Biodegradable polyurethane oil-absorbing material and preparation method thereof

An oil-absorbing material, biodegradable technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of oil-absorbing materials not being biodegradable, high cost, polluting the environment, etc., and achieve good biodegradability and environmental protection The effect of friendliness, high production efficiency and simple molding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

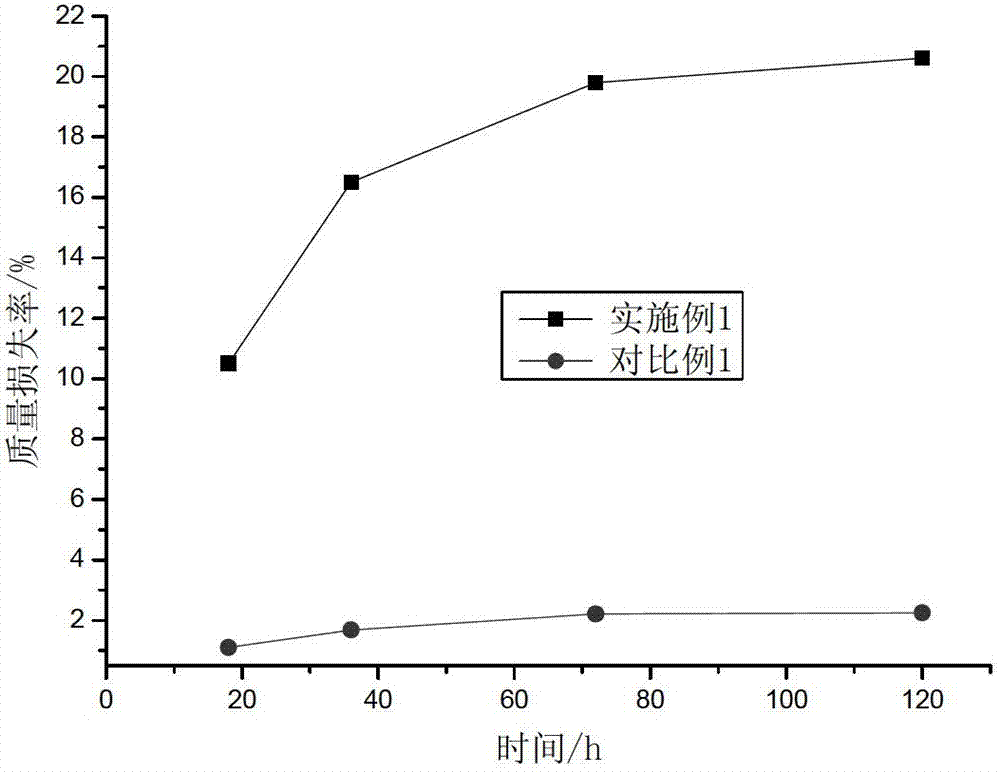

Embodiment 1

[0036] Composite liquefaction reagent is composed of polyethylene glycol 400, glycerin and concentrated sulfuric acid in a mass ratio of 100:20:5. Transfer the prepared liquefaction reagent and cornstarch to a three-necked bottle equipped with a stirrer and a condenser in a mass ratio of 4:1, and keep the temperature in an oil bath to 120°C in advance, and react for 2 hours under stirring and reflux conditions, Immediately after the reaction, transfer to cold water lower than 40° C., and cool to room temperature to obtain a biodegradable oligomeric polyol with a hydroxyl value of 280 mgKOH / g.

[0037]In a reactor equipped with a stirrer, a thermometer, and a reflux condenser, add 100 g of the above-mentioned biodegradable oligomeric polyol, the hydroxyl value is 100 mgKOH / g polyether polysiloxane diol 15 g, stannous octoate 0.2 g, triethylenediamine 0.5g, foam stabilizer polyether modified silicone surfactant 0.5g, deionized water 5g, stir well at room temperature, let stand f...

Embodiment 2

[0039] Composite liquefaction reagent is composed of polyethylene glycol 400, glycerin and concentrated sulfuric acid in a mass ratio of 100:10:5. Transfer the prepared liquefaction reagent and bagasse to a three-necked bottle equipped with a stirrer and a condenser in a mass ratio of 5:1, and keep the temperature in an oil bath to 130°C in advance, and react for 1.5 hours under the conditions of stirring and reflux , immediately transferred to cold water lower than 40°C after the reaction was completed, and cooled to room temperature to obtain a biodegradable oligomeric polyol with a hydroxyl value of 230 mgKOH / g.

[0040] In a reactor equipped with a stirrer, a thermometer, and a reflux condenser, add 100 g of the above-mentioned biodegradable oligomeric polyol with a hydroxyl value of 90 mgKOH / g polyether polysiloxane diol 18 g, dilauric acid di Butyl tin 0.3g, triethylenediamine 0.5g, foam stabilizer polyether modified silicone surfactant 1.3g, deionized water 6.5g, stir a...

Embodiment 3

[0042] Composite liquefaction reagent is composed of polyethylene glycol 400, glycerin and concentrated sulfuric acid in a mass ratio of 100:18:5. Transfer the prepared liquefaction reagent and bagasse to a three-necked bottle equipped with a stirrer and a condenser in a mass ratio of 5:1, and keep the temperature in an oil bath to 130°C in advance, and react for 1.5 hours under the conditions of stirring and reflux , immediately transferred to cold water lower than 40°C after the reaction was completed, and cooled to room temperature to obtain a biodegradable oligomeric polyol with a hydroxyl value of 310 mgKOH / g.

[0043] In a reactor equipped with a stirrer, a thermometer, and a reflux condenser, add 100 g of the above-mentioned biodegradable oligomeric polyol with a hydroxyl value of 150 mgKOH / g polyether polysiloxane diol 30 g, dilauric acid di Butyl tin 0.35g, triethylenediamine 0.5g, foam stabilizer polyether modified silicone surfactant 1.6g, deionized water 7.2g, stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com