Patents

Literature

33results about How to "Improved Wall Thickness Accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

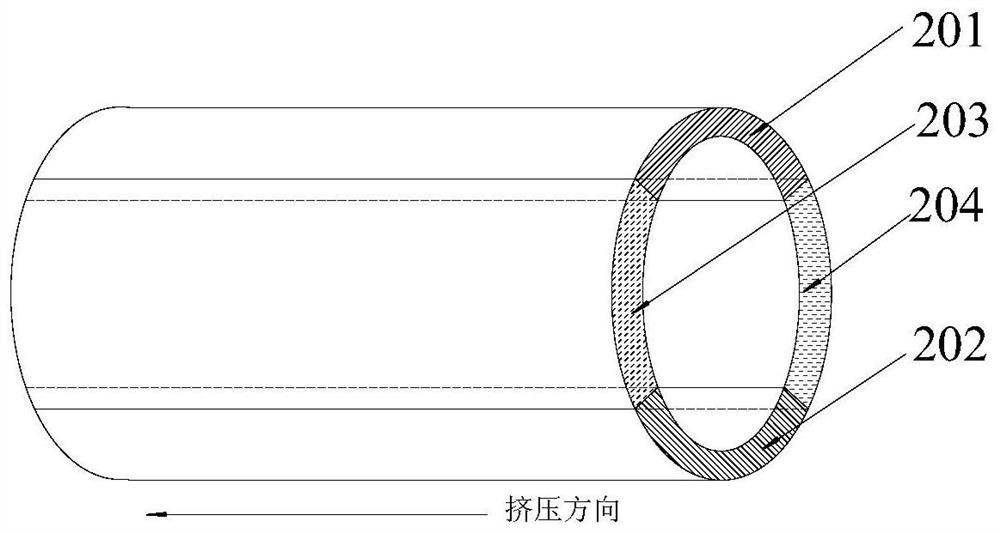

Method for preparing composite pipe by expanding secondary pouring dual-metal pipe billets

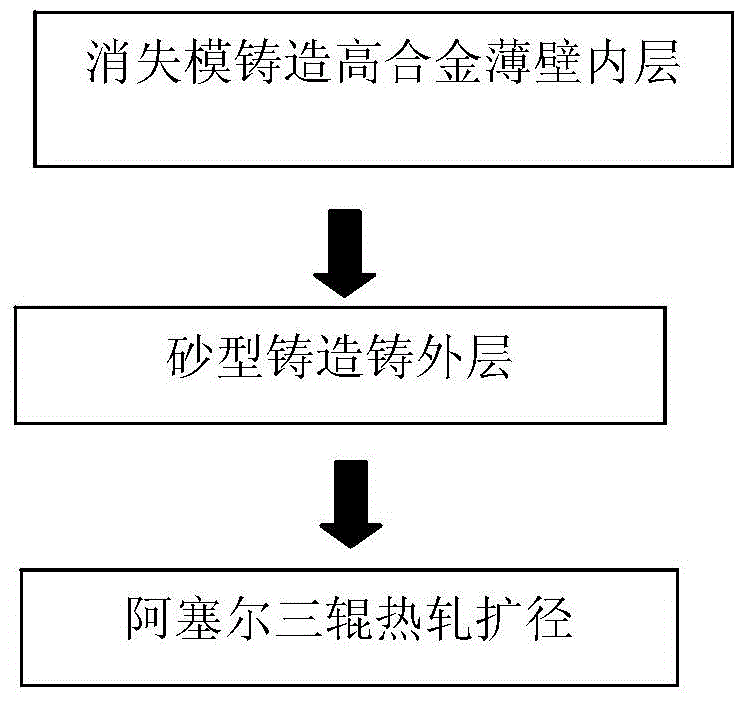

The invention discloses a method for preparing a composite pipe by expanding a secondary pouring dual-metal pipe billet. The secondary pouring dual-metal pipe billet is manufactured by the following steps: by adopting an evaporative pattern casting process, pouring to obtain an inner-layer thin-walled high-alloy corrosion-resistant pipe billet, and by adopting a sand casting method, pouring to obtain an outer-layer carbon steel pipe billet, thereby obtaining the dual-metal pipe billet. The expanding process is characterized by comprising the following steps: by adopting the dual-metal pipe billet prepared by secondary pouring, performing three-roller hot-rolling expanding deformation, thereby obtaining the dual-metal composite pipe. According to fusion of the inner and outer layers of metals in the casting process and plastic deformation in the hot-rolling expanding process, the dual-metal composite pipe with good metallurgical bonding property can be obtained. According to the dual-metal composite pipe disclosed by the invention, the high-precision inner-layer metal surface is obtained by virtue of the evaporative pattern casting process, and the inner-layer metal thickness is controllable; and moreover, due to the three-roller hot-rolling expanding process, high-strength metallurgical bonding among the inner and outer layers of metals is realized, the inner-layer surface precision is high, the ellipticity is high, and the wall thickness precision is high.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Method for manufacturing cylinder barrel for hydraulic cylinder

The invention discloses a method for manufacturing a cylinder barrel for a hydraulic cylinder. According to the method, a hot rolled coil plate serves as a raw material, and the method comprises the following steps that (1) a coiled plate is cut into strip steel; (2) the strip steel forms a welded pipe by ERW welding; (3) tempering heat treatment is carried out on the welded pipe; (4) cold reduction is performed on the welded pipe; (5) precise straightening is performed on the welded pipe; (6) nondestructive detection is performed on the welded pipe; (7) the fixed ruler of the welded pipe is cut off; and (8) finish machining is performed on the inner surface and the outer surface of the welded pipe. According to the method, the outer diameter and the wall thickness of the ERW welding pipeare fully utilized, the material with high precision and tempering heat treatment is high in strength and toughness, the high-precision and high-precision high-surface finish is achieved, the efficiency is high, the straightness and the roundness of the steel pipe are improved precisely, the straightness and the roundness of the steel pipe are improved, the reliability of the cylinder barrel is improved without damage detection, the outer circle machining allowance is small when the multi-stage cylinder is used, the efficiency is high, and the high concentricity of the welded pipe and the machining allowance of scraping and rolling of an inner hole are small and high in precision and efficiency.

