Patents

Literature

44results about How to "Improve production convenience" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

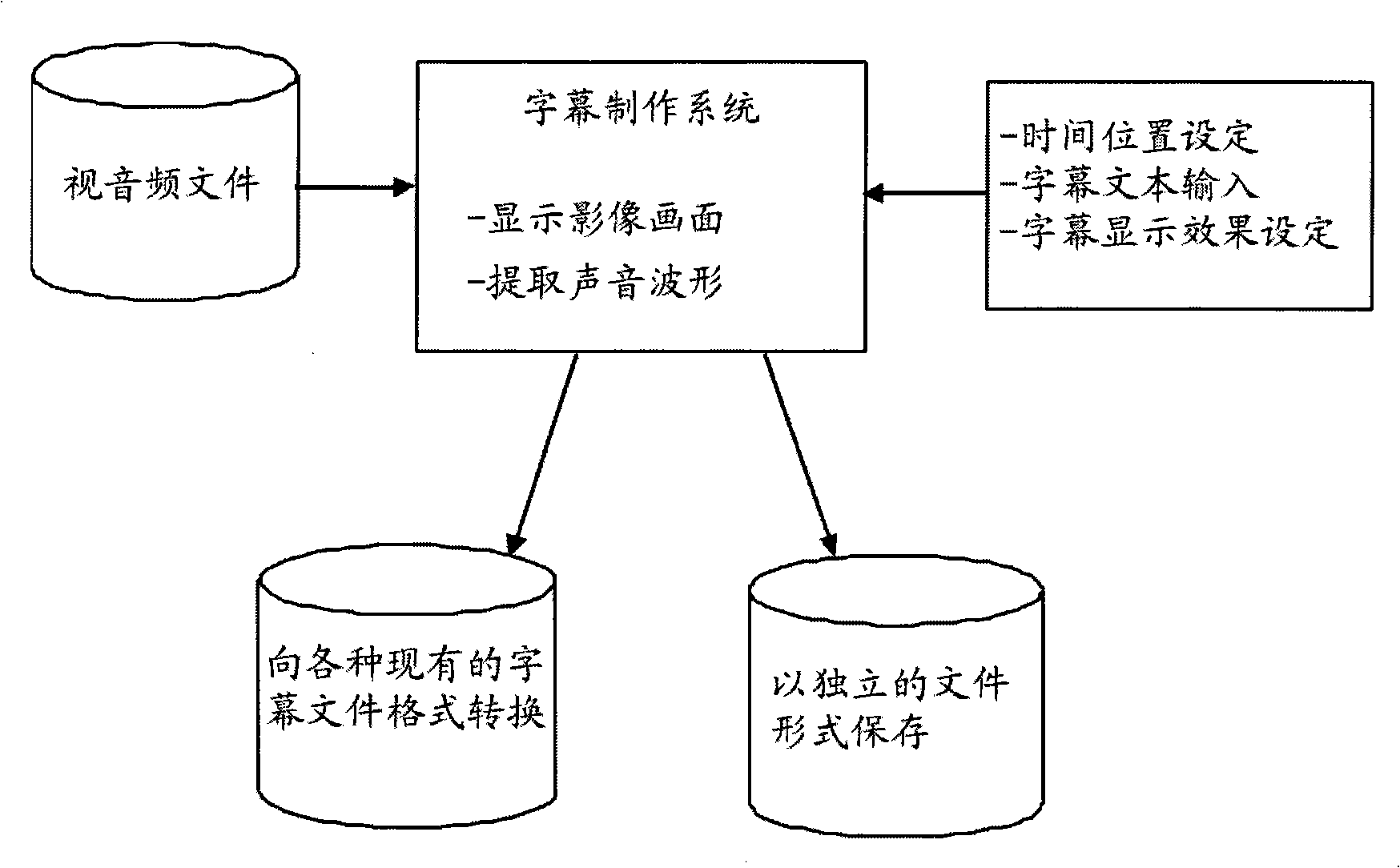

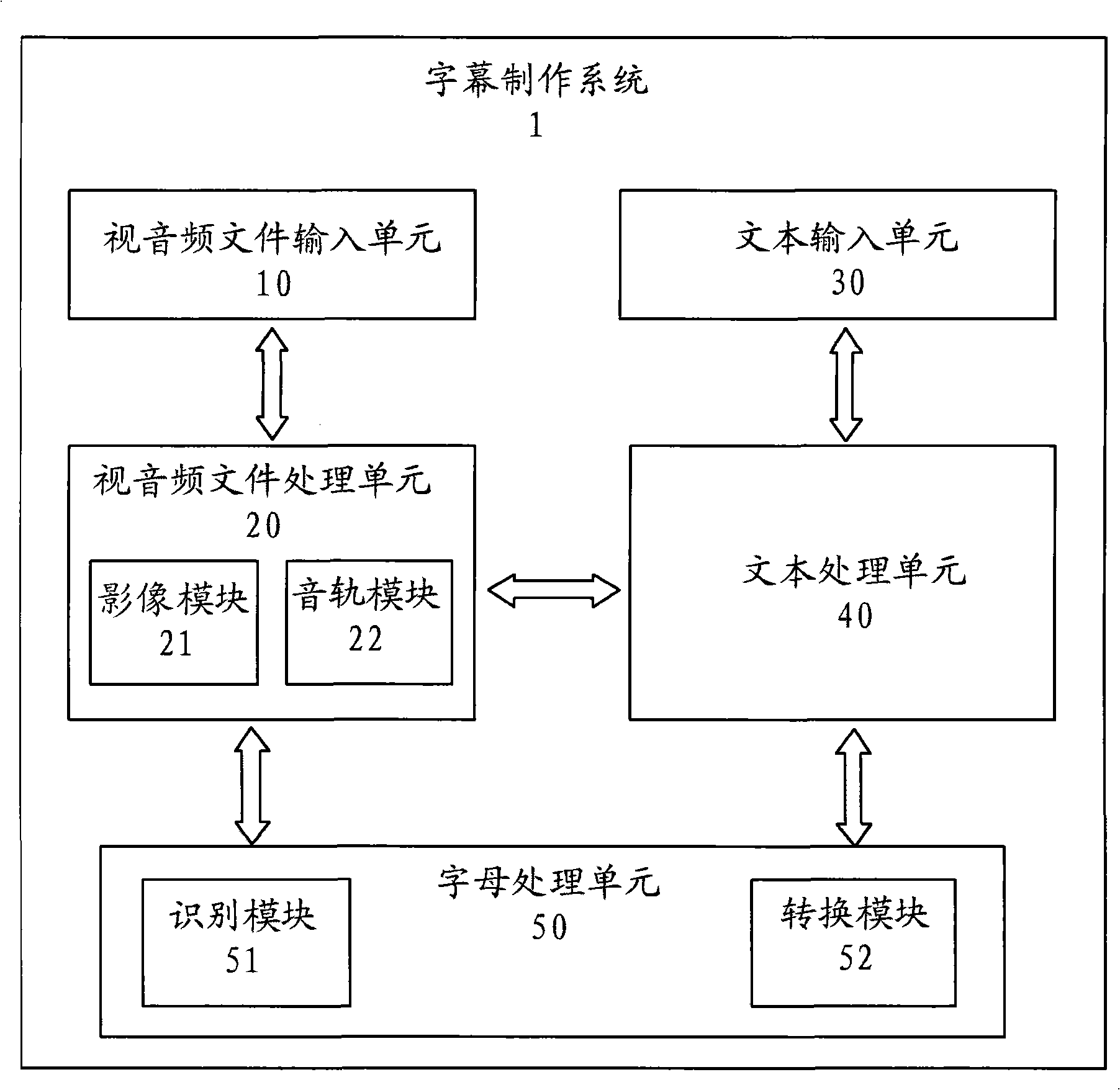

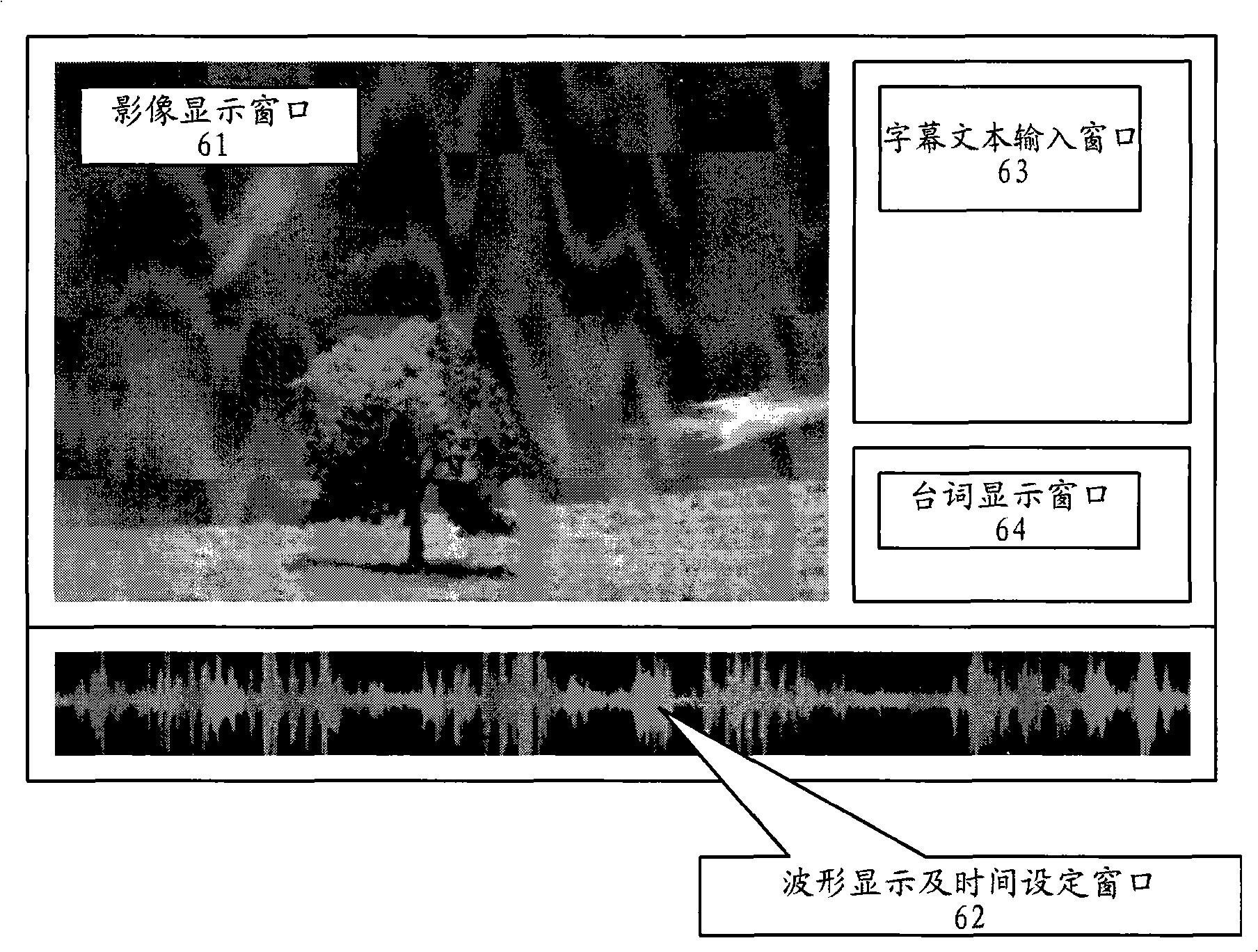

Caption producing system and caption producing method

InactiveCN101540847AImprove production convenienceQuality assuranceTelevision system detailsColor television detailsComputer scienceAudio frequency

The invention relates to a caption producing system and a caption producing method based on a video-audio file. The system comprises a video-audio file input unit, a video-audio file processing unit, a text input unit, a text processing unit and a caption processing unit, wherein the video-audio file input unit is used for storing or receiving video-audio files provided by the external; the video-audio file processing unit is used for receiving the video-audio files from the video-audio file input unit and extracting video-audio information from the video-audio files; the text input unit is used for storing or receiving a caption text provided by the external; the text processing unit is used for receiving the caption text from the text input unit, and adjusting the attribute of the caption text so as to generate text attribute information related with caption; and the caption processing unit is used for generating a caption project file based on the video-audio information, the caption text and the text attribute information. The caption producing system and the caption producing method can remarkably improve the flexibility and convenience of caption production and modification and language transformation processes, and realize full compatibility of various film and television work formats and related caption formats simultaneously.

