Zr-Cu-Ni-Al-Nb bulk amorphous alloy with high zirconium content

A technology of amorphous alloy and zirconium content, which is applied in the field of Zr-Cu-Ni-Al-Nb bulk amorphous alloy with high zirconium content, can solve the problems of increasing the specific gravity of the alloy, and achieve the effect of reducing the specific gravity and content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

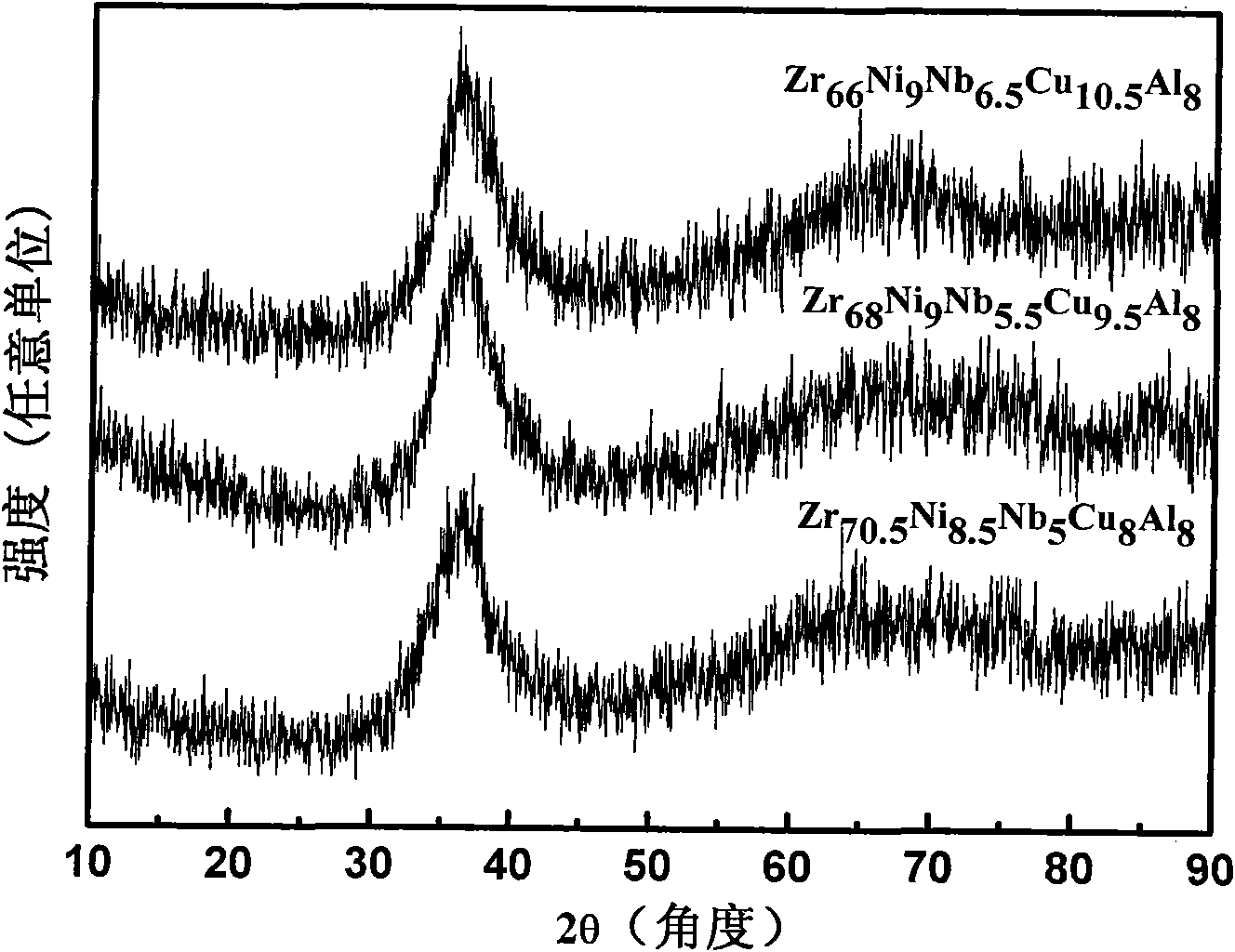

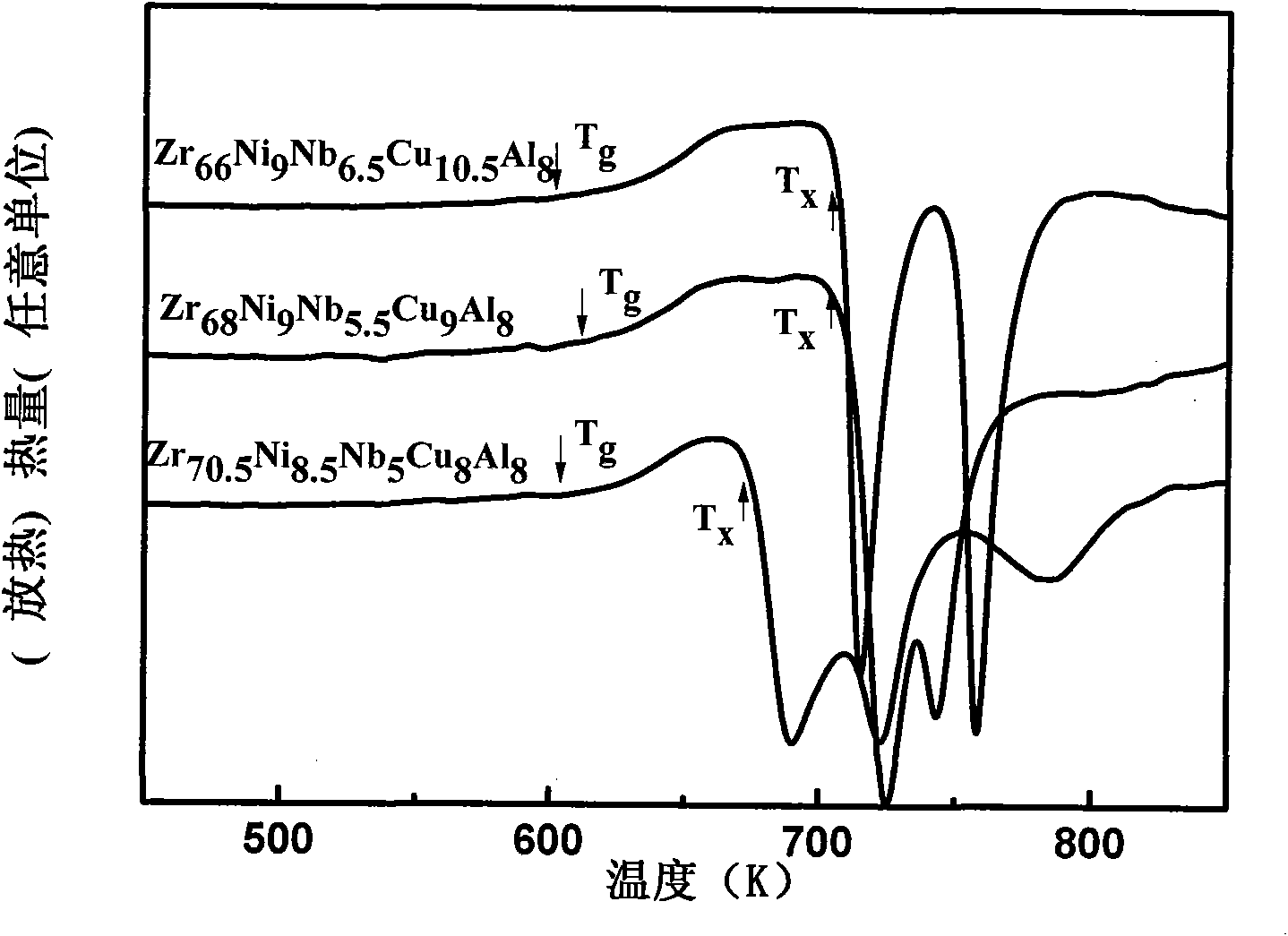

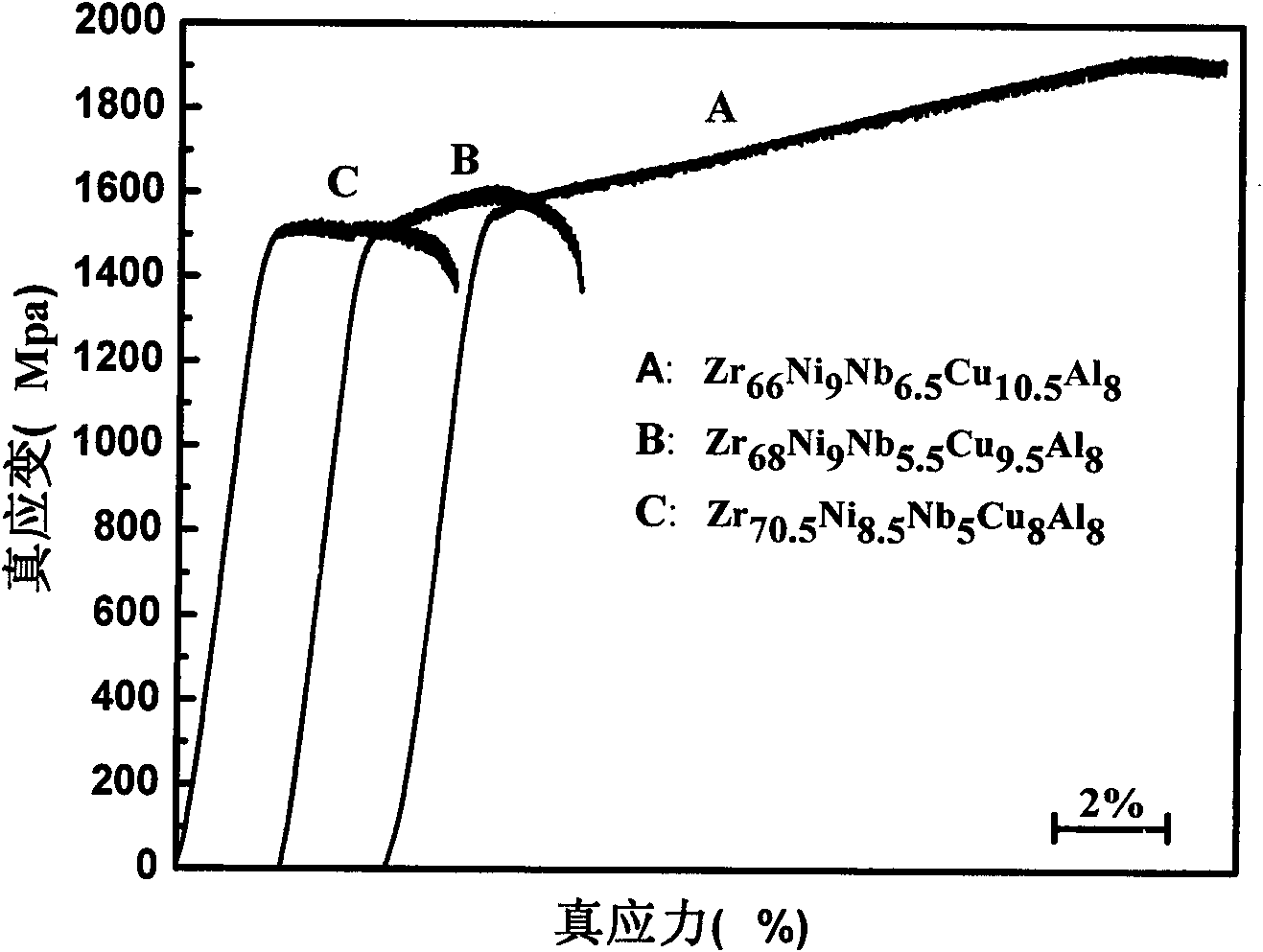

[0024] The zirconium-based bulk amorphous alloy with high zirconium content has the following chemical composition (atomic percentage): Zr66.0%, Ni9.0%, Nb6.5%, Al8.0%, Cu10.5%. After using a water-cooled copper mold to cast a round rod with a diameter of 2mm, the X-ray diffraction spectrum of the cross-section of the round rod sample confirms that the entire sample is an amorphous structure, see figure 1 The upper curve; from the continuous heating DSC crystallization curve, a very typical exothermic step due to glass transition and exothermic reaction caused by crystallization transition can be observed, see figure 2 The upper curve, the initial