Owner:潘克云

Preparation method for bimetal metallurgy composite pipe of three-layer structure

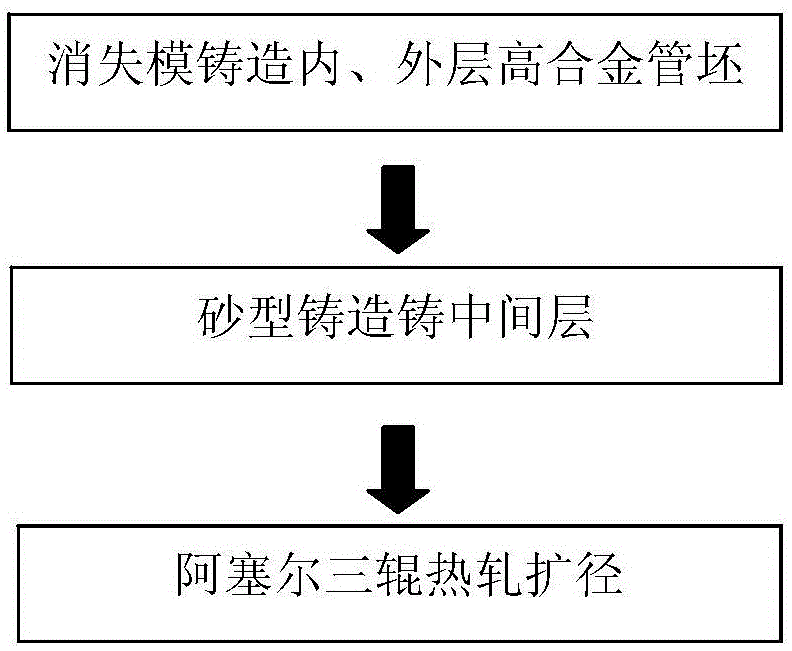

The invention discloses a preparation method for a bimetal metallurgy composite pipe of a three-layer structure. The method includes the steps that firstly, a thin-walled high alloy anti-corrosion pipe blank on the inner layer and a thin-walled high alloy anti-corrosion pipe blank on the outer layer are prepared through pouring according to a lost foam casting method; then, an interlayer carbon steel pipe blank is prepared through pouring and EPS modeling with the high alloy pipe blanks on the inner layer and the outer layer as mold cores, and a stainless steel / carbon steel / stainless steel bimetal composite pipe blank of a three-layer structure is obtained; and the bimetal composite pipe of the three-layer structure is manufactured by conducting three-roller hot rolling expanding deformation on the obtained bimetal pipe blank of the three-layer structure. The high-accuracy metal surfaces on the inner layer and the outer layer are obtained according to the lost foam casting method, and the metal thickness of the inner layer and the outer layer can be controlled. The resistance to three-roller hot rolling expanding deformation is small. The three layers of metal are combined through high-strength metallurgy. The surfaces on the inner layer and the outer layer are high in accuracy, good in ovality and high in wall thickness accuracy.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