Owner:株式会社康巴思

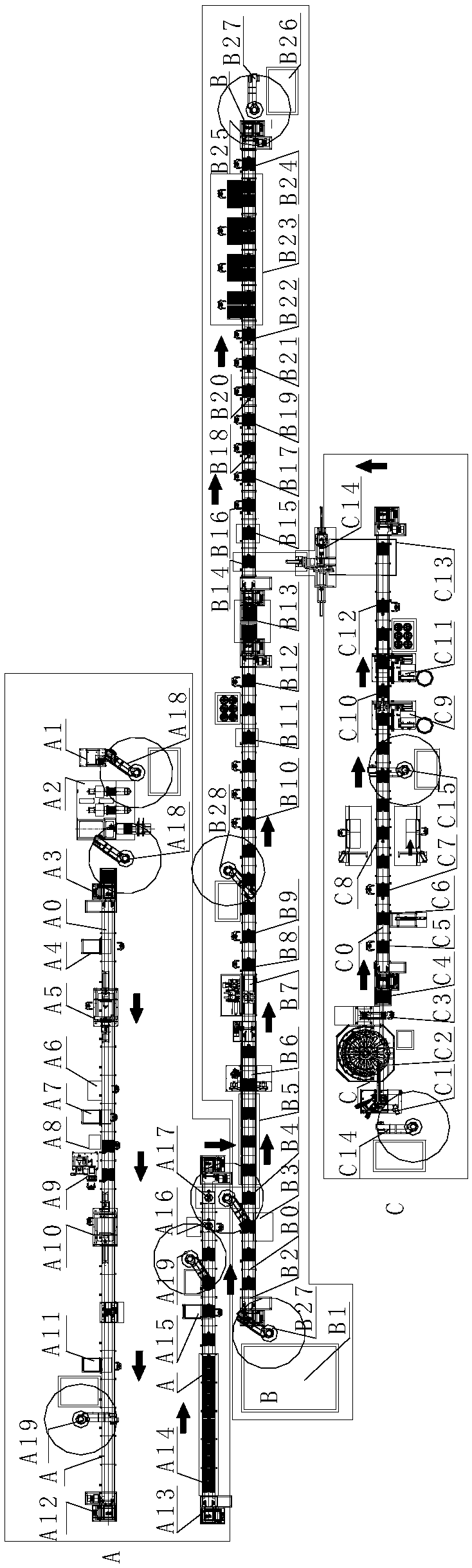

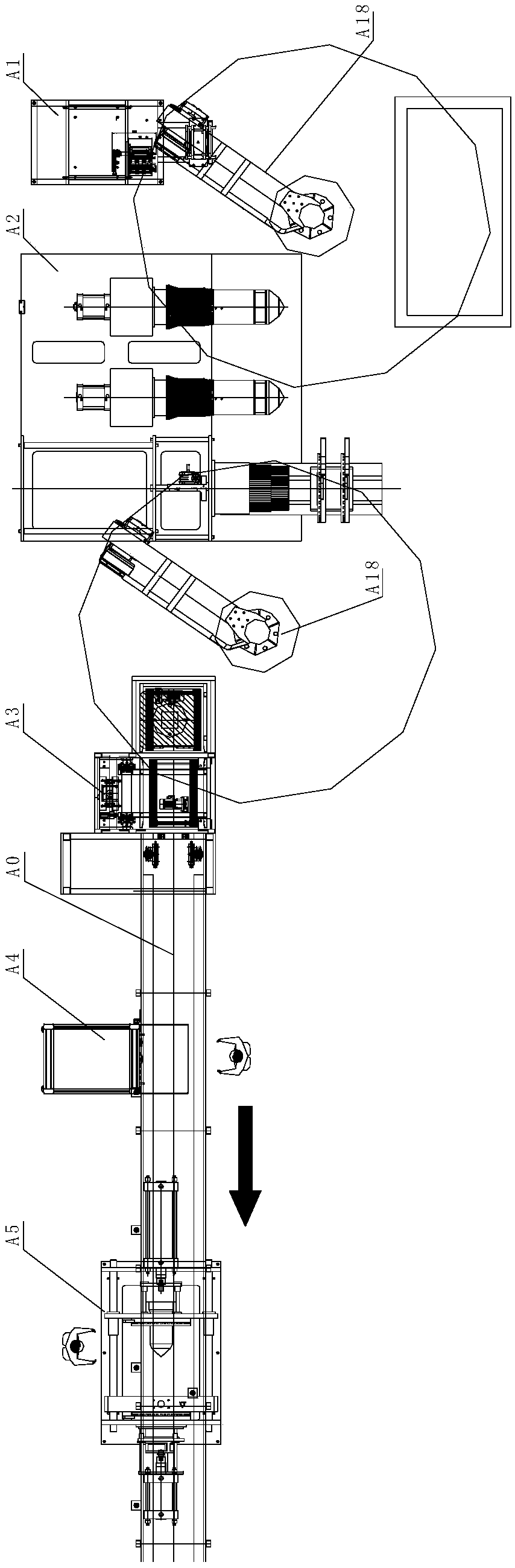

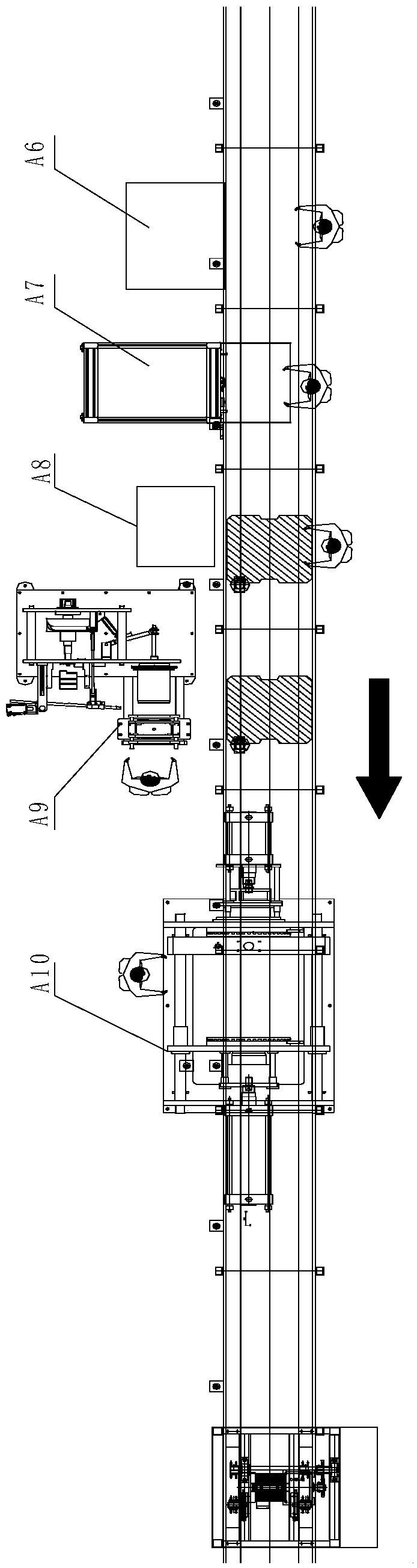

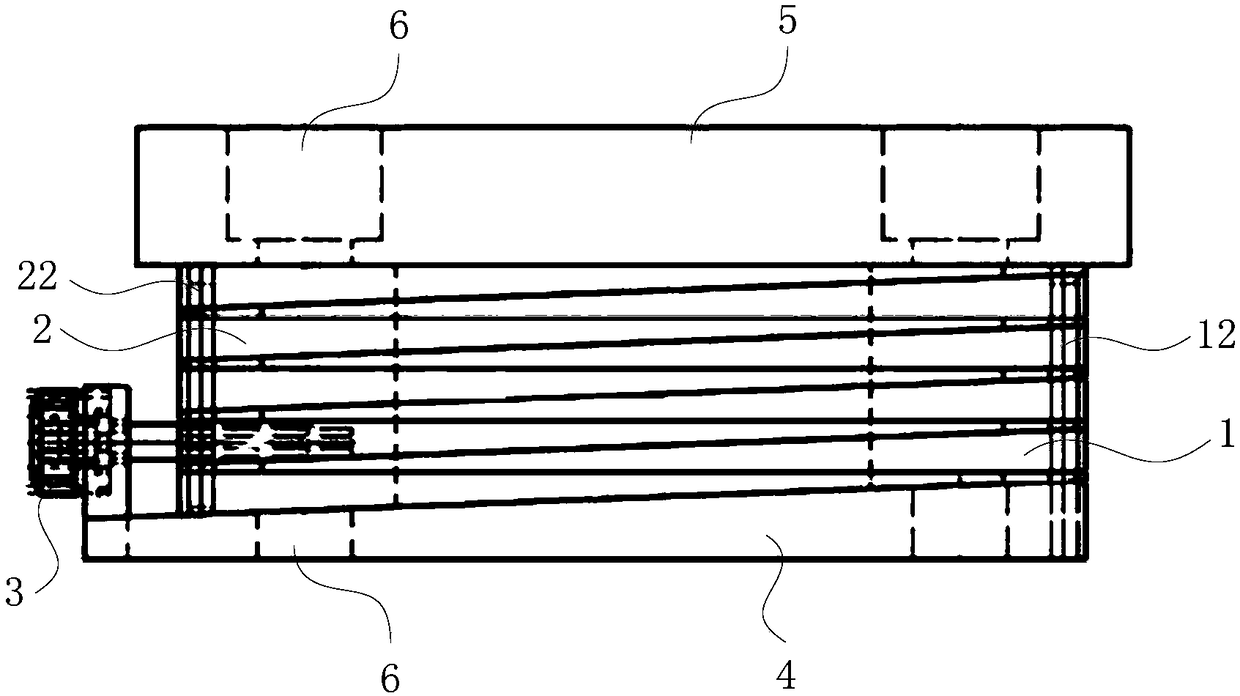

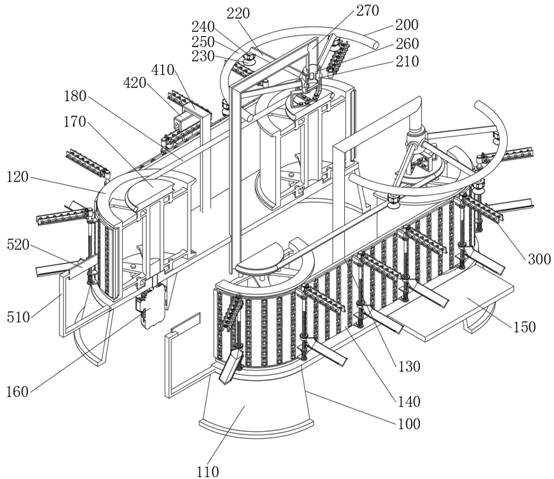

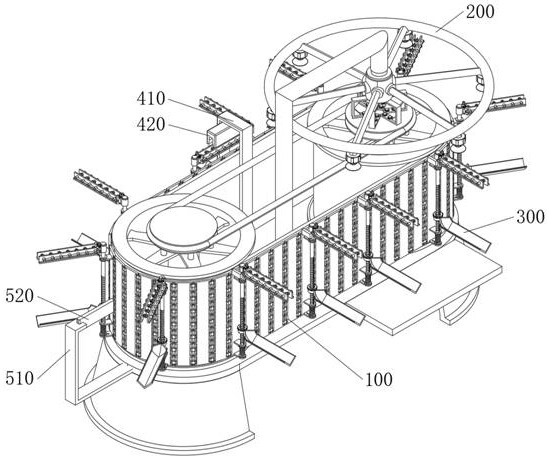

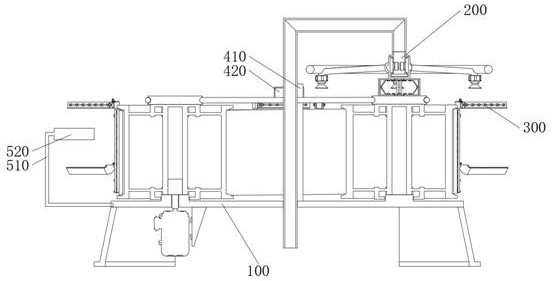

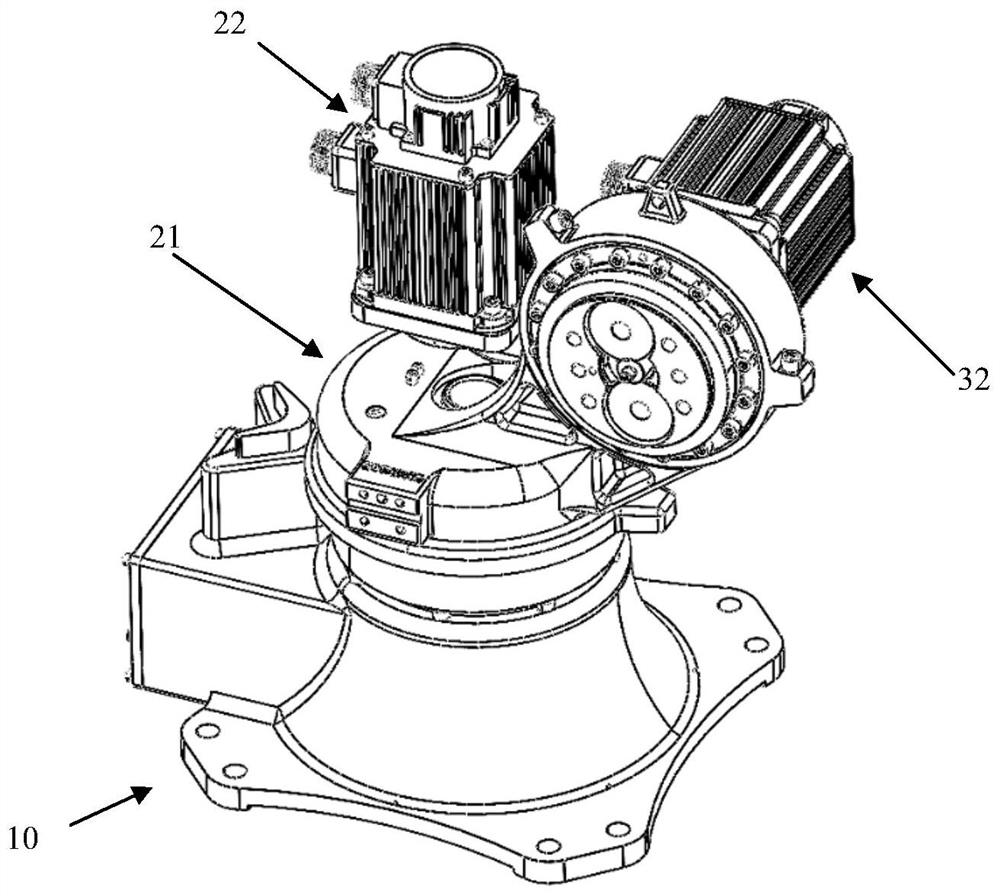

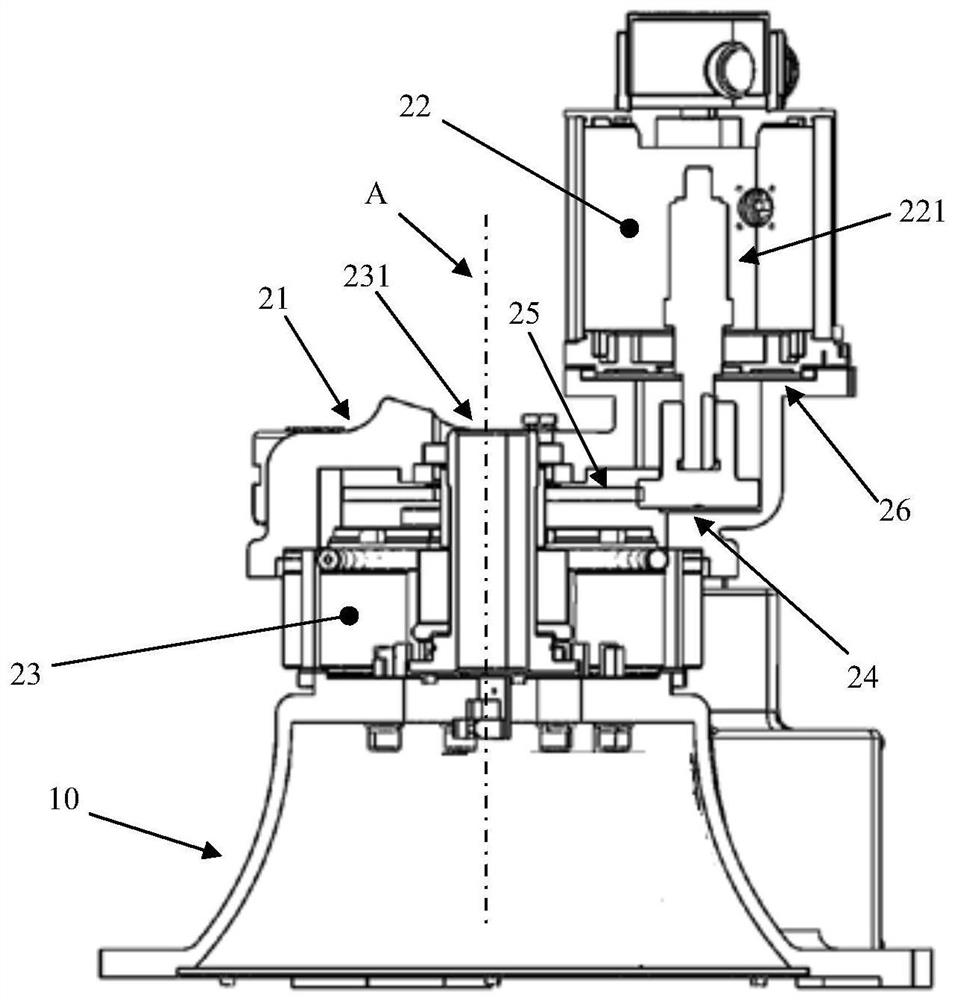

Permanent-magnet motor assembling production line

ActiveCN108880134AReduce dispatch timeAvoid wastingElectric machinesManufacturing stator/rotor bodiesProduction lineDynamic balance

The invention discloses a permanent-magnet motor assembling production line, comprising a stator assembling section, a rotor assembling section and a final assembling section. A stator assembling transmission line of the stator assembling section is sequentially provided with a stator paper inserting machine, a coil inserting and expanding integrated machine, a stator putting-in-line buffer table,a coil shaping table, a first paint stripping table, a star point extruding table, a binding table, a final shaping table, a paint dipping table, a sampling table, a stator air cooling channel, a second paint stripping table and a stator transferring preparation table along the way; The rotor assembling section comprises a rotor assembling transmission line, and the rotor assembling transmissionline is sequentially provided with an automatic magnetic steel inserting and glue dripping integrated machine, a drying machine, a rotating shaft feeding machine, a rotor putting-in-line buffer table,a nut pre-tightening table, an automatic screw cap screwing machine, a screw rod dismounting table , a dynamic balance adjusting table, a first bearing pressing machine, an automatic rotating table,a second bearing pressing machine, a rear end cover pressing table and a rotor transferring preparation table along the way. The permanent-magnet motor assembling production line has the advantages ofintegration and human-machine interaction, saving manpower and reducing costs.

Owner:浙江巨龙自动化设备股份有限公司

Superhigh-strength cold rolling band steel with anti-tensile strength above 880Mpa and its production

ActiveCN1940108AReduce the temperatureHigh strengthFurnace typesHeat treatment process controlAcid washingStrip steel

High strength cold-strip steel whose tensile strength is over 880Mpa , its component is ( weight percentage): C:0.14-0.24%;Si:0.2-1.2%;Mn:1.5-2.5%;P:<0.02%; S:<0.02%;N:<=0.005%;Ti:0.03-0.1%;Nb:0-0.04%;B:0.002- 0.006%;Al:0.02-0.08%;the other is composed of Fe and other inevitable impurity. Its method is as following: Steel billet-> hot-rolling-> acid-washing-> cold rolling-> continuous annealing; its main manufacture technological parameter is as following: The anneal temperature is between750DEG C-850DEG C, heat preservation time is controlled to between 40s-150s; Air cooling speed is 30-60DEG C / s, cooling down to350-500DEG C; The hydrocooling temperature is below 200DEG C; The drawing-back temperature is 150-300DEG C, drawing-back time is 100-300s; the unknit rate is 0-0.8%.

Owner:BAOSHAN IRON & STEEL CO LTD

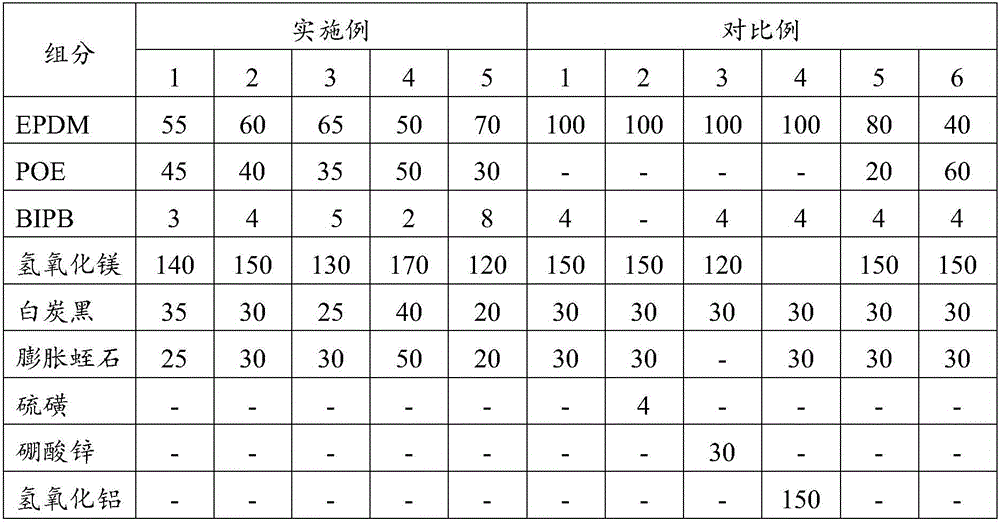

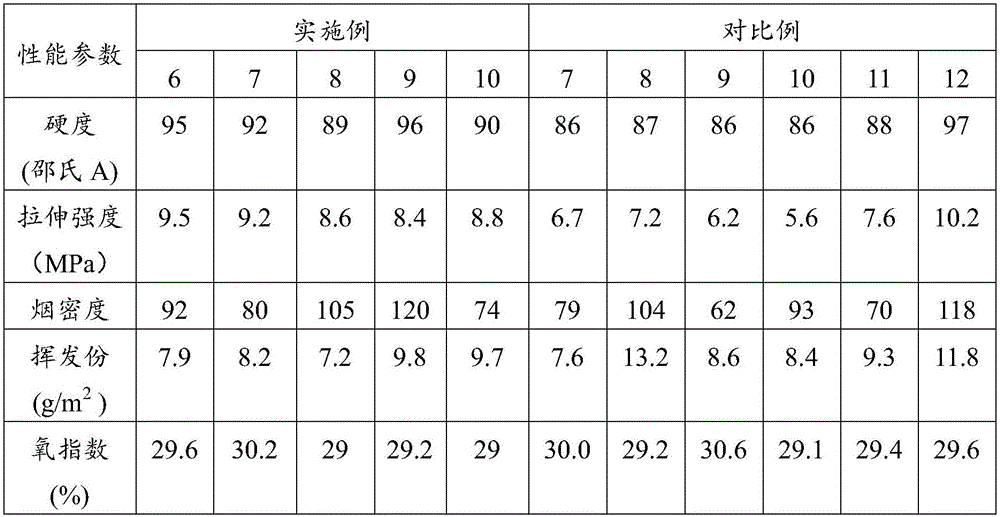

Rubber floor cloth composition, rubber floor cloth prepared from rubber floor cloth composition and applications of rubber floor cloth composition and rubber floor cloth

The invention provides a rubber floor cloth composition for preparation of rubber floor cloth. The composition is prepared from, by weight, 50-70 parts of EPDM (ethylene propylene diene monomer) rubber, 30-50 parts of POE (polyolefin elastomer), 2-8 parts of BIPB (Bis(tert-butylperoxy Isopropyl)benzene), 120-170 parts of silane modified magnesium hydrate, 20-50 parts of expanded vermiculite and 20-40 parts of silane modified white carbon black, wherein the sum of weight parts of the EPDM and the POE is 100. The invention further provides application of the composition to preparation of the rubber floor cloth, a preparation method of the rubber floor cloth with the composition serving as a raw material and application of the rubber floor cloth to railway vehicles. The rubber floor cloth has advantages of thickness uniformity, high strength, low volatile matter content, nontoxicity, safety and the like.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +2

