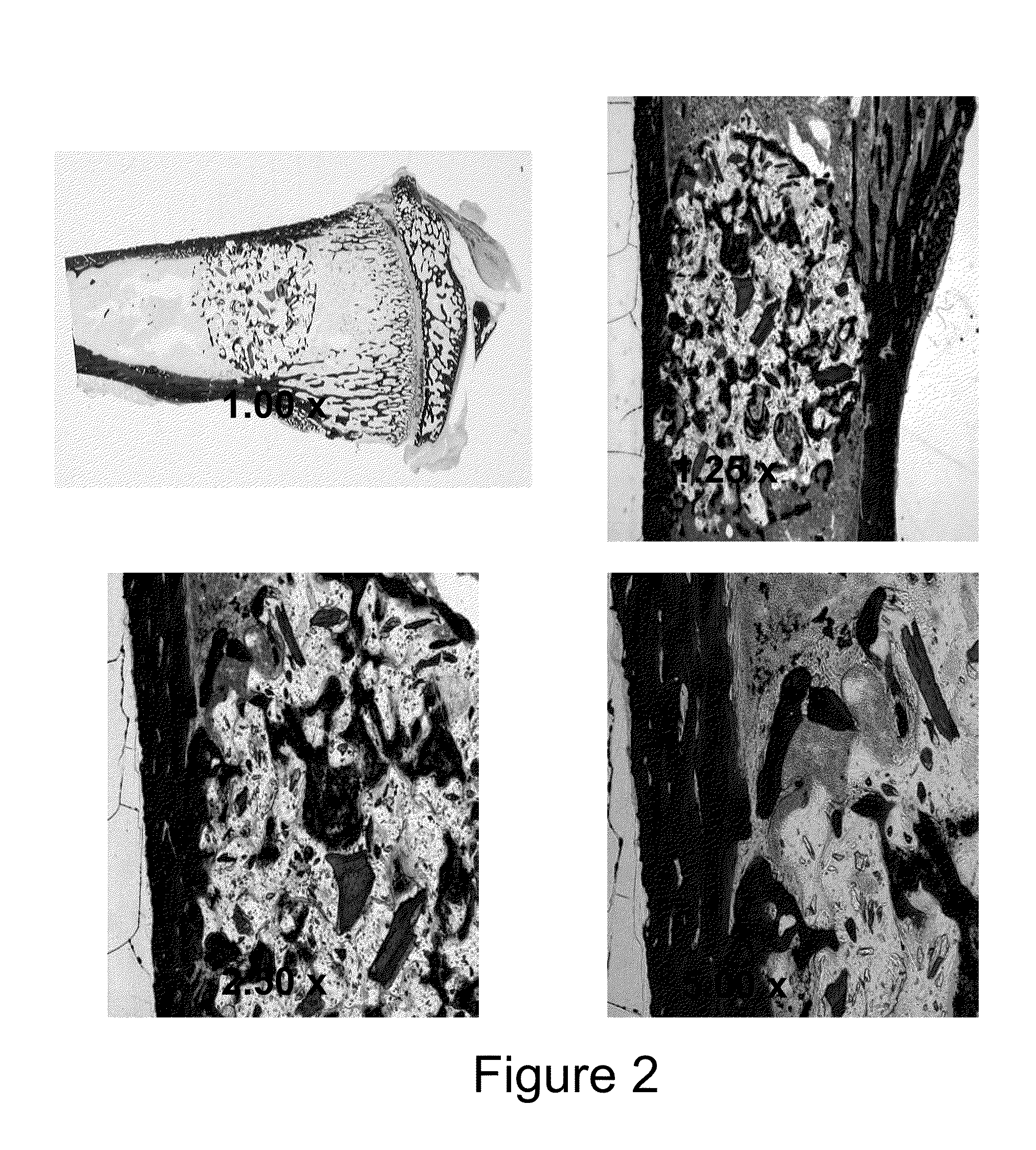

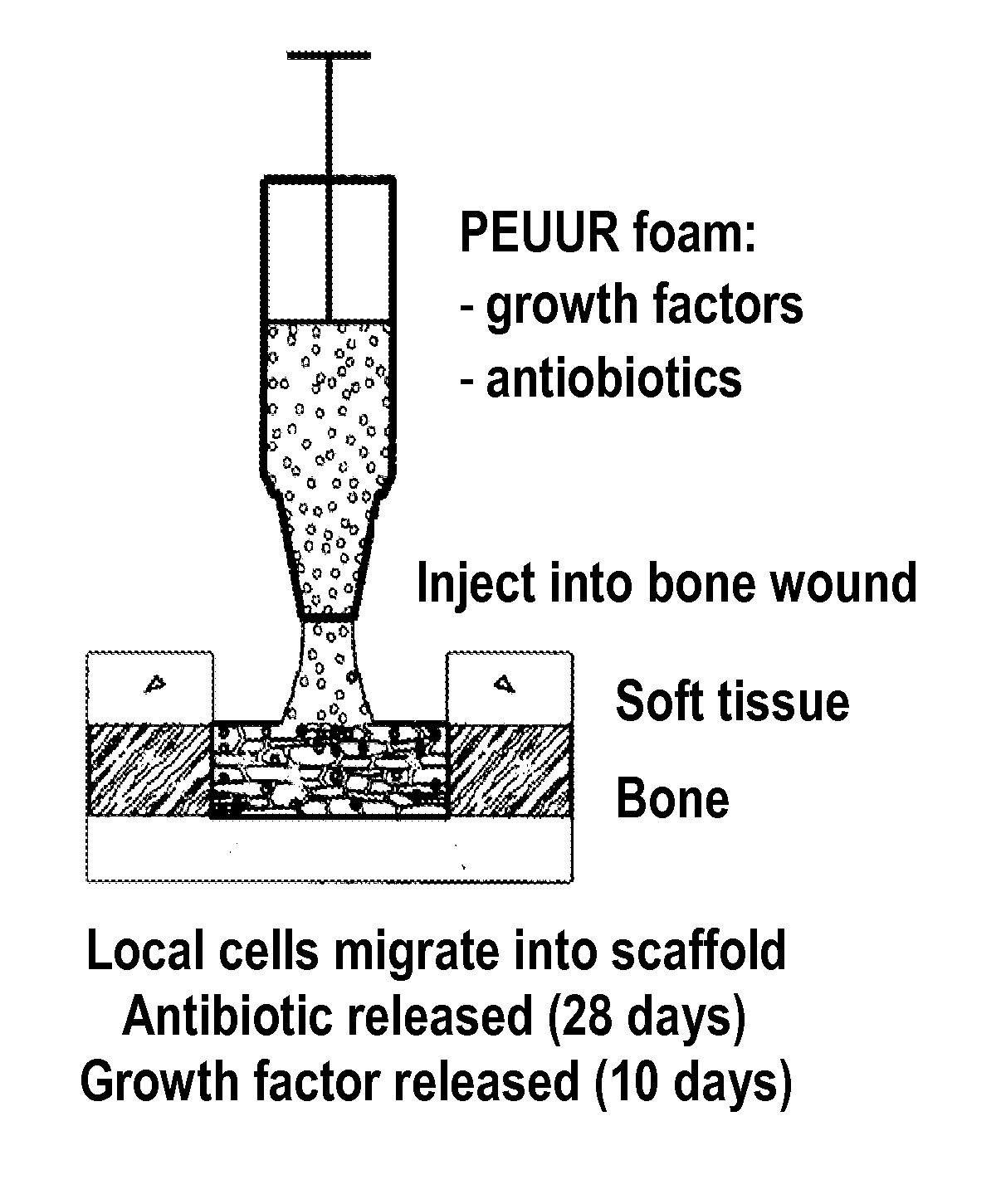

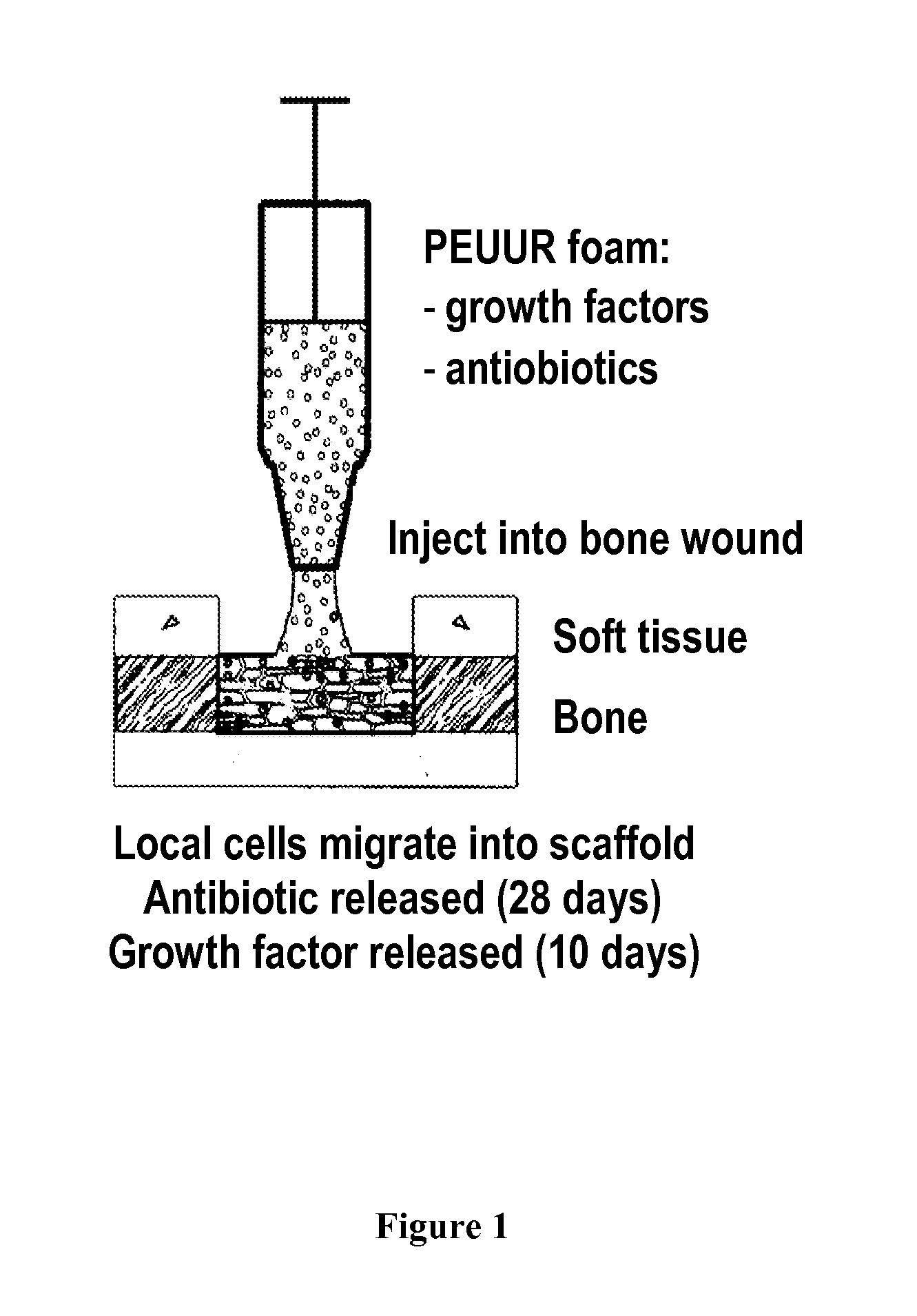

The present invention relates to biocompatible, biodegradable polyurethane / urea polymeric compositions that are capable of in-vivo curing with low heat generation to form materials suitable for use in scaffolds in tissue engineering applications such as bone and cartilage repair. The polymers are desirably flowable and injectable and can support living biological components to aid in the healing process. They may be cured ex-vivo for invasive surgical repair methods, or alternatively utilized for relatively non-invasive surgical repair methods such as by arthroscope. The invention also relates to prepolymers useful in the preparation of the polymeric compositions, and to methods of treatment of damaged tissue using the polymers of the invention.

Owner:POLYNOVO BIOMATERIALS PTY LTD

Biodegradable polyurethane and polyurethane ureas

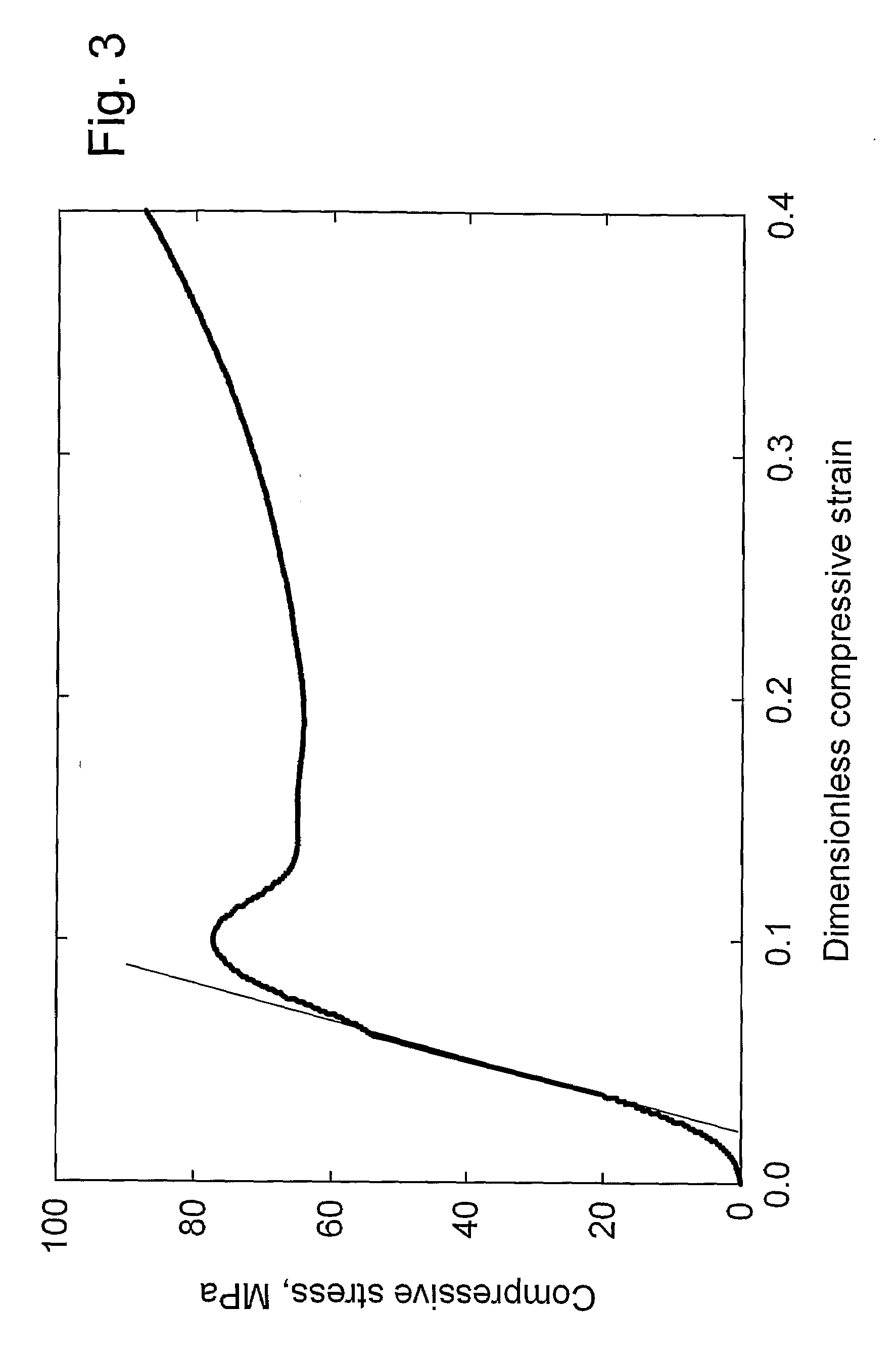

ActiveUS20060051394A1Fast formingEasily degradableOrganic active ingredientsSurgeryPolyolInsertion stent

This invention relates to biocompatible, biodegradable thermoplastic polyurethane or polyurethane / ureas comprising isocyanate, polyol and a conventional chain extender and / or a chain extender having a hydrolysable linking group and their use in tissue engineering and repair applications, particularly as stents and stent coating.

Owner:POLYNOVO BIOMATERIALS PTY LTD

Biodegradable polyurethane and polyurethane ureas

ActiveUS20090081270A9Easily degradableEasily degradable hard segmentOrganic active ingredientsSurgeryPolyolInsertion stent

This invention relates to biocompatible, biodegradable thermoplastic polyurethane or polyurethane / ureas comprising isocyanate, polyol and a conventional chain extender and / or a chain extender having a hydrolysable linking group and their use in tissue engineering and repair applications, particularly as stents and stent coating.