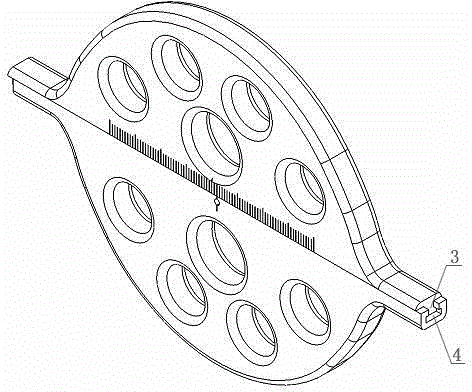

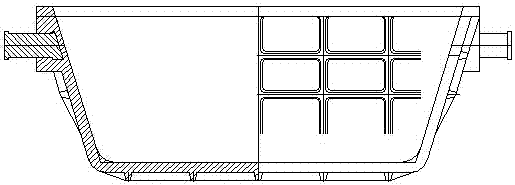

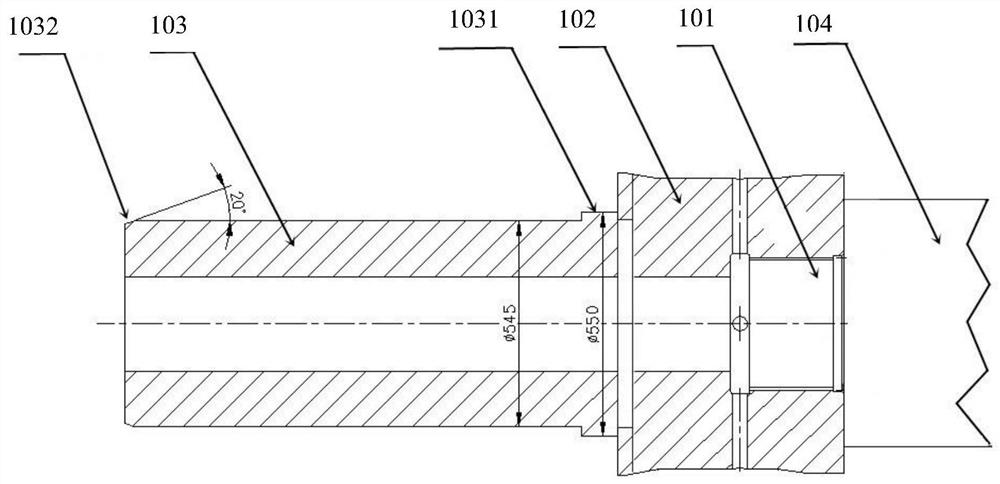

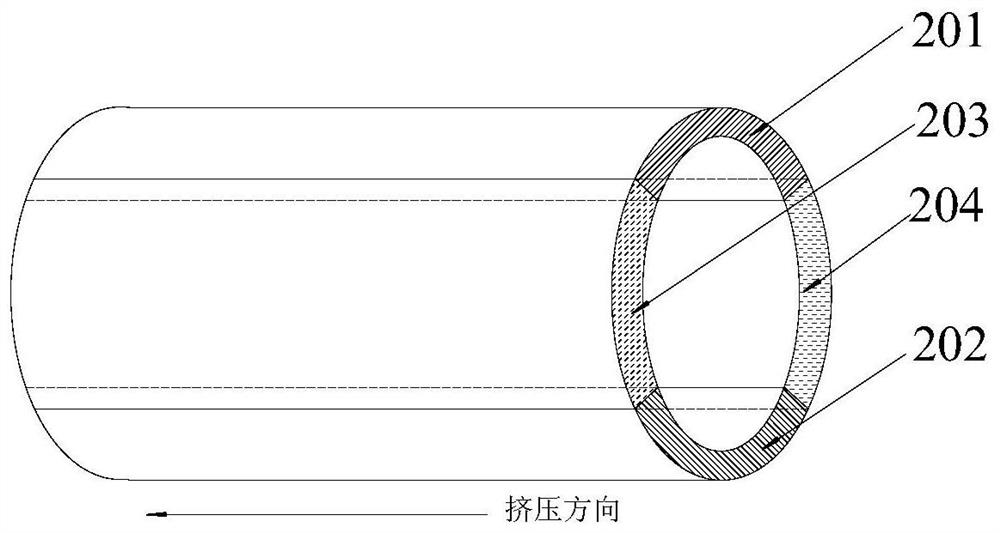

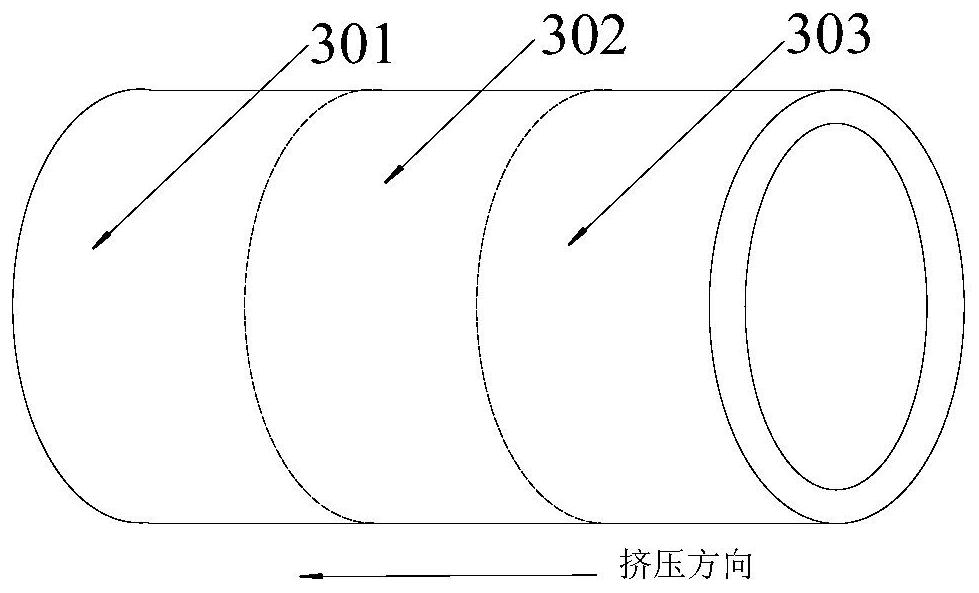

Large-width aluminum alloy ribbed plate, production method thereof and extrusion perforating needle

ActiveCN112547831AInhibition of recrystallizationImprove solid solubilityFurnace typesHeat treatment furnacesIngotMaterials processing

