Ion palladium activating agent as well as preparation method and application thereof

An activator, ion technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problems of limited activation controllability, difficult storage and transportation, electrochemical corrosion of circuit boards, etc., to increase production Convenience, improved activation controllability, easy storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

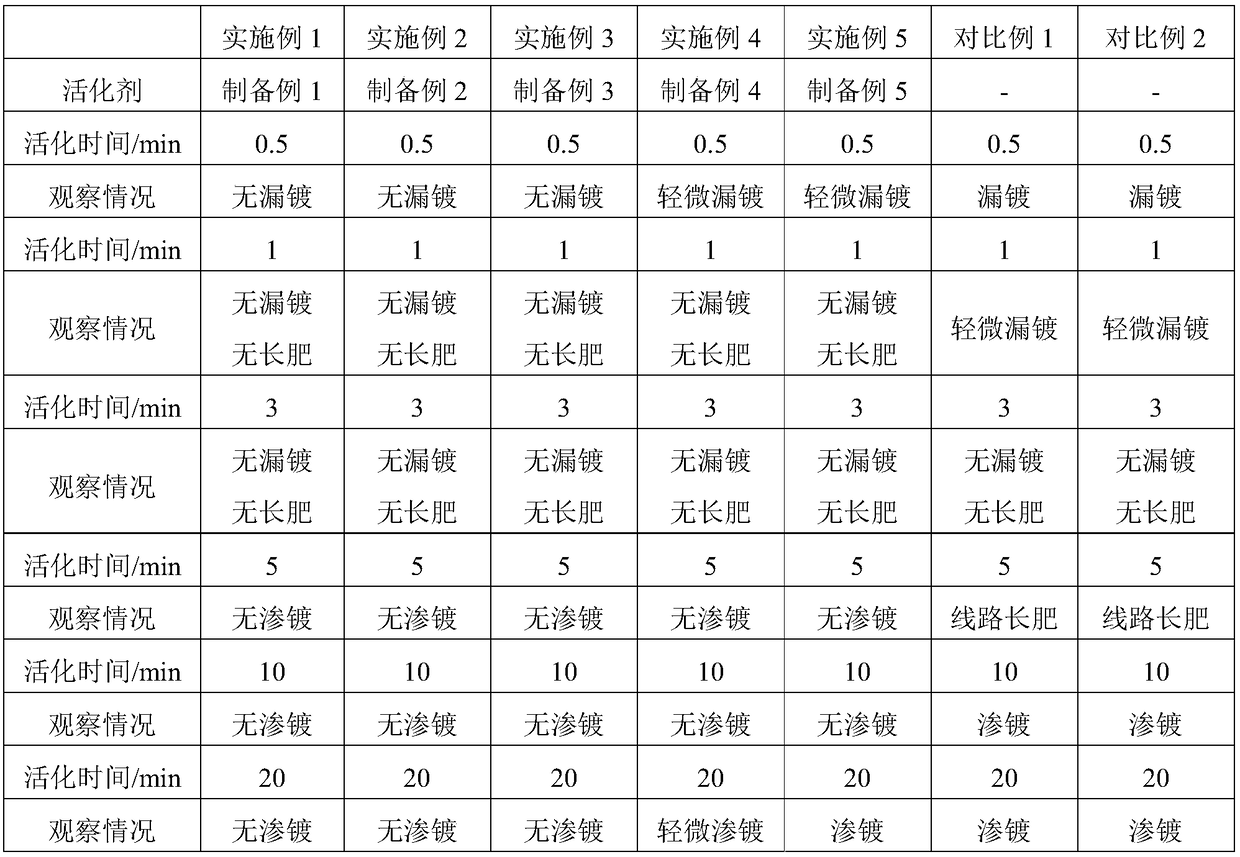

preparation example 1

[0034] An ionic palladium activator is composed of the following components: tetraammine palladium sulfate, surfactant, complexing agent, pH regulator and water.

[0035] Wherein, the content of palladium tetraammine sulfate is 20ppm, the content of complexing agent is 60ppm, the content of surfactant is 15ppm, and the pH regulator adjusts the pH of ionic palladium activator to 7.0.

[0036] Wherein, the complexing agent is a composition obtained by combining 2,2-bipyridine and ethylenediamine in any proportion, and the surfactant is DuPont fluorocarbon surfactant.

[0037] The preparation method is as follows:

[0038] (1) tetraammine palladium sulfate, complexing agent and tensio-active agent are added in water, mix homogeneously, obtain preliminary product;

[0039] (2) Using a pH regulator to adjust the pH value of the mixed solution obtained in step (1) to 7.0 to obtain an ionic palladium activator.

preparation example 2

[0041] An ionic palladium activator is composed of the following components: tetraammine palladium sulfate, surfactant, complexing agent, pH regulator and water.

[0042] Wherein, the content of palladium tetraammine sulfate is 10ppm, the content of the complexing agent is 30ppm, the content of the surfactant is 5ppm, and the pH regulator adjusts the pH of the ionic palladium activator to 6.5.

[0043] Wherein, the complexing agent is a composition obtained by combining tetrasodium iminosuccinate, sulfamic acid and ethylenediamine in any proportion, and the surfactant is fatty alcohol polyoxyethylene ether.

[0044] The preparation method is as follows:

[0045] (1) tetraammine palladium sulfate, complexing agent and tensio-active agent are added in water, mix homogeneously, obtain preliminary product;

[0046] (2) Using a pH regulator to adjust the pH value of the mixed solution obtained in step (1) to 6.5 to obtain an ionic palladium activator.

preparation example 3

[0048]An ionic palladium activator is composed of the following components: tetraammine palladium sulfate, surfactant, complexing agent, pH regulator and water.

[0049] Wherein, the content of palladium tetraammine sulfate is 50ppm, the content of complexing agent is 100ppm, the content of surfactant is 30ppm, and the pH regulator adjusts the pH of the ionic palladium activator to 7.5.

[0050] Wherein, the complexing agent is a combination of picoline and glycine in any proportion, and the surfactant is sodium dodecylbenzenesulfonate.

[0051] The preparation method is as follows:

[0052] (1) tetraammine palladium sulfate, complexing agent and tensio-active agent are added in water, mix homogeneously, obtain preliminary product;

[0053] (2) Using a pH regulator to adjust the pH value of the mixed solution obtained in step (1) to 7.5 to obtain an ionic palladium activator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com