Owner:POLYNOVO BIOMATERIALS PTY LTD

ABA type triblock biodegradable polyurethane with amino side chains and preparation method and uses thereof

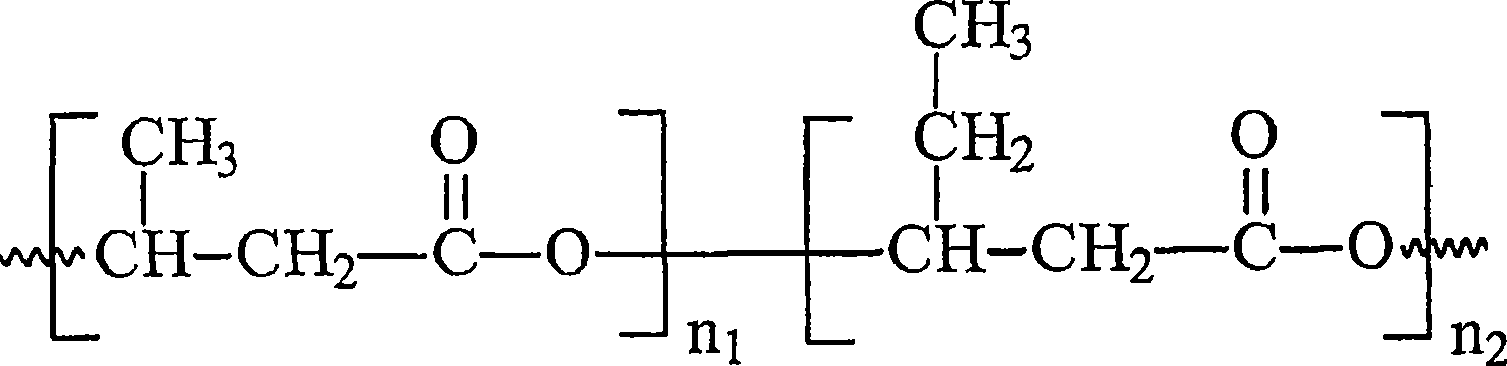

InactiveCN103497306ASimple structureMolecular weight controllablePharmaceutical non-active ingredientsIn-vivo testing preparationsSide chainFluorescence

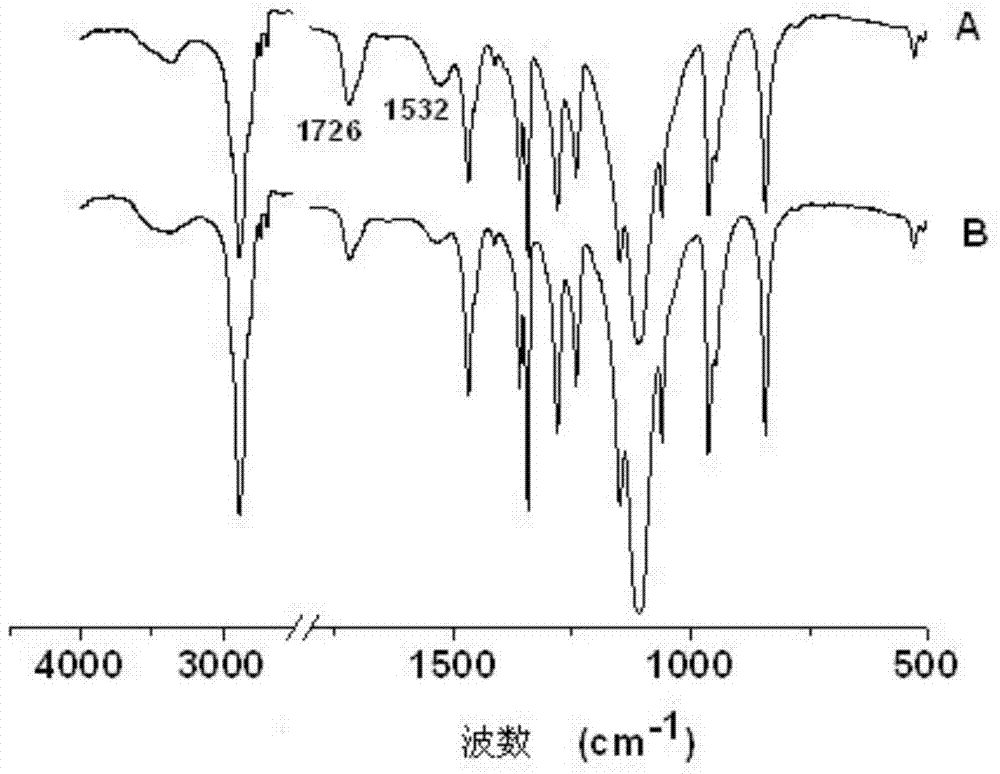

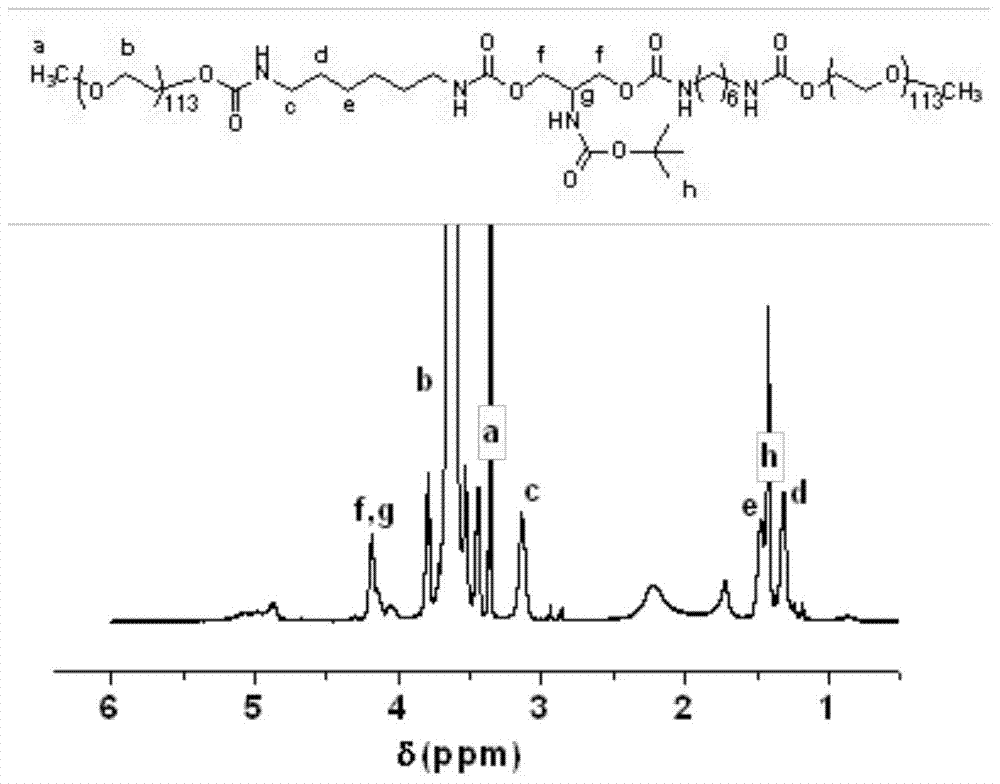

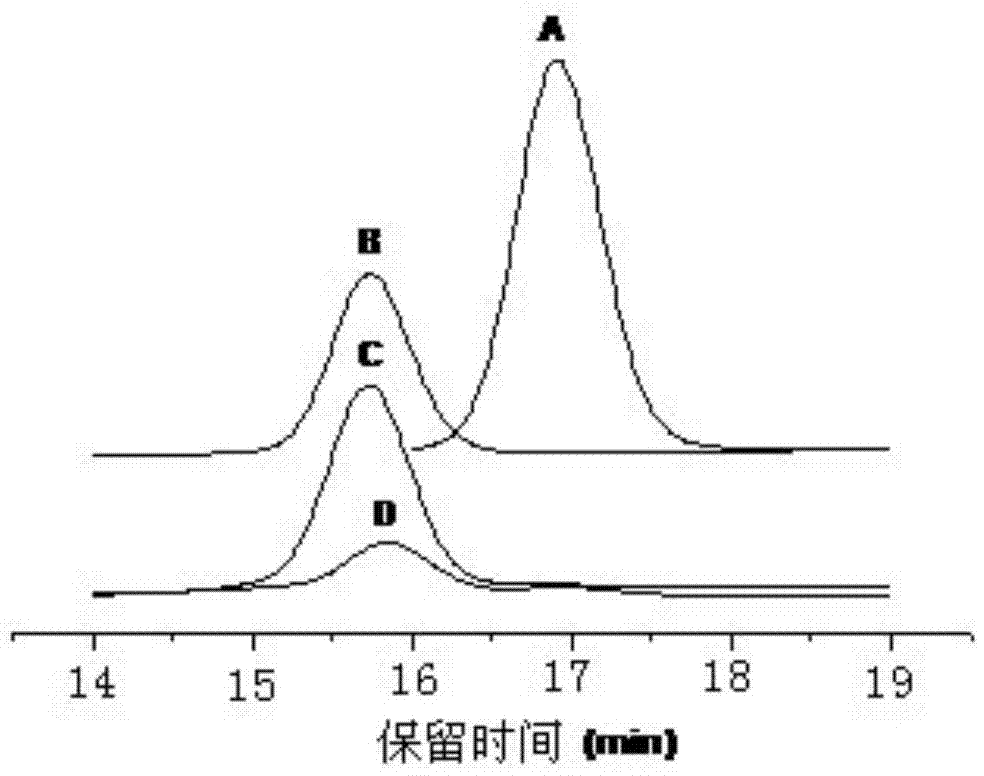

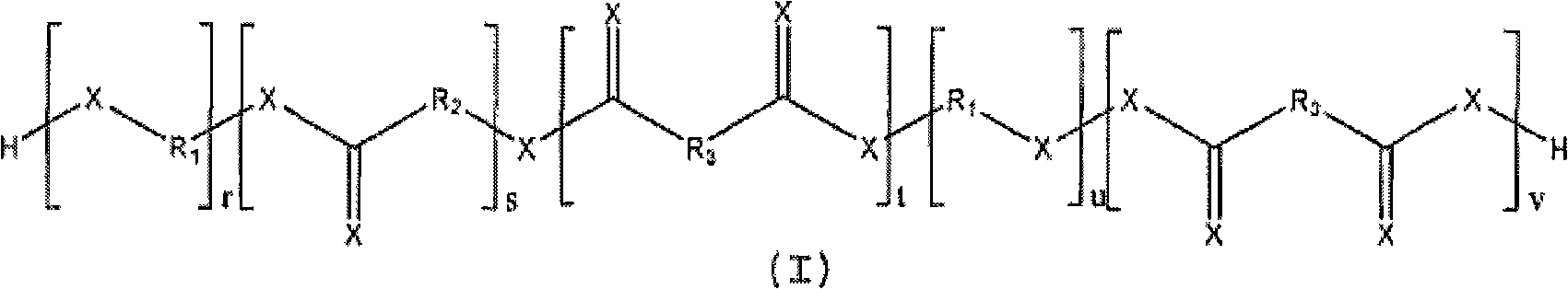

The invention provides ABA type triblock biodegradable polyurethane with amino side chains and a preparation method and uses thereof, belongs to the field of biomedical materials and solves the problem that the existing biodegradable polyurethane has molecular weight uncontrollable, wide molecular distribution index and complexity in self-assembly. The ABA type triblock biodegradable polyurethane with amino side chains is shown as in a structural formula I or II. The ABA type triblock biodegradable polyurethane is controllable in polymer molecular weight and wide in molecular weight distribution and can serve as a drug carrier; drug molecules, target molecules or fluorescence molecules are grafted to active side groups of the polyurethane by means of physical encapsulation or chemical bonding, so that a carrier drug system having one or multiple of functions such as being untargeted, being targeted, pH sensitivity, photosensitivity, enzyme sensitivity and fluorescence probing is constructed.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Injectable bone/polymer composite bone void fillers

InactiveUS20100068171A1High porosityPrevent shrinkageOrganic active ingredientsSkeletal disorderPorosityPolyol

