A biodegradable polyurethane releasing agent and a preparing method thereof

A biodegradable polyurethane technology, applied in the field of high-resolution additives, can solve the problems of inconspicuous demoulding effect and high cost, and achieve good heat insulation effect, low cost and good demoulding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

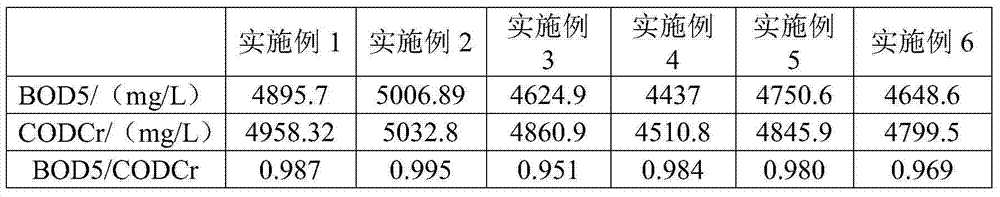

Examples

Embodiment 1

[0032] A biodegradable polyurethane release agent, in parts by weight, comprises the following components:

[0033] 10 parts of natural wax liquid, 20 parts of amino silicone oil emulsion,

[0034] 5 parts of polydimethylsiloxane emulsion,

[0035] 1 part of silica airgel, 2 parts of other additives,

[0036] 20 parts of deionized water.

[0037] Its preparation method comprises the following steps:

[0038] A preparation method of biodegradable polyurethane release agent, comprising the following steps:

[0039] (1) 10 parts of natural wax liquid, 5 parts of polydimethylsiloxane emulsion, 20 parts of amino silicone oil emulsion and deionized water were mixed and stirred evenly, and ultrasonicated for 2 hours at a power of 500W to obtain a mixed emulsion;

[0040] (2) Transfer the mixed emulsion obtained in step (1) to an autoclave, add 1 part of silica airgel and 2 parts of other additives, seal, heat up to 40°C, and ultrasonicate in a water bath for 40 minutes to obtain ...

Embodiment 2

[0042] A biodegradable polyurethane release agent, in parts by weight, comprises the following components:

[0043] 20 parts of natural wax liquid, 30 parts of amino silicone oil emulsion,

[0044] 10 parts of polydimethylsiloxane emulsion,

[0045] 8 parts of silica airgel, 5 parts of other additives,

[0046] 30 parts of deionized water.

[0047] Its preparation method comprises the following steps:

[0048] A preparation method of biodegradable polyurethane release agent, comprising the following steps:

[0049] (1) 20 parts of natural wax liquid, 10 parts of polydimethylsiloxane emulsion, 30 parts of amino silicone oil emulsion and deionized water were mixed and stirred evenly, and ultrasonicated for 5 hours at a power of 800W to obtain a mixed emulsion;

[0050] (2) Transfer the mixed emulsion obtained in step (1) to an autoclave, add 8 parts of silica airgel and 5 parts of other additives, seal it, raise the temperature to 60°C, and ultrasonicate in a water bath for ...

Embodiment 3

[0052] A biodegradable polyurethane release agent, in parts by weight, comprises the following components:

[0053] 12 parts of natural wax liquid, 22 parts of amino silicone oil emulsion,

[0054] 6 parts of polydimethylsiloxane emulsion,

[0055] 2 parts of silica airgel, 3 parts of other additives,

[0056] 22 parts of deionized water.

[0057] Its preparation method comprises the following steps:

[0058] A preparation method of biodegradable polyurethane release agent, comprising the following steps:

[0059] (1) 12 parts of natural wax liquid, 6 parts of polydimethylsiloxane emulsion, 22 parts of amino silicone oil emulsion and deionized water were mixed and stirred evenly, and ultrasonicated at a power of 550W for 2.5 hours to obtain a mixed emulsion;

[0060] (2) Transfer the mixed emulsion obtained in step (1) to an autoclave, add 2 parts of silica airgel and 3 parts of other additives, seal it, heat up to 45°C, and ultrasonicate in a water bath for 45 minutes to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com