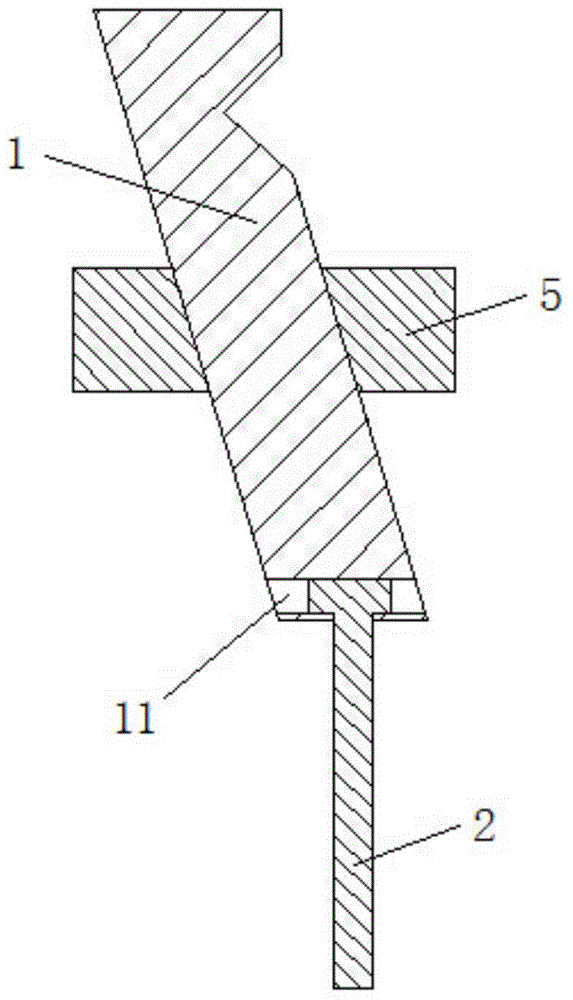

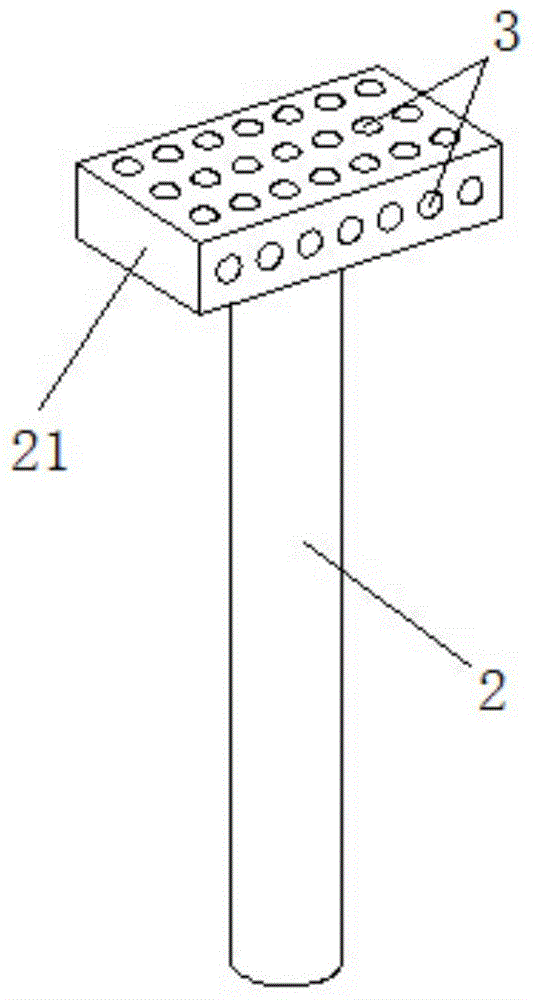

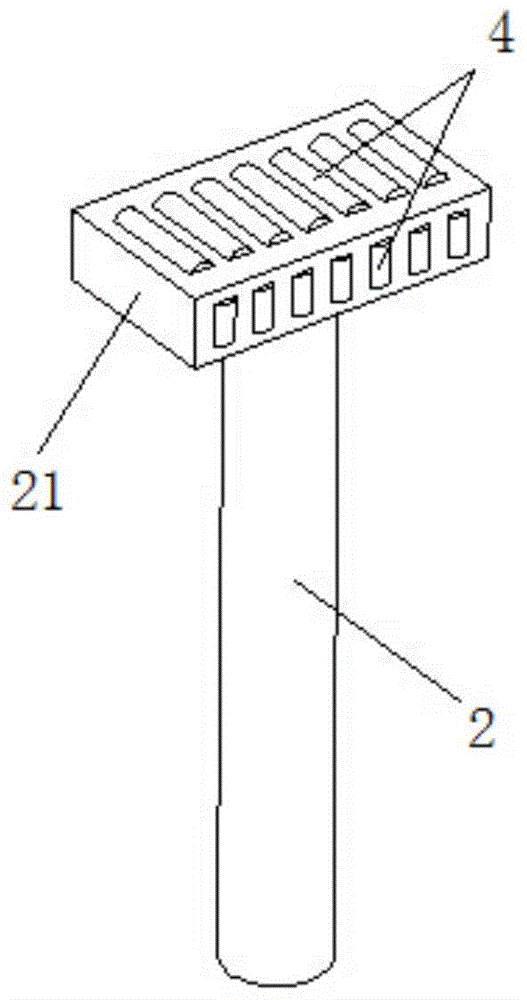

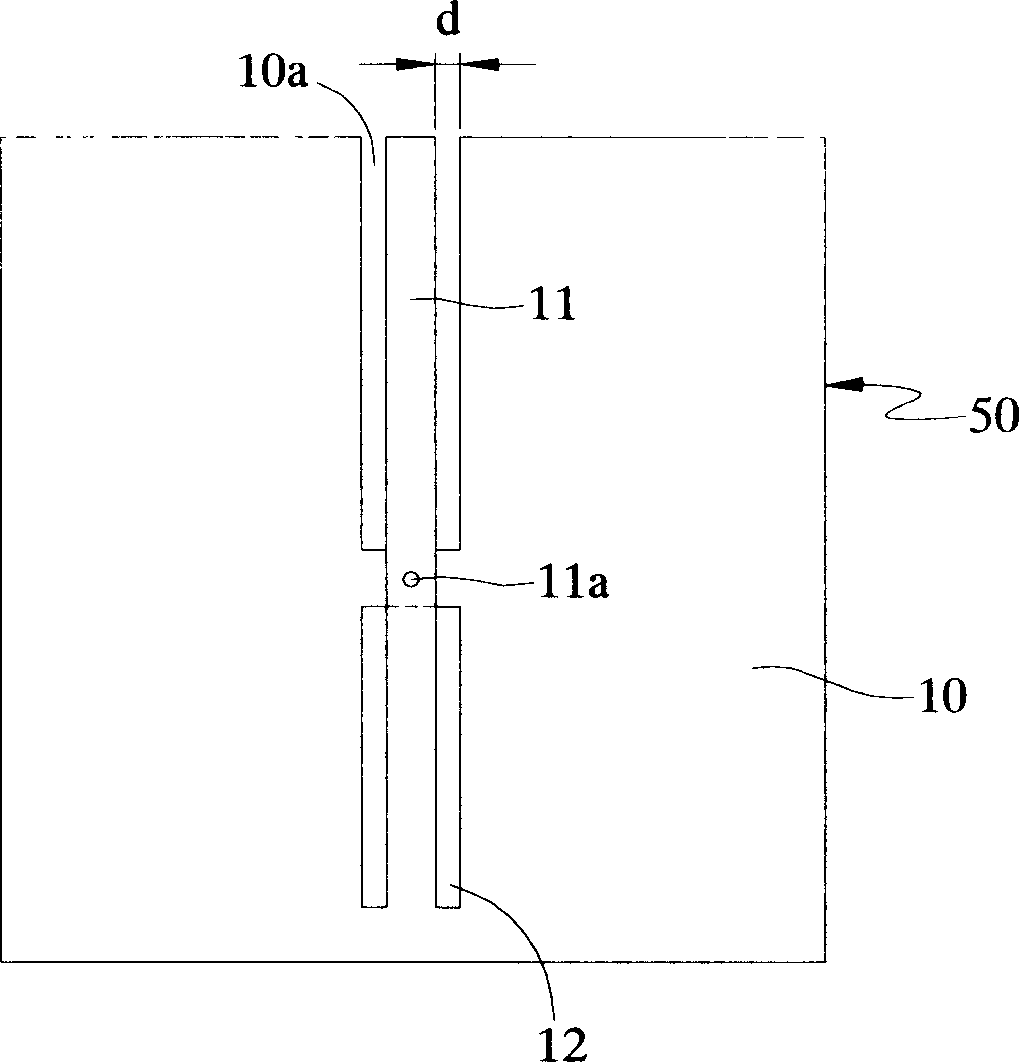

Large angle ejection mechanism for injection molding

Owner:常州市升越模塑股份有限公司

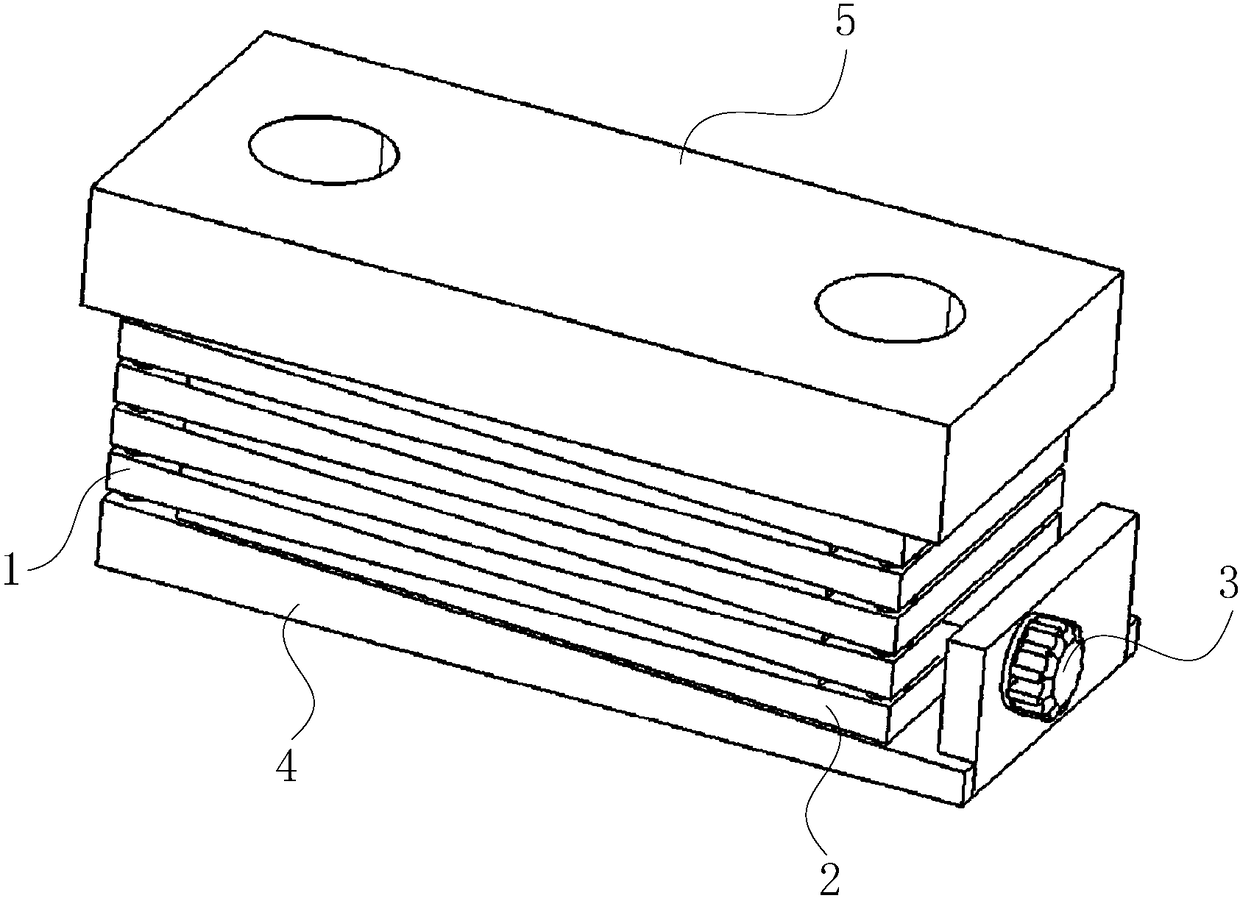

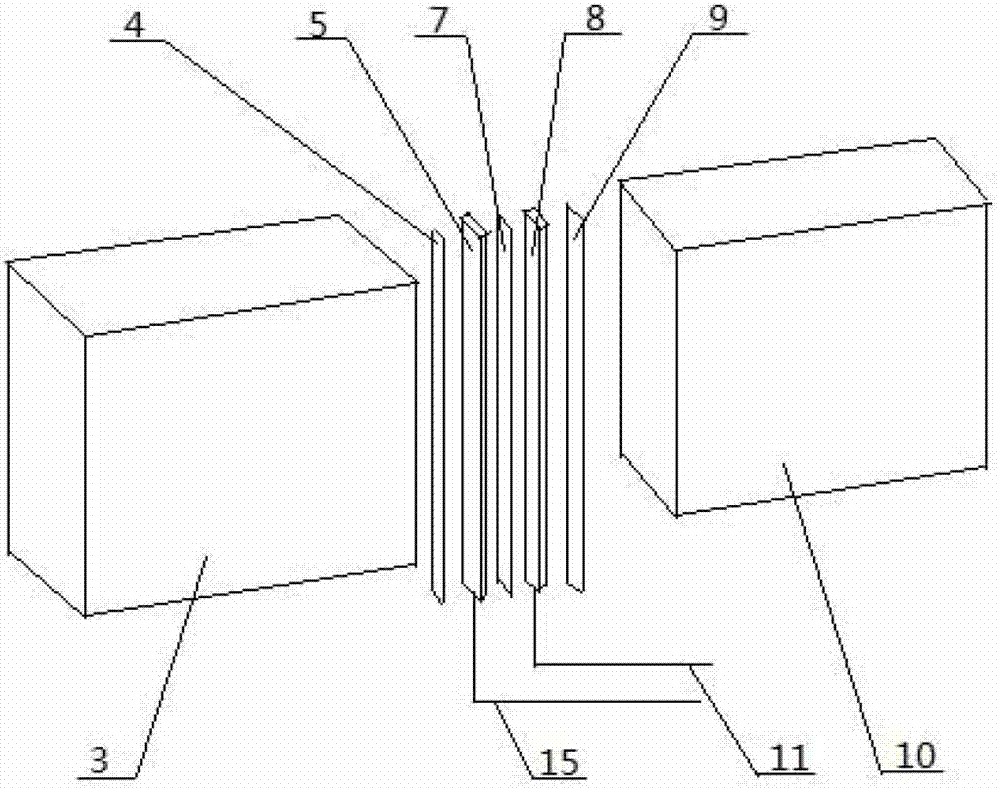

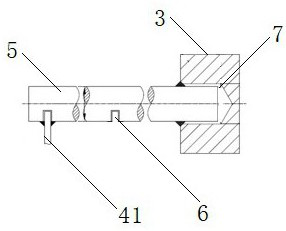

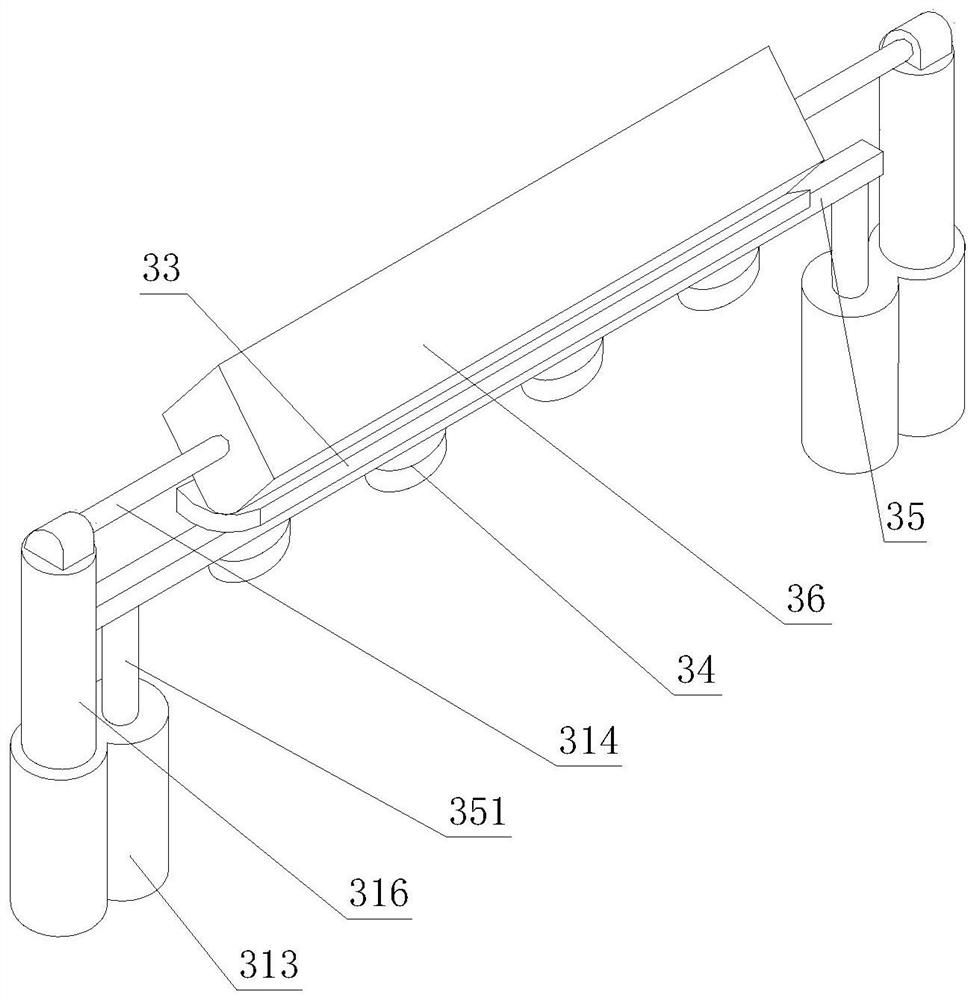

Adjustable cushion block

The invention provides an adjustable cushion block. The adjustable cushion block comprises a first wedge piece set, a second wedge piece set and a driving rod. The first wedge piece set comprises a plurality of stacked first wedge pieces, each first wedge piece is provided with a first end and a thicker second end, and the second ends of all the first wedge pieces are in series connection. The second wedge piece set comprises a plurality of stacked second wedge pieces, each second wedge piece is provided with a first end and a thicker second end, and the second ends of all the second wedge pieces are in series connection. The first wedge pieces and the second wedge pieces are overlapped alternately. The driving rod is connected to the second end of one of the second wedge pieces in a threaded mode. The alternately overlapped area of all the first wedge pieces and all the second wedge pieces is increased along with in-situ axial reverse rotation of the driving rod, and the total thickness of the first wedge piece set and the second wedge piece set is increased; and the alternately overlapped area of all the first wedge pieces and all the second wedge pieces is decreased along with in-situ axial forward rotation of the driving rod, and the total thickness of the first wedge piece set and the second wedge piece set is decreased. According to the adjustable cushion block, the second wedge piece set is driven by the driving rod to move relative to the first wedge piece set, thus fine adjustment of the thickness is achieved, and the efficiency is improved.

Owner:杨光明

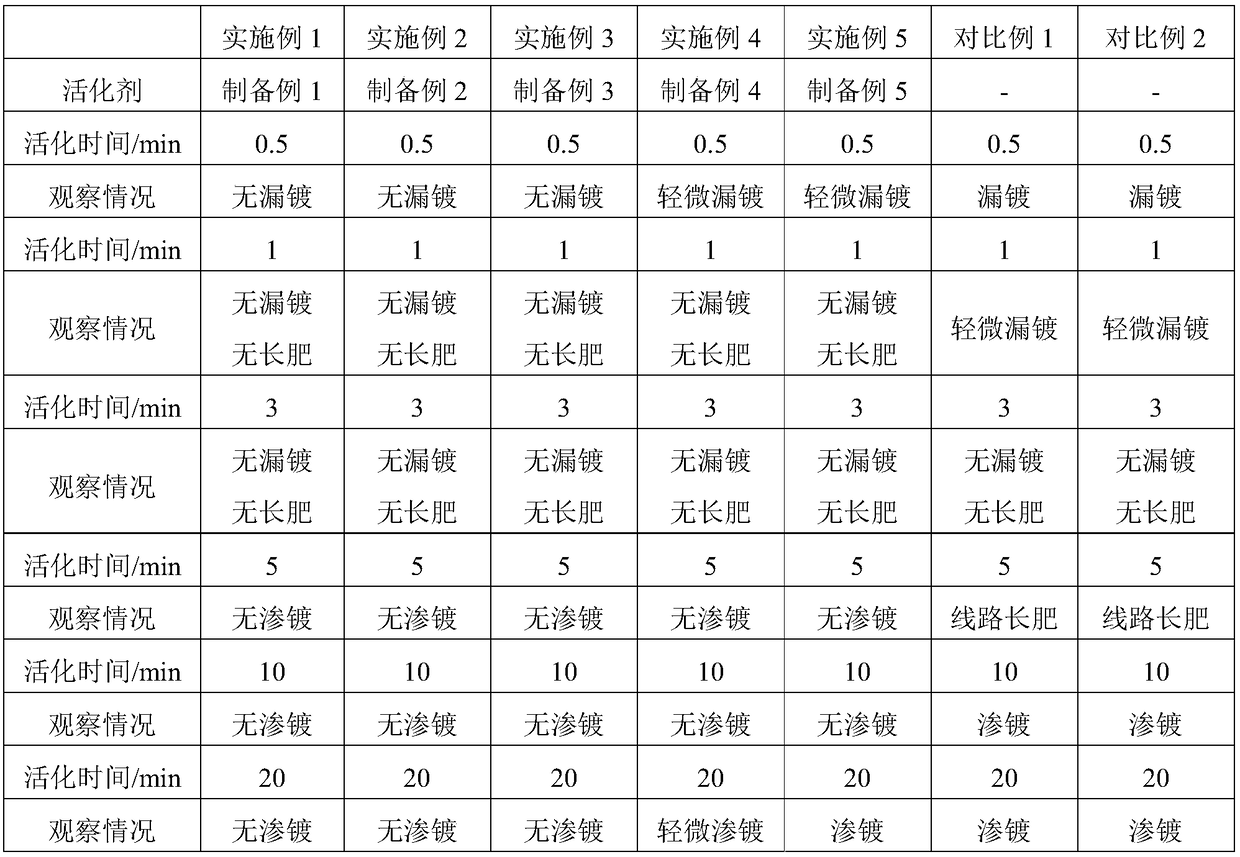

Ion palladium activating agent as well as preparation method and application thereof

PendingCN108728830AEasy to store and transportImprove stabilityLiquid/solution decomposition chemical coatingSulfateTetramine

The invention provides an ion palladium activating agent as well as a preparation method and application thereof. The ion palladium activating agent is prepared from palladium tetramine sulfate, wherein in the ion palladium activating agent, the content of palladium tetramine sulfate is 10 to 50 ppm. Palladium tetramine sulfate used in the ion palladium activating agent provided by the invention is stably preserved in a solid form at the room temperature and is easy to store and transport; and moreover, palladium tetramine sulfate is high in stability in a neutral solution, the activating agent does not need to be adjusted to be strong acidic, so that the corrosion of an acidic solution for a product or device can be reduced.