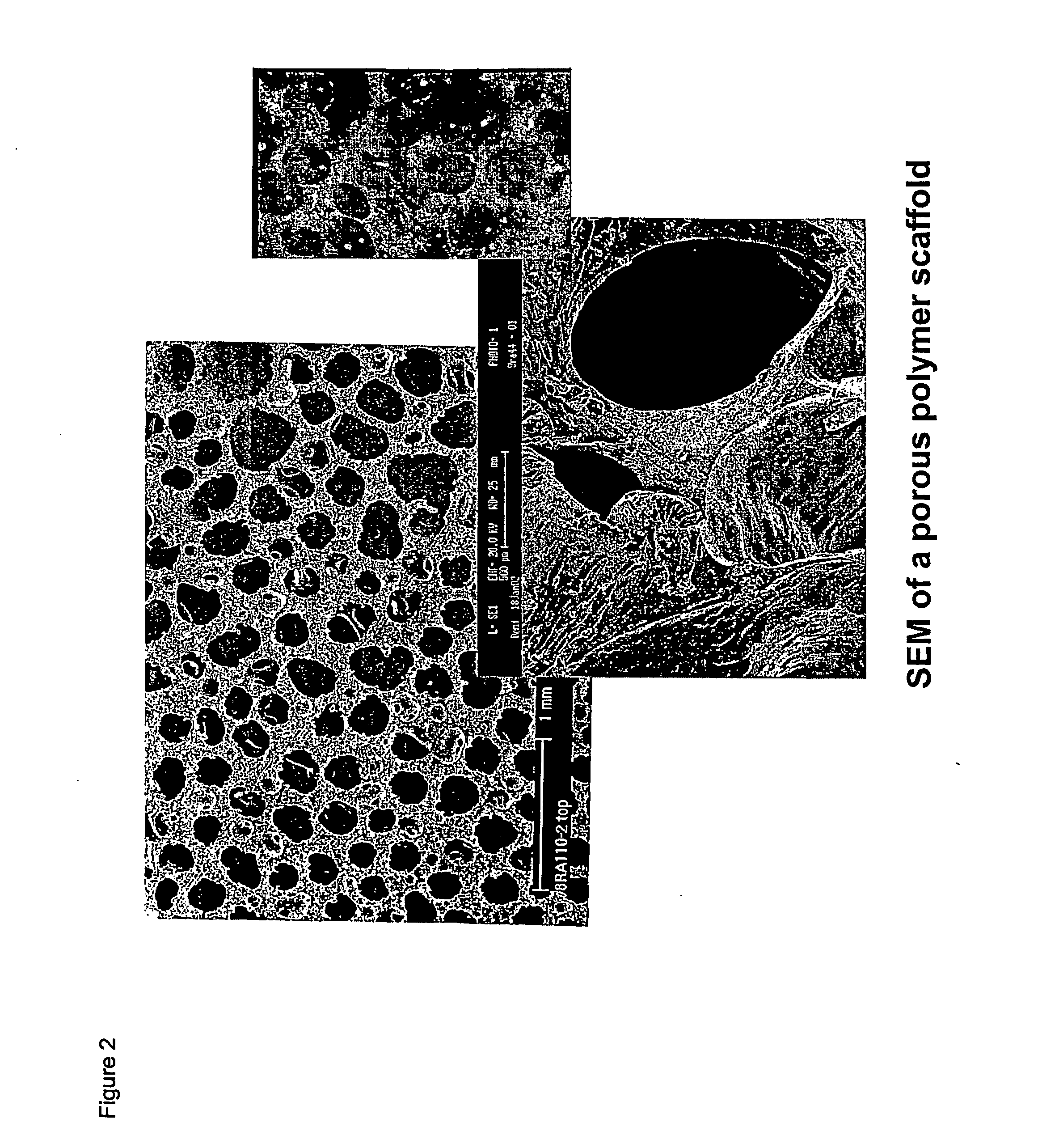

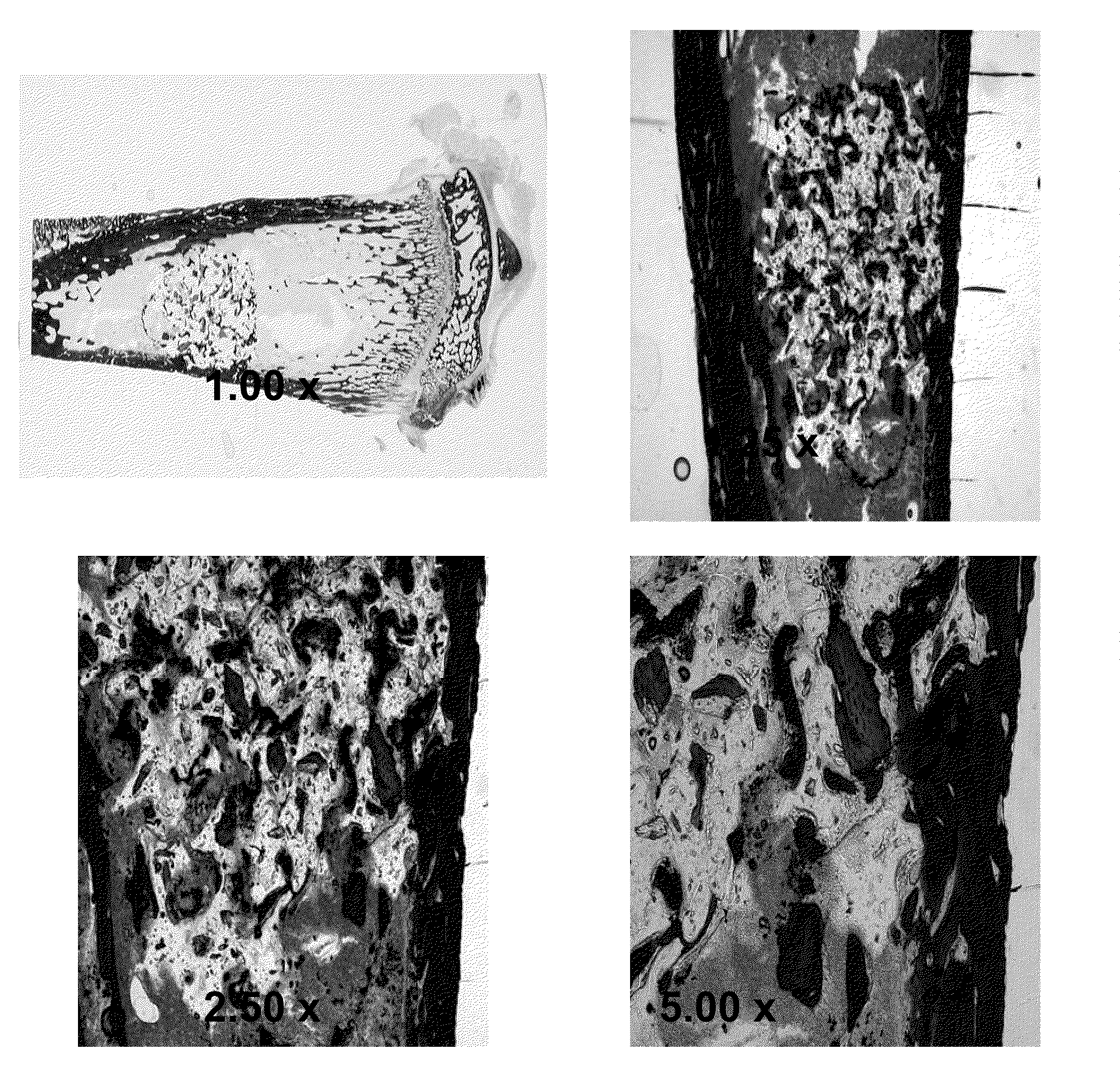

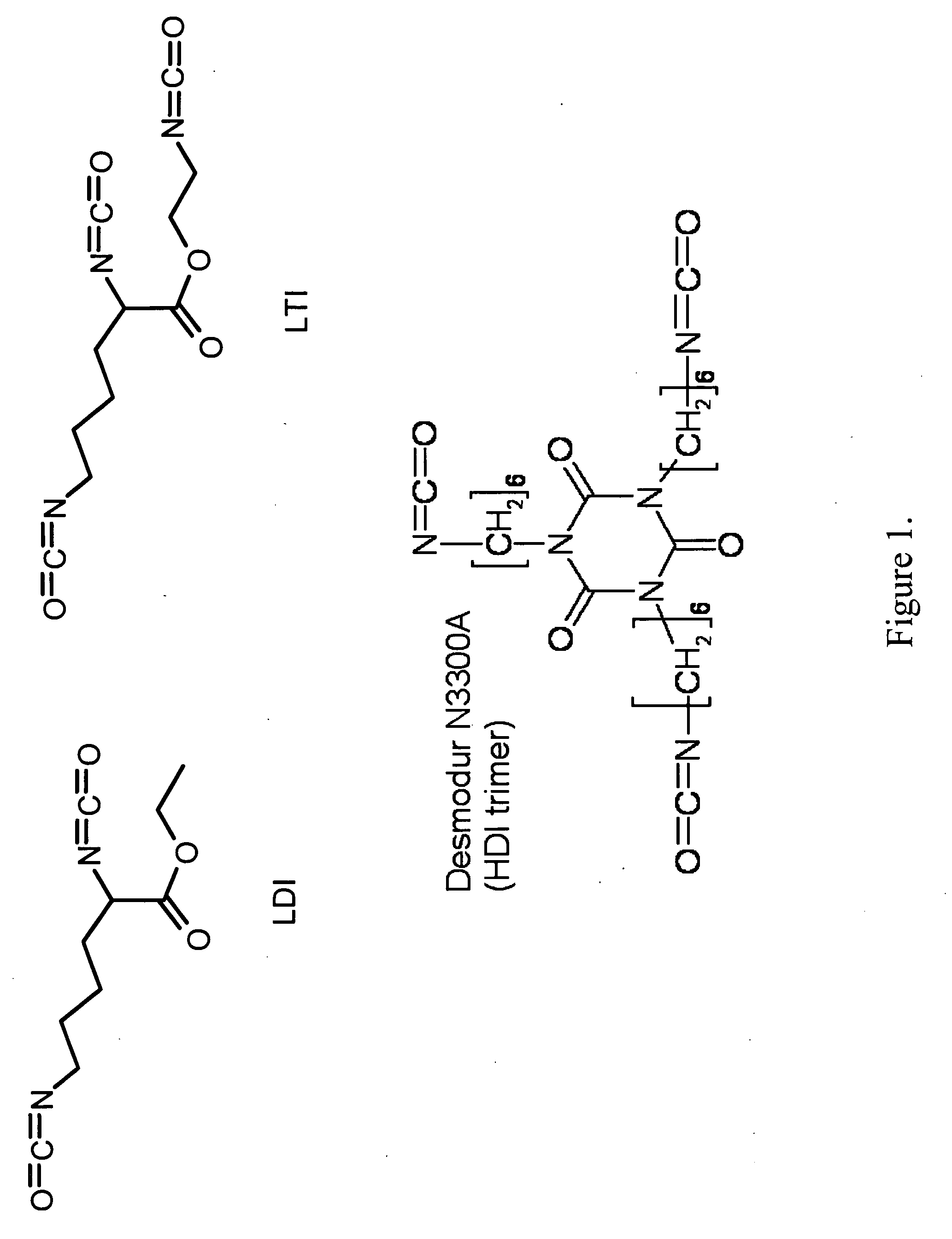

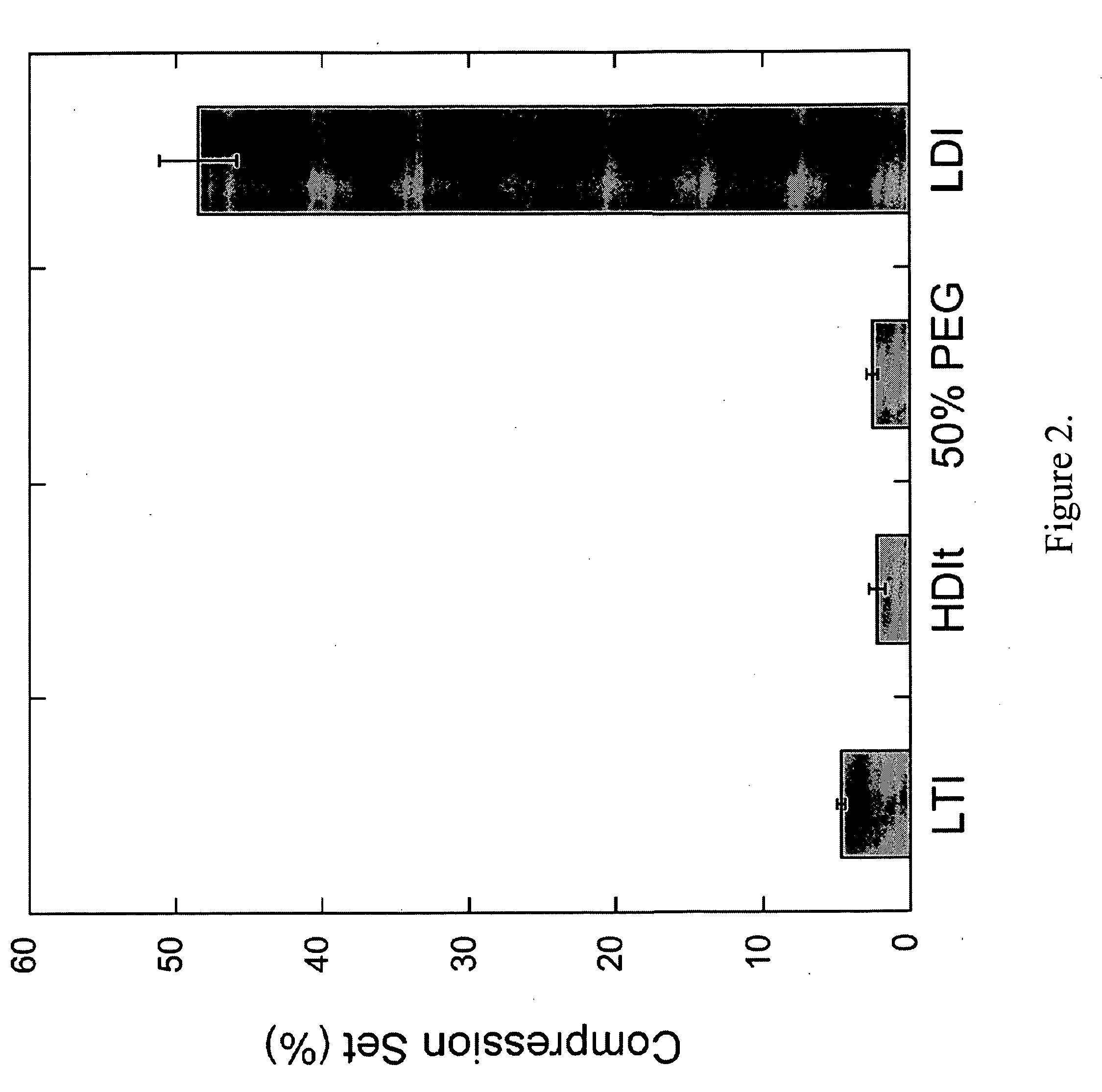

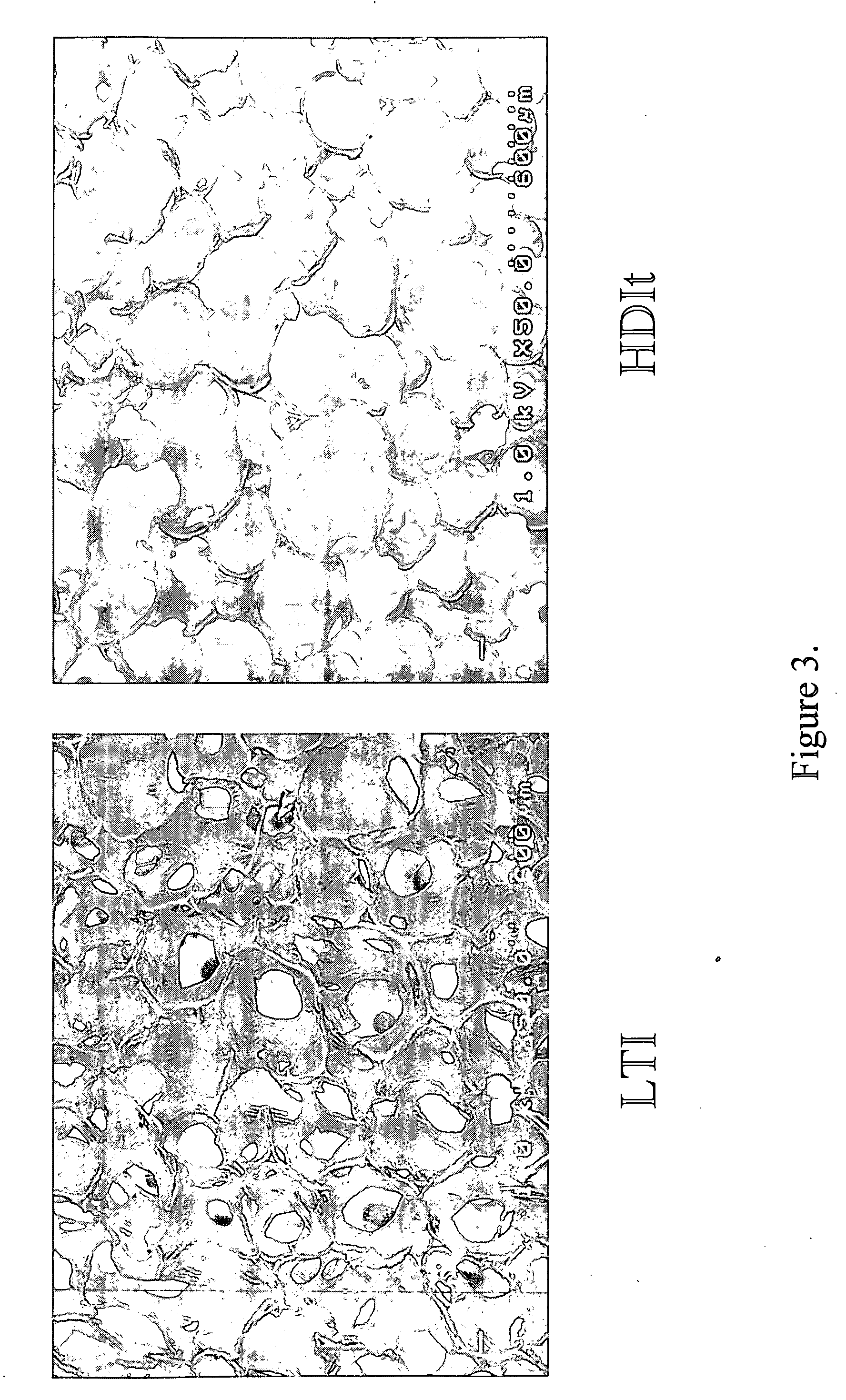

A biodegradable polyurethane scaffold that includes a HDI trimer polyisocyanate and at least one polyol; wherein the density of said scaffold is from about 50 to about 250 kg m−3 and the porosity of the scaffold is greater than about 70 (vol %) and at least 50% of the pores are interconnected with another pore. The scaffolds of the present invention are injectable as polyurethane foams, and are useful in the field of tissue engineering.

Owner:VANDERBILT UNIV

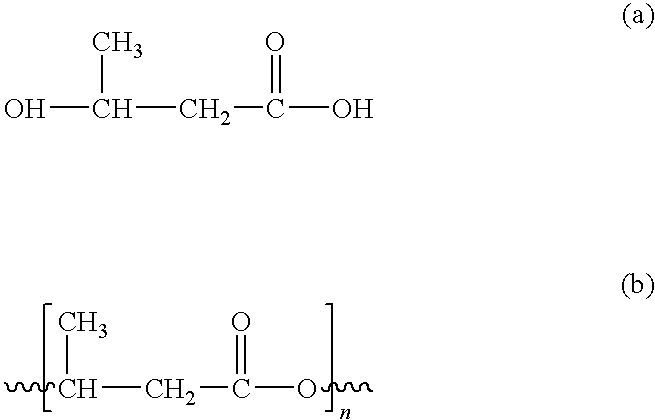

Composition for preparing a biodegradable polyurethane- based foam and a biodegradable polyurethane foam

InactiveUS20090253816A1Simple and fast and inexpensive processingAggressive to environmentPolymer sciencePolyol

Composition for preparing a biodegradable polyurethane-based foam and a biodegradable polyurethane foam, comprising mixtures based on poly(hydroxybutyrate) polymer, polyols of renewable source, isocyanates and additives, with the object of preparing biodegradable polyurethane foams. In the process, the poly(hydroxybutyrate) plus the polyol, the isocyanate and the additives are previously mixed in specific mixers; once the homogenization is reached, the mixture is poured in mold for growing. After curing, the resulting product presents foam characteristics, with its density, toughness and cell size varying according to the proportion of the reagents and allowing the manufacture of several products.

