Anionic-sodium-alginate-based production method of pH-responsive intestine-targeted active factor carrying system

A technology of sodium alginate and targeting activity, which is applied in the directions of organic active ingredients, medical preparations with non-active ingredients, and medical preparations containing active ingredients, etc. Broken and other problems, to achieve the effect of improving the embedding effect, low cost and easy large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

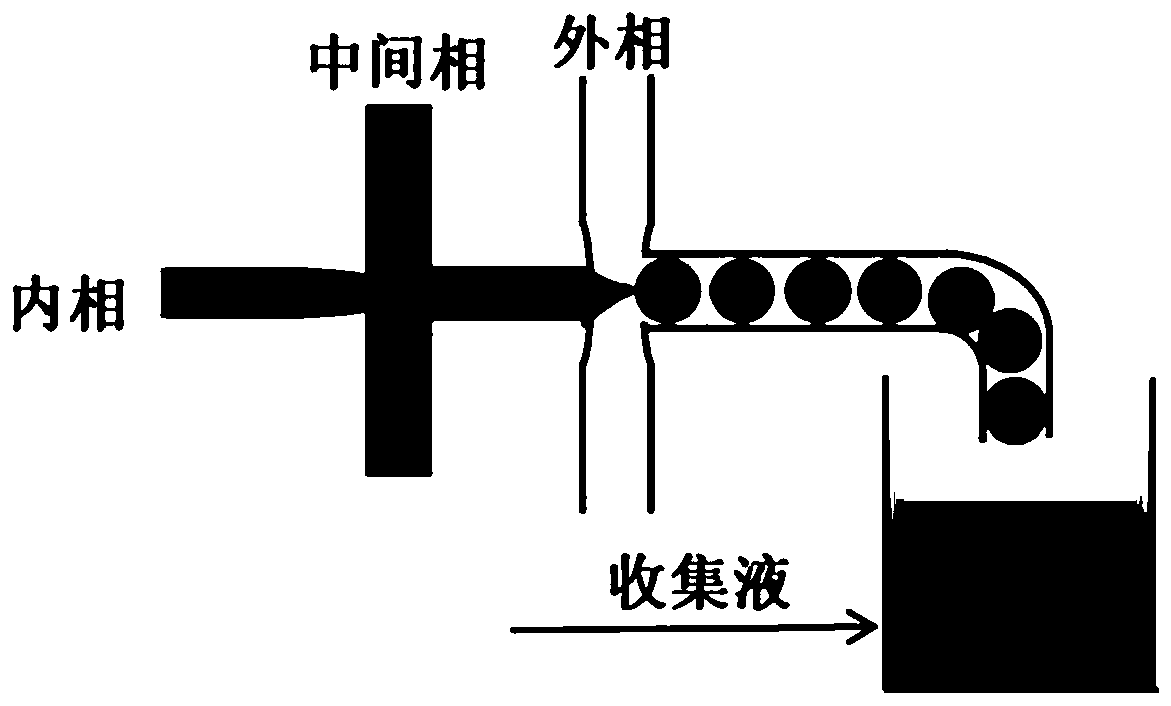

[0054] A preparation method of a pH-responsive intestinal targeting active factor delivery system based on anionic sodium alginate, using proanthocyanidin as the active factor, anionic sodium alginate as the wall material, and using microfluidic technology to prepare the active factor by using the in-situ gel method The delivery system was modified by layer-by-layer self-assembly of chitosan, and the embedding effect, stability, pH-stimulated release and targeting of the active factor delivery system were characterized. Including the following steps:

[0055] S1. Prepare internal phase proanthocyanidin-sodium carboxymethyl cellulose solution: mix the sodium carboxymethyl cellulose solution and proanthocyanidin aqueous solution evenly to obtain the internal phase; the final concentration of sodium carboxymethyl cellulose in the internal phase is 9-9. 11mg / mL, the final concentration of the proanthocyanidins is 4~6mg / mL;

[0056] S2. Prepare the interphase sodium alginate-edeta...

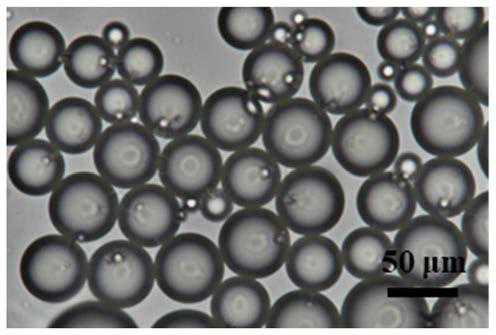

Embodiment 1

[0066] A preparation method of a pH-responsive intestinal targeting active factor delivery system based on anionic sodium alginate, comprising the steps of:

[0067] S1, preparation of inner phase proanthocyanidin-sodium carboxymethyl cellulose solution:

[0068] Add sodium carboxymethylcellulose into water, stir at 600 rpm for 6 hours until it dissolves, and prepare a sodium carboxymethylcellulose solution with a concentration of 20 mg / mL;

[0069] Take proanthocyanidins and add them to water, sonicate for 10 minutes under the condition of power 100W, and prepare an aqueous solution of proanthocyanidins with a concentration of 10mg / mL;

[0070] Mix the sodium carboxymethylcellulose solution with a concentration of 20 mg / mL and the aqueous solution of proanthocyanidins with a concentration of 10 mg / mL according to the volume ratio of 1:1 to obtain the inner phase;

[0071] S2. Preparation of mesophase sodium alginate-edetate disodium calcium solution:

[0072] Add sodium alg...

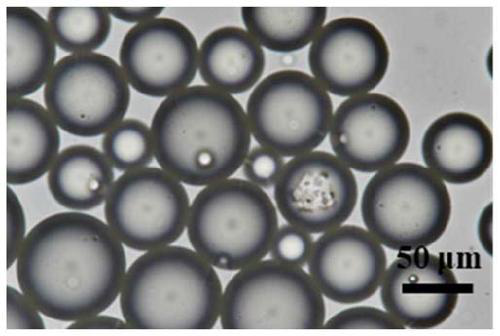

Embodiment 2

[0084] A preparation method of a pH-responsive intestinal targeting active factor delivery system based on anionic sodium alginate, comprising the steps of:

[0085] S1, preparation of inner phase proanthocyanidin-sodium carboxymethyl cellulose solution:

[0086] Add sodium carboxymethylcellulose into water, stir at 600 rpm for 6 hours until it dissolves, and prepare a sodium carboxymethylcellulose solution with a concentration of 20 mg / mL;

[0087] Take proanthocyanidins and add them to water, sonicate for 10 minutes under the condition of power 100W, and prepare an aqueous solution of proanthocyanidins with a concentration of 10 mg / mL;

[0088]Mix the sodium carboxymethylcellulose solution with a concentration of 20 mg / mL and the aqueous solution of proanthocyanidins with a concentration of 10 mg / mL according to the volume ratio of 1:1 to obtain the inner phase;

[0089] S2. Preparation of mesophase sodium alginate-edetate disodium calcium solution:

[0090] Add sodium alg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com