Owner:深圳市化讯半导体材料有限公司

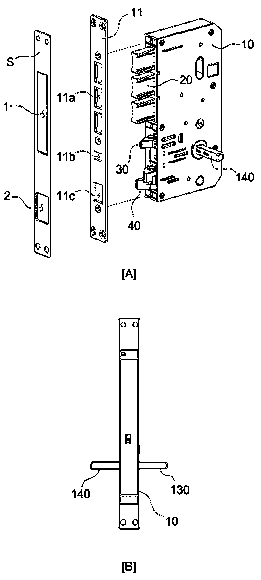

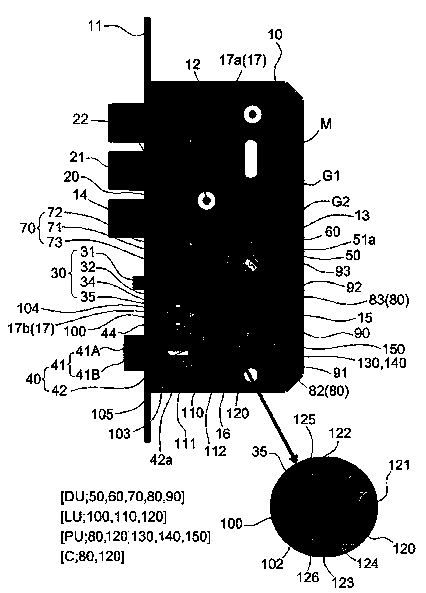

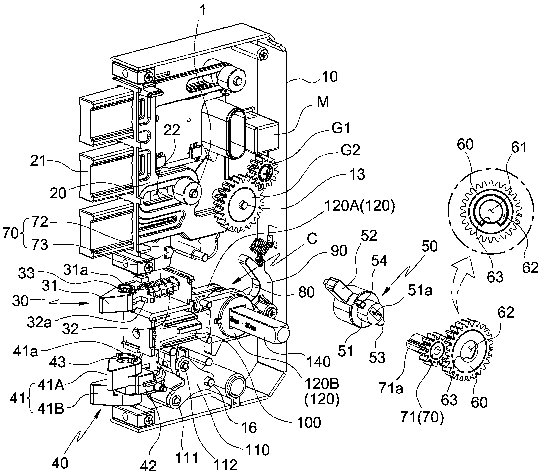

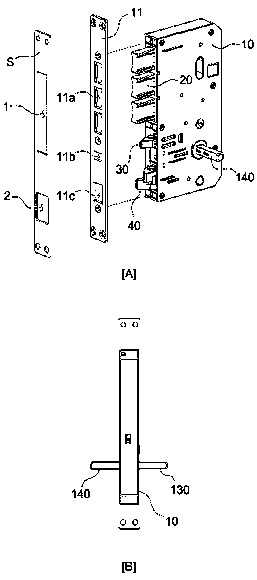

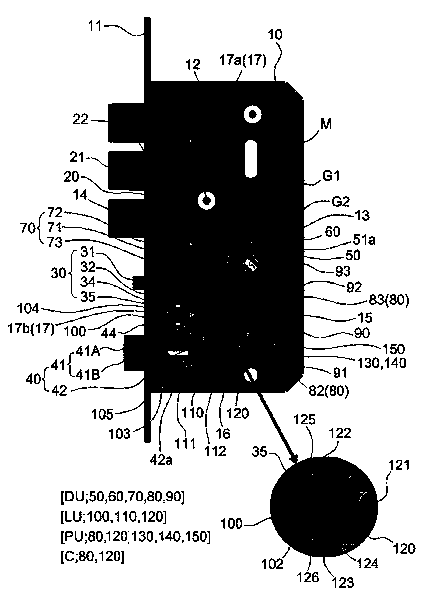

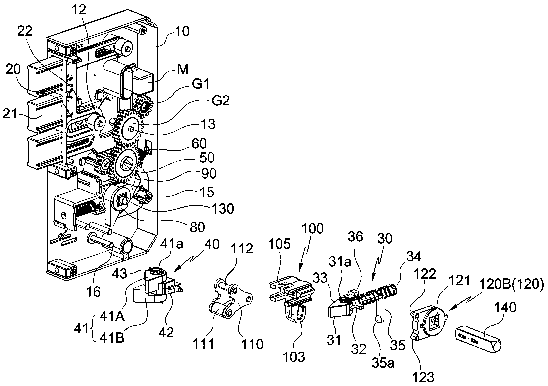

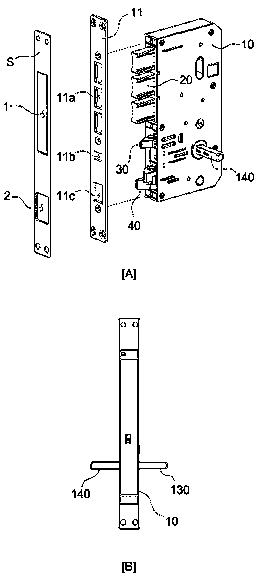

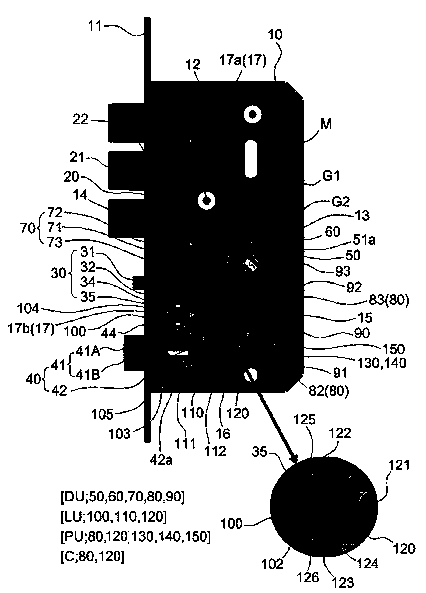

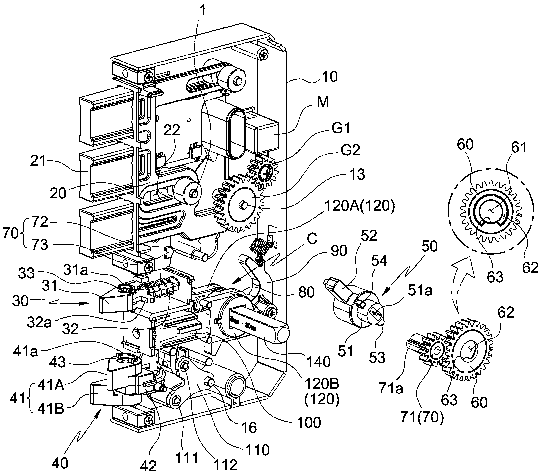

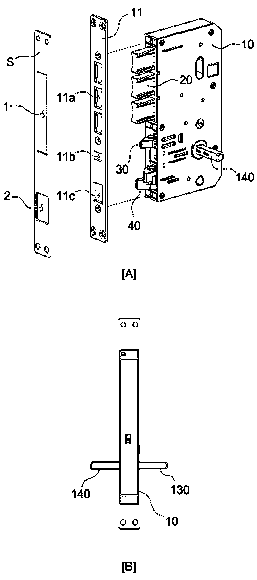

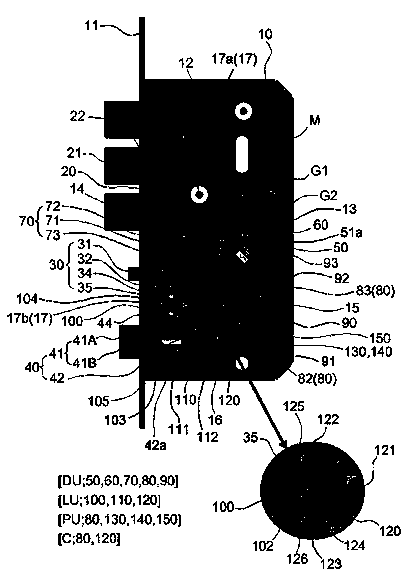

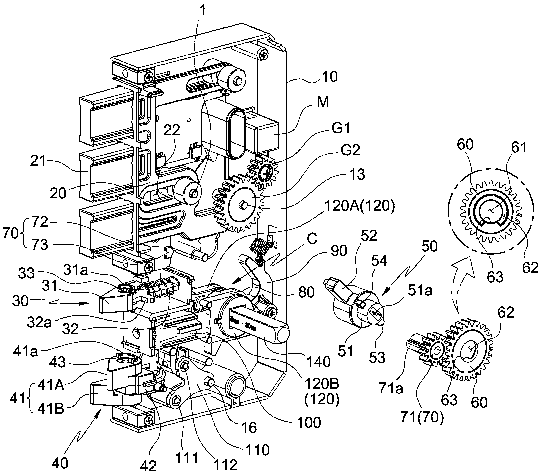

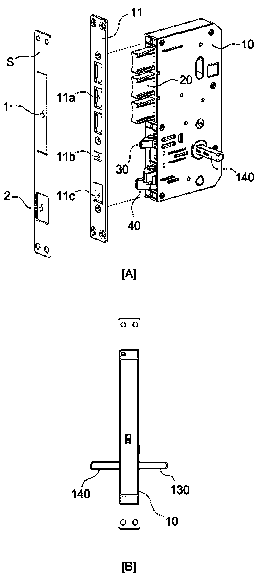

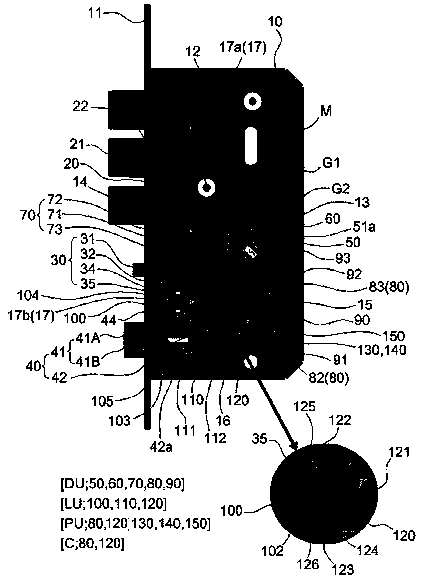

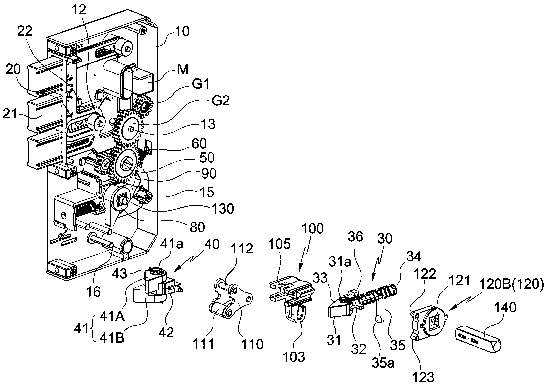

Mortise without load generation in bolt opseration

ActiveCN108729759ASmooth movementPrevent ejectionNon-mechanical controlsElectric permutation locksPasswordLoad generation

The invention provides a mortise without load generation in bolt operation. The mortise includes a deadbolt a sub latch, a main latch, and a deadbolt operation unit to lock and unlock a door. In particular, a deadbolt operation member and a driven gear are coupled to be able to rotate by using a guide groove so that a locking protrusion and a pressing protrusion part are separated from each otheron opposite sides, and the mortise includes a control means to control a motor in order to allow the driven gear to operate the deadbolt operation member and then to be returned to an original position thereof. Accordingly, when the deadbolt is locked and unlocked manually by using a key or a handle, or through operation of the motor by an input of a password, the deadbolt operation member or thedriven gear is rotated at first in a non-load state, thereby smoothly performing locking and unlocking operations of the deadbolt.

Owner:INNO ELECTRIC INC

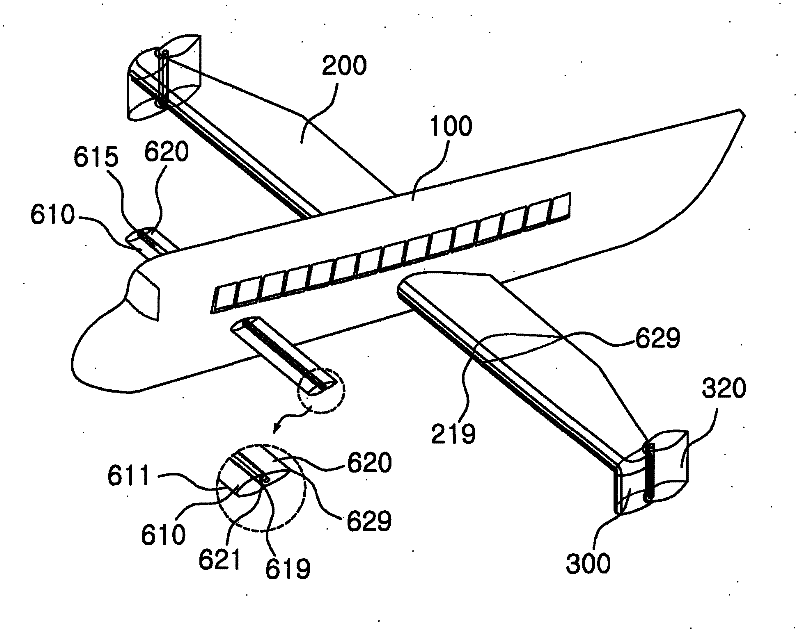

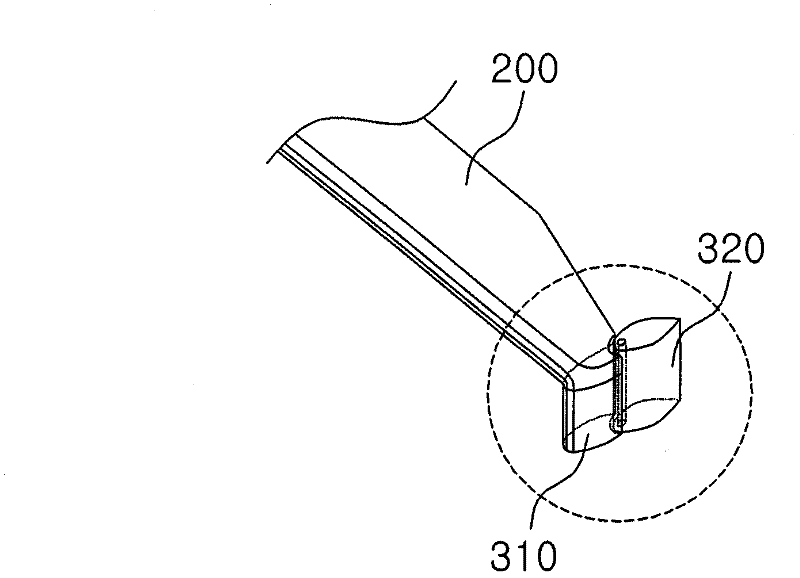

Wig vehicle excluding horizontal stabilizer

InactiveCN102131696AEnsure consistencyReduce the amount of variationAircraft stabilisationDrag reductionLeading edgeTrailing edge

The present invention relates to a WIG vehicle wing structure characterized in that in the WIG vehicle comprising a body including a fuselage, a wing unit including a main wing, and a propulsion unit including an engine, the wing unit comprises a main wing protruding out from the lateral center of the WIG vehicle fuselage, a downward wing which is vertically and downwardly installed on the outer tip of the main wing, and a canard which protrudes out horizontally from the front end of the fuselage, which is in the moving direction of the WIG vehicle from the main wing. The downward wing comprises a downward plate which is integrally and downwardly installed on the tip of the main wing, and a variable rudder which is installed to face the rear surface of the downward plate. In the lateral cross section shape, the front surface portion including the leading edge is round at a proper thickness to prevent flow separation, the thickness of a portion having the peak thickest narrows, and the trailing edge is sharp and straight. The vertical cross section of the entire downward wing is airfoil-shaped. Accordingly, the present invention is able to resolve the design problem of the horizontal stabilizer caused by a ground effect because the WIG vehicle comprises a canard for stabilizing vertical disturbance instead of a horizontal stabilizer.

Owner:WING SHIP TECH CO LTD

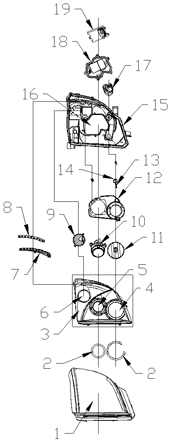

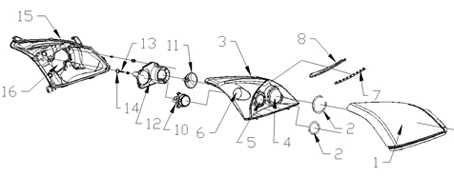

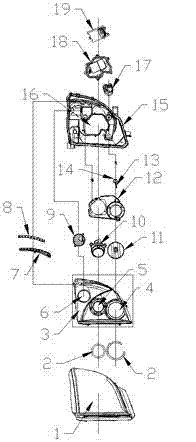

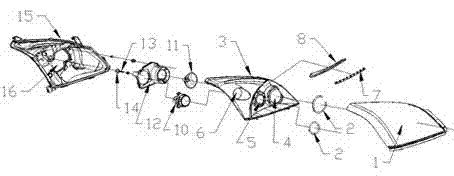

Automobile headlight

InactiveCN101893196AStructural accuracy requirements are lowEasy to producePoint-like light sourceOptical signallingEngineering

The invention discloses an automobile headlight, which solves the problems that the conventional automobile headlight has monotonous luminous mode and cannot well meet the requirement of pursuing fashion. The invention adopts the technical measures that the automobile headlight comprises a transparent lampshade, a bracket and a base, wherein the bracket is positioned between the base and the lampshade, the bracket is provided with a lens hole and a reflector hole which are communicated, a lens group with lenses is arranged in the lens hole, and a bowl reflector is arranged in the reflector hole. The automobile headlight is characterized in that a luminous ring is arranged at the outer edge ports of the lens hole and the reflector hole of the bracket respectively. The lens group and the bowl reflector can be preassembled on a plate lamp frame so as to realize quick assembly of the automobile headlight.

Owner:浙江龙鼎车业有限公司

Mortise capable of limit insertion of main latch and provided with sub latch

ActiveCN108843149APop-up blockEnsure locking functionNon-mechanical controlsLatching locksEngineeringMechanical engineering

The present invention relates to a mortise capable of limit insertion of a main latch and provided with a sub latch, including a dead bolt, a sub latch, a main latch, and a dead bolt operating unit tolock and unlock a door. Specifically, the mortise permits insertion of a latch bolt when the door is open and blocks the insertion of the latch bolt when the door is locked. So, the latch bolt performs a locking function of the door with the dead bolt so that security of the mortise can be improved. To achieve the same, a pressing unit of the sub latch and a pressing protrusion of a latch cam permit a backward movement of a latch transfer while the sub latch half-protrudes due to a closure of the door. So, while the latch stopper rotates in one direction, a locking protrusion blocks the insertion of the latch bolt. When the insertion and the withdrawal of the sub latch are completed as the door is opened and closed by a handle, the pressing unit or the pressing protrusion moves the latchtransfer forward. So, the latch stopper rotates in the other direction, and the locking protrusion permits the insertion of the latch bolt, so that when a door is closed, the main latch is inhibited to be inserted by the mortise; and the main latch is inserted only if the door is opened, so that along with the dead bolt, the main latch itself has a locking function, thereby enhancing security.

Owner:INNO ELECTRIC INC

Macromolecular fireproof and moistureproof plugging material

PendingCN112356520AMoisture-proof sealing performanceFire and moisture-proof sealing safetySynthetic resin layered productsConstructions elementsCorrosion preventionEngineering

The invention relates to the technical field of polymer plugging materials, and discloses a macromolecular fireproof and moistureproof plugging material, which comprises a first plugging layer and a second plugging layer; the exterior of the first plugging layer is fixedly connected with a first inner bonding layer, and the other side, far away from the first bonding layer, of the first plugging layer is fixedly connected with a first outer sealing strip; a first waterproof layer is fixedly connected to the inner side of the first outer sealing strip, a first inflaming retarding anti-corrosionlayer is fixedly connected to the outer portion of the first waterproof layer, a first outer bonding layer is fixedly connected to the outer portion of the first inflaming retarding anti-corrosion layer, and a second inner bonding layer is fixedly connected to the outer portion of the second blocking layer. The macromolecular fireproof and moistureproof plugging material is simple in overall structure and convenient for effective flame retardance, corrosion resistance and external protection under the condition of good plugging performance, so that the problem that the plugging performance ofthe macromolecular plugging material is difficult to guarantee when the macromolecular plugging material is used for a long time in an environment with large temperature difference or severe environment is effectively solved.