Owner:PHB IND +1

Degradable Polyurethane Foams

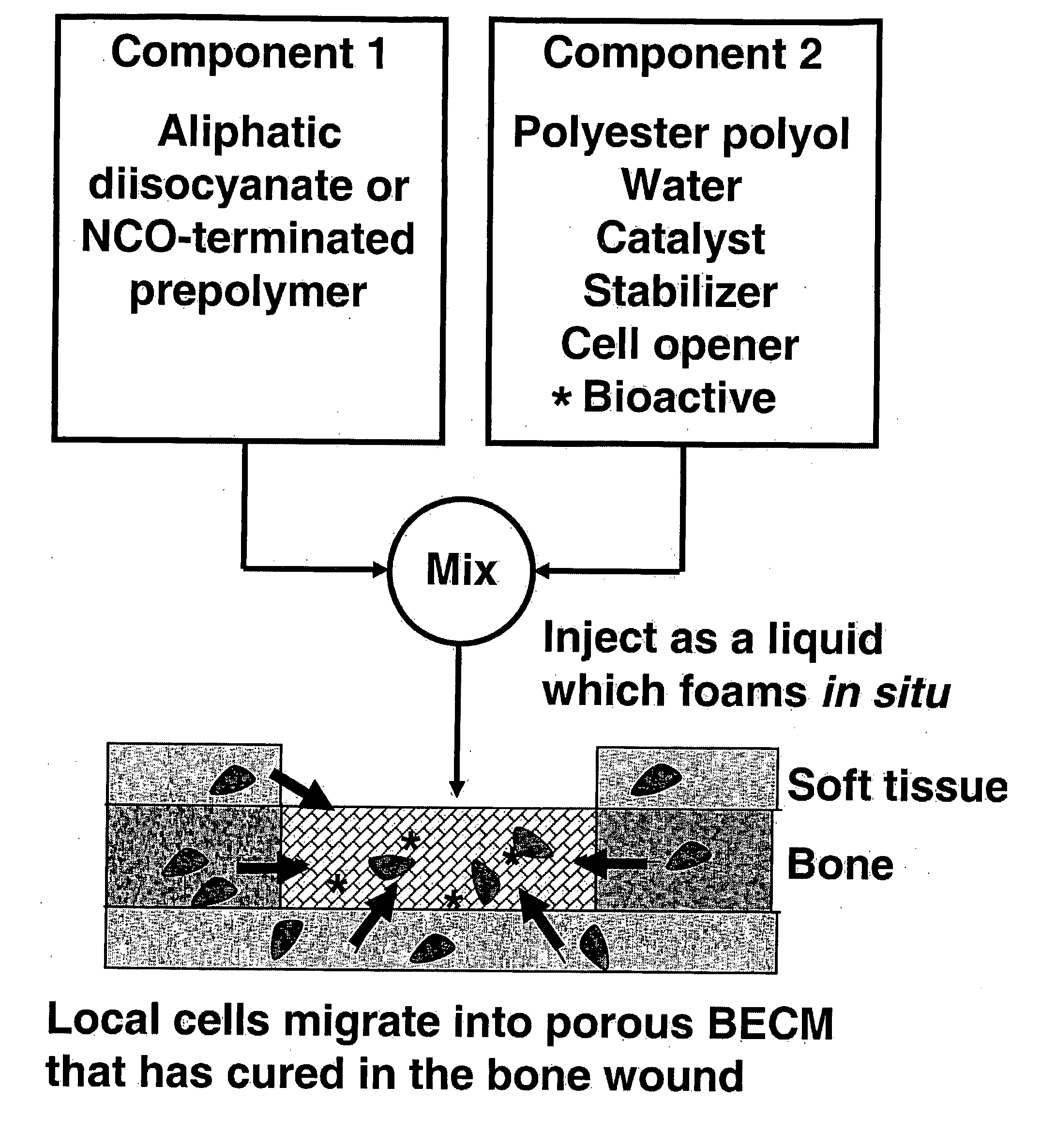

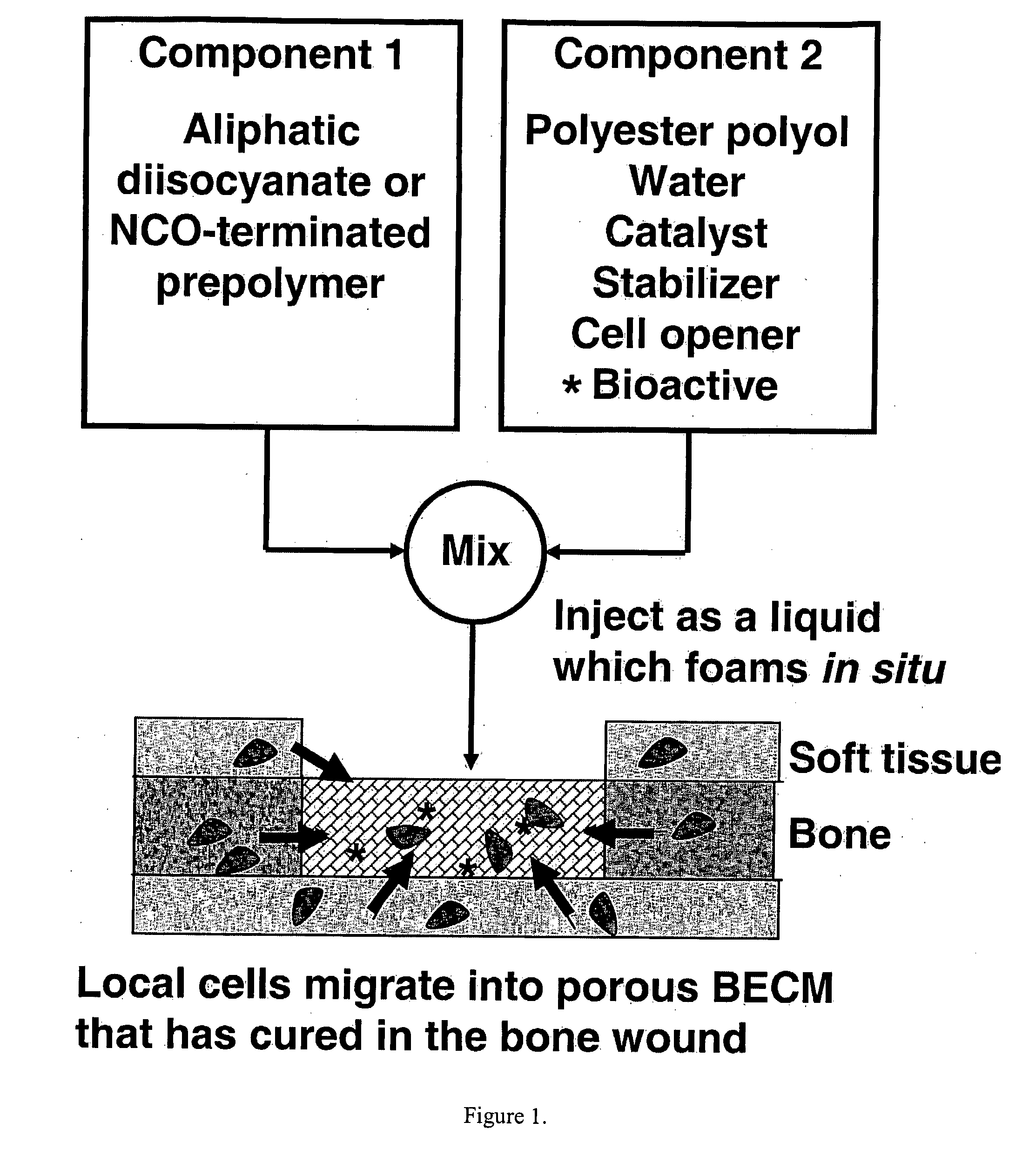

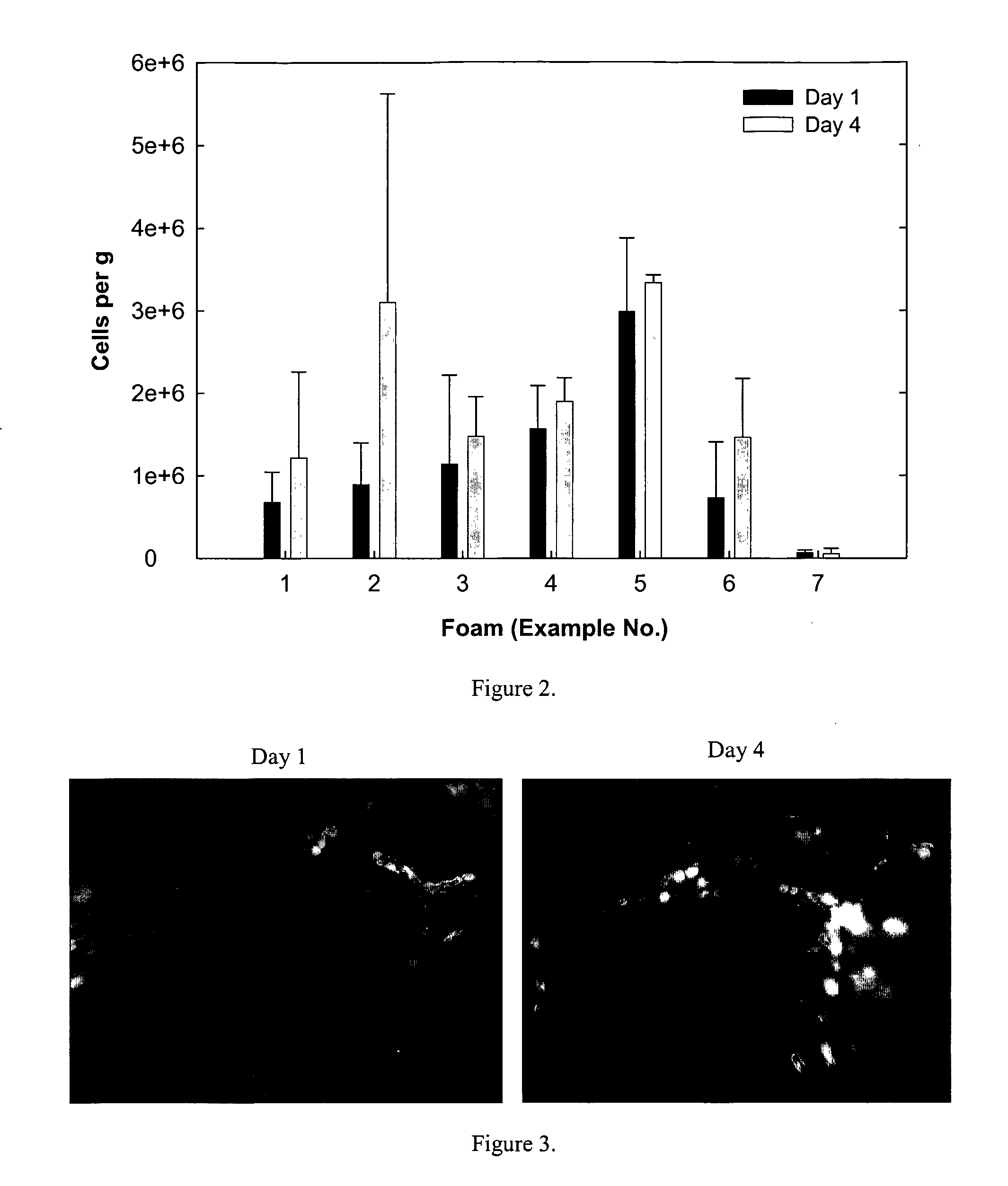

A method of synthesizing of a biocompatible and biodegradable polyurethane foam includes the steps of: mixing at least one biocompatible polyol, water, at least one stabilizer, and at least one cell opener, to form a resin mix; contacting the resin mix with at least one polyisocyanate to form a reactive liquid mixture; and reacting the reactive liquid mixture form a polyurethane foam. The polyurethane foam is preferably biodegradable within a living organism to biocompatible degradation products. At least one biologically active molecule having at least one active hydrogen can be added to form the resin mix.

Owner:CARNEGIE MELLON UNIV +1

Poly (ester urethane) urea foams with enhanced mechanical and biological properties

InactiveUS20090130174A1High porosityPrevent shrinkageBiocidePeptide/protein ingredientsPorosityPolyol

A biodegradable polyurethane scaffold that includes a HDI trimer polyisocyanate and at least one polyol; wherein the density of said scaffold is from about 50 to about 250 kg m-3 and the porosity of the scaffold is greater than about 70 (vol %) and at least 50% of the pores are interconnected with another pore. The scaffolds of the present invention are injectable as polyurethane foams, and are useful in the field of tissue engineering.

Owner:VANDERBILT UNIV

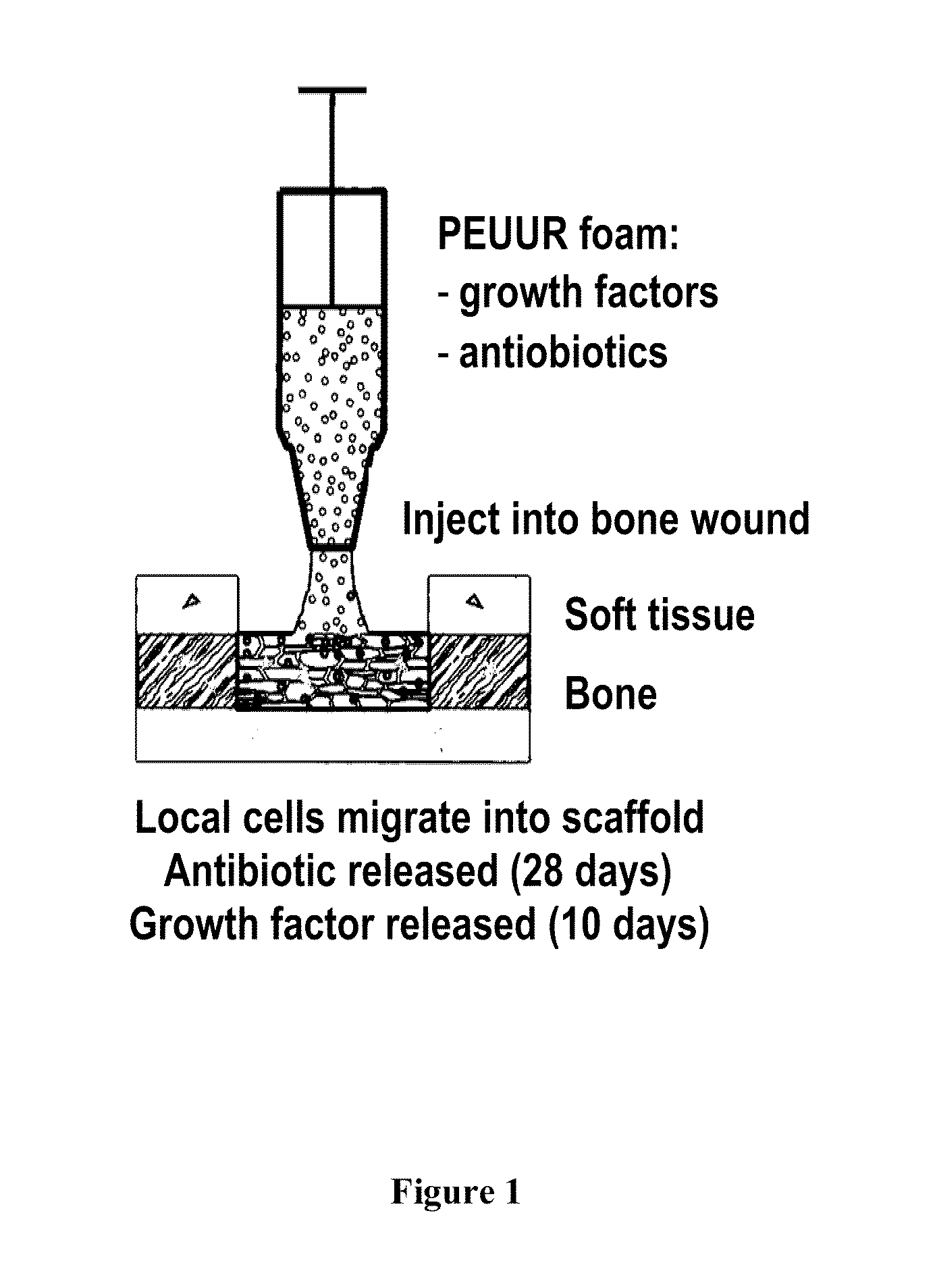

Injectable dual delivery allograph bone/polymer composite for treatment of open fractures

InactiveUS20110236501A1Shorten healing timeHealing is often complicatedBiocidePeptide/protein ingredientsPolyesterPorosity

A biodegradable polyurethane scaffold, comprising at least one polyisocyante, polyisocyanate prepolymer, or both, at least one polyester polyol, at least one catalyst, wherein the density of said scaffold is from about 50 to about 250 kg m-3 and the porosity of the scaffold is greater than about 70 (vol %) and at least 50% of the pores are interconnected with another pore, and wherein the scaffold incorporates at least one biologically active component in powder form.

Owner:VANDERBILT UNIV

Biodegradale polyurethane capsules and manufacturing method thereof

InactiveUS20040084791A1Improve responsePromote decompositionSynthetic resin layered productsCellulosic plastic layered productsCoated surfaceThermal insulation

The present invention relates to biodegradable polyurethane capsules for molded product of polyurethane foam and to methods for manufacturing the same, the inventive biodegradable polyurethane capsule comprises a powder made from a biodegradable material, first coating layer of calcium alginate gel formed on the surface of said power and second coating layer of foamable polyurethane resin formed on the surface of said first coating layer. Products manufactured from the biodegradable polyurethane capsule according to the present invention can be widely used as heat isolating materials and heat isolating structural materials because the basic physical properties such as heat insulation are good. And, since the biodegradable material inside the capsule is decomposed by microbes in the nature after a certain period, the efficiency of destruction is considerably improved, so it is possible to minimize the conventional problems of soil, air, and sea pollution caused by fill-in or incineration of the wastes of polyurethane molded foam product.

Owner:BIOREPLA CORP

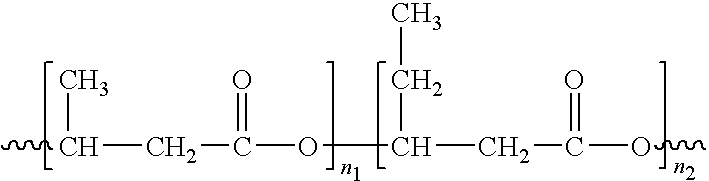

Biodegradable polyurethane material based on piperazine block D, L-polylactic acid and preparation method thereof

The invention relates to a biodegradable polyurethane material based on piperazine block D, L-polylactic acid and a preparation method thereof. The polyurethane material takes piperazine block end hydroxyl D, L-polylactic acid as a prepolymer, is prepared by taking diisocyanate and active double-amine functional group piperazine as a chain extender and belongs to the degradable polyurethane material containing a contain quantity of rapid piperazine rings. The biodegradable polyurethane material based on the piperazine block D, L-polylactic acid is a high polymer material which integrates favorable biocompatibility, biodegradability and high mechanical strength as a whole. The invention can control the material performance by regulating the compositions of the polymer and has wide application potential in the biomedical engineering field.

Owner:CHONGQING UNIV

Method for preparing biodegradable polyurethane rigid foam from bamboo waste liquefaction products

InactiveCN101362818ARealize the purpose of turning waste into treasureReduce dependencePolymer scienceReaction temperature

The invention discloses a method for preparing biodegradable rigid polyurethane foam with liquefaction products of bamboo waste, which comprises the following steps: 1 mass portion of crude glycerin / polyethylene glycol liquefying solvent and 0.02-0.04 mass portion of concentrated sulfuric acid are added into a reaction vessel, heated till the temperature reaches 120-180 DEG C after a reflux condensation tube is connected to the reaction vessel; 0.2-0.5 mass portion of crushed and dried bamboo waste is added, reacted for 90-180min with stirring, taken out and cooled and neutralized by MgO till being neutral; 1 mass portion of liquefaction products of bamboo waste, 0.02-0.08 portion of a dibutyl tin dilaurate / triethylene diamine mixed catalyst, 0.02-0.06 portion of silicone oil, 0.02-0.1 portion of water and 0.1-0.15 portion of fire retardant are added into a container, premixed for 20-30s when stirred at 2,000r / min, added with sufficient PAPI with the molar ratio between isocyanato-NCO in PAPI and hydroxyl group-OH in bamboo waste liquefaction products being 0.6-1.2, stirred for 10s-15s at 1,000r / min, put into a mould, foamed with standing at room temperature, placed for slaking and mould separating at room temperature for 24h-72h after reaction. The method fully utilizes resources, reduces liquefaction cost, and has a mild reaction temperature and stable liquefaction products; the performance of obtained foam meets the national standard and biodegradability.

