Method for preparing biodegradable polyurethane material with pH responsiveness

A polyurethane material and biodegradation technology, which is applied in the field of pH-responsive polymer material preparation, can solve the problems such as unreported polyurethane preparation research, and achieve the effects of diversification of structure and function, mature process, and improvement of utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039]Take 3g of p-hydroxyethylpiperazine (HEP) and 80ml of toluene in a 150ml three-necked flask, and add 10ml of dichloromethane (solvent), after the PEG is dissolved, azeotropically distill 28ml of the mixed solution of hydrated toluene under nitrogen protection To remove the water in the reaction system, add 4.8gL-lysine butyl diisocyanate (LDI-B) and 0.04g dibutyltin dilaurate as a catalyst, under the protection of nitrogen, heat up to the boiling point of the solvent, reflux for 8 hours, and cool to 60°C, add 0.1g of methanol to block, react for 1 hour, after cooling, precipitate with ether, precipitate a light yellow solid, dissolve with dichloromethane, precipitate with ether, repeat 3 times, dry to obtain 6.2g of product, yield 80% .

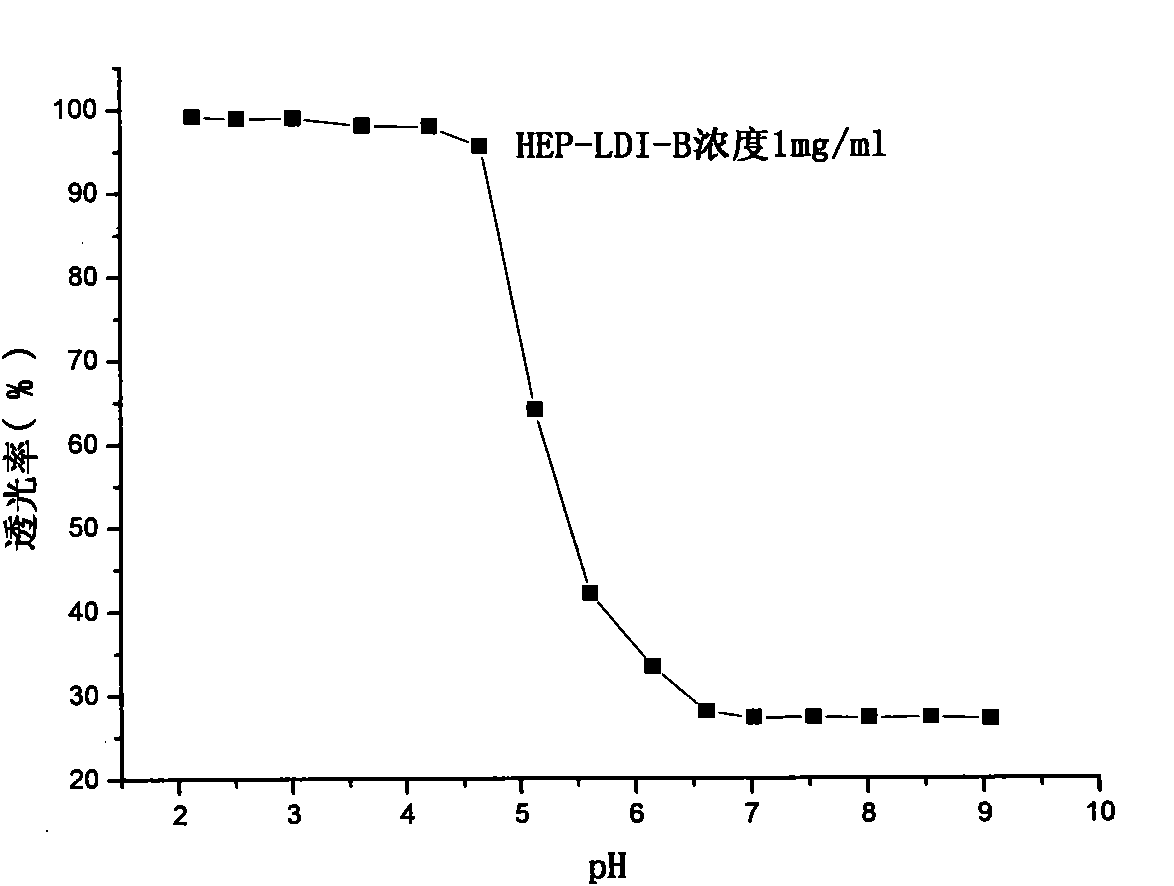

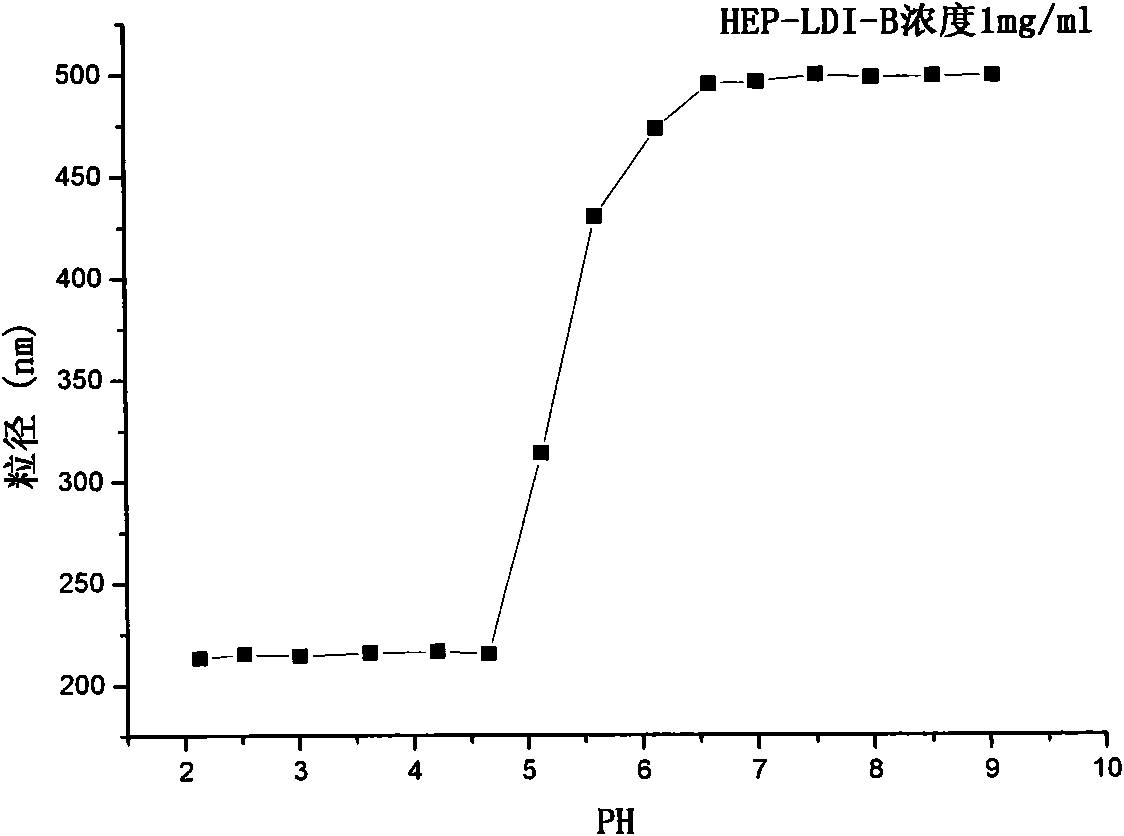