Owner:镇江宝瑞电器有限公司

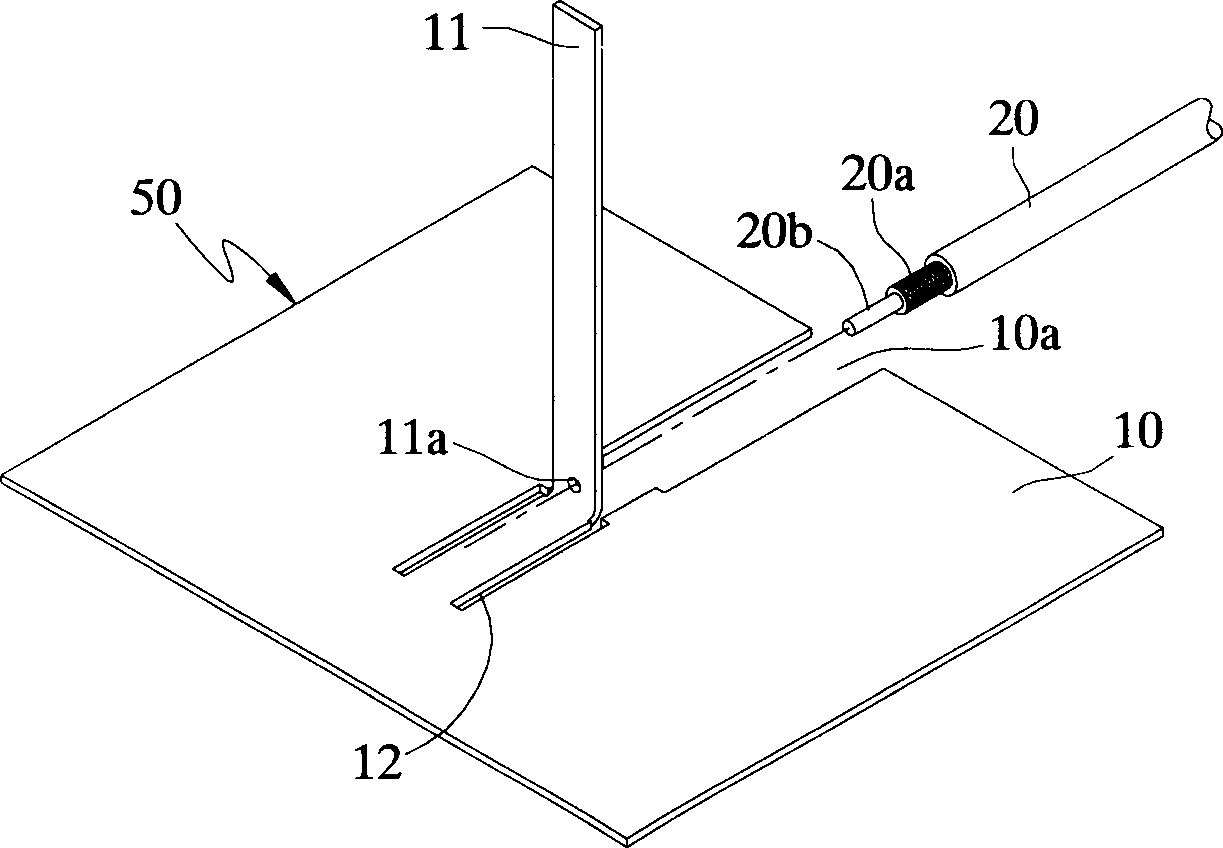

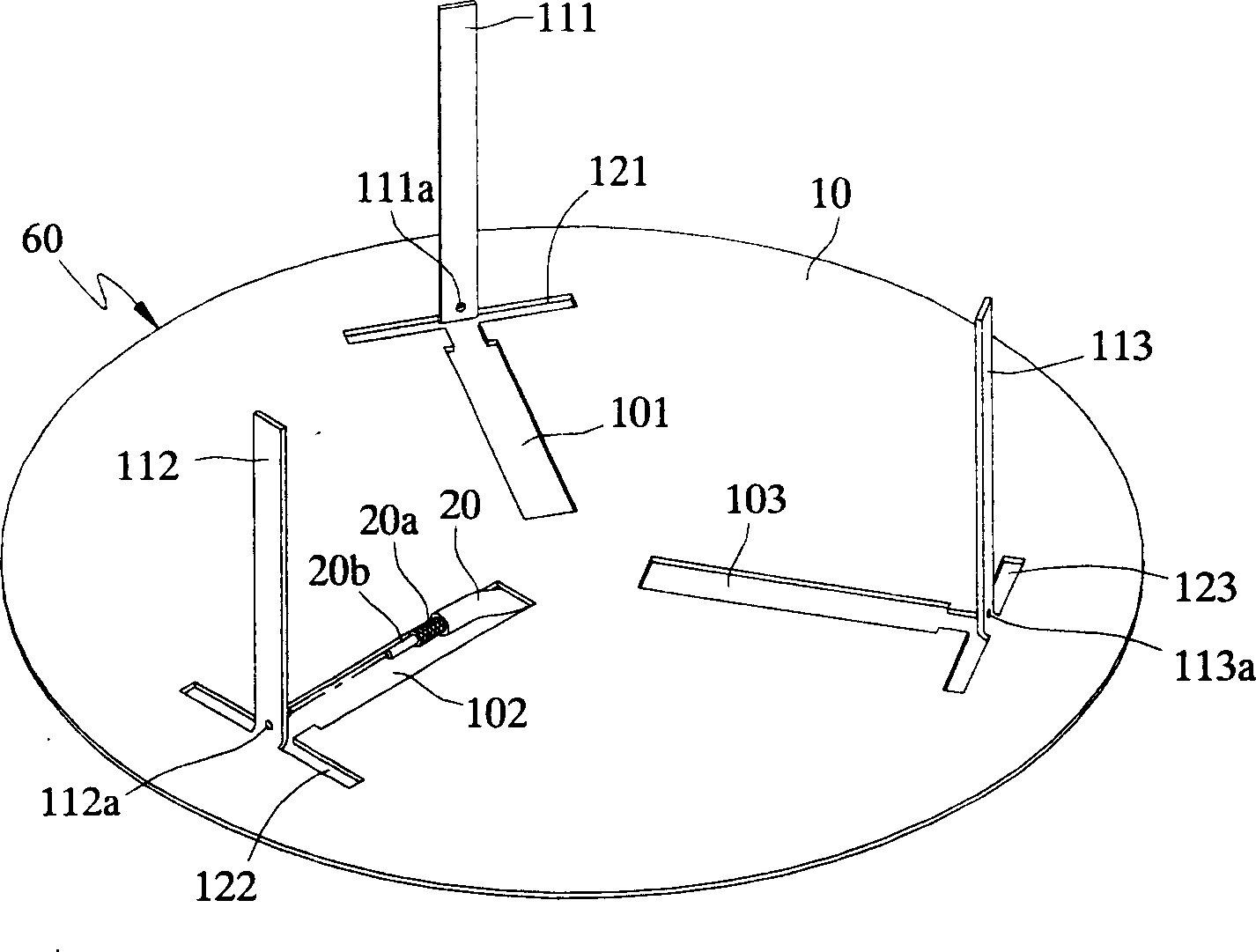

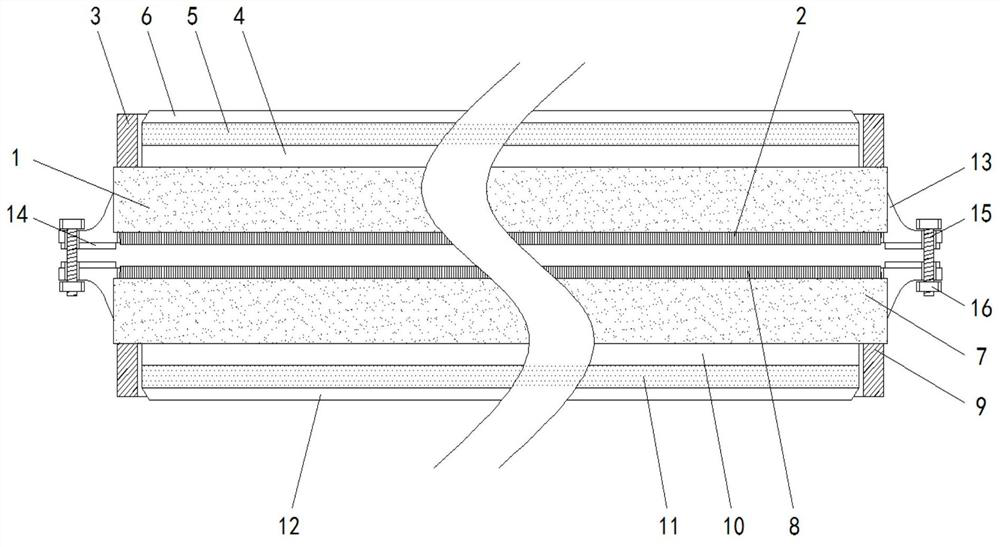

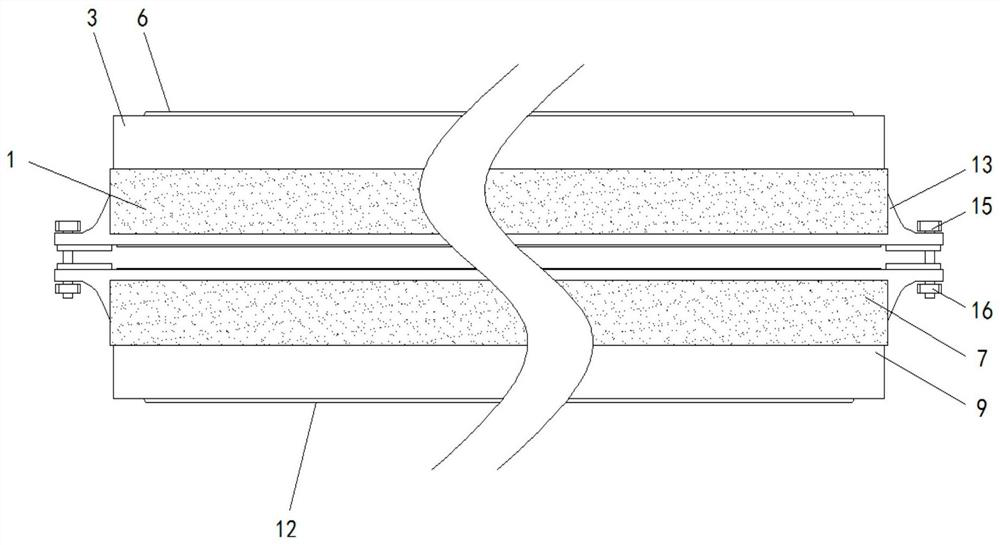

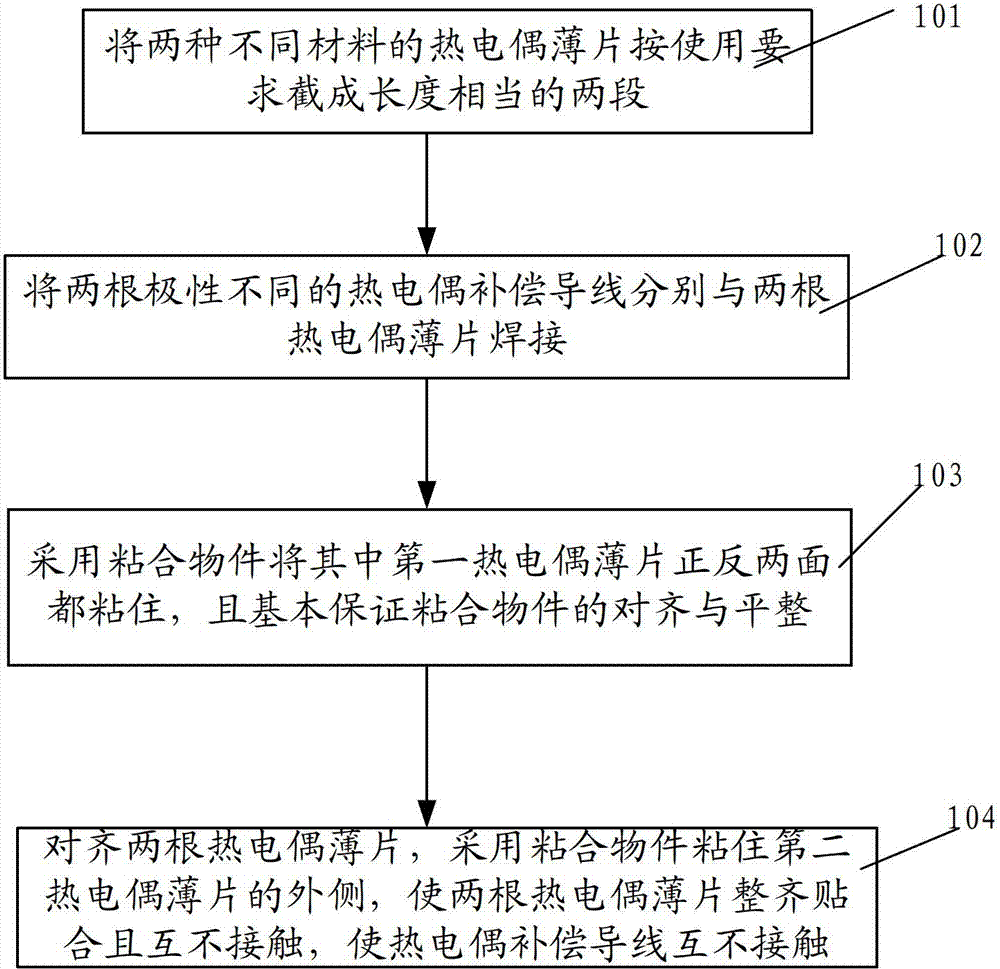

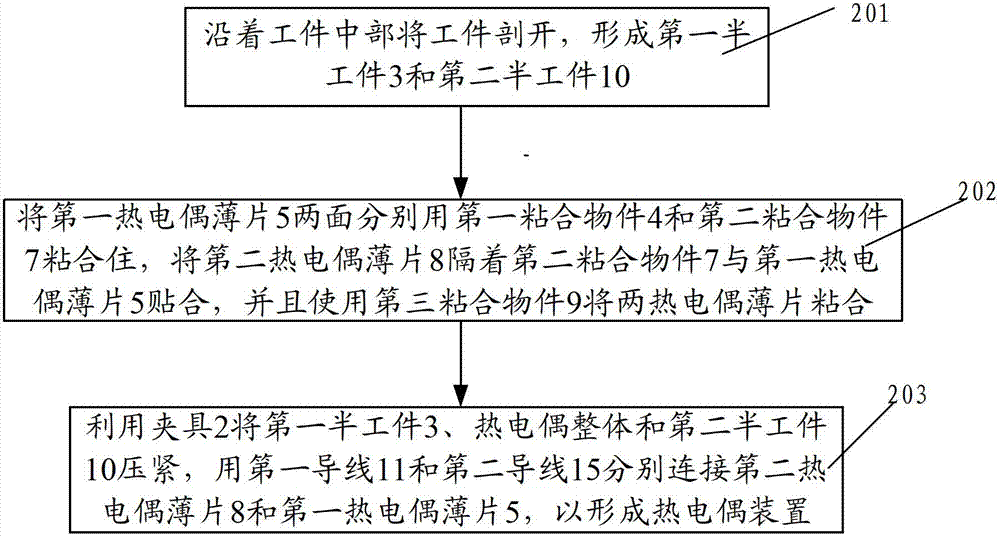

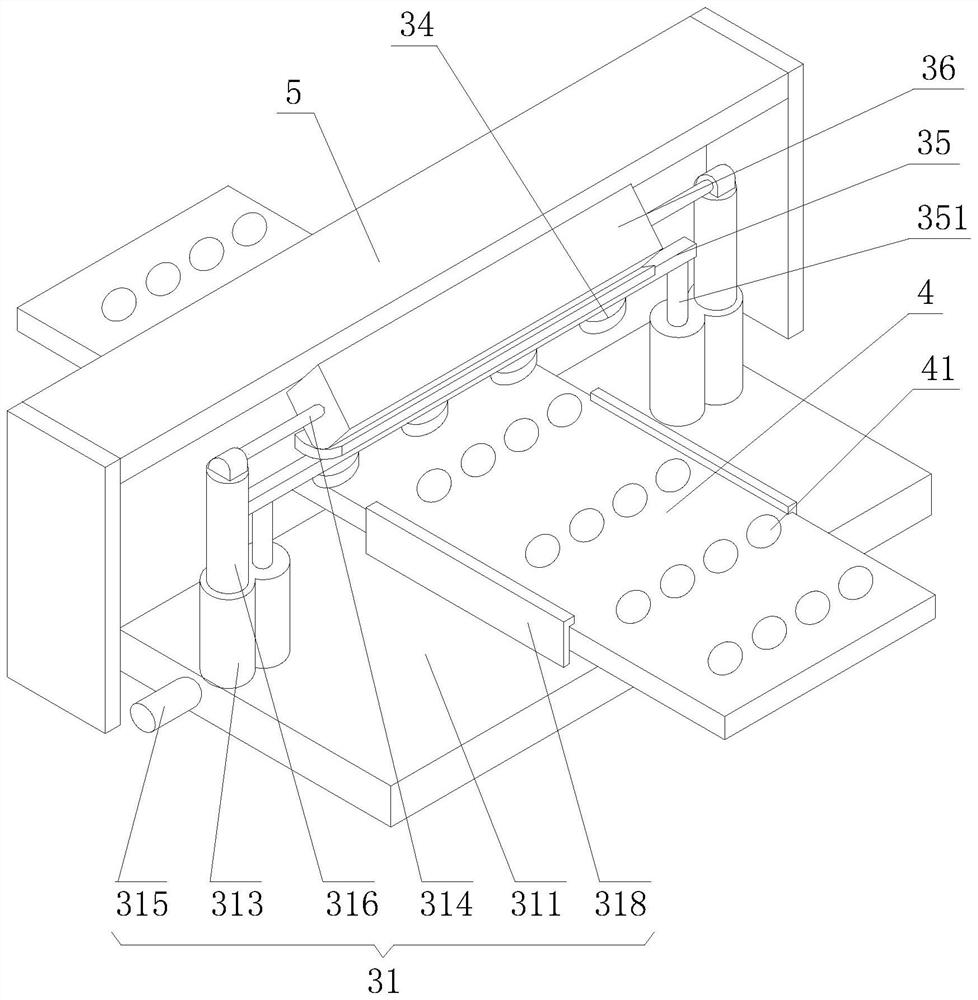

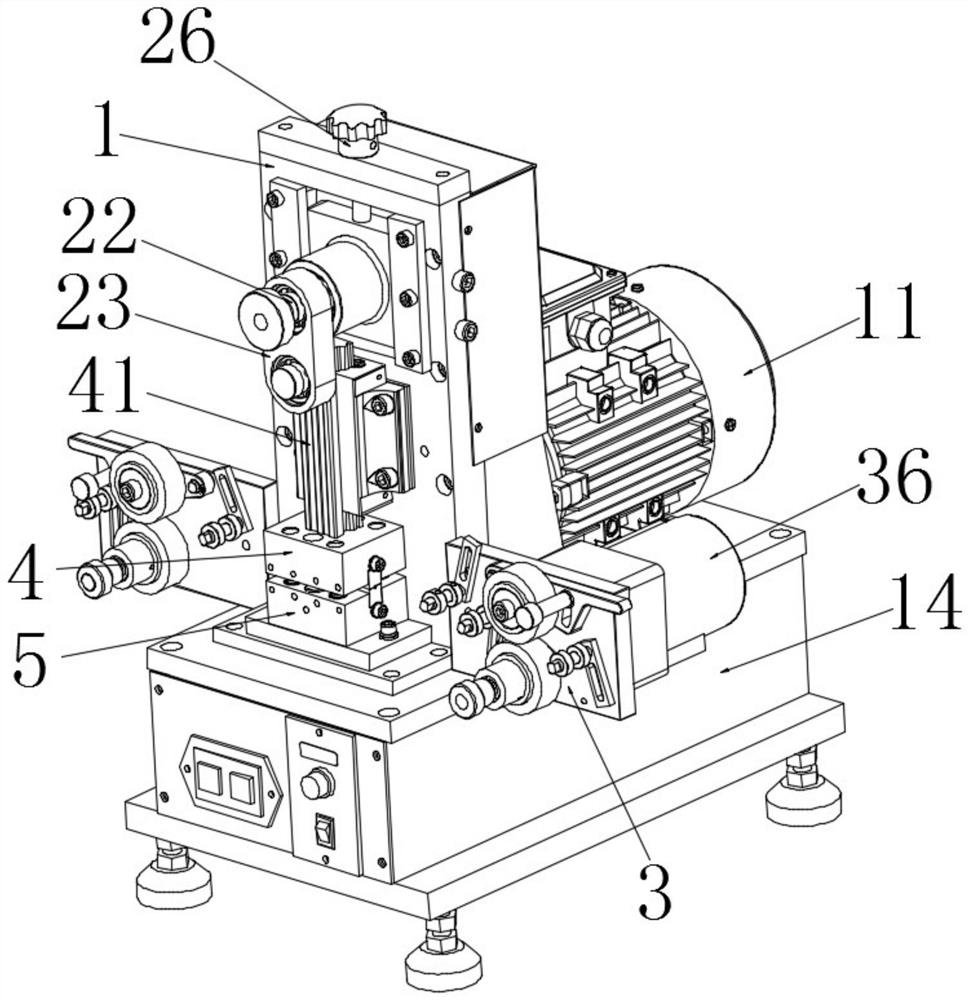

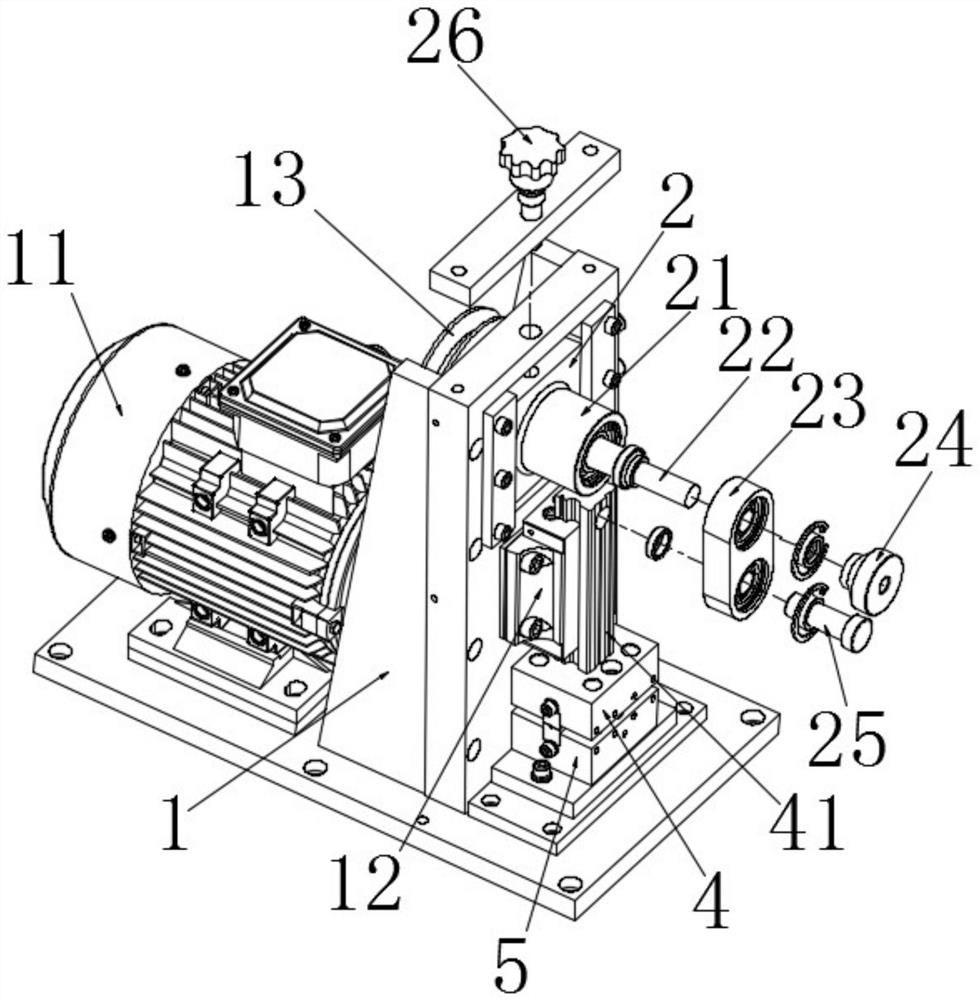

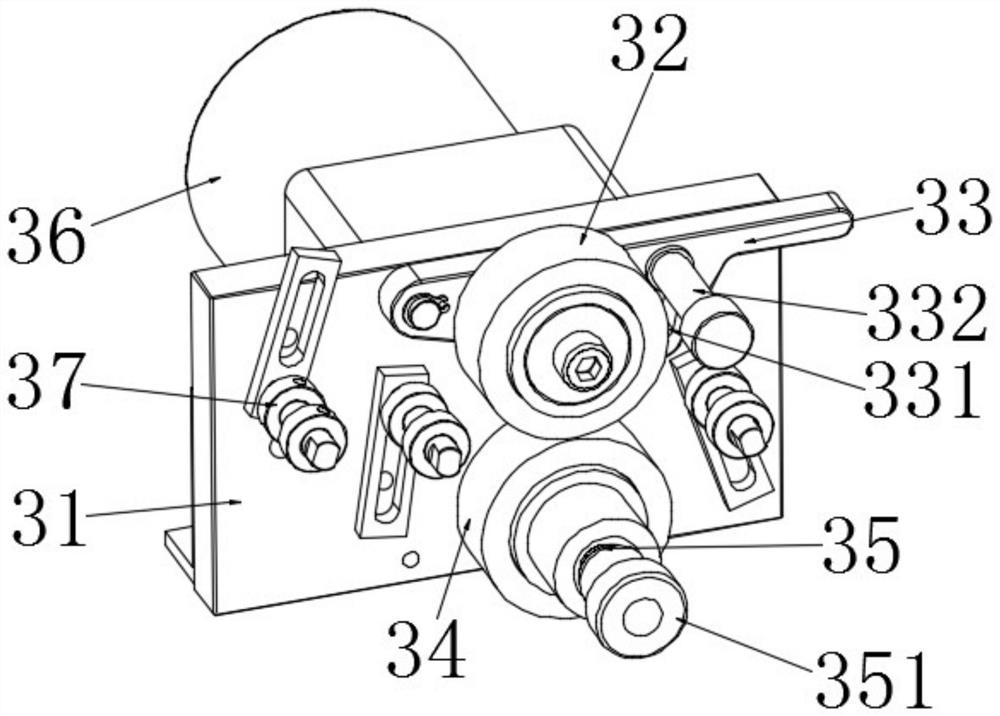

Manufacturing method of bipolar thermocouple test piece and thermocouple device and grinding and temperature-measuring device

InactiveCN103196579AImprove production convenienceAvoid bendingThermometers using electric/magnetic elementsUsing electrical meansElectrical polarityEngineering

The invention discloses a manufacturing method of a bipolar thermocouple test piece and a thermocouple device and a grinding and temperature-measuring device. The manufacturing method of the bipolar thermocouple test piece includes the following steps: cutting a thermocouple slice made of two different materials into two sections with equal lengths according to use requirements, respectively welding two thermocouple compensation wires with different polarities with the two thermocouple slices, adhering the front side and the reverse side of the first thermocouple slice with an adhesive element, enabling the two thermocouple slices to be aligned with each other, and adhering the outer side of the second thermocouple slice with an adhesive element so that the two thermocouple slices are attached but do not contact with each other and the thermocouple compensation wires do not contact with each other. The manufacturing method of the bipolar thermocouple test piece and the thermocouple device and the grinding and temperature-measuring device can reduce breaking possibility of mica pieces on an insulating layer, improves insulating reliability of two poles of a thermocouple, is stable and reliable in thermoelectric signal, and improves convenience of manufacturing of the thermocouple.