Owner:NANCHANG UNIV

Low-melting-point biodegradable polyurethane elastomer

The invention provides a low-melting-point biodegradable polyurethane elastomer. The low-melting-point biodegradable polyurethane elastomer is prepared by adopting the following steps of: step one, weighing the following components: 70-100 parts by weight of polyester polyol, 1-10 parts by weight of polyether polyol and 20-90 parts by weight of diisocyanate; step two, heating and fusing the polyester polyol and the polyether polyol to obtain a fused mixture; step three, fully drying the fused mixture, and adding a catalyst and the diisocyanate for reaction; step four, adding a chain extender, and continuously reacting to obtain the low-melting-point biodegradable polyurethane elastomer. The biodegradable polyurethane elastomer provided by the invention has excellent mechanical property, the temperature of fusion processing is reduced, meanwhile, the relatively fast crystallization speed of the low-melting-point biodegradable polyurethane elastomer is maintained, so that the blending modification processing is facilitated, and therefore, the polyurethane elastomer material provided by the invention is suitable for the modification of biodegradable high polymer materials.

Owner:南通华盛高聚物科技股份有限公司

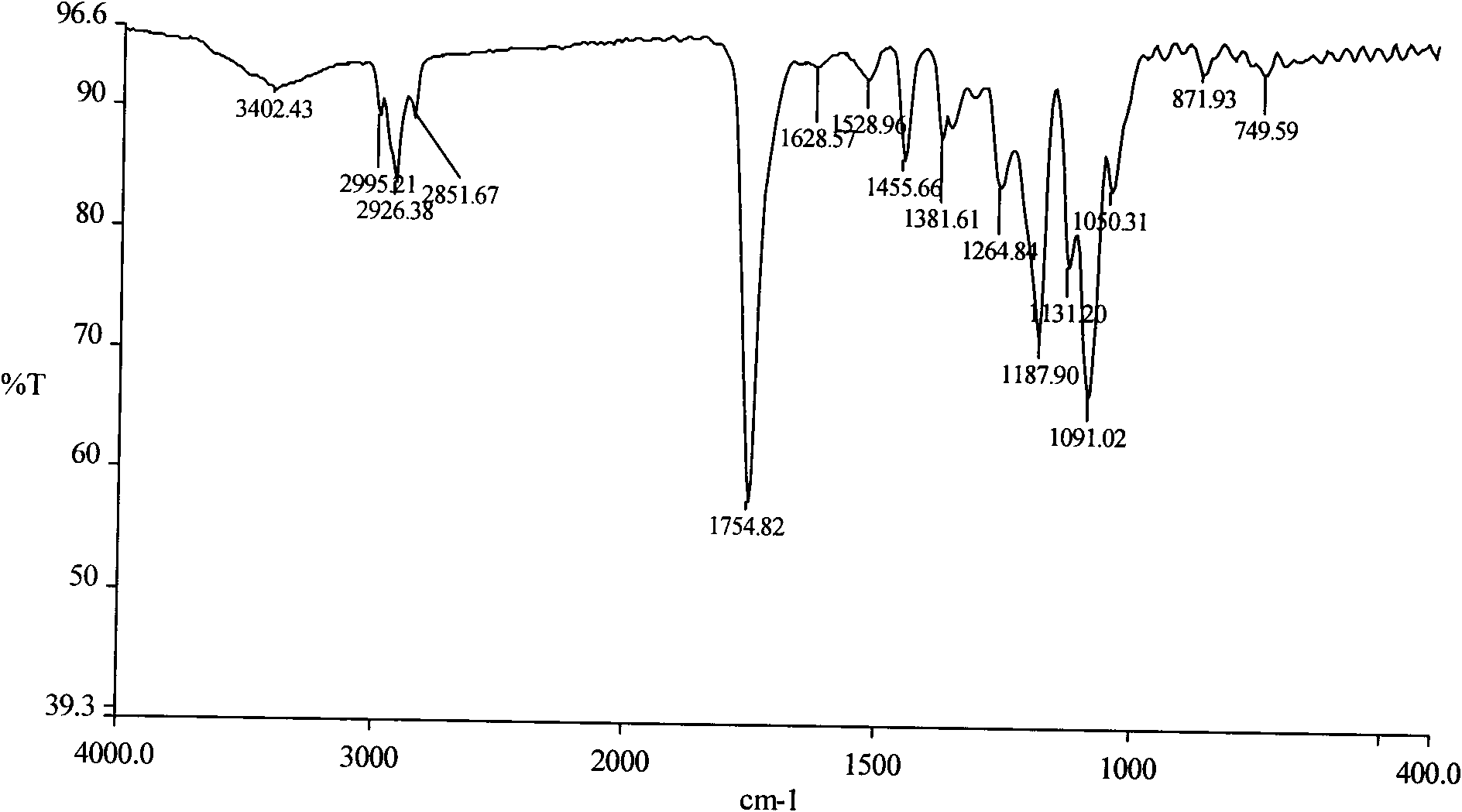

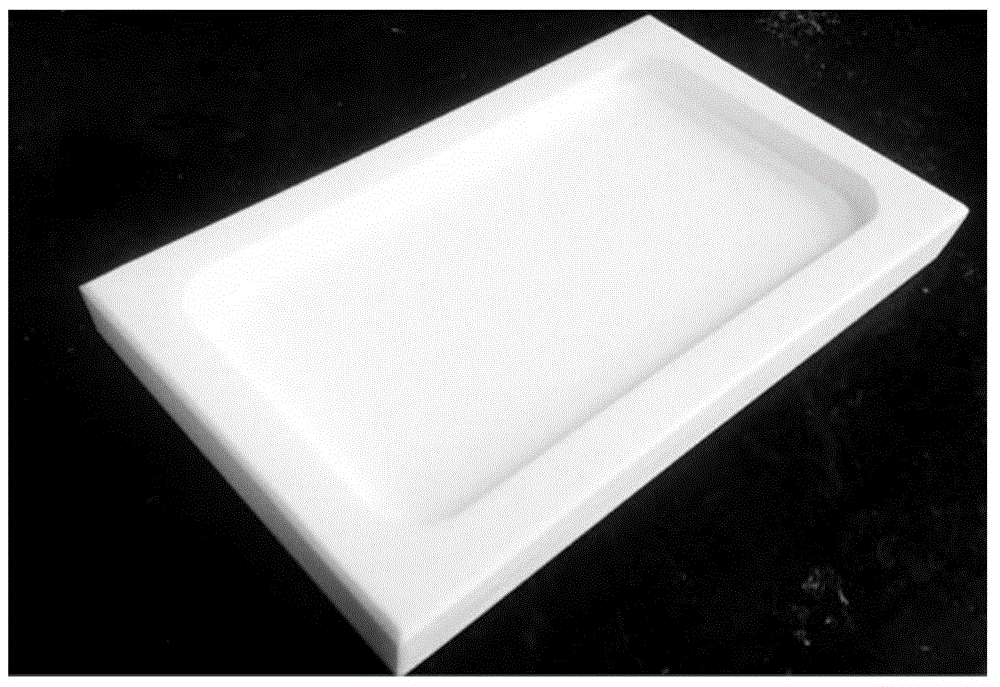

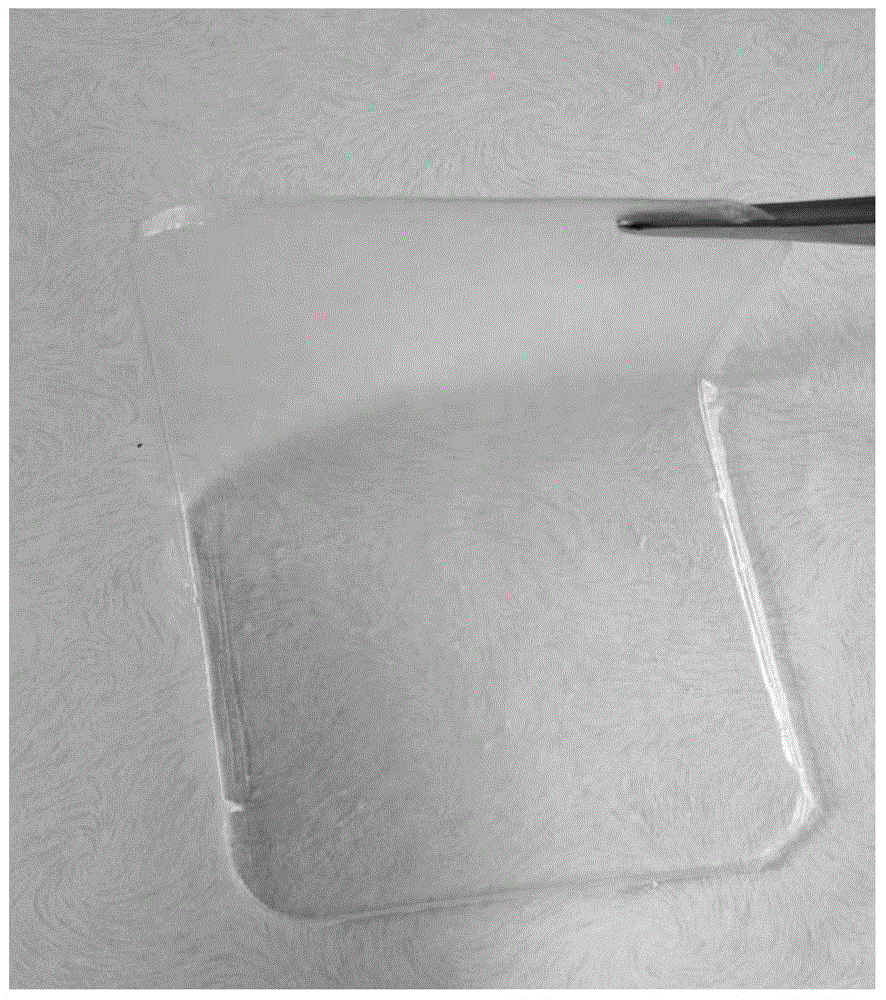

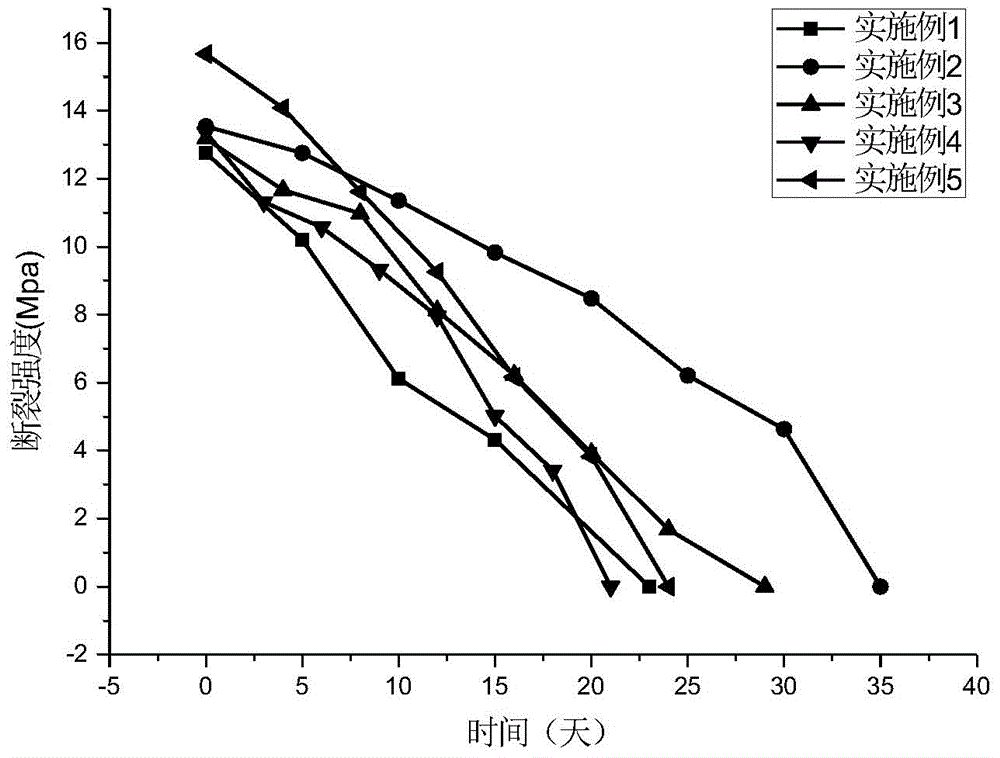

Preparation method of biodegradable polyurethane film material

ActiveCN104788695AEasy to controlEasy to operateSurgeryPharmaceutical non-active ingredientsBreaking strengthPolymer science

The invention relates to a preparation method of a biodegradable polyurethane film material. The preparation method comprises the following steps: (1) synthesizing a dihydroxyl-terminated prepolymer: mixing cyclic lactide or cyclic lactone or a mixture of the two with an initiator and a catalyst, performing vacuum ring-opening reaction on the cyclic lactide or the cyclic lactone, and then performing polymerization reaction on a system to prepare the dihydroxyl-terminated prepolymer; (2) synthesizing a diisocyanate-terminated prepolymer: dropping the dihydroxyl-terminated prepolymer into excess diisocyanate, and performing reaction to remove excess diisocyanate to obtain the diisocyanate-terminated prepolymer; (3) preparing polyurethane: dissolving a chain extender in a solvent, then dropping into the dihydroxyl-terminated prepolymer and performing reaction to obtain a polyurethane material; and (4) preparing the film material. The film has uniform thickness distribution and high tensile strength and elongation at break, wherein the elongation at break of the film is more than 1000%, and the breaking strength is more than 10MPa. The film material can ensure that the film is not broken under high-strength motion of an organ performing continuous motion of a human body.

Owner:南通药享科技有限公司

Method for preparing biodegradable polyurethane foam by liquefied modification of bark powder and lignin

InactiveCN102675581AIncrease the phenolic hydroxyl contentIncrease responsivenessApparent densityPolymer science

The invention relates to a method for preparing biodegradable polyurethane foam by liquefied modification of bark powder and lignin. The method comprises the following steps: 1. adding phenol into alkaline solution, heating, then adding larch bark powder and the lignin, stirring evenly, carrying out reaction adequately, and cooling for use; 2. heating liquefied product, adding formaldehyde and catalyst to obtain methylolated lignin, phenolic hydroxyl lignin and methylolated tannin; 3. mixing above modified product, polyether, a foam homogenizing agent and catalyst according to a certain proportion, and mixing with isocyanate for foaming. The rigid foam material foamed by mixing, provided by the invention, has an apparent density of 0.03-0.05g / cm<3>, compressive strength greater than 0.15MP, thermal conductivity of 0.023W / (M.K), and water absorption of 3%. The method provided by the invention can improve the utilization of lignin, save resources, does not cause environmental pollution, and is high in production efficiency. The foam is good in lame retardant property.

Owner:BEIHUA UNIV

Biodegradable polyurethane and polyurethane ureas

ActiveUS20070275033A9Easily degradableEasily degradable hard segmentOrganic active ingredientsSurgeryPolyolInsertion stent

This invention relates to biocompatible, biodegradable thermoplastic polyurethane or polyurethane / ureas comprising isocyanate, polyol and a conventional chain extender and / or a chain extender having a hydrolysable linking group and their use in tissue engineering and repair applications, particularly as stents and stent coating.

Owner:POLYNOVO BIOMATERIALS PTY LTD

Preparation method of natural macromolecular modified thermoplastic polyurethane elastomer

InactiveCN102911335AGood biocompatibilityAdapt to the needs of different usesPolymer sciencePolyethylene glycol

The invention discloses a preparation method of natural macromolecular modified thermoplastic polyurethane elastomer. The preparation method comprises the following steps of: (1) heating polycaprolactone glycol and polyethylene glycol in a proportion to react, dropwise adding a titanate or organic tin catalyst under a nitrogen environment, then adding diisocyanate and heating to react so as to obtain polyurethane prepolymer; (2) adding a natural macromolecular substance, stirring and dissolving; (3) heating under protection of nitrogen, dropwise adding a divalent alcohol chain extender and preserving heat for a period of time; and (4) adjusting temperature, then taking the substance in the reactor out, and drying in a vacuum drying box to obtain the natural macromolecular modified thermoplastic polyurethane elastomer. According to the preparation method, fully biodegradable polymer is used as a polybasic alcohol component of polyurethane and reacts with the diisocyanate to synthesize non-toxic, safe, biologically absorbable and biodegradable polyurethane elastomer; and the polyurethane elastomer is mixed with biomacromolecules, so that better biocompatibility is realized.

Owner:奥斯汀新材料(张家港)有限公司

Biodegradable polyurethane oil-absorbing material and preparation method thereof

The invention discloses a biodegradable polyurethane oil-absorbing material. The oil-absorbing material is prepared from raw materials comprising biodegradable oligomer polyol with hydroxyl value of 200-400 mgKOH / g, diisocyanate, polyether polysiloxane dihydric alcohol, a catalyst, a foam stabilizing agent and a foaming agent through a polymerization reaction. The oil-absorbing material has density of 30-100Kg / m<3> and diesel absorption ratio of 50-100 times. The biodegradable polyurethane oil-absorbing material has advantages of biodegradability, no toxicity, no pollution, low cost, and capability of on-site foam. As an ecological polyurethane oil-absorbing material, it can be used for adsorption of water surface spill oil, and is especially suitable for emergency treatment of surface oil spill for river and lake water.

Owner:江苏瑞丰科技实业有限公司

Composition for preparing a biodegradable polyurethane- based foam and a biodegradable polyurethane foam

Composition for preparing a biodegradable polyurethane- based foam and a biodegradable polyurethane foam, comprising mixtures based on poly(hydroxybutyrate) polymer, polyols of renewable source, isocyanates and additives, with the object of preparing biodegradable polyurethane foams. In the process, the poly(hydroxybutyrate) plus the polyol, the isocyanate and the additives are previously mixed in specific mixers; once the homogenization is reached, the mixture is poured in mold for growing. After curing, the resulting product presents foam characteristics, with its density, toughness and cell size varying according to the proportion of the reagents and allowing the manufacture of several products.

