Method for preparing hydrophilic graphene with pH sensitivity

A hydrophilic and graphene technology, applied in the direction of graphene, nanotechnology, nanocarbon, etc., can solve the problems of environmental pollution, solubility in several specific organic solvents, and low stability of graphene, and achieve simple process, The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Add 40.4 mg 4-cyanopentanoic acid dithiobenzoic acid (CTP), 10.2 mg 4,4'-azo-(4-cyano)valeric acid (V-501) into a 25 mL single-necked bottle ( Make the molar ratio of CTP to V-501 4:1), and add 0.5 mL of dioxane to dissolve it completely; after dissolving 2.01 g of dimethylaminoethyl methacrylate (DMAEMA) in 6 mL of deionized water , adjust the pH to 4 and add it to a one-necked bottle, place it in a water bath with a magnetic heating stirrer under nitrogen protection, raise the temperature to 70°C and react for 9 h, after the reaction is completed, cool the reaction bottle to room temperature and ventilate to the atmosphere for 30 min. Then the product was dialyzed in deionized water with a pH of 4.5 for 3 days (the molecular weight cut-off of the dialysis bag was 1000), and then freeze-dried for 48 h to obtain a hydrophilic polymer PDMAEMA.

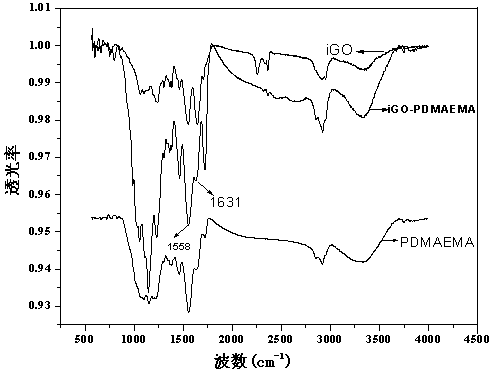

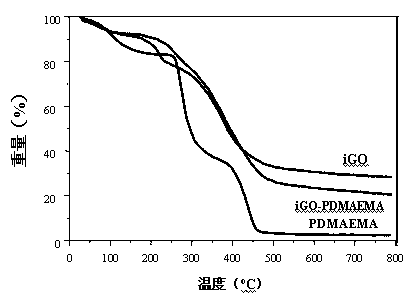

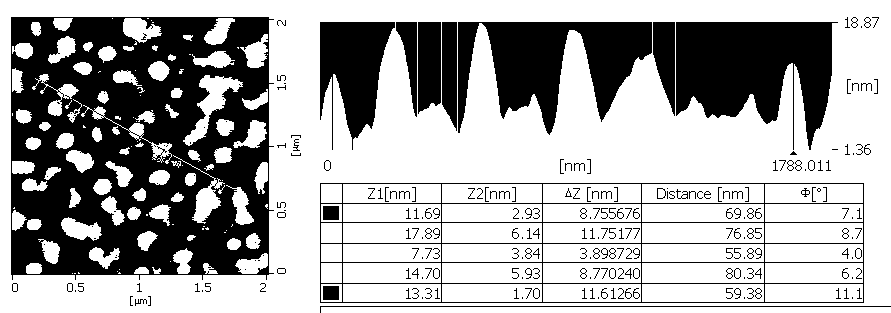

[0027]Add 100 mg of graphite oxide (iGO) and 10 mL of anhydrous N,N-dimethylformamide into a 50 mL round-bottomed flask, and ul...

Embodiment 2

[0031] Same as Example 1, but the consumption of 4-cyano-4-(thiobenzoyl) valeric acid in the first step of the reaction is changed from 40.4 mg to 50.3 mg, and the consumption of dimethylaminoethyl methacrylate is changed from 2.01 g becomes 2.51 g, N-3-aminopropylmethacrylamide hydrochloride, 4-cyano-4-(thiobenzoyl)valeric acid) and 4,4'-azo-( The molar ratio of 4-cyanovaleric acid) was changed from 100:1:0.25 to 88:1:0.2, and the others remained unchanged.

Embodiment 3

[0033] Same as Example 1, but the amount of 4,4'-azo-(4-cyanovaleric acid) in the first step of the reaction was changed from 10.2 mg to 20.3 mg, and in the system dimethylaminoethyl methacrylate, 4- The molar ratio of cyano-4-(thiobenzoyl)valeric acid to 4,4'-azo-(4-cyanovaleric acid) was changed from 100:1:0.25 to 88:1:0.5, and the others remained unchanged .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com