Owner:SHANGHAI DIANJI UNIV

Automobile headlight

InactiveCN101893196BStructural accuracy requirements are lowEasy to producePoint-like light sourceOptical signallingEngineering

Owner:浙江龙鼎车业有限公司

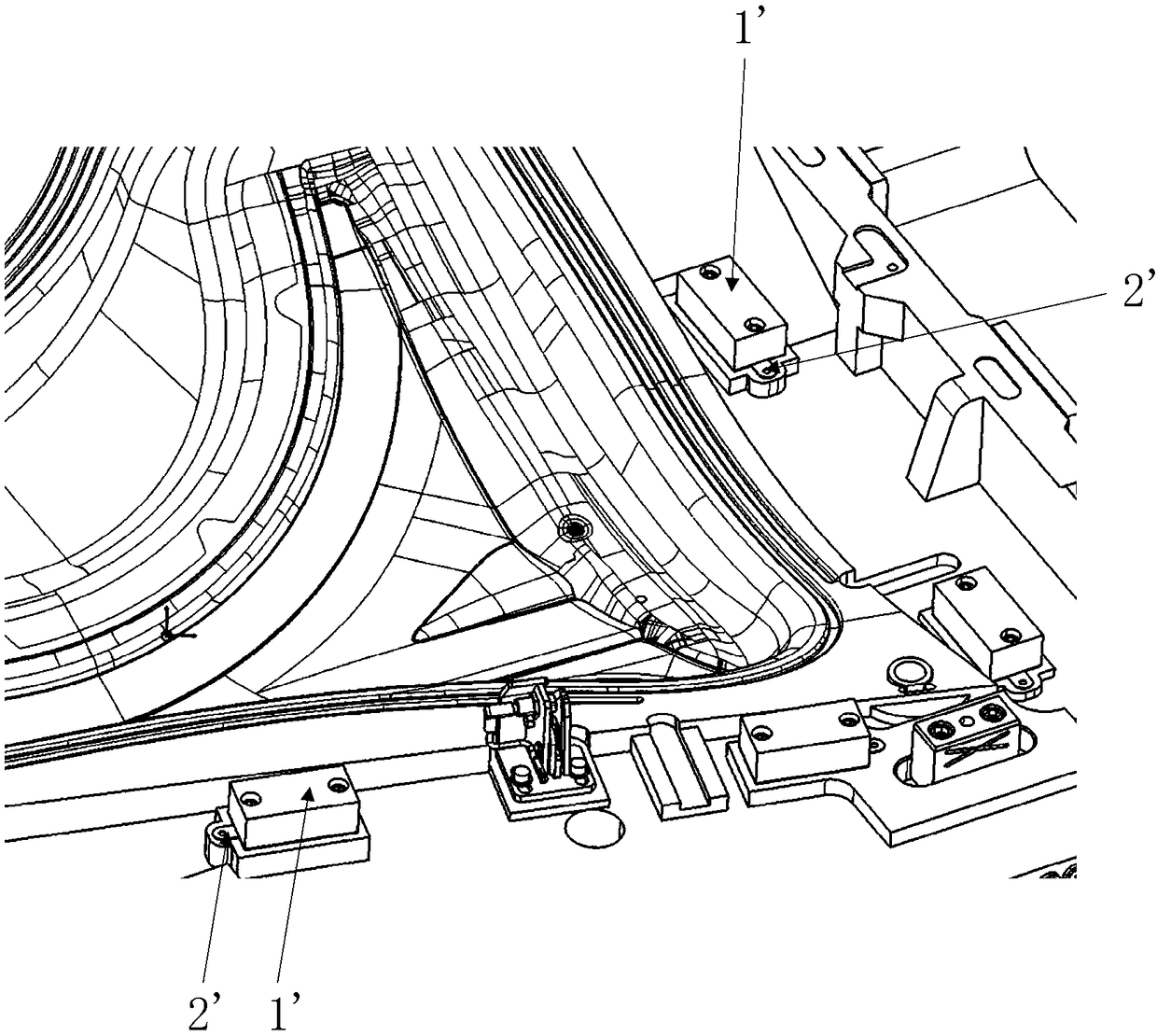

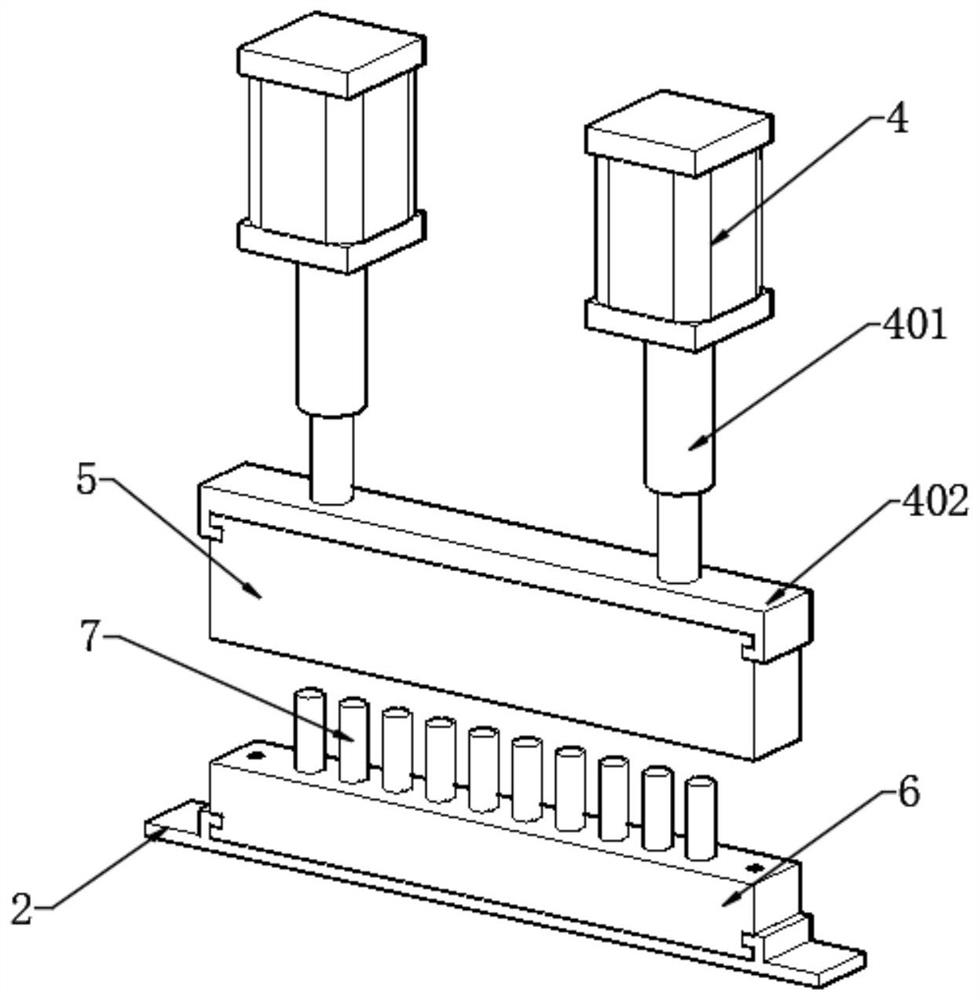

Intelligent power module manufacturing tool and method

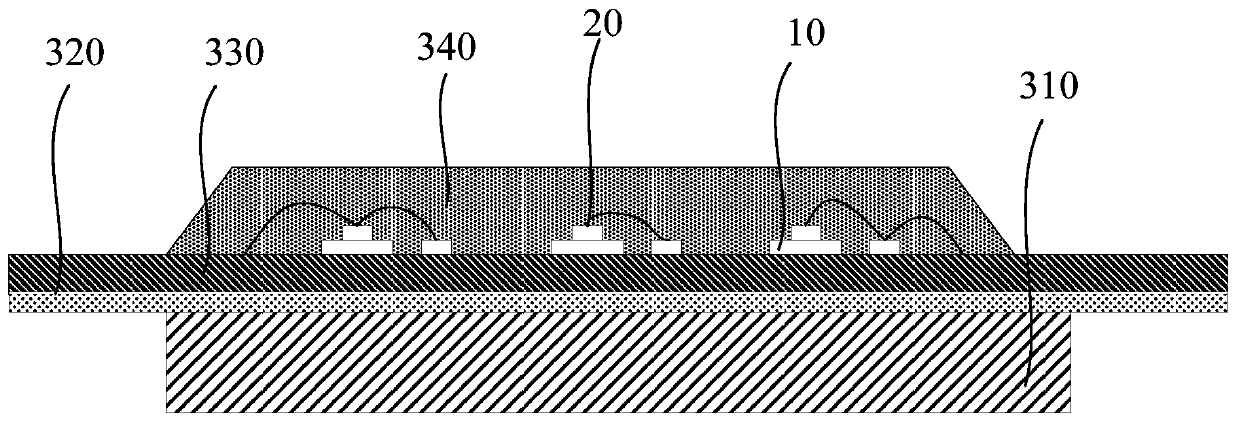

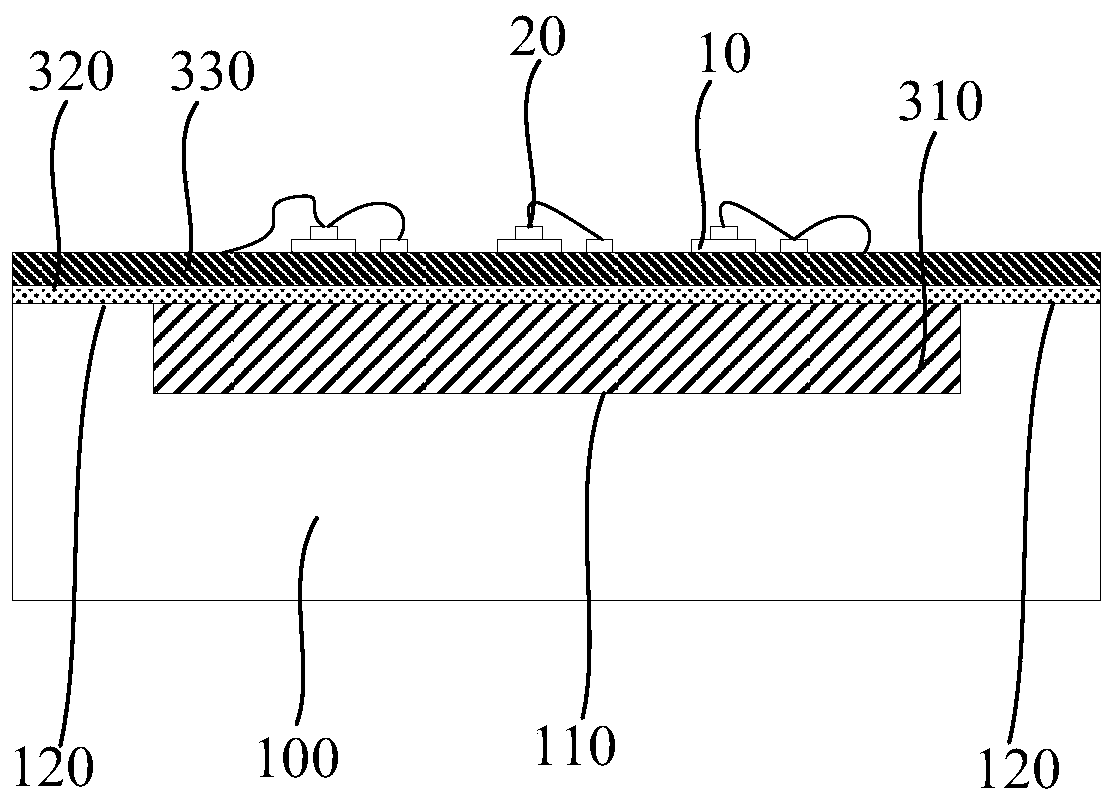

ActiveCN110289230AKeep the water levelImprove production convenienceSolid-state devicesSemiconductor/solid-state device manufacturingComputer moduleHeight difference

The invention discloses an intelligent power module manufacturing tool and method. The intelligent power module comprises a heat dissipation layer, an insulating substrate and a flexible copper-clad layer, wherein the orthographic projection of the heat dissipation layer on the insulating substrate and the flexible copper-clad layer is located in the edge of the insulating substrate and the flexible copper-clad layer. The manufacturing tool comprises a support structure and a fixing frame, wherein a support position is provided with a first support portion for supporting the heat dissipation layer and a second support portion for supporting the insulating substrate, the second support portion is disposed around the first support portion and the height difference between the second support portion and the first support portion is equal to the thickness of the heat dissipation layer; and the fixing frame comprises a frame portion and multiple first conductive strips extending inward from the frame portion, the multiple first conductive strips are welded on the mounting positions of the flexible copper-clad layer, and thus, pins of the intelligent power module are formed. The problems that in the intelligent power module manufacturing process, as the flexible mounting substrate is hard to fix, the flexible mounting substrate is too soft and is likely to be sunken, and deformation or splitting happens can be solved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Packaging equipment capable of adapting to double-bag filling of different sizes

InactiveCN112550842AAvoid stopImprove filling efficiencyWrapper twisting/gatheringLiquid materialMechanical engineeringWheel cylinder

The invention relates to the technical field of filling equipment, in particular to packaging equipment capable of adapting to double-bag filling of different sizes. The packaging equipment comprisesa filling equipment main body; the filling equipment main body comprises a base; rotating wheel cylinders are symmetrically and rotationally connected to the left side and the right side of the top ofthe base; the outer sides of the two rotating wheel cylinders are sleeved with a conveying belt; the two rotating wheel cylinders are in transmission connection through the conveying belt; an operation table top is fixedly welded to the outer side of the conveying belt and the right side of the front surface of the base; a first servo motor is fixedly connected to the bottom of one rotating wheelcylinder; and a material filling mechanism is fixedly installed at the top of the other rotating wheel cylinder. According to the packaging equipment, through rotation, a spray head is rotationally moved corresponding to a clamping mechanism on the conveying belt, so that the spray head and a bag body are moved synchronously, the equipment can move and convey the bag body at the same time when filling the bag body, stopping of the conveying device is effectively avoided, and the filling efficiency of the equipment is greatly improved.

Owner:安徽菠萝传媒有限公司

Intelligent cap packaging machine for producing lithium battery and packaging mode thereof

InactiveCN112786972AAvoid pick and placeAvoid work accidentsAssembling battery machinesFinal product manufactureElectric machineryDrive motor

The invention relates to the technical field of lithium battery production equipment, and discloses an intelligent cap packaging machine for producing the lithium battery and a packaging mode thereof. The intelligent cap packaging machine comprises a packaging machine body, a conveying device and a lithium battery, and one end of the conveying device penetrates through the packaging machine body and is arranged on the upper portion of a discharging slope; the upper surface of a top plate is provided with a recess, an air cylinder is embedded in the recess, the lower portion of the air cylinder is connected with a telescopic rod and a fixing plate, the fixing plate is provided with an upper mold in a clamping mode through a second clamping hook, and a control box is installed on one side of the packaging machine body; the conveying device comprises a chain plate, a driving motor, a first rotating roller and a second rotating roller; the chain plate is arranged around the outer sides of the first rotating roller and the second rotating roller, and the upper portion of the chain plate is provided with a lower mold in a clamped mode through a first clamping hook. According to the intelligent cap packaging machine for producing the lithium battery and the packaging mode of the intelligent cap packaging machine, industrial accidents caused by faults or misoperation of the packaging machine body are prevented, and the production convenience, the production efficiency and the yield are improved.