Owner:PHB IND +1

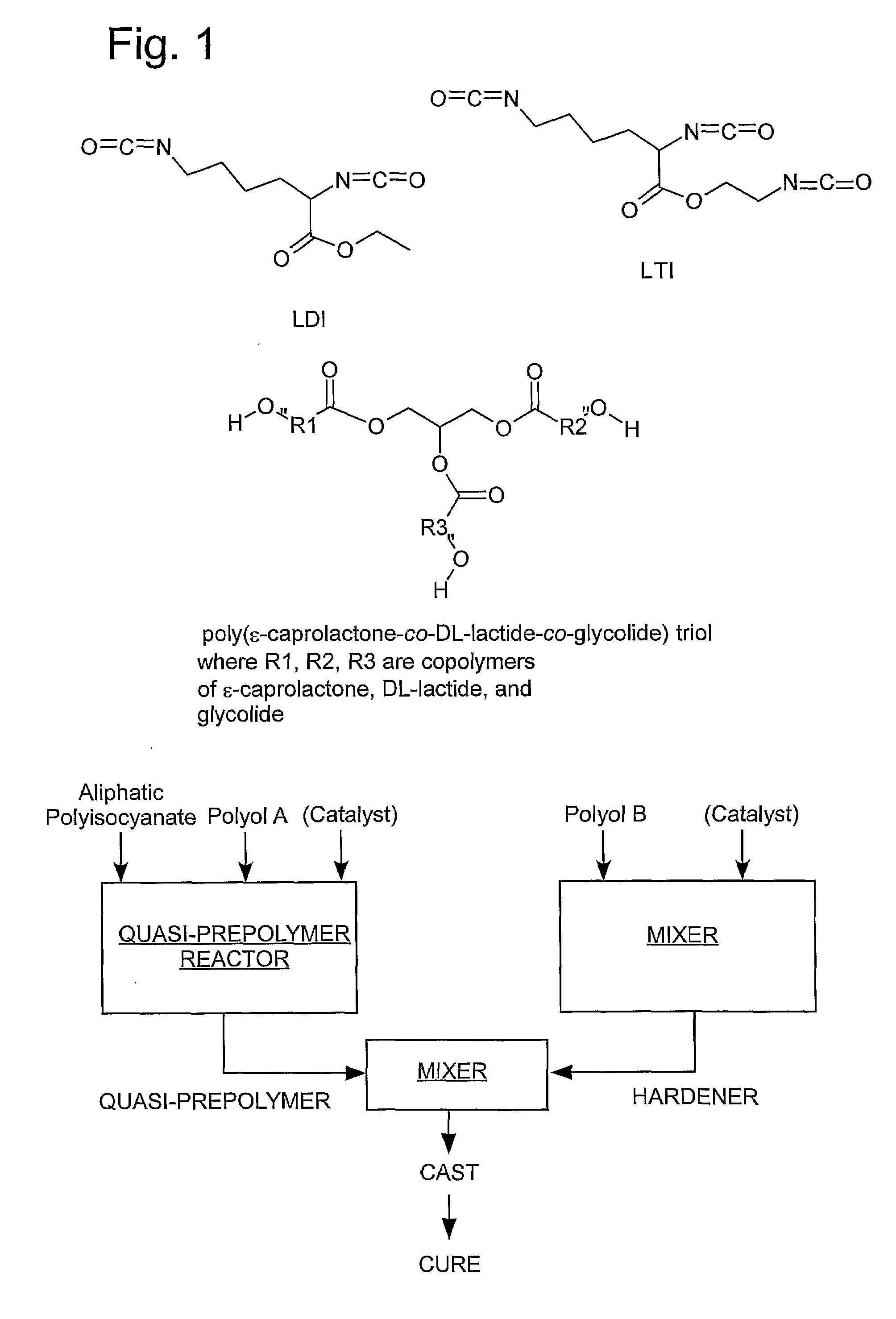

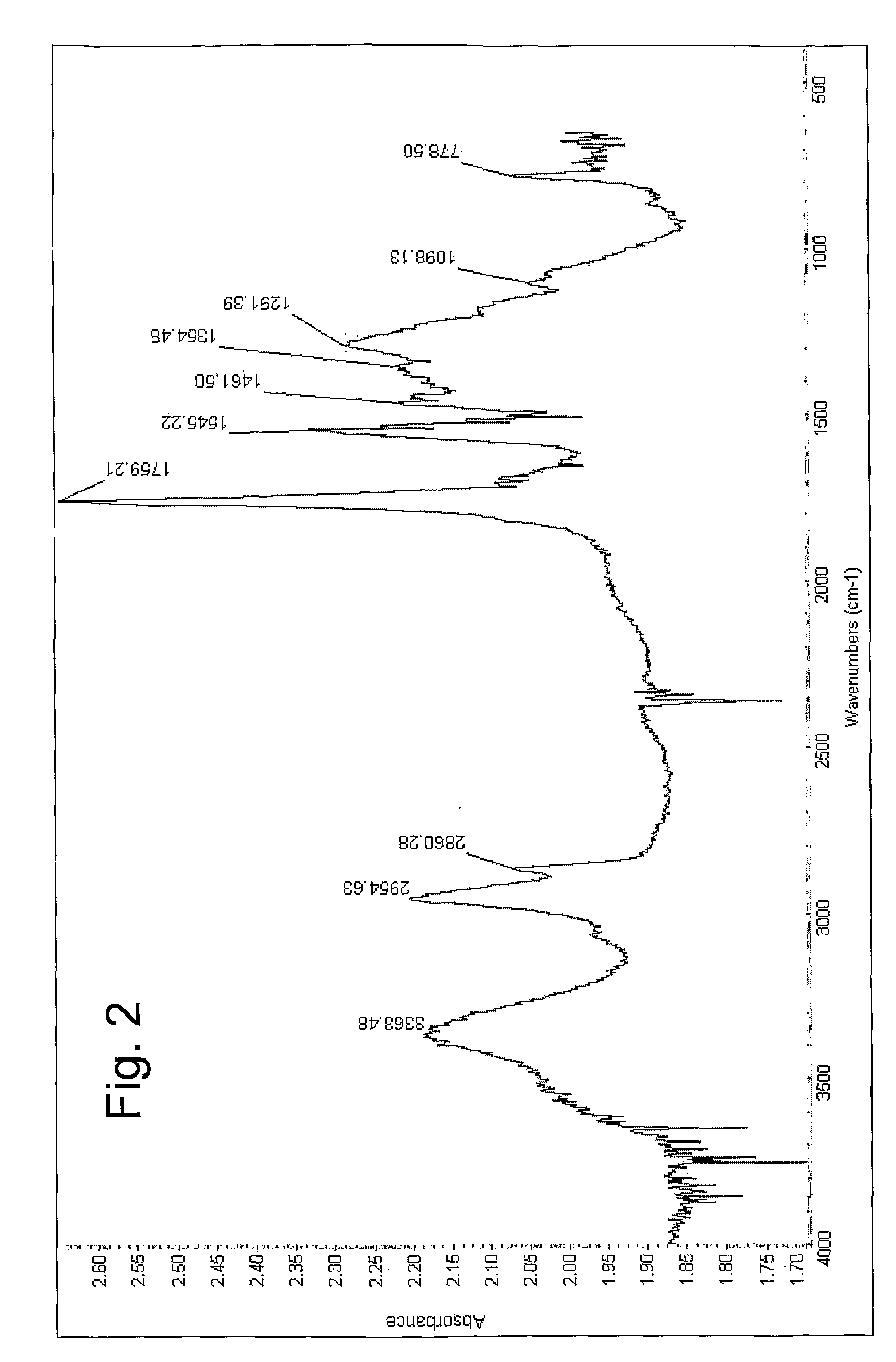

Biodegradable polyurethanes

A method for preparing biodegradable polyurethanes includes contacting a flowable quasi-pre-polymer including free aliphatic polyisocyanate compounds with a polyester polyol hardener having a functionality of at least two to form a reactive liquid mixture. The quasi-prepolymer can, for example, be formed by contacting a polyisocyanate component comprising at least one aliphatic polyisocyanate compound with a polyol component comprising at least one polyol compound to form an adduct of the polyisocyanate component and the polyol component wherein a sufficient excess of the polyisocyanate component is used to form the quasi-prepolymer.

Owner:WARSAW ORTHOPEDIC INC +1

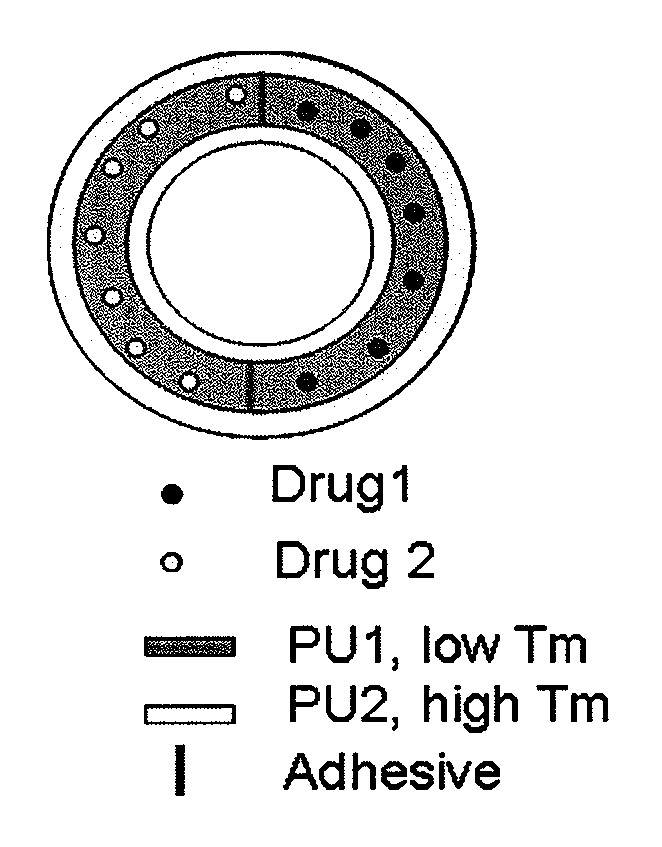

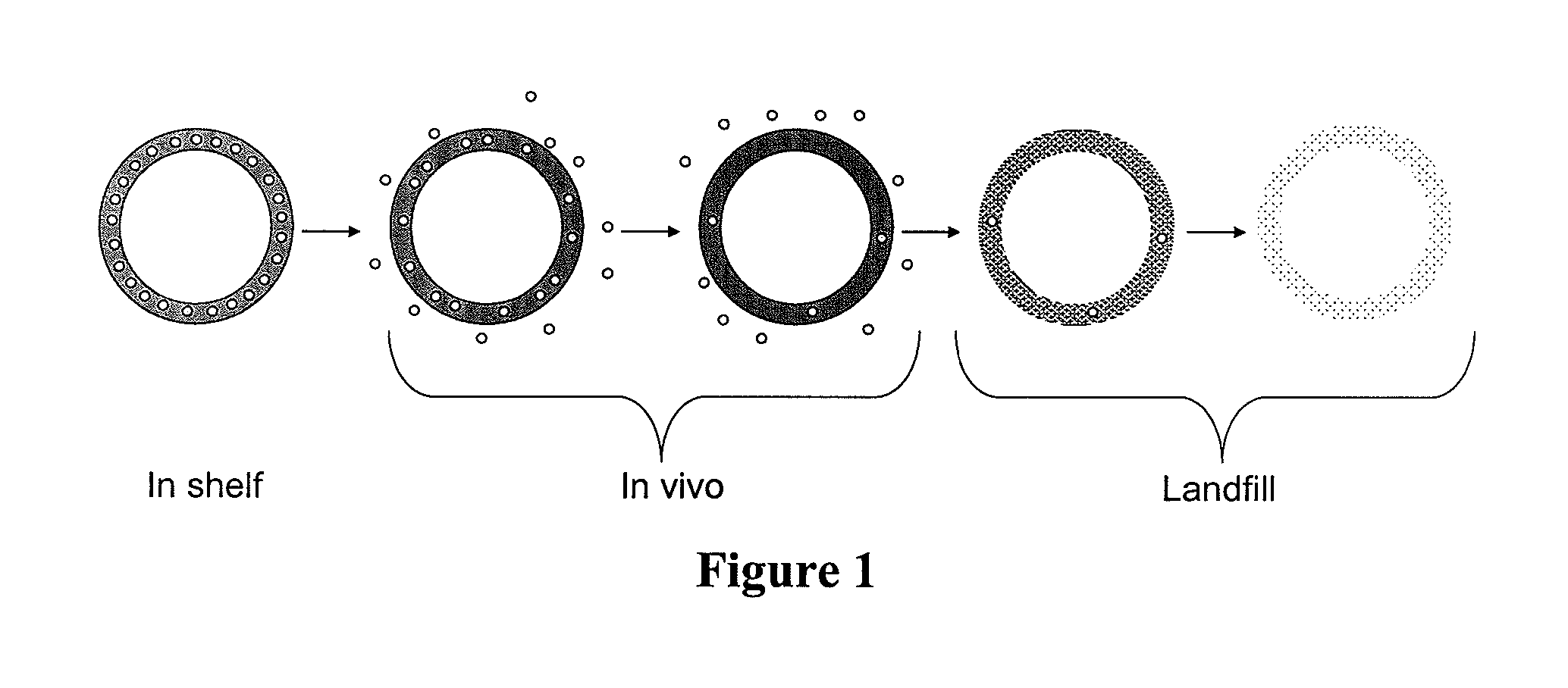

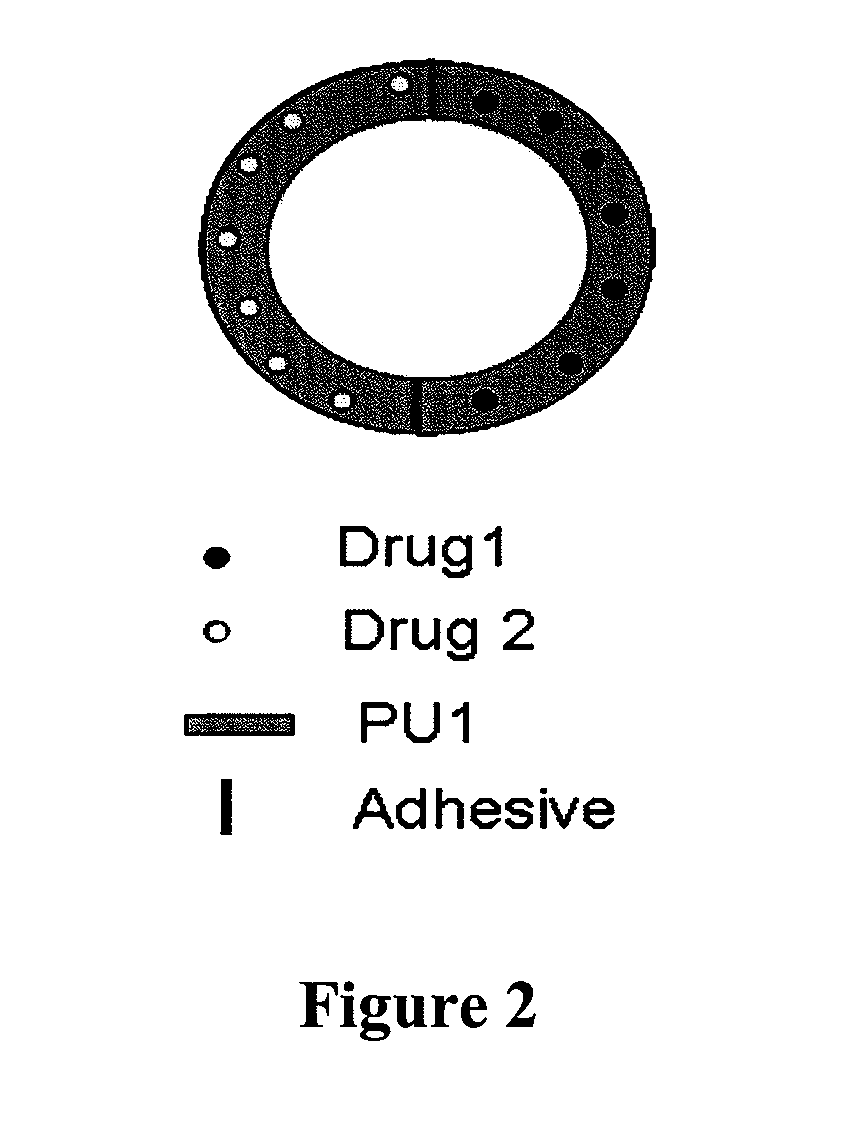

Biodegradable intravaginal devices for delivery of therapeutics

Owner:UNIV OF UTAH RES FOUND +1

Biodegradable high polymer marine antifouling material as well as preparation and application thereof

ActiveCN107163224AAdjusting the self-polishing rateEffective control of crystallinityAntifouling/underwater paintsPaints with biocidesPolymer scienceSolvent

The invention belongs to the technical field of marine antifouling materials and discloses a biodegradable high polymer marine antifouling material as well as preparation and application thereof. The method comprises the following steps: (1) preparing polyurethane, namely dehydrating controllable degradation polyhydric alcohols so as to obtain a dehydration product; adding a solvent and diisocyanate into the dehydration product for reacting under the inert gases and stirring conditions, adding a chain extender and a catalyst to continue reacting so as to obtain a solution containing main-chain biodegradable polyurethane; and (2) adding a metallic compound, a hydrolytic monomer and a solvent into the solution, reacting at the temperature of 80-140 DEG C, thereby obtaining the biodegradable high polymer marine antifouling material. The material disclosed by the invention has excellent surface self-updating property and mechanical property and can keep high self-updating rate under static or low-navigational speed conditions; and the material is a green and environment-friendly antifouling material and is used for preparing a marine antifouling coating. The method disclosed by the invention is simple, low in cost and suitable for industrialized production.