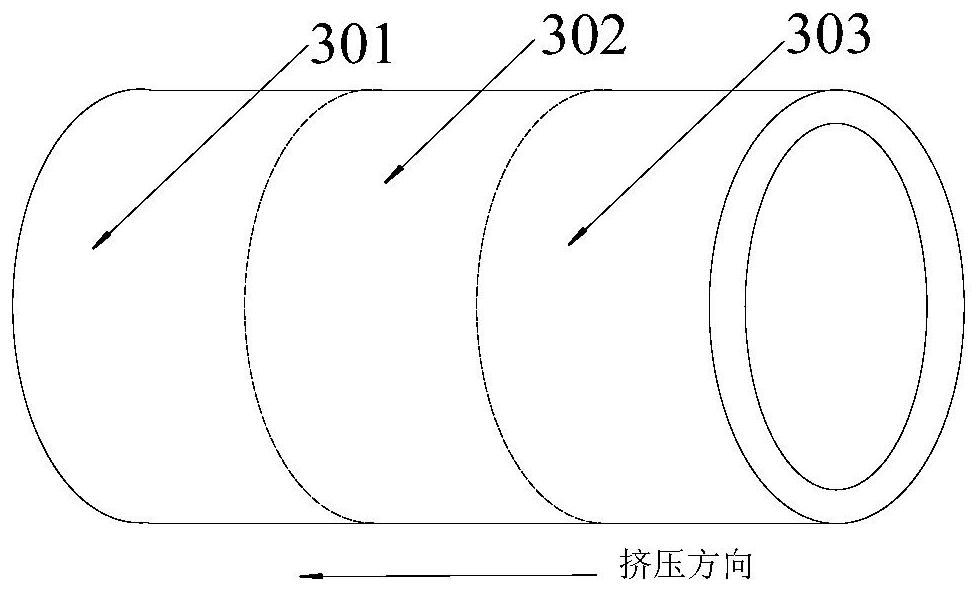

The invention discloses a large-width aluminum alloy ribbed plate, a production method thereof and an extrusion perforating needle, and belongs to the field of aluminum alloy material processing. Theproduction method of the large-width aluminum alloy ribbed plate comprises the steps that an aluminum alloy ribbed pipe is manufactured through casting, preheating and extrusion, cutting and flattening are conducted after quenching, then heat treatment is conducted, and the ultra-wide, high-strength and high-corrosion-resistance large-width aluminum alloy ribbed plate used for a ship body is obtained. In addition, an extrusion perforating needle is provided for extrusion, and compared with extrusion of an aluminum alloy solid cast ingot, the performance can be further improved. According to the production method, the welding pass of friction stir welding adopted in order to achieve large-width aluminum alloy ship plate batch production in the prior art can be avoided, the number of weld joints is reduced, the overall strength and sealing performance of a ship are greatly improved, the production cost is reduced, and the production efficiency is improved.