crystallization temperature T of the sample x is 706K, the glass transition temperature T g is 603K, the width of the supercooled liquid phase region ΔT x It is 103K, see Table 1, indicating that the thermal stability and glass forming ability are very good; room temperature compression plastic deformation curve, see image 3 (A)...

Embodiment 2

[0026] The zirconium-based bulk amorphous alloy with high zirconium content has the following chemical composition (atomic percentage): Zr68.0%, Ni9.0%, Nb5.5%, Al8.0%, Cu9.5%. This alloy is in Zr 66 Ni 9 Nb 6.5 Cu 10.5 Al 8 In the alloy, the atomic percentage content of zirconium element and copper element is increased, and the relative content of niobium element is reduced. After using a water-cooled copper mold to cast a round rod with a diameter of 2mm, the X-ray diffraction spectrum of the cross-section of the round rod sample confirms that the entire sample is an amorphous structure, see figure 1 Middle curve; from the continuous heating DSC crystallization curve, one can observe a very typical exothermic step due to glass transition and exothermic reaction caused by crystallization transition, see figure 2 In the middle curve, the initial crystallization temperature T of this alloy x 701K, glass transition temperature T g is 614K, the width of the supercooled li...

Embodiment 3

[0028] The zirconium-based bulk amorphous alloy with high zirconium content has the following chemical composition (atomic percentage): Zr70.5%, Ni8.5%, Nb5.0%, Al8.0%, Cu8.0%. This alloy is in Zr 68 Ni 9 Nb 5.5 Cu 9.5 al 8 In the alloy, it is obtained by continuing to increase the atomic percentage content of zirconium and copper elements. After using a water-cooled copper mold to cast a round rod with a diameter of 2mm, the X-ray diffraction spectrum of the cross-section of the round rod sample confirms that the entire sample is an amorphous structure, see figure 1 Lower curve; from the continuous heating DSC crystallization curve, a very typical exothermic step due to glass transition and exothermic reaction caused by crystallization transition can be observed, see figure 2 The lower curve, the initial crystallization temperature T of this alloy x is 674K, the glass transition temperature T g is 604K, the width of the supercooled liquid phase region ΔT x It is 70K,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com