Owner:SOUTH CHINA UNIV OF TECH

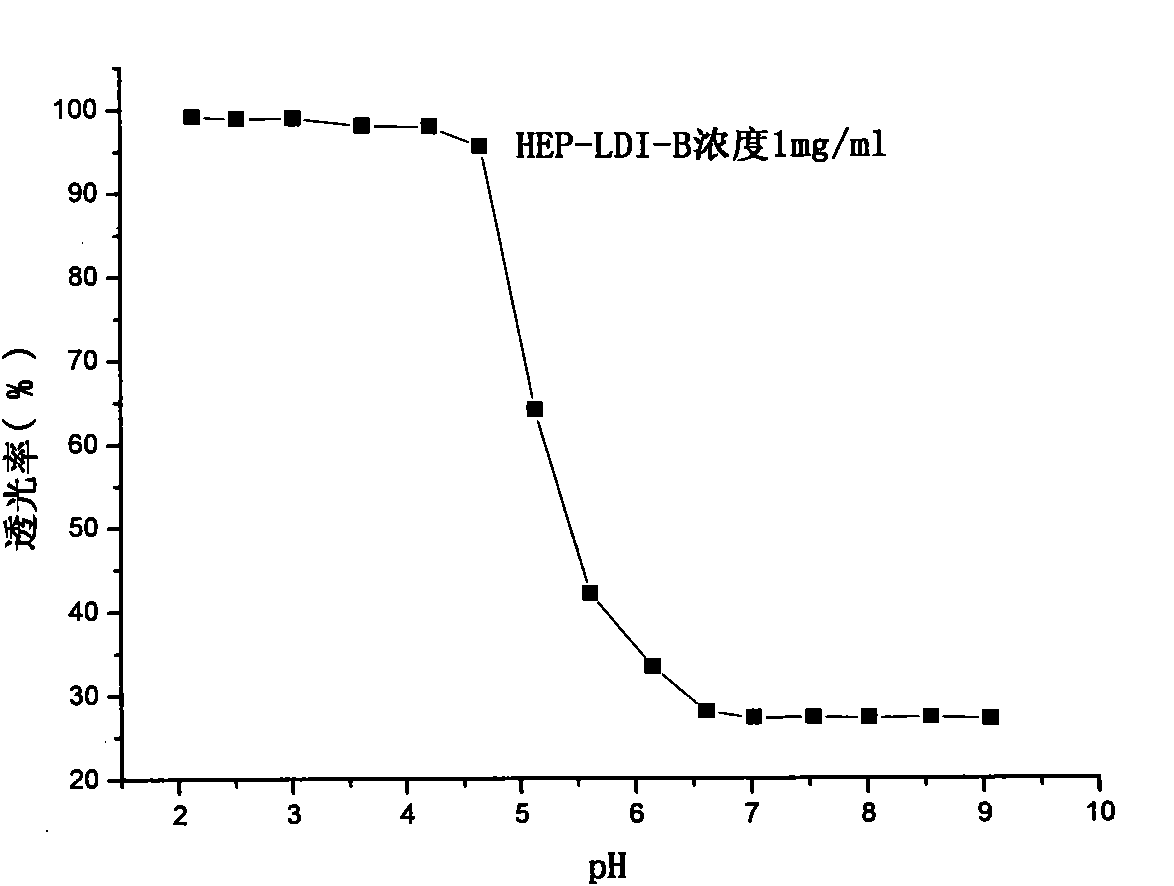

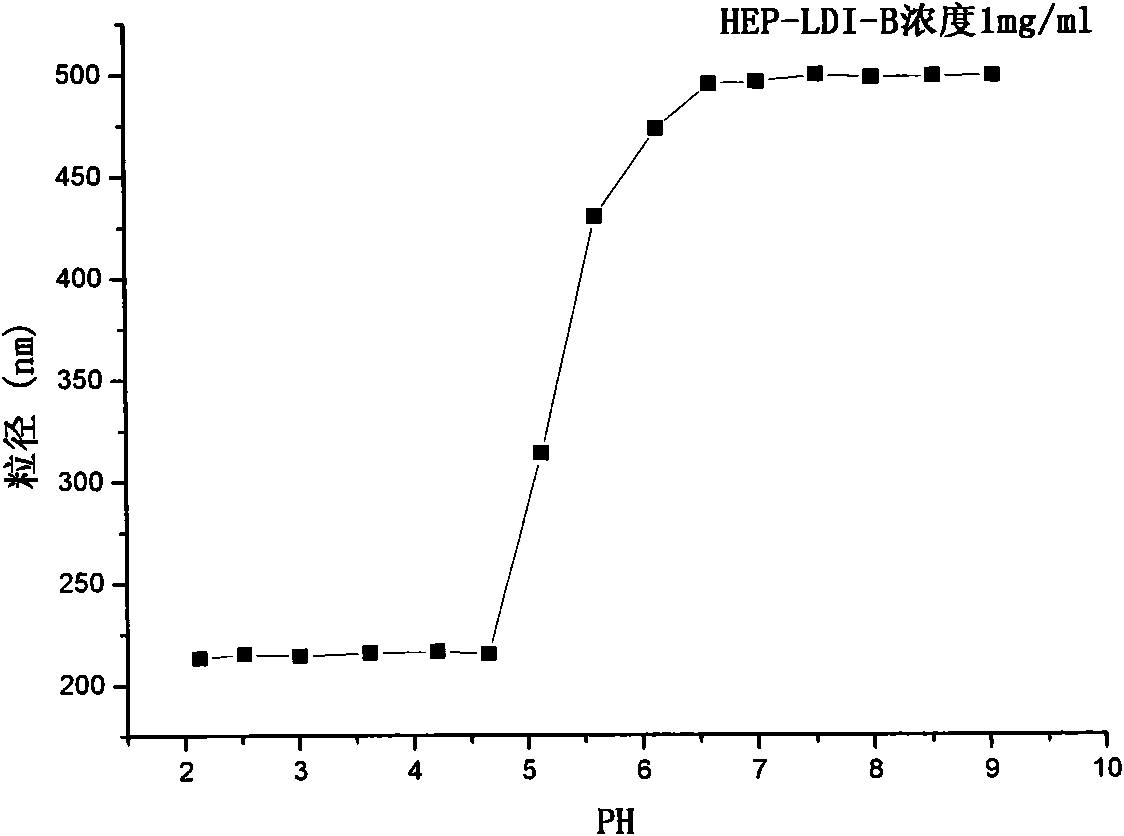

Method for preparing biodegradable polyurethane material with pH responsiveness

InactiveCN102030882APH sensitiveEasy Macromolecular ModificationPharmaceutical non-active ingredientsBlock structureRaw material

The invention discloses a method for preparing a biodegradable polyurethane material with pH responsiveness. Diisocyanate compounds and amino derivatives of polyhydroxyl compounds or amino derivatives of polyhydroxyl polymers serve as raw materials, and a conventional in-situ reaction method in solution polymerization is adopted to prepare the material in the presence of a catalyst. The invention has the advantages that: the preparation method is simple, is easy to operate and is suitable for industrial production, the raw materials are readily available, and the product efficiency is high; the prepared multi-block polyurethane material has a special characteristic of pH sensitivity, can be assembled into the needed structure and shape, has an alternating block structure and a plurality of reactivity points, is easily subjected to macromolecular modification, and is introduced with functional groups to realize structural and functional diversity. For instance, the material is combined with targeting molecules in the field of medicines to serve as a targeted release carrier material and the like; meanwhile, the material has biodegradability, meets the environmentally-friendly requirement of society, and can be widely applied to the fields of materials science, biology, medical science and the like.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

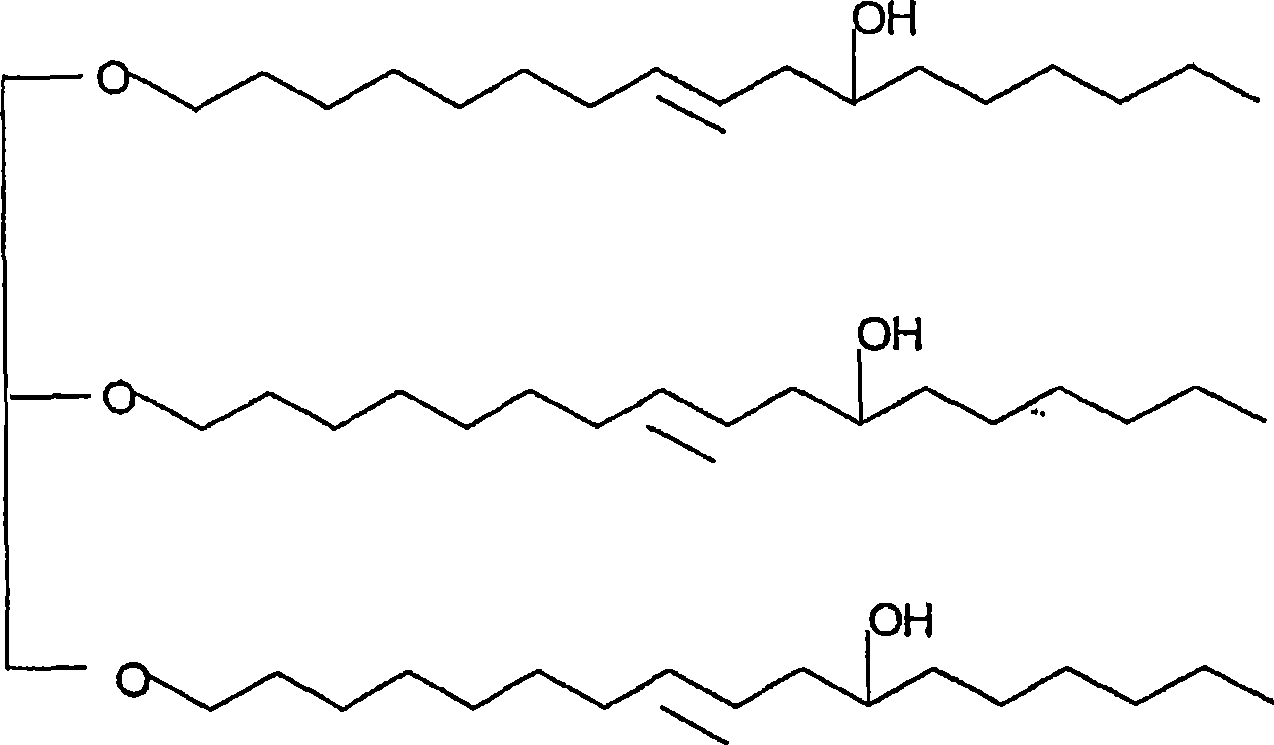

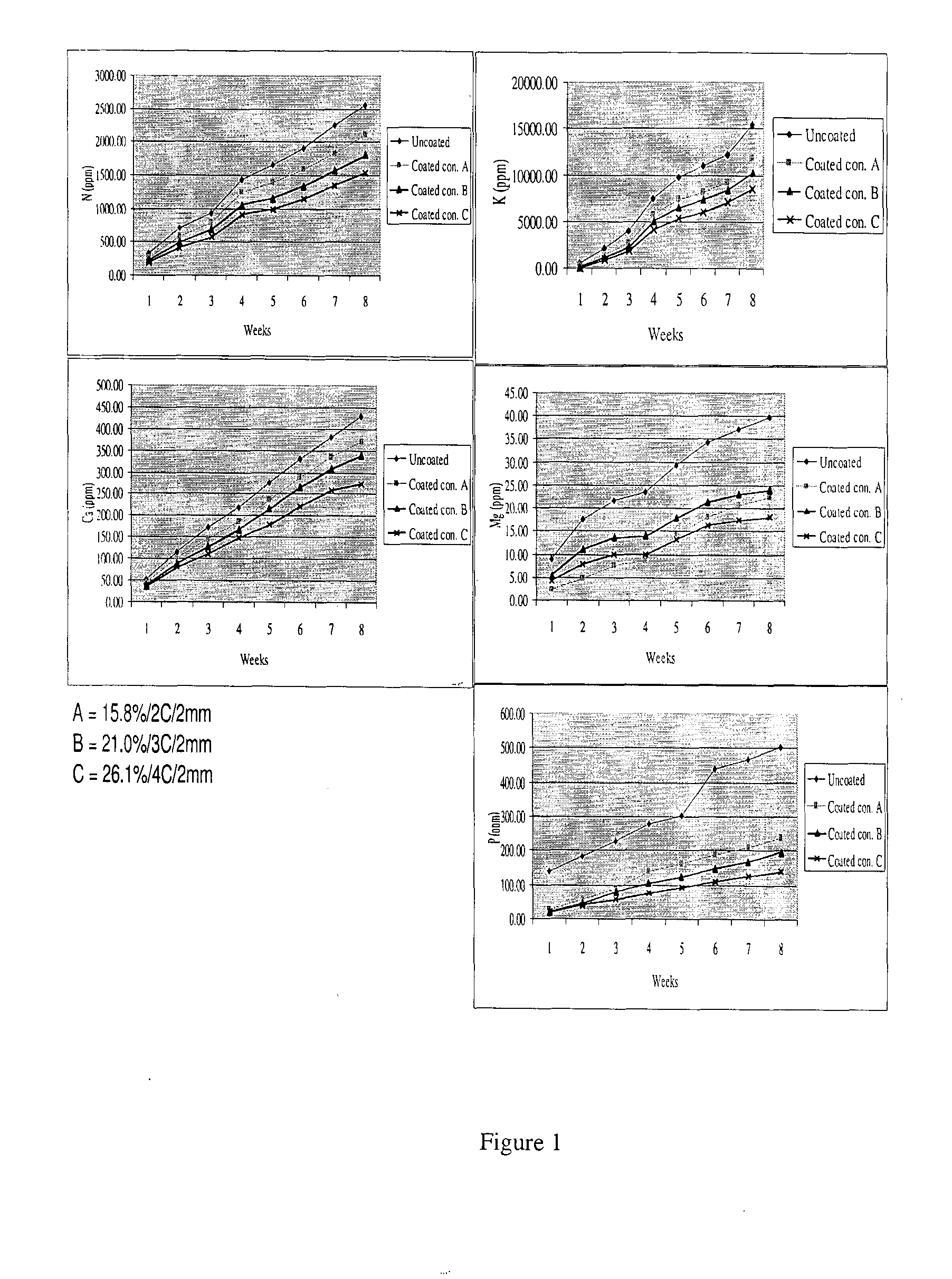

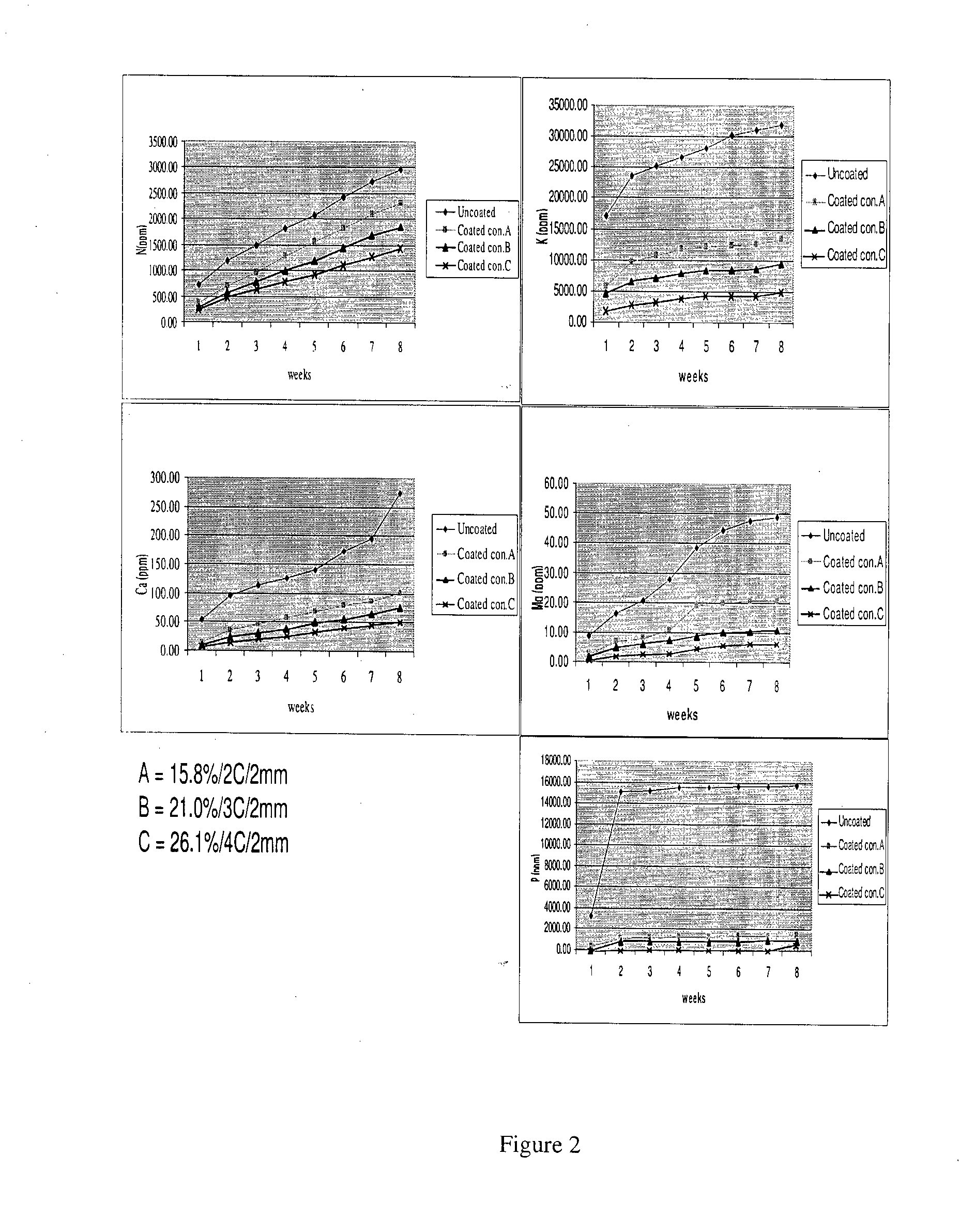

Controlled-Release Fertilizer

InactiveUS20140290319A1Increase resistanceEfficient releaseOrganic fertilisersLayered/coated fertilisersPolyolControl release

A controlled-release fertilizer comprising fertilizer particles encapsulated in a biodegradable polyurethane obtained from a reaction between a polyisocyanate and an isocyanate-reactive component, which is formed by a polyol and a methyl ester derivative of a natural oil, in the presence of an amine catalyst.