Owner:NORTHEASTERN UNIV

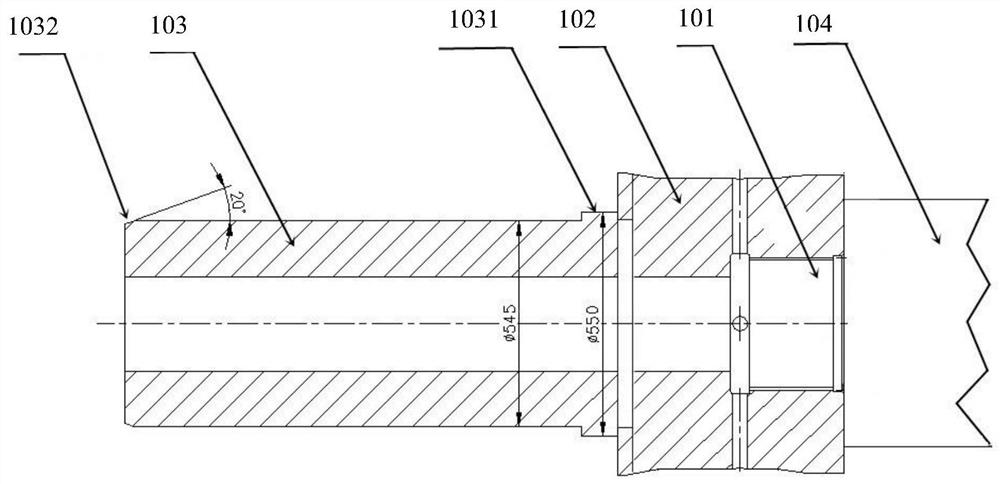

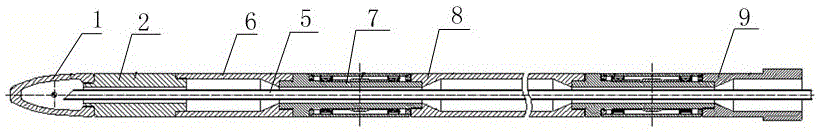

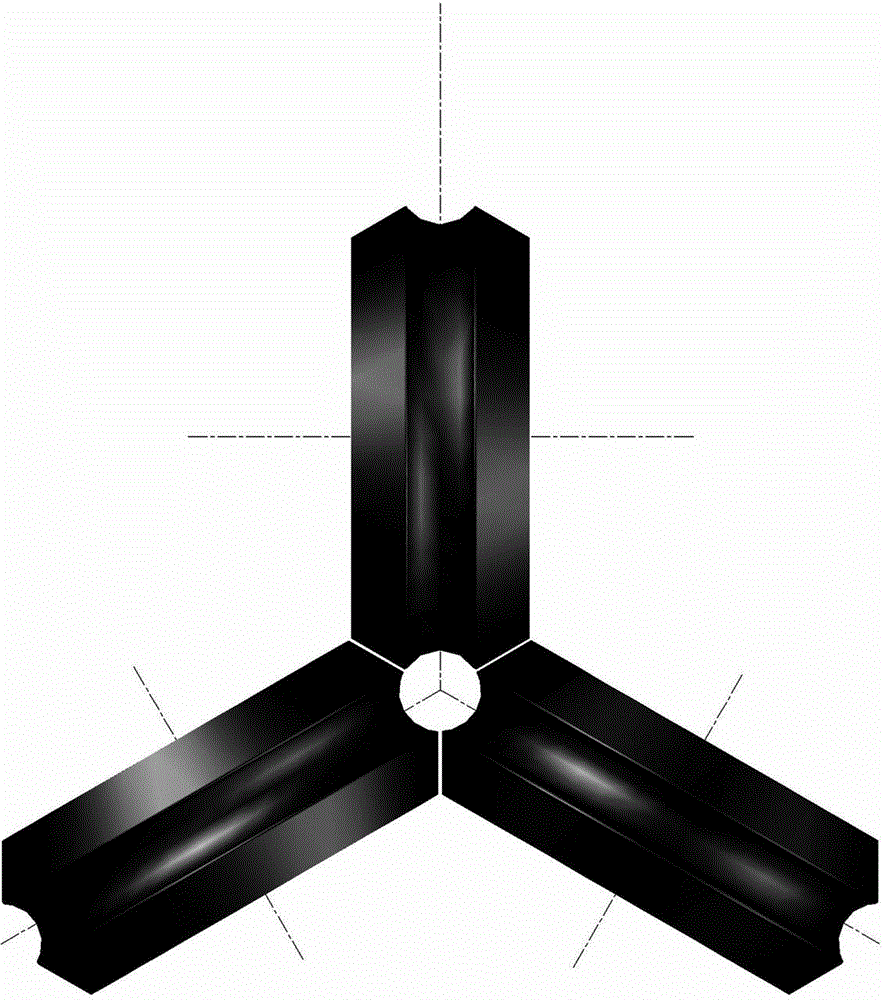

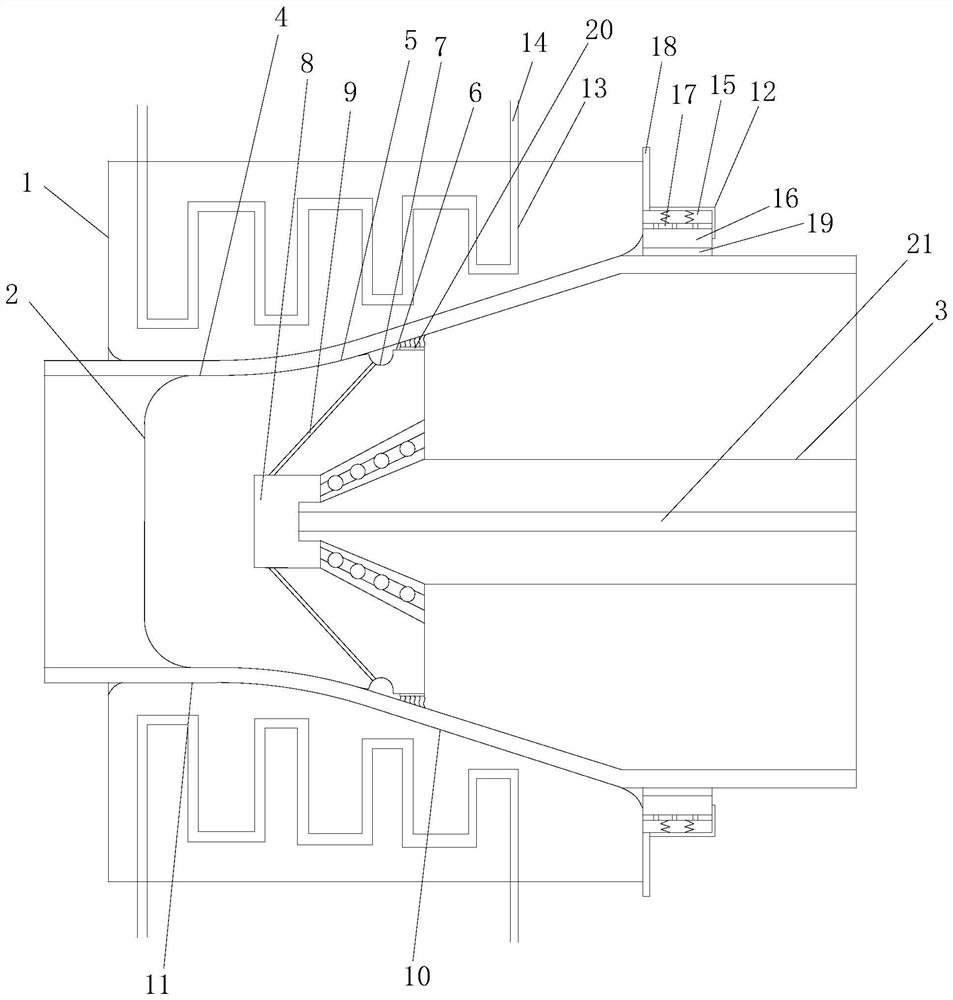

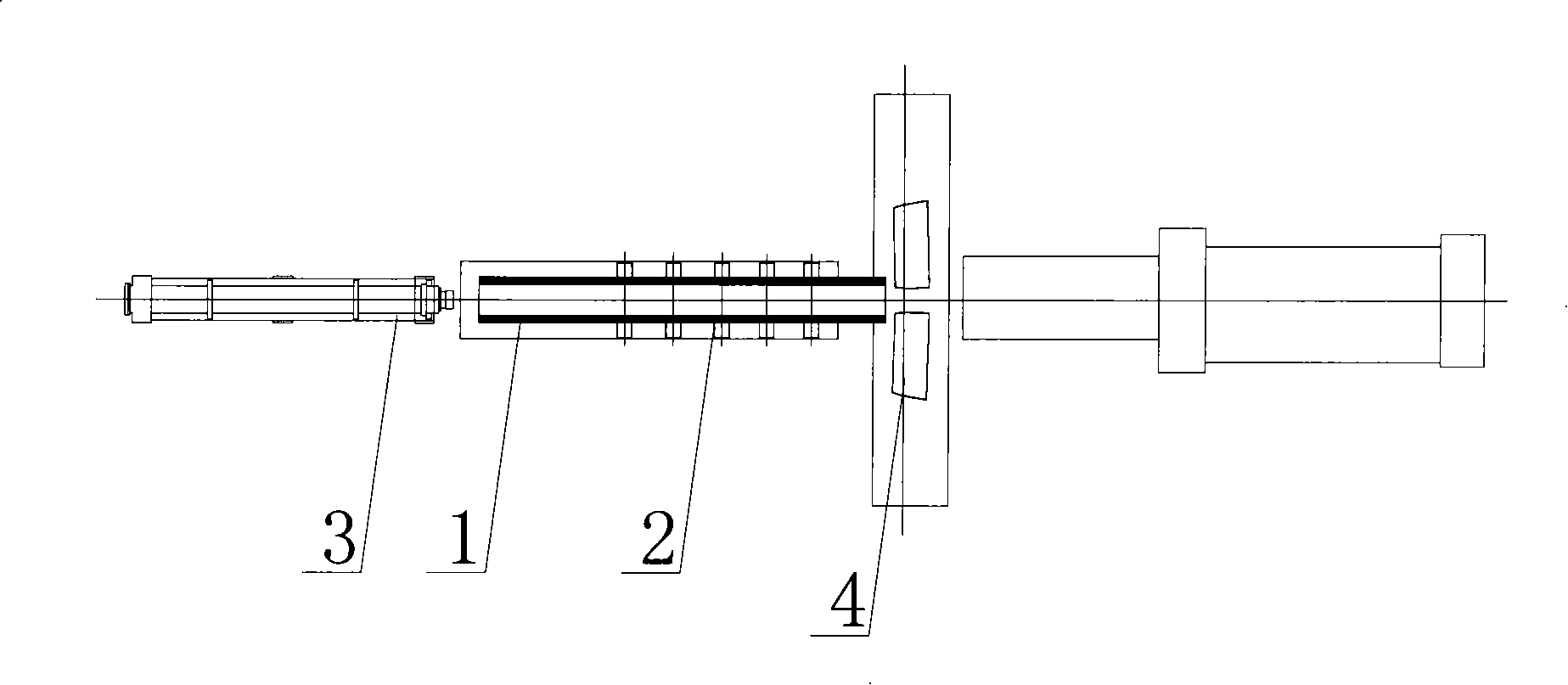

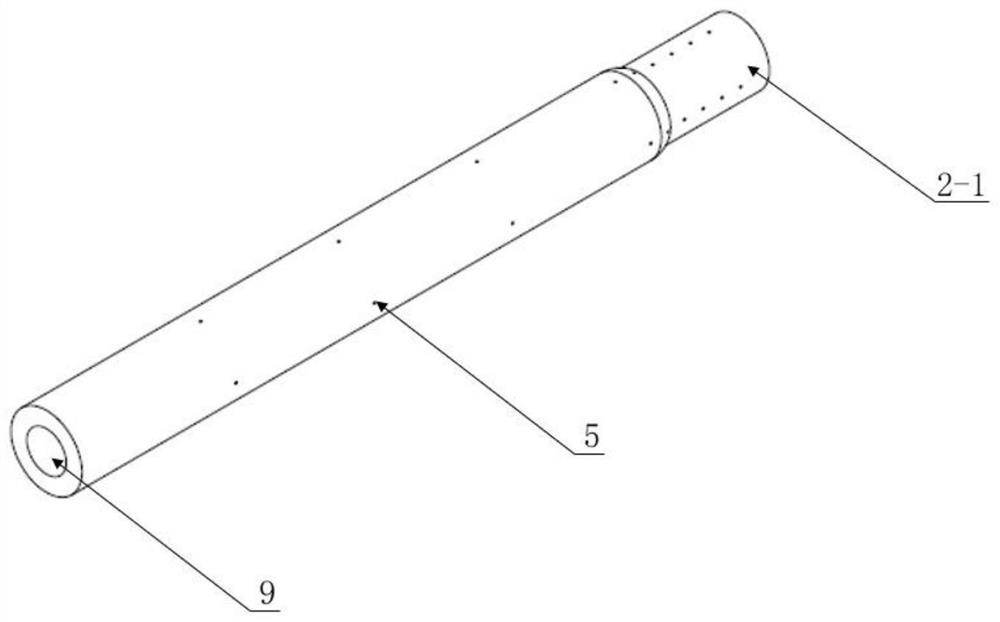

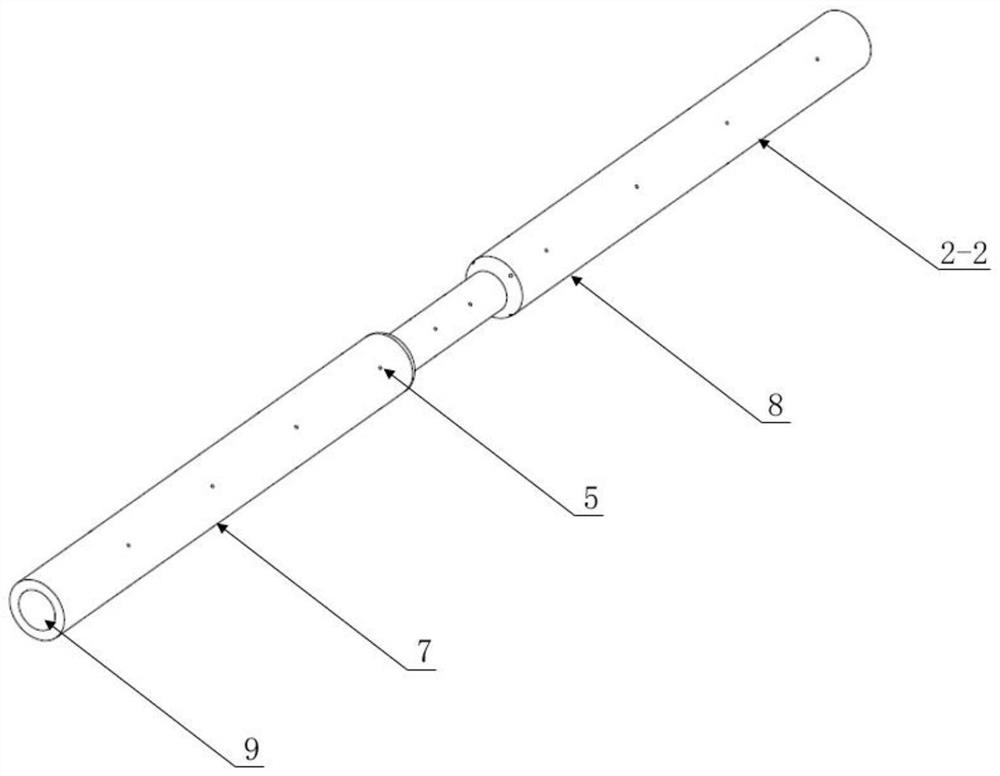

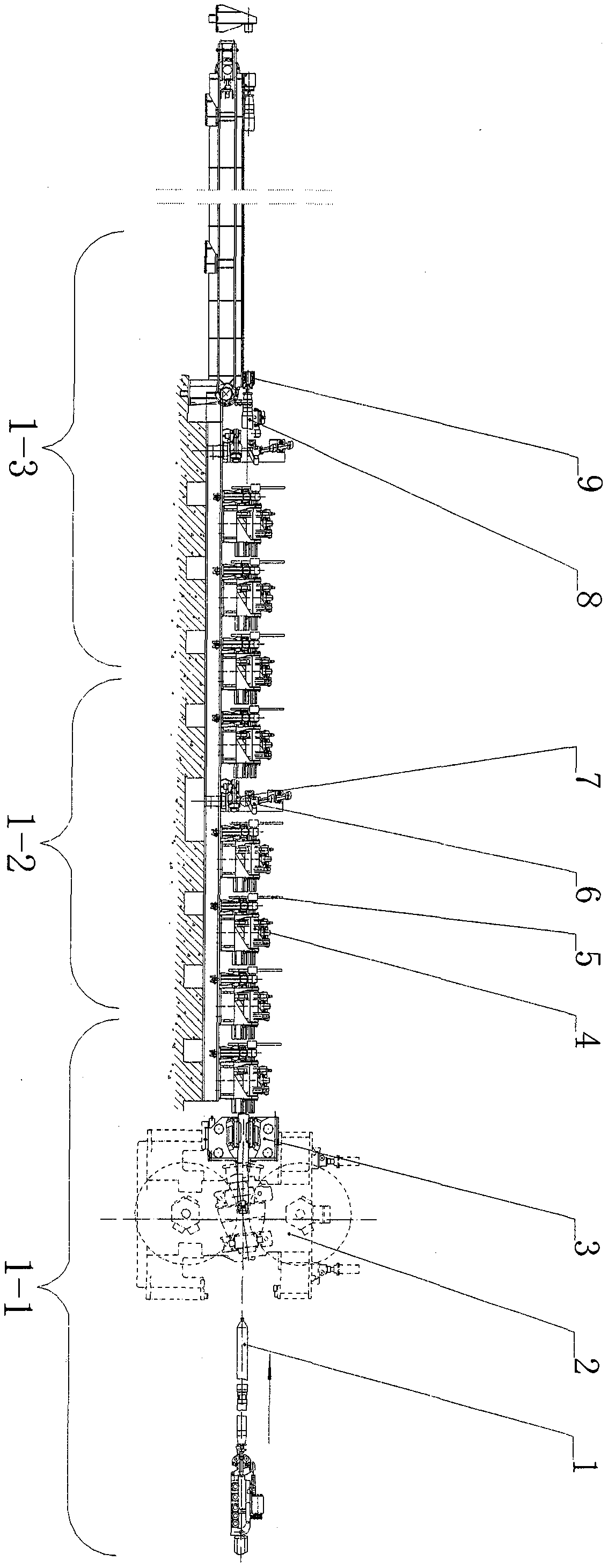

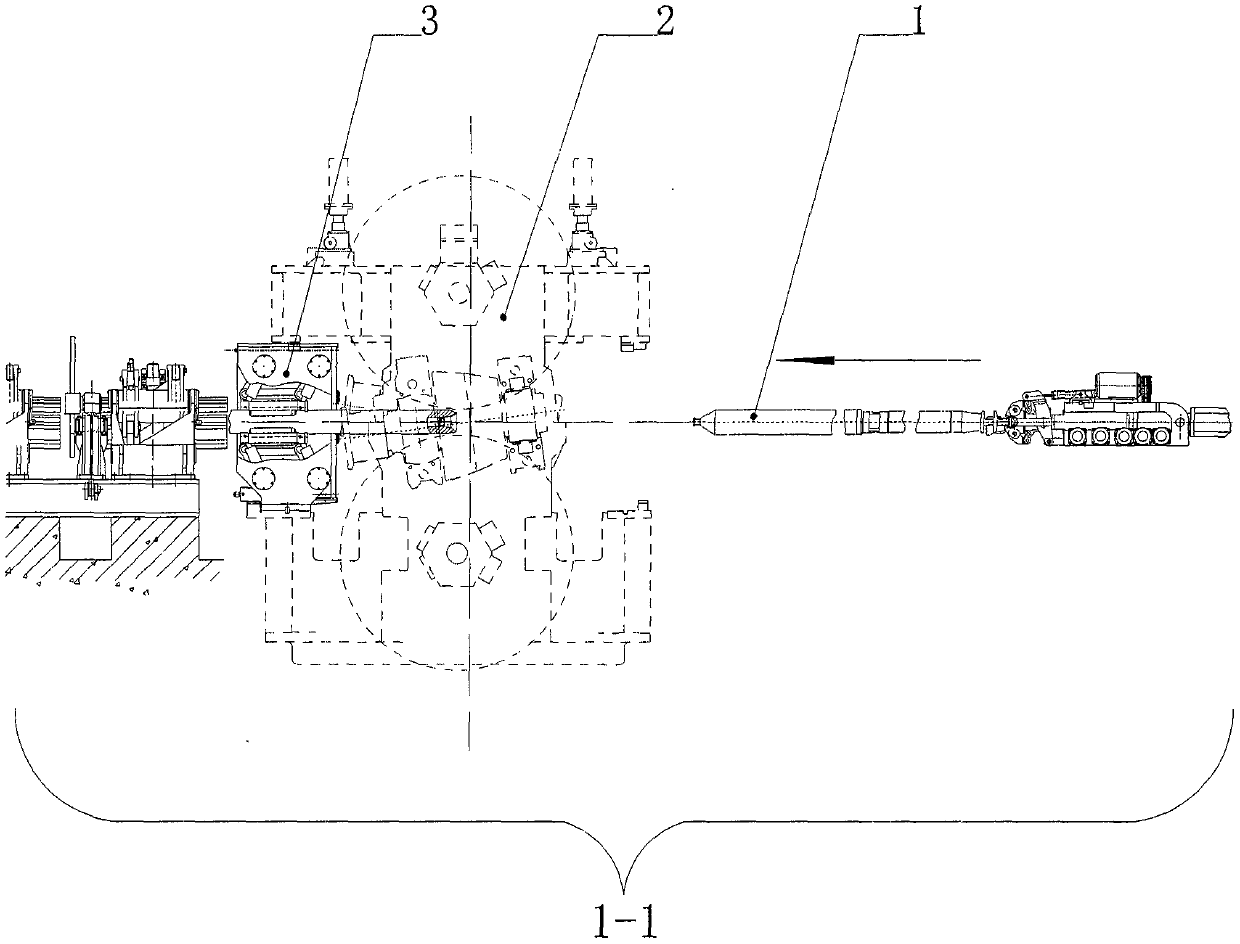

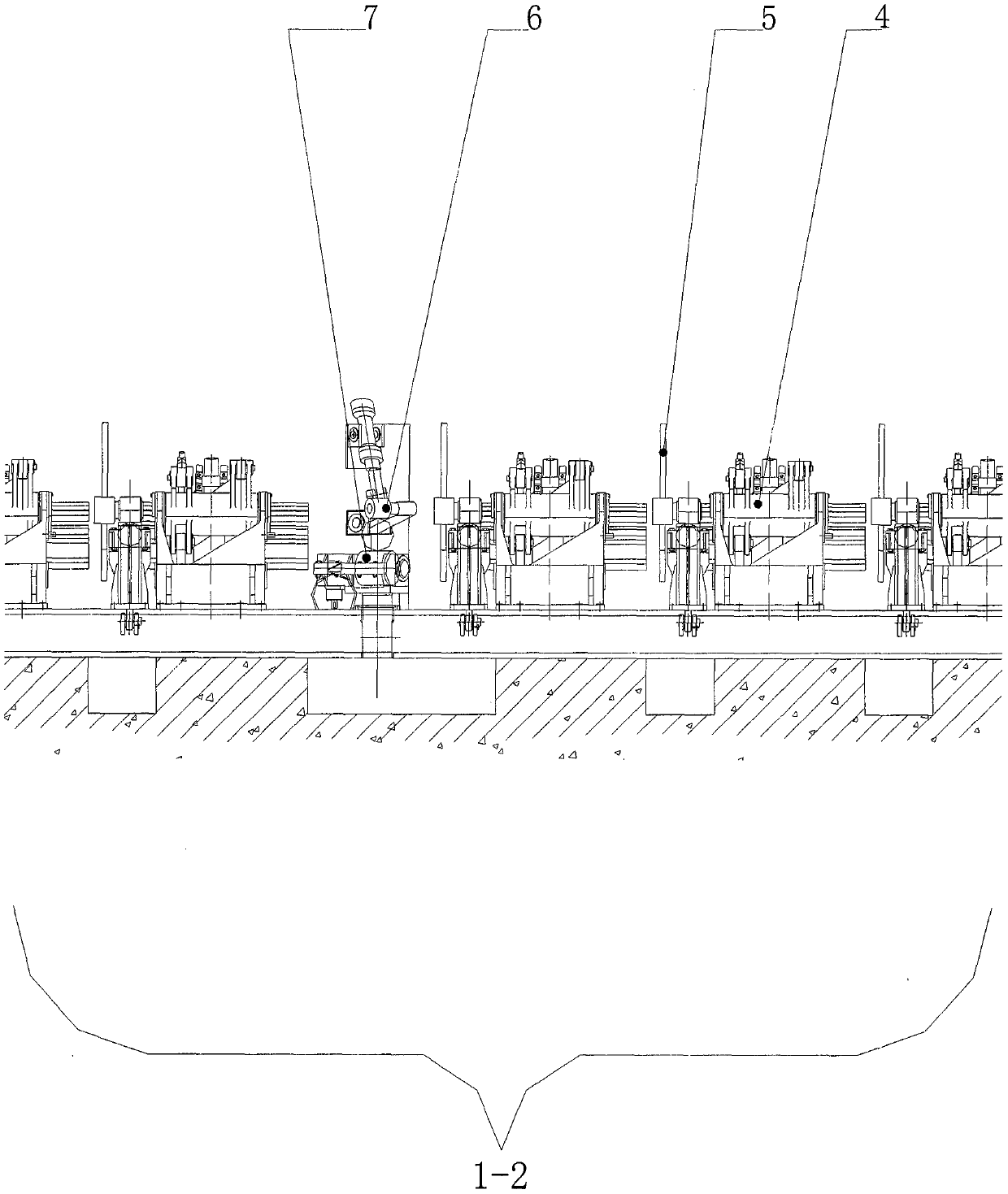