Owner:合肥北恒新能源科技有限公司

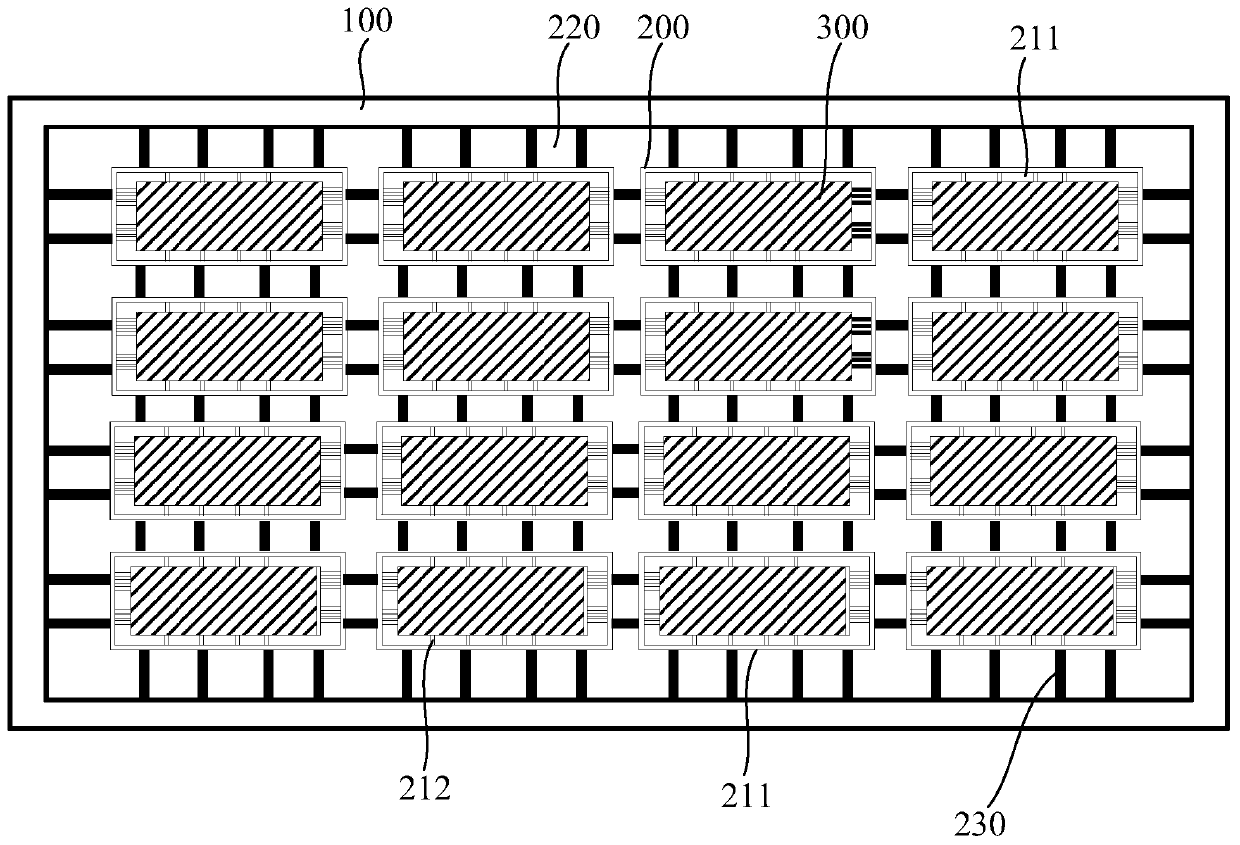

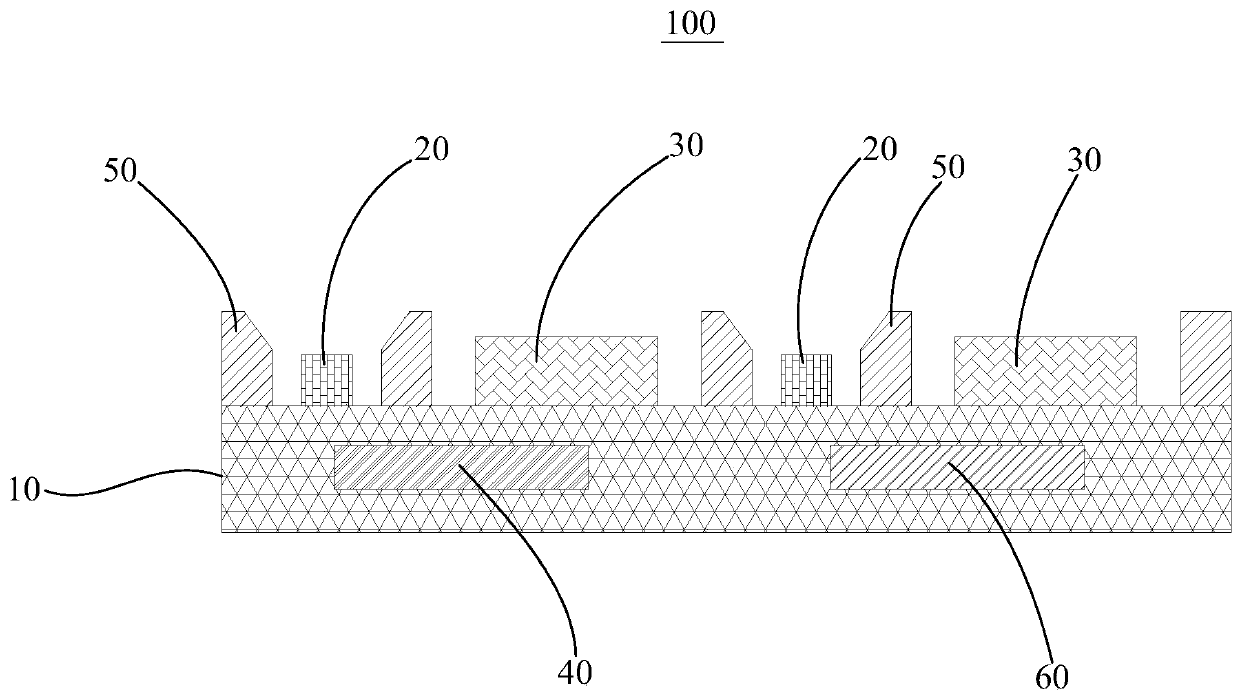

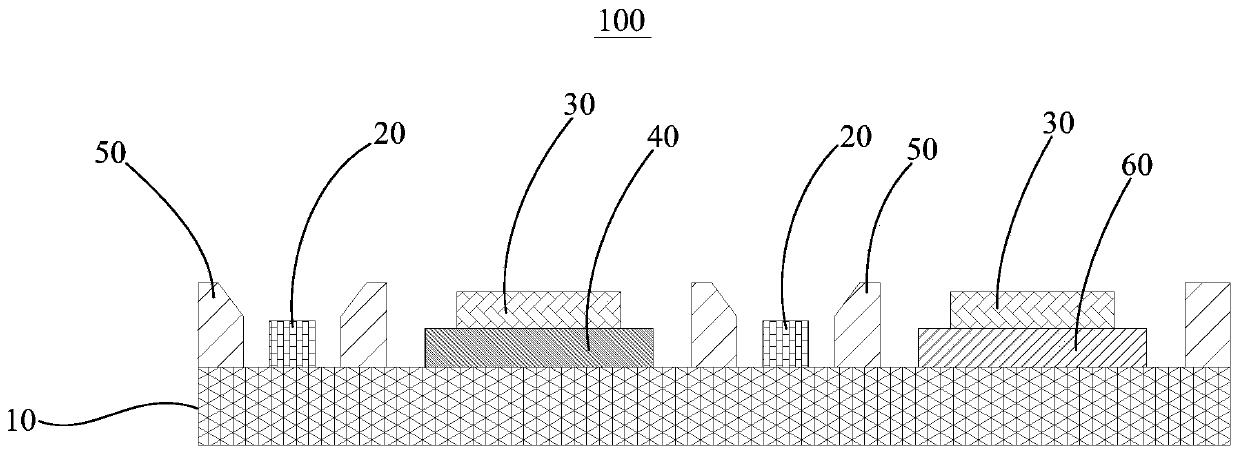

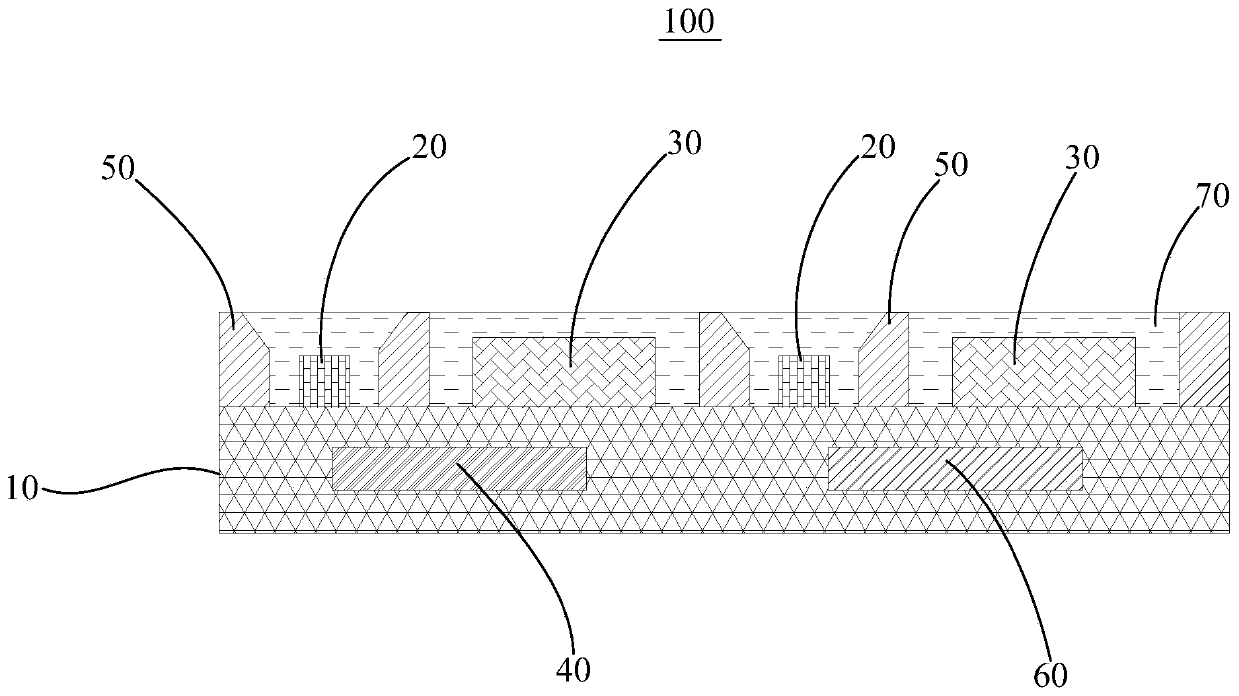

System-in-package structure and electronic device

InactiveCN110649012ASimple structureImprove production convenienceSemiconductor/solid-state device detailsSolid-state devicesEngineeringPhotoelectric conversion

The invention discloses a system-in-package structure and an electronic device using the same. The system-in-package structure comprises: a substrate which is provided with an installation surface; alight source arranged on the installation surface and electrically connected with the substrate; a photoelectric conversion device arranged on the installation surface, electrically connected with thesubstrate and spaced from the light source; and an analog front end arranged on the substrate and electrically connected with the substrate. According to the technical scheme, the structure of the electronic equipment can be simplified, and the manufacturing convenience is improved.

Owner:QINGDAO GOERTEK INTELLIGENT SENSOR CO LTD

Mortise lock with no load when the bolt operates

ActiveCN108729759BSmooth movementPrevent ejectionNon-mechanical controlsElectric permutation locksPasswordLoad generation

The invention provides a mortise without load generation in bolt operation. The mortise includes a deadbolt a sub latch, a main latch, and a deadbolt operation unit to lock and unlock a door. In particular, a deadbolt operation member and a driven gear are coupled to be able to rotate by using a guide groove so that a locking protrusion and a pressing protrusion part are separated from each otheron opposite sides, and the mortise includes a control means to control a motor in order to allow the driven gear to operate the deadbolt operation member and then to be returned to an original position thereof. Accordingly, when the deadbolt is locked and unlocked manually by using a key or a handle, or through operation of the motor by an input of a password, the deadbolt operation member or thedriven gear is rotated at first in a non-load state, thereby smoothly performing locking and unlocking operations of the deadbolt.

Owner:INNO ELECTRIC INC

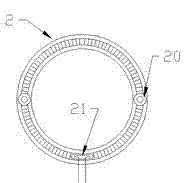

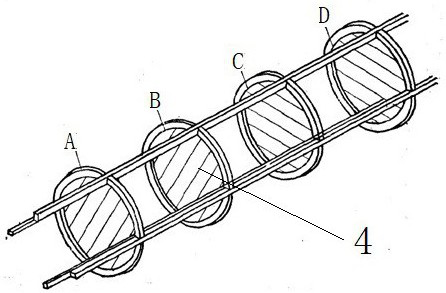

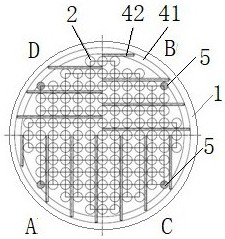

Baffling grid connecting structure

PendingCN112240726AWon't fall offIncrease stiffnessHeat exchanger casingsEngineeringHeat transfer efficiency

The invention discloses a baffling grid connecting structure. The structure comprises a plurality of distance fixing rods, wherein grooves matching baffling grids are formed in the distance fixing rods at equal intervals, the baffling grids are clamped in the grooves and are fixed through welding, distance fixing rod pipe distribution limiting circles are concentric with the baffling grids and arelarger than the inner diameters of the baffling grids, the other ends of the distance fixing rods match blind holes formed in a tube plate and are fixed to the blind holes through welding, the four to six distance fixing rods are evenly distributed in the circumferential direction, the baffling grids are clamped in the grooves through baffling rings and are fixed through welding, the distance fixing rods are cylindrical, and the diameters of the distance fixing rods are equal to or smaller than the diameter of a heat exchange tube. The structure has the advantages that 1, the connection is reliable; 2, the rigidity of the distance fixing rods is high; 3, the positioning precision is high; and 4, the width of the baffling rings is small. By means of the structure, the defects that in the prior art, connection reliability is poor, and the heat transfer efficiency is greatly affected are effectively overcome.

Owner:沈阳汇博热能设备有限公司

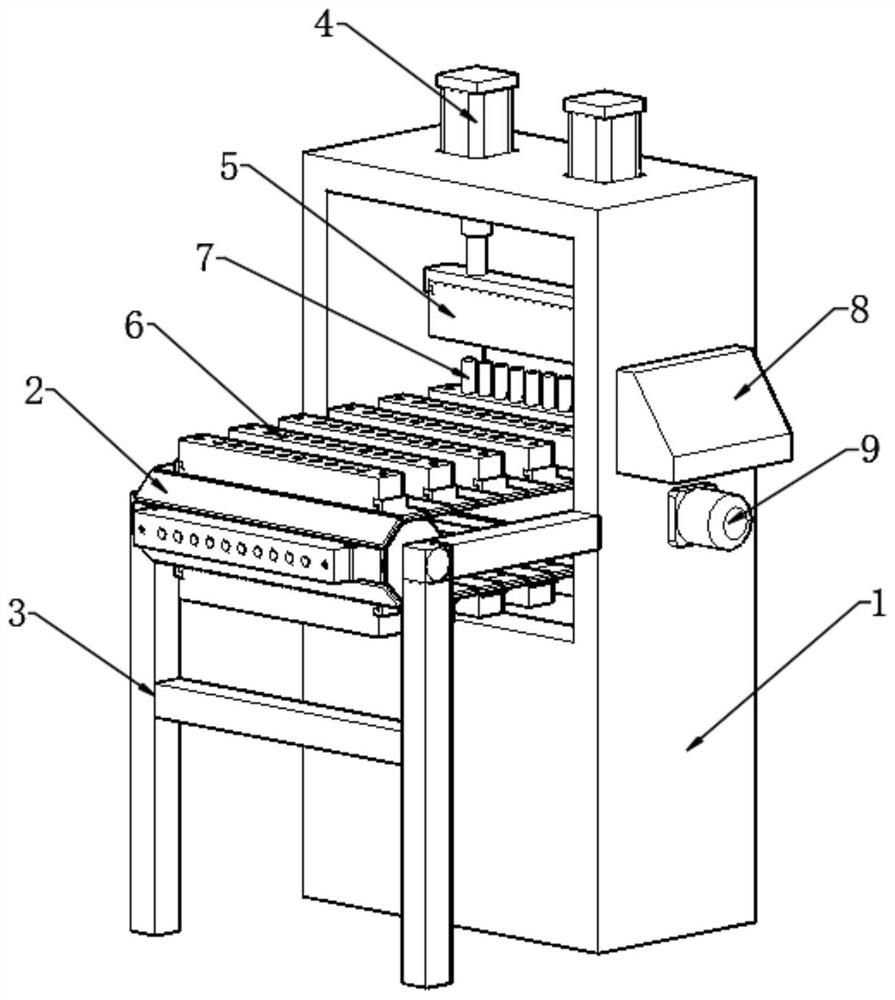

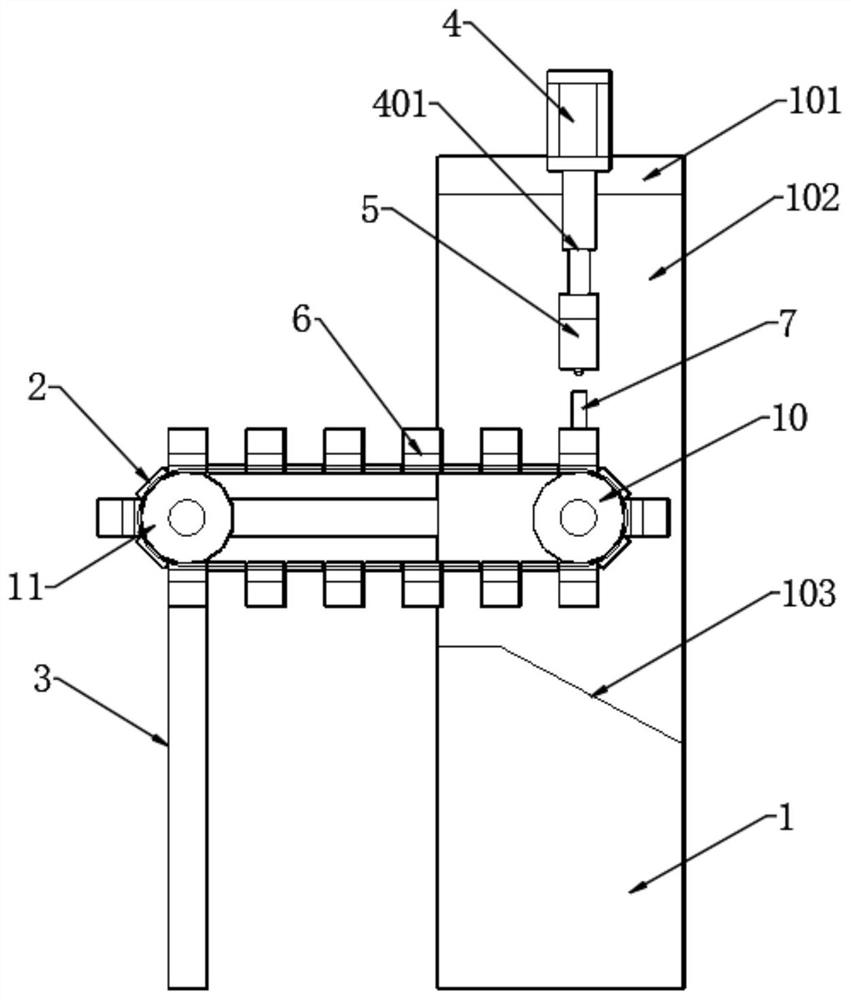

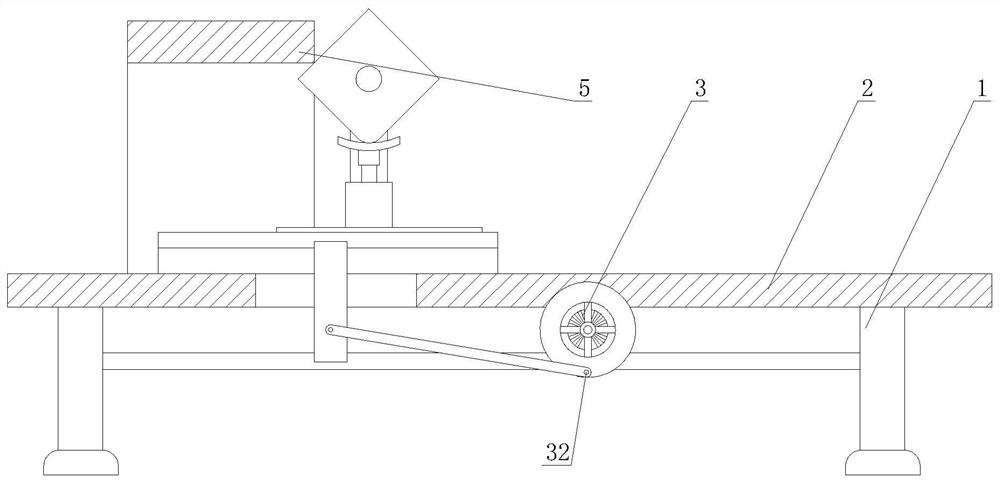

An automatic press machine for loudspeaker production

ActiveCN110814686BEasy to processImprove work efficiencyMetal working apparatusReciprocating motionEngineering

The invention discloses an automatic pressing machine used for loudspeaker production. The automatic pressing machine comprises a base, an operating platform, a pressing assembly and a portal frame, wherein both the pressing assembly and the portal frame are mounted on the operating platform; a feeding belt is further mounted on the operating platform; a loudspeaker assembly base which is uniformly distributed is arranged above the feeding belt; and the pressing assembly comprises a supporting table, a reciprocating mechanism, a stress stable, a pressing head, a stress frame and a square barrel. According to the automatic pressing machine used for the loudspeaker production disclosed by the invention, a slide block in the reciprocating mechanism drives a stress column in the supporting table, so that the supporting table is in linear reciprocating motion; and while in contact with the portal frame, the square tube moves downwards, and the square barrel moves downwards to drive the drive stress stable, the stress frame and the pressing head to move downwards, so that the pressing head just presses a to-be-pressed loudspeaker. The automatic pressing machine is good in processing effect, is high in working efficiency; and an automatic station supplementing assembly can automatically and regularly moves the feeding belt to a processing station, so that automation degree is high, and production convenience is greatly improved.

Owner:安徽井利电子有限公司

Mortise lock with no-load controller for deadbolt

The present invention relates to a mortise with a load-free controller for a door bolt and capable of fastening and releasing a dead bolt through manual operation or operation by a motor. Specifically, a dead bolt operating member and a driven gear are connected to rotate so that a hanging protrusion and a pressing protrusion unit are separated toward opposite sides by using a guiding groove. Also, the mortise includes a control unit controlling a motor in order for the driven gear to return to an initial position after the driven gear operates the dead bolt operating member. So, when the deadbolt is manually fastened and released by using a key or a handle, or when the dead bolt is fastened and released by operation of the motor such as input of a password, the dead bolt operating memberor the driven gear rotates for first time in a no-load state. So, the dead bolt is smoothly fastened and released.

Owner:INNO ELECTRIC INC

Superhigh-strength cold rolling band steel with anti-tensile strength above 880Mpa and its production

ActiveCN100430505CReduce the temperatureHigh strengthFurnace typesHeat treatment process controlAcid washingStrip steel

High strength cold-strip steel whose tensile strength is over 880Mpa , its component is ( weight percentage): C:0.14-0.24%;Si:0.2-1.2%;Mn:1.5-2.5%;P:<0.02%; S:<0.02%;N:<=0.005%;Ti:0.03-0.1%;Nb:0-0.04%;B:0.002- 0.006%;Al:0.02-0.08%;the other is composed of Fe and other inevitable impurity. Its method is as following: Steel billet-> hot-rolling-> acid-washing-> cold rolling-> continuous annealing; its main manufacture technological parameter is as following: The anneal temperature is between750DEG C-850DEG C, heat preservation time is controlled to between 40s-150s; Air cooling speed is 30-60DEG C / s, cooling down to350-500DEG C; The hydrocooling temperature is below 200DEG C; The drawing-back temperature is 150-300DEG C, drawing-back time is 100-300s; the unknit rate is 0-0.8%.

Owner:BAOSHAN IRON & STEEL CO LTD

Mortise lock with sub-lock with limited bolt spring

ActiveCN108843149BPop-up blockEnsure locking functionNon-mechanical controlsLatching locksEngineeringCam

The present invention relates to a mortise capable of limit insertion of a main latch and provided with a sub latch, including a dead bolt, a sub latch, a main latch, and a dead bolt operating unit tolock and unlock a door. Specifically, the mortise permits insertion of a latch bolt when the door is open and blocks the insertion of the latch bolt when the door is locked. So, the latch bolt performs a locking function of the door with the dead bolt so that security of the mortise can be improved. To achieve the same, a pressing unit of the sub latch and a pressing protrusion of a latch cam permit a backward movement of a latch transfer while the sub latch half-protrudes due to a closure of the door. So, while the latch stopper rotates in one direction, a locking protrusion blocks the insertion of the latch bolt. When the insertion and the withdrawal of the sub latch are completed as the door is opened and closed by a handle, the pressing unit or the pressing protrusion moves the latchtransfer forward. So, the latch stopper rotates in the other direction, and the locking protrusion permits the insertion of the latch bolt, so that when a door is closed, the main latch is inhibited to be inserted by the mortise; and the main latch is inserted only if the door is opened, so that along with the dead bolt, the main latch itself has a locking function, thereby enhancing security.

Owner:INNO ELECTRIC INC

Chain hammering device

PendingCN112642977AReduce processing timeReduce processing costsForging/hammering/pressing machinesForging press drivesSlide plateMachine

The invention discloses a chain hammering device which comprises a machine base, a vertical frame connected to the upper portion of the machine base and chain guide mechanisms arranged on the two sides of the vertical frame and used for guiding a chain. A host is connected to the rear portion of the vertical frame, a sliding plate is arranged in the center of the vertical frame in a sliding mode, and the upper end of the vertical frame is in threaded connection with a screw connected with the sliding plate. A flange seat is connected to the surface of the sliding plate, an eccentric shaft connected with the host is arranged in the center of the flange seat, a connecting sleeve is connected to the end of the eccentric shaft, a sliding block is movably connected to the lower portion of the connecting sleeve, a top die is connected to the lower portion of the sliding block, and a bottom die connected with the machine seat and used for containing and the hammering the chain is arranged under the top die. The chain hammering device has the advantages of being simple in structure and convenient to use, the chain is automatically input between the top die and the bottom die for corresponding hammering machining, the gap for hammering between the top die and the bottom die can be adjusted according to the requirements of a user, and chain hammering convenience and hammering efficiency are effectively improved.