Owner:MALASIAN PALM OIL BOARD

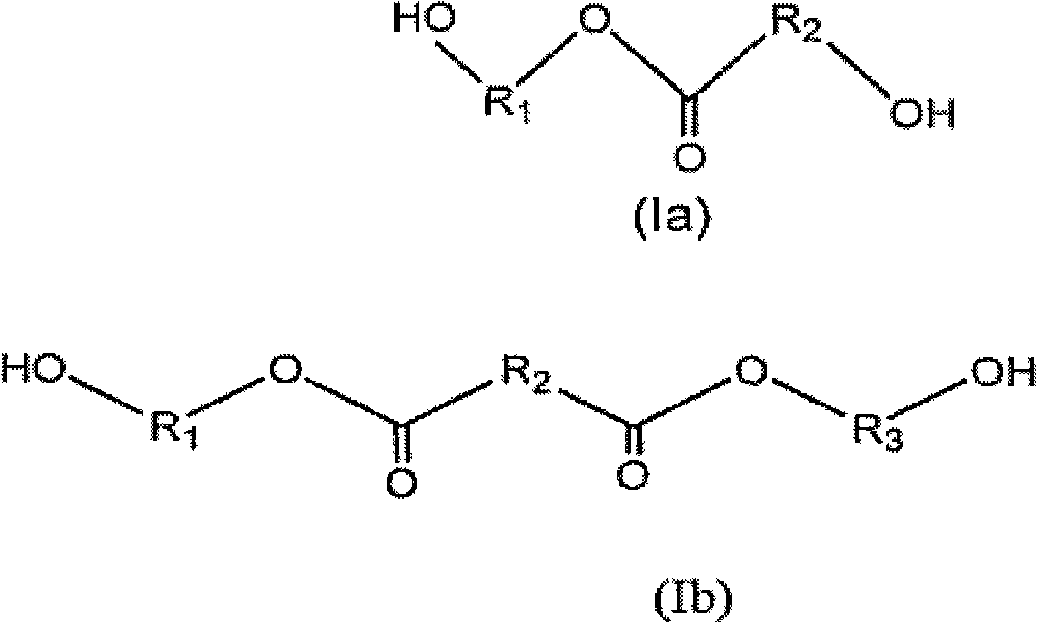

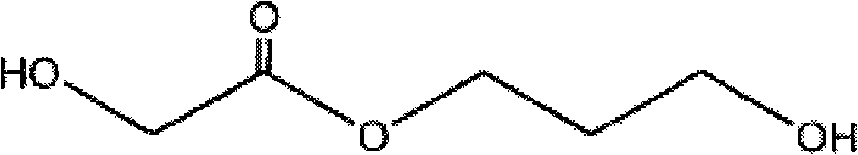

Chain extenders

Owner:POLYNOVO BIOMATERIALS PTY LTD

A biodegradable polyurethane releasing agent and a preparing method thereof

A biodegradable polyurethane releasing agent is disclosed. The releasing agent comprises following components by weight: 10-20 parts of natural liquid wax, 20-30 parts of amino silicone oil emulsion, 5-10 parts of polydimethylsiloxane emulsion, 1-8 parts of silica aerogel, 2-5 parts of other auxiliary agents and 20-30 parts of deionized water. A preparing method of the releasing agent is also disclosed. The releasing agent is good in biodegradability, safe, nontoxic, good in releasing effects, and free of influence on product quality and molds after releasing. The preparing method is simple and low in cost.

Owner:SUZHOU JINGRO TECH

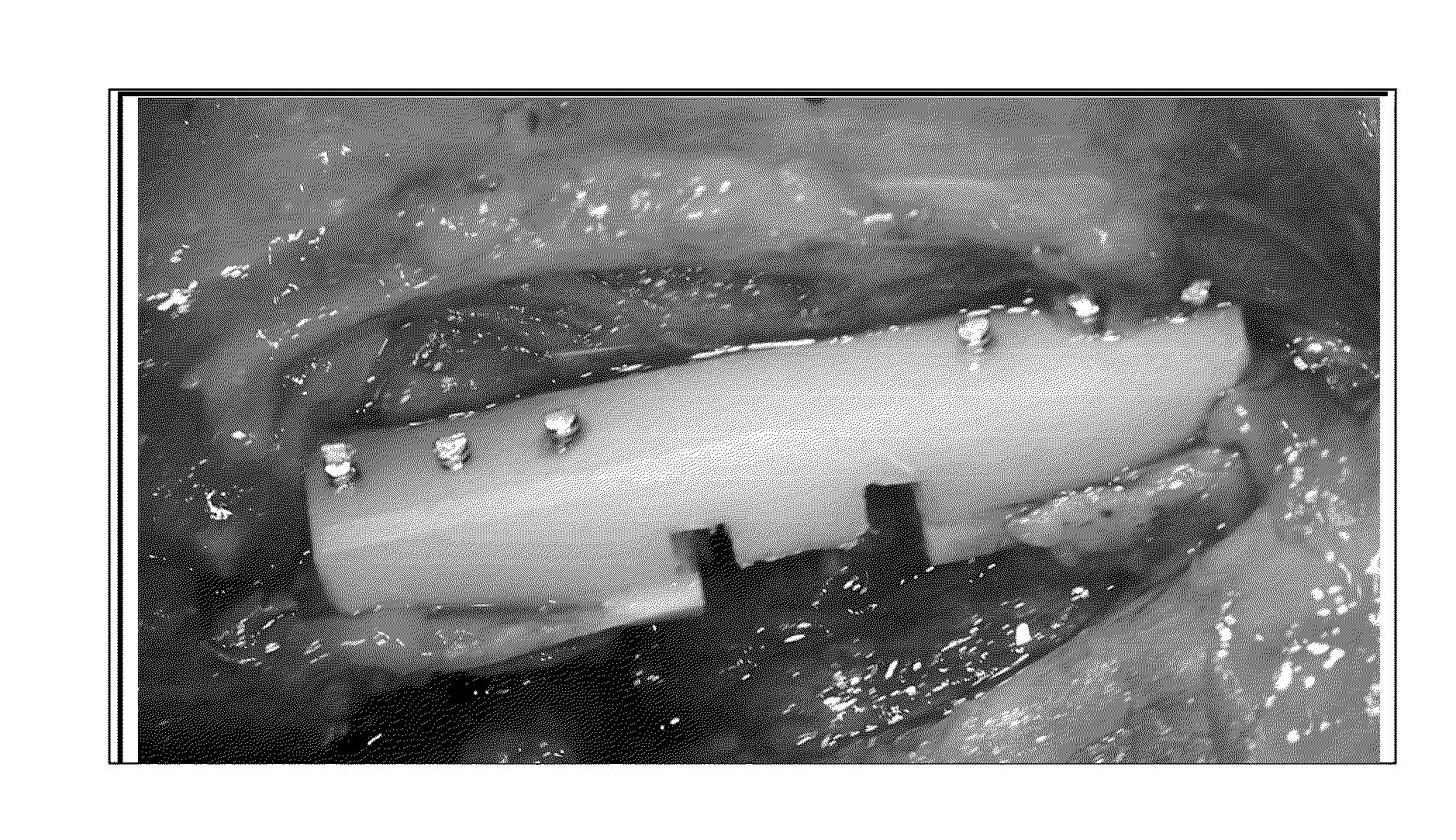

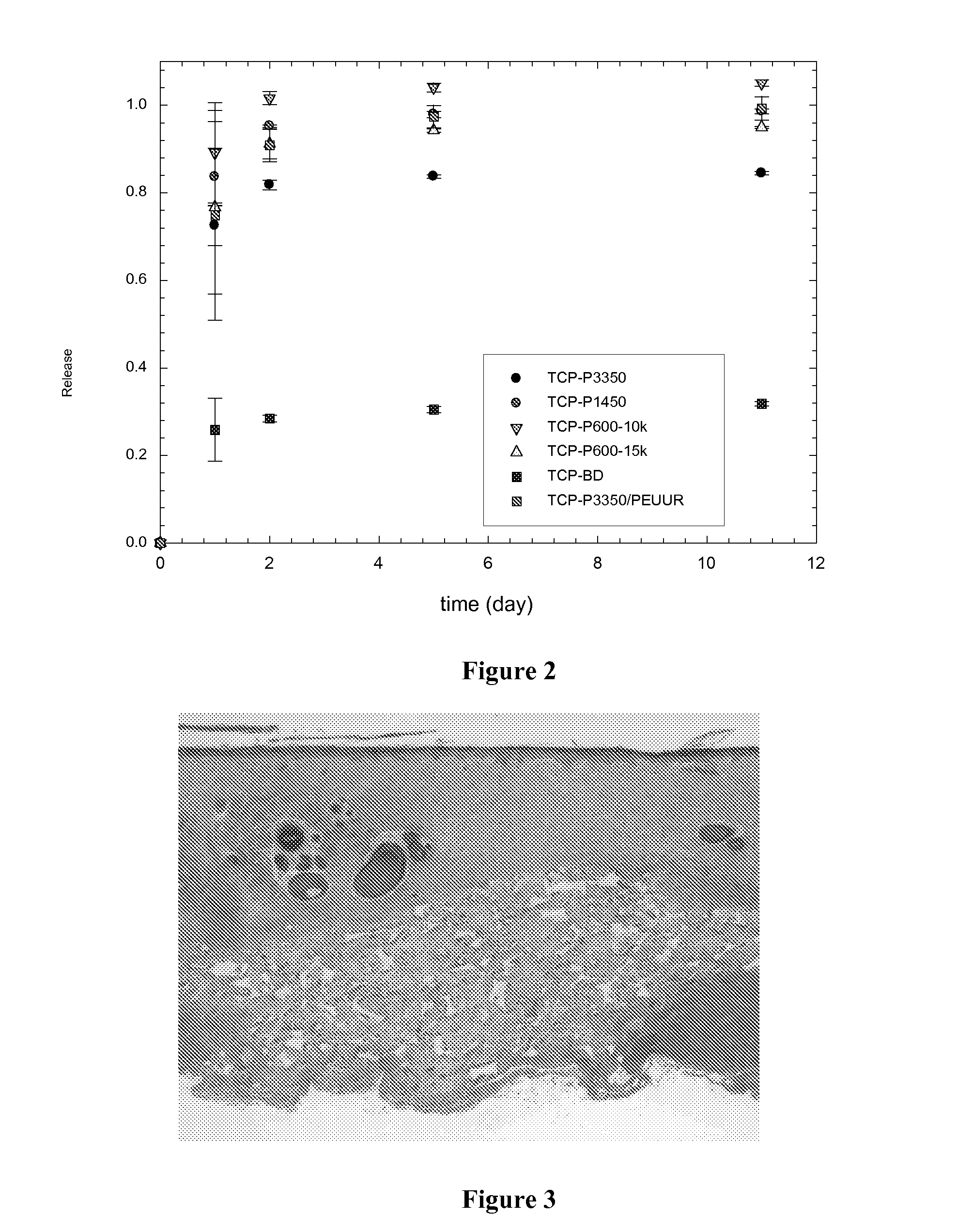

Release of antibiotic from injectable, biodegradable polyurethane scaffolds for enhanced bone fracture healing

InactiveUS20110038946A1Shorten healing timeHealing is often complicatedBiocidePeptide/protein ingredientsPolyesterPorosity

A biodegradable polyurethane scaffold, comprising at least one polyisocyante, polyisocyanate prepolymer, or both, at least one polyester polyol, at least one catalyst, wherein the density of said scaffold is from about 50 to about 250 kg m-3 and the porosity of the scaffold is greater than about 70 (vol %) and at least 50% of the pores are interconnected with another pore, and wherein the scaffold incorporates at least one biologically active component in powder form.

Owner:VANDERBILT UNIV

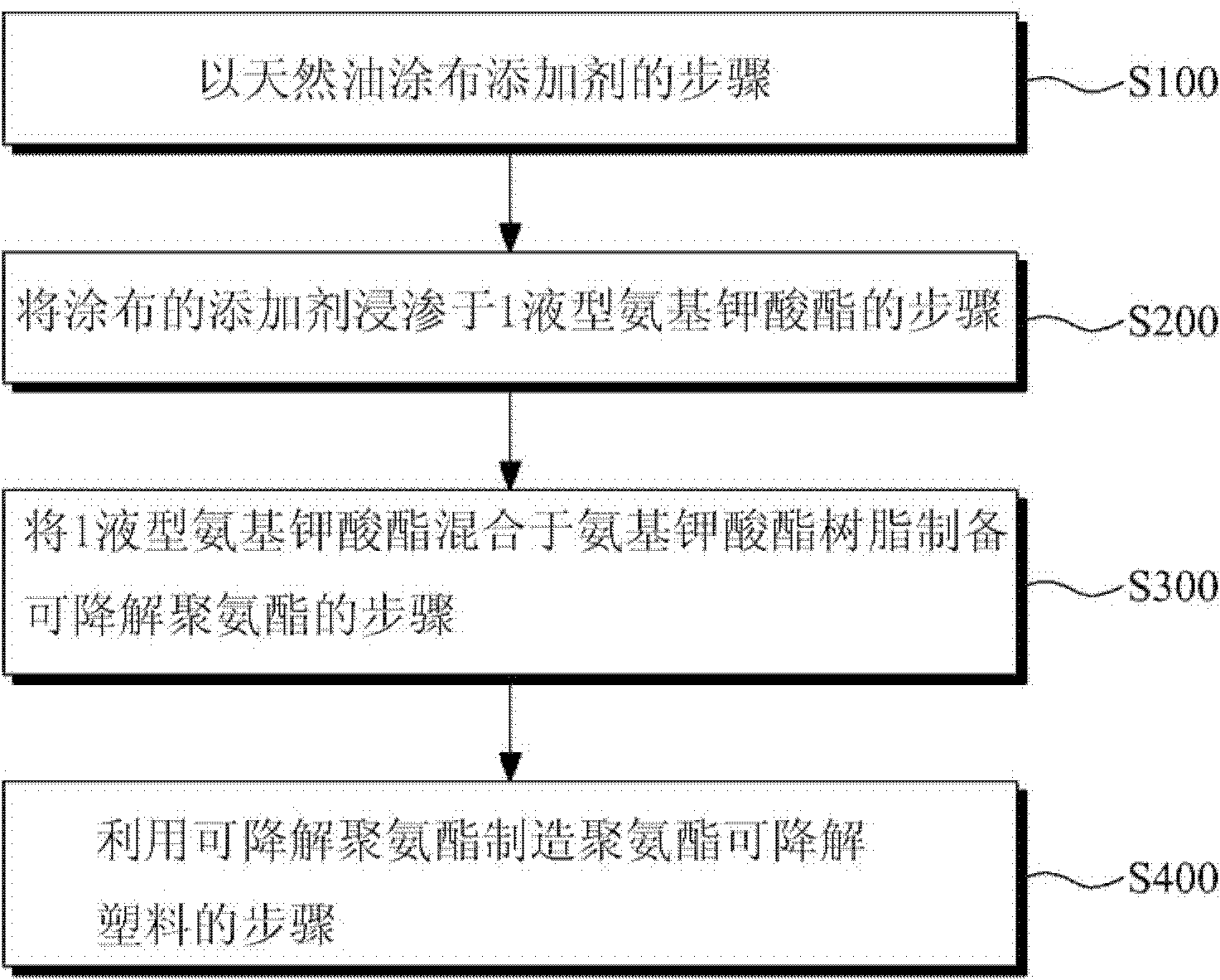

Biodegradable polyurethane plastic using phosphorus pentoxide

ActiveCN102675855AGood physical propertiesActive degradationThin material handlingColor changesMoisture

Owner:DONGAH CHEM

Peelable and biodegradable polyurethane protective film, preparation method and application thereof

ActiveCN105907282AImprove mechanical propertiesIncrease elastic strengthAntifouling/underwater paintsPaints with biocidesPlasticizerThermoplastic polyurethane

The invention discloses a peelable and biodegradable polyurethane protective film, a preparation method and application thereof. The protective film comprises the following raw materials by weight: 40-70 parts of thermoplastic polyurethane, 10-30 parts of biodegradable polyester, 0.01-0.5 part of a corrosion inhibitor, 1-10 parts of filler and 5-30 parts of a plasticizer. The preparation method comprises: 1) selecting materials according to the composition and weight part of each component prescribed in the formula; 2) putting the raw materials into a banbury mixer, performing stirring at 140-180DEG C for 5-15min till uniform mixing melting; 3) carrying out extrusion granulation and cooling to obtain an anti-bump and anti-corrosion protective film particle semi-finished product, during use, heating the semi-finished product to 160DEG C to melt it into liquid, then spraying the liquid on a metal component surface, and conducting cooling so as to form a 3-5micrometer protective film. The peelable and biodegradable polyurethane protective film provided by the invention has a simple formula and no pollution, and is especially suitable for temporary protection of metal raw materials and semi-finished products. The peelable and biodegradable polyurethane protective film is convenient to make and use, has no residual protective film after peeling, and can be biodegradable after abandonment.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com