Baffling grid connecting structure

A connection structure and a baffle grid technology, applied in the field of the baffle grid connection structure, can solve the problem that it is difficult to ensure that the baffle grid is perpendicular to the heat exchange tube, the baffle grid spacing is difficult to accurately control, and the heat exchange tube layout limit circle is reduced. and other problems, to achieve the effect of reducing the range of fluid dead zone, reducing material cost, and achieving good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

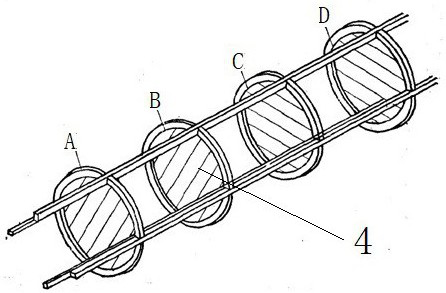

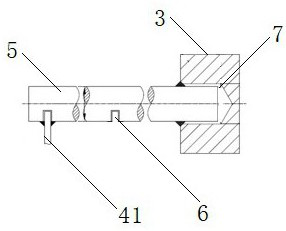

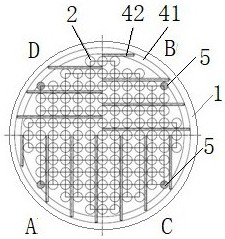

[0015] Such as figure 1 -3 shows a baffle grid connection structure of the present invention, which is used to fix the baffle grid 4 in the heat exchanger, and the heat exchanger includes a heat exchanger cylinder 1, a heat exchange tube 2, and a tube plate 3 A plurality of blind holes 7 are arranged on the tube sheet; the baffle grid 4 includes a baffle ring 41 and a baffle rod 42 . The connection structure of the baffle grid includes a plurality of spacer bars 5 arranged equiangularly in a circumferential shape, and a plurality of grooves 6 matching with the baffle grid are equidistantly arranged on the spacer bars, and the baffle grid is clamped on the In the groove and fixed by welding with the spacer bar, the spacer bar pipe limits the circle (the smallest circle surrounding all the spacer bars is the outer diameter of the circle) concentric with the baffle grid and larger than the inner diameter of the baffle grid (specifically, the baffle The inner diameter of the baff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com