Mortise capable of limit insertion of main latch and provided with sub latch

A deadbolt and sub-lock technology, which is used in construction locks, locks with spring bolts, and non-mechanical transmission-operated locks, etc., which can solve the problem of reducing the locking function of the deadbolt, unable to forcibly stop the deadbolt, and reducing operational safety. The problem is to prevent the lock tongue locking phenomenon, prevent the door bolt from being stuck, and simplify the operation structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

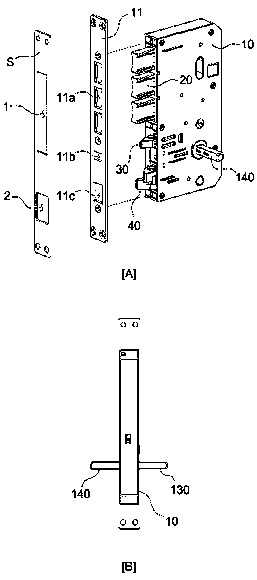

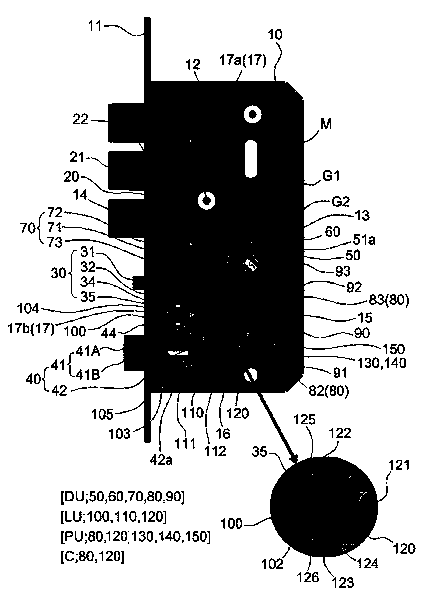

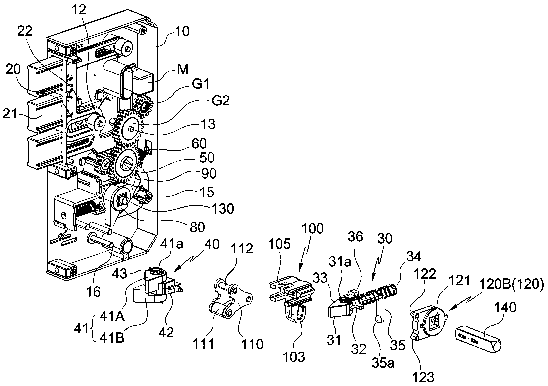

[0029] Hereinafter, the present invention will be further described based on preferred embodiments with reference to the accompanying drawings. The present invention can have various modifications and various forms.

[0030] But this does not limit the form of the present invention, and all changes, equivalents and even substitutes belonging to the idea and technical scope of the present invention are within the protection scope of the present invention.

[0031] The same reference symbols on the drawings, especially, tens digits and one digits or the same symbols of tens digits, one digits and English letters indicate the same or similar function accessories. If there is no special statement, the drawings indicate The symbol can be regarded as an accessory specified in accordance with the above requirements.

[0032] In addition, for the convenience of understanding, various components on the drawings are enlarged (thickened) or reduced (thinned), but this approach is not in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com