Owner:浙江立新珠宝科技股份有限公司

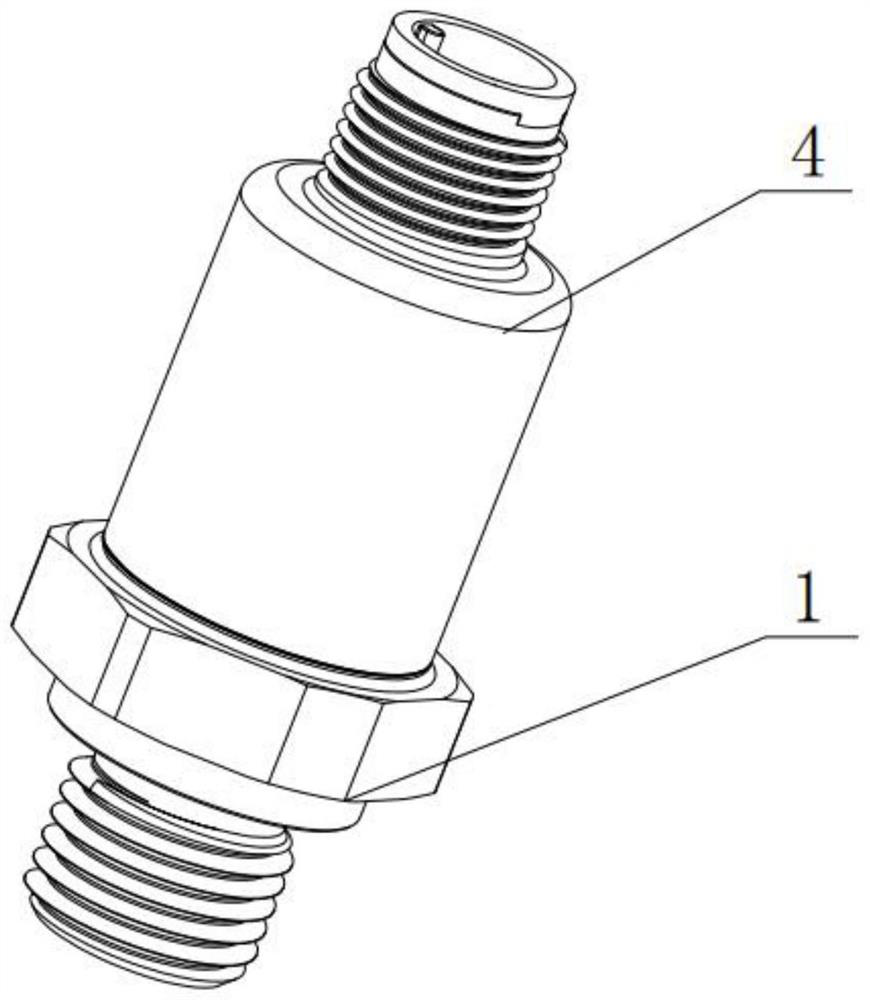

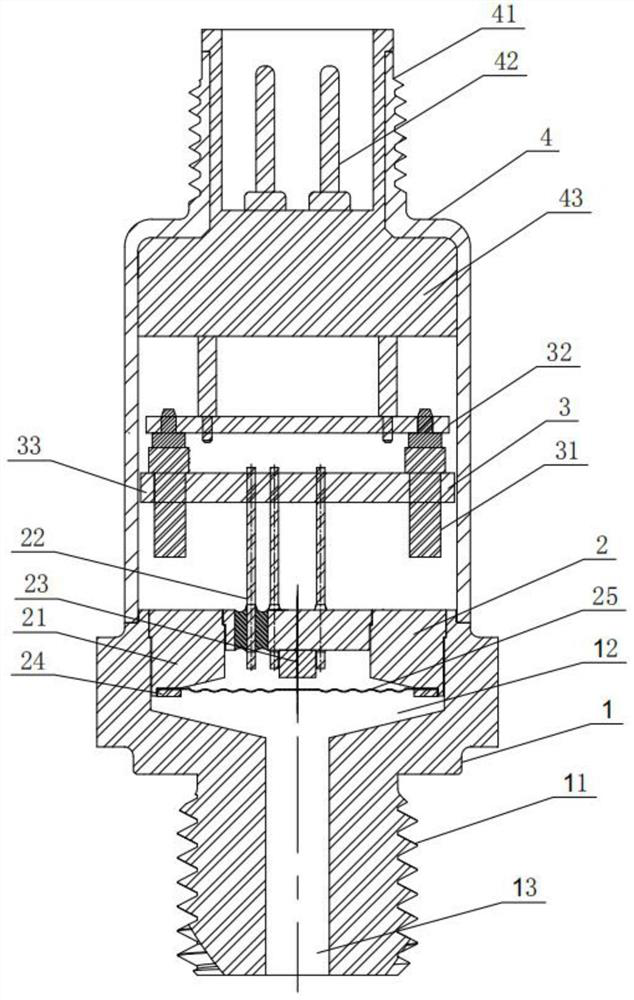

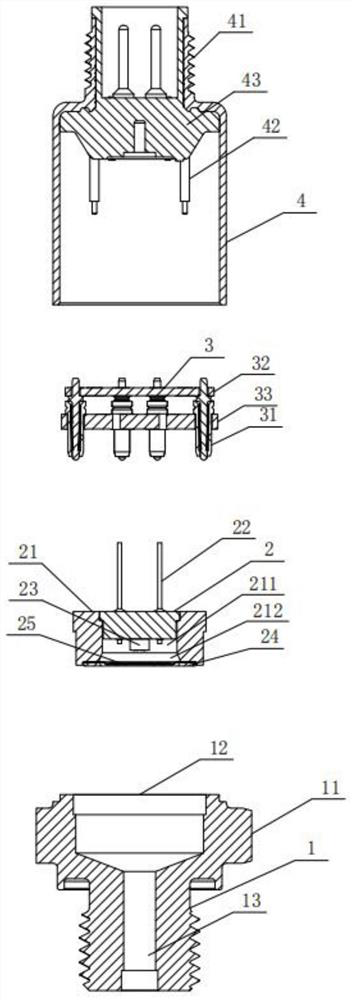

Modularly designed MEMS diffused silicon pressure sensor and manufacturing method thereof

PendingCN111982363AReduce complexityQuality improvementFluid pressure measurement using ohmic-resistance variationForce measurementManufacturing technologyModular design

The invention provides a modularly designed MEMS diffused silicon pressure sensor. The modularly designed MEMS diffused silicon pressure sensor comprises a pressure input module, a pressure sensing module, a signal processing module and a signal output module. The pressure input module is responsible for inputting external pressure, and a cavity is formed in the center of the pressure input modulein the vertical direction. The pressure sensing module is responsible for sensing a pressure signal and is embedded into the upper part of the cavity. The signal processing module is responsible foramplifying, operating, shaping, compensating and calibrating the pressure signal, is arranged above the pressure sensing module and is in signal connection with the top end of the pressure sensing module. The signal output module is responsible for outputting pressure signals, is located above the signal processing module, wraps the signal processing module, is in signal connection with the top end of the signal processing module and is fixedly connected with the upper end of the pressure input module. The sensor has the beneficial effects that the complexity of the production process is effectively simplified through the modular design and manufacturing process, the cost of the production process is reduced, and the stability of the product quality and the production efficiency are improved.

Owner:唐中山

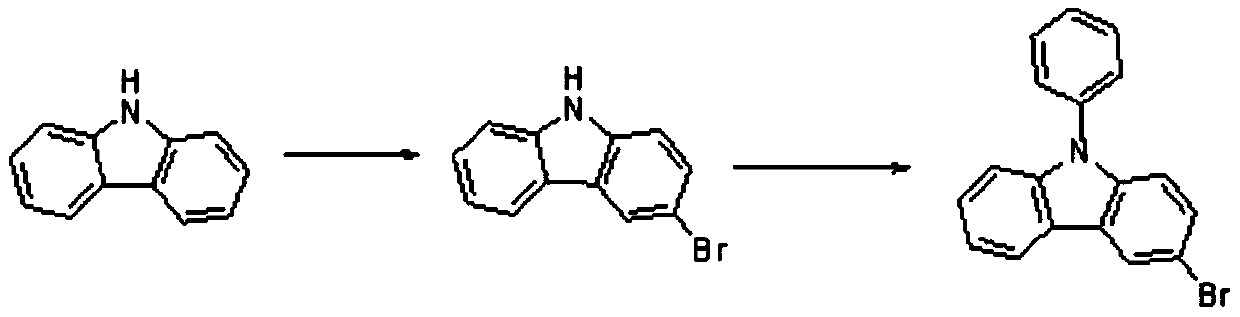

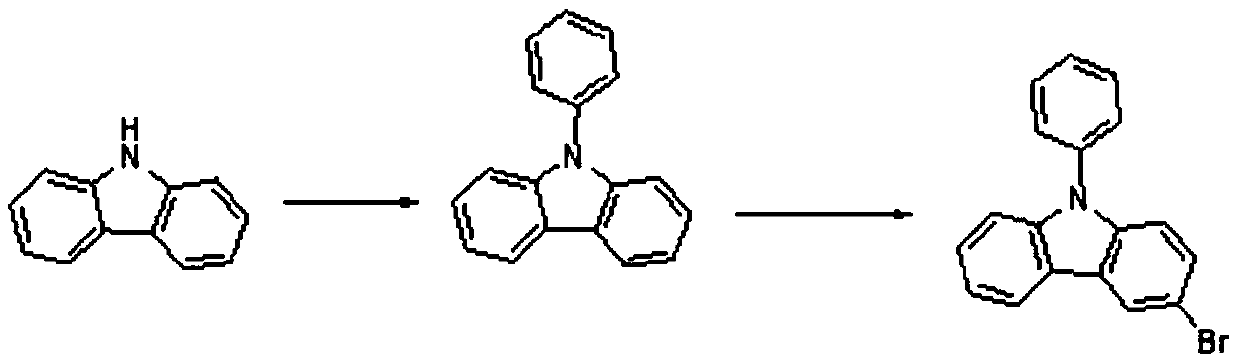

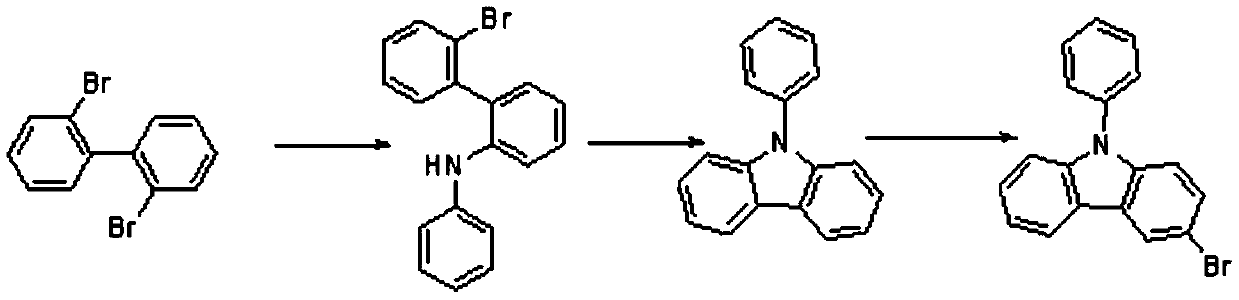

A kind of preparation method of high-purity 3-bromo-9-phenylcarbazole

ActiveCN107445886BRaw materials are cheap and easy to getMild reaction conditionsOrganic chemistryChemical synthesisCarbazole

Owner:BEIJING BAYI SPACE LCD MATERIALS TECH

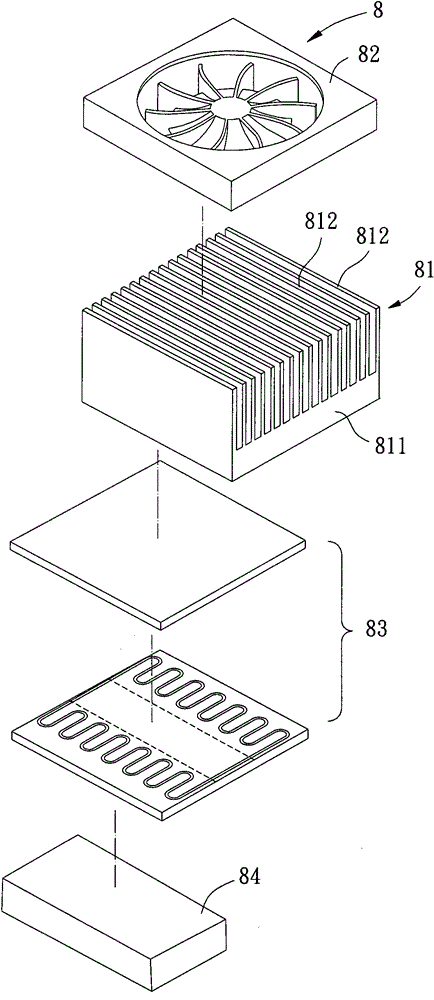

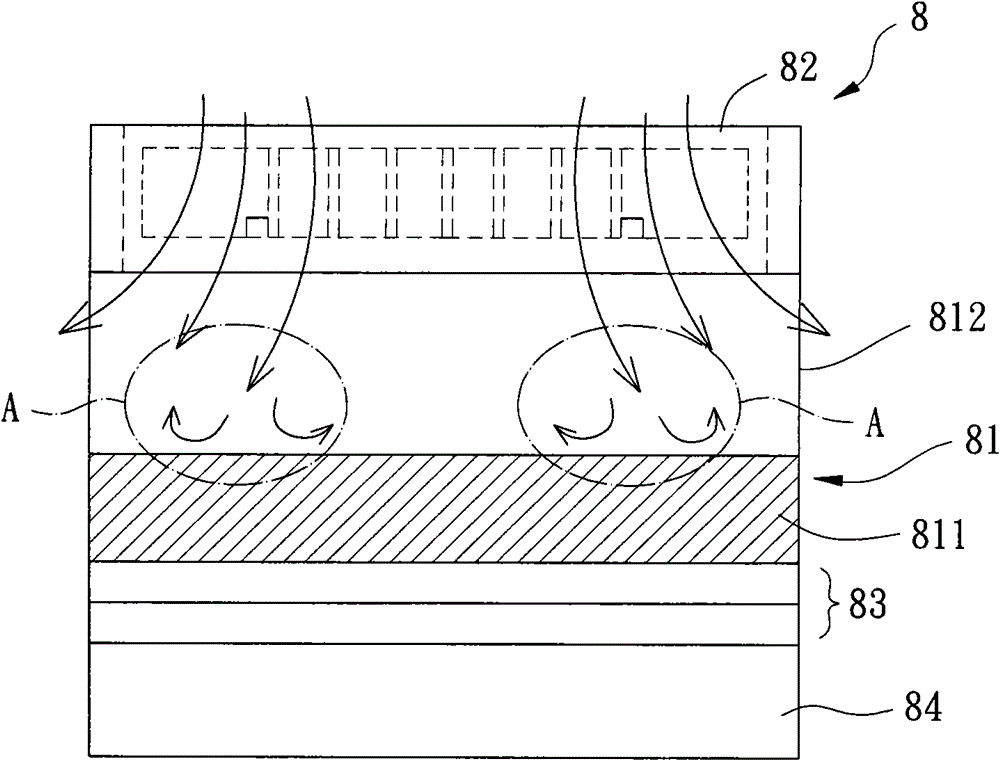

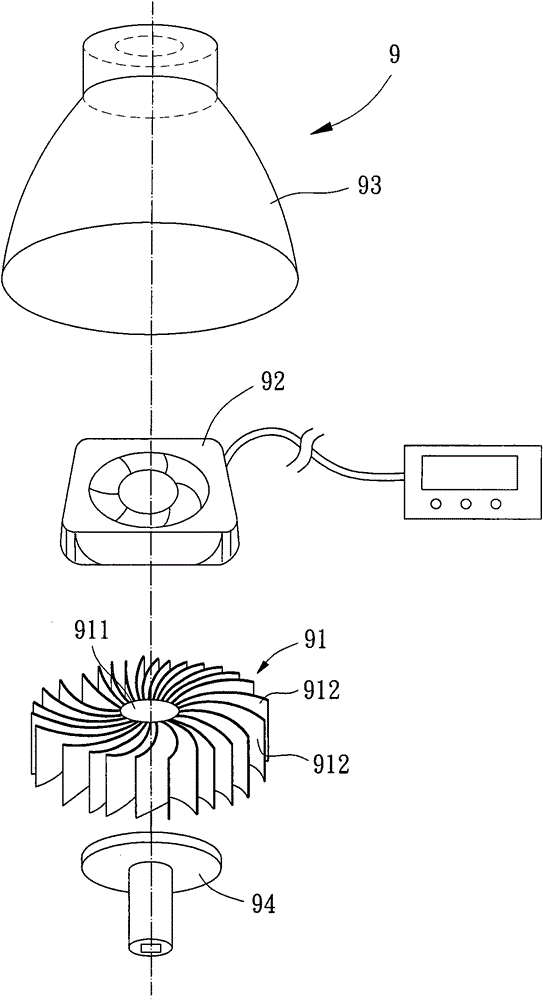

Radiating module

ActiveCN102262427BInhibit sheddingImprove production convenienceDigital data processing detailsSemiconductor/solid-state device detailsEngineeringHeat spreader

Owner:SUNON ELECTRONICS KUNSHAN

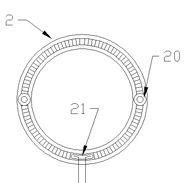

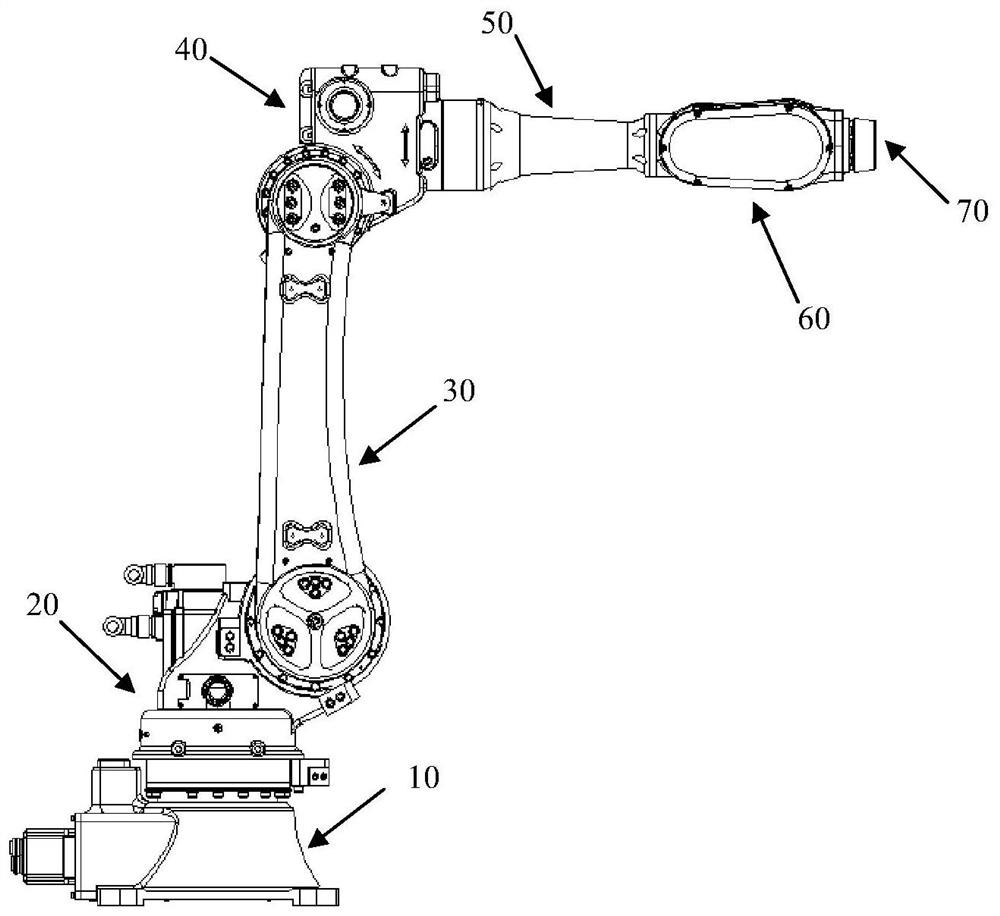

Industrial robot center distance adjusting ring

PendingCN113997318AImprove installation efficiencyEasy to shapeManipulatorGear wheelControl engineering

An industrial robot center distance adjusting ring comprises a cylindrical outer ring side face. The industrial robot center distance adjusting ring is used for being fixedly connected with a driving motor or a driving speed reducer, and during connection, the axis of an output shaft of the driving motor or the axis of an input shaft of the driving speed reducer is parallel to but does not coincide with the axis of the side face of the outer ring. Compared with the prior art, the industrial robot center distance adjusting ring has the advantages that the distance between the axis of the output shaft of the motor and the axis of the input shaft of the speed reducer can be changed by rotating the center distance adjusting ring, the adjustment of the center distance between the output gear and the input gear is quickly realized, and the mounting efficiency of the industrial robot is improved.

Owner:伯朗特机器人股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com