[0040] Take 5 mg of the product, dissolve it in 5 ml of DMF, dialyze for 48 hours, and prepare a 1 mg / ml solution. Measure the light transmittance and particle size at different pH values. It has pH responsiveness at pH 4.5-6.5. As the...

Embodiment 2

[0042] Take 3g of triethanolamine (TEA) and 80ml of toluene and place them in a 150ml three-neck flask. After the TEA is dissolved, 18ml of the mixed solution of toluene hydrate is azeotropically distilled under the protection of nitrogen to remove the water in the reaction system, and 0.64g of lysine methyl ester is added. Diisocyanate (LDI-M) and 0.02g dibutyltin laurate as a catalyst, under the protection of nitrogen, heat up to the boiling point of the solvent, reflux for 8 hours, cool down to 60°C, add 0.1g methanol to block, react for 1 hour, after cooling, use Diethyl ether precipitated, and a yellow solid was precipitated, dissolved in chloroform, diethyl ether precipitated, repeated 4 times, and dried to obtain 3.3 g of the product, with a yield of 90.6%.

[0043] Take 5 mg of the polymer, dissolve it in 10 ml of DMF, dialyze for 48 hours, and prepare a 0.5 mg / ml solution. Measure its light transmittance and particle size at different pH values, and find that its pH r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com