Rubber floor cloth composition, rubber floor cloth prepared from rubber floor cloth composition and applications of rubber floor cloth composition and rubber floor cloth

A technology of rubber floor and composition, applied in the field of synthetic rubber, can solve the problems of affecting product quality and aesthetics, affecting product quality, difficult continuous production by calendering, etc., to overcome the release of toxic gas, improve preparation convenience, and improve product compactness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

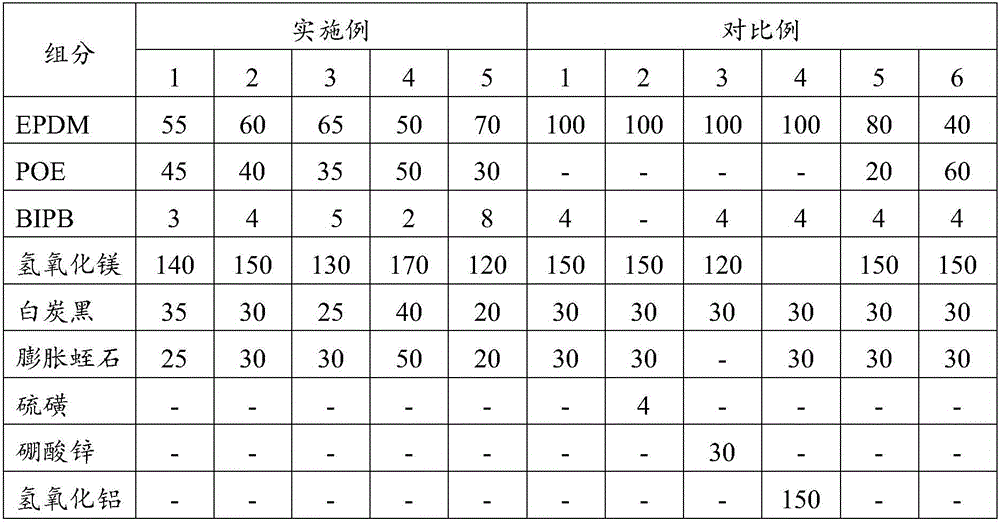

[0076] Example 1 A kind of composition for preparing rubber floor cloth

[0077] The composition of the composition and the parts by weight of each component are shown in Table 1, wherein 1 part by weight=1 kg.

Embodiment 2

[0078] Example 2 A kind of composition for rubber floor cloth

[0079] The composition of the composition and the parts by weight of each component are shown in Table 1, wherein 1 part by weight=1 kg.

Embodiment 3

[0080] Example 3 A kind of composition for rubber floor cloth

[0081] The composition of the composition and the parts by weight of each component are shown in Table 1, wherein 1 part by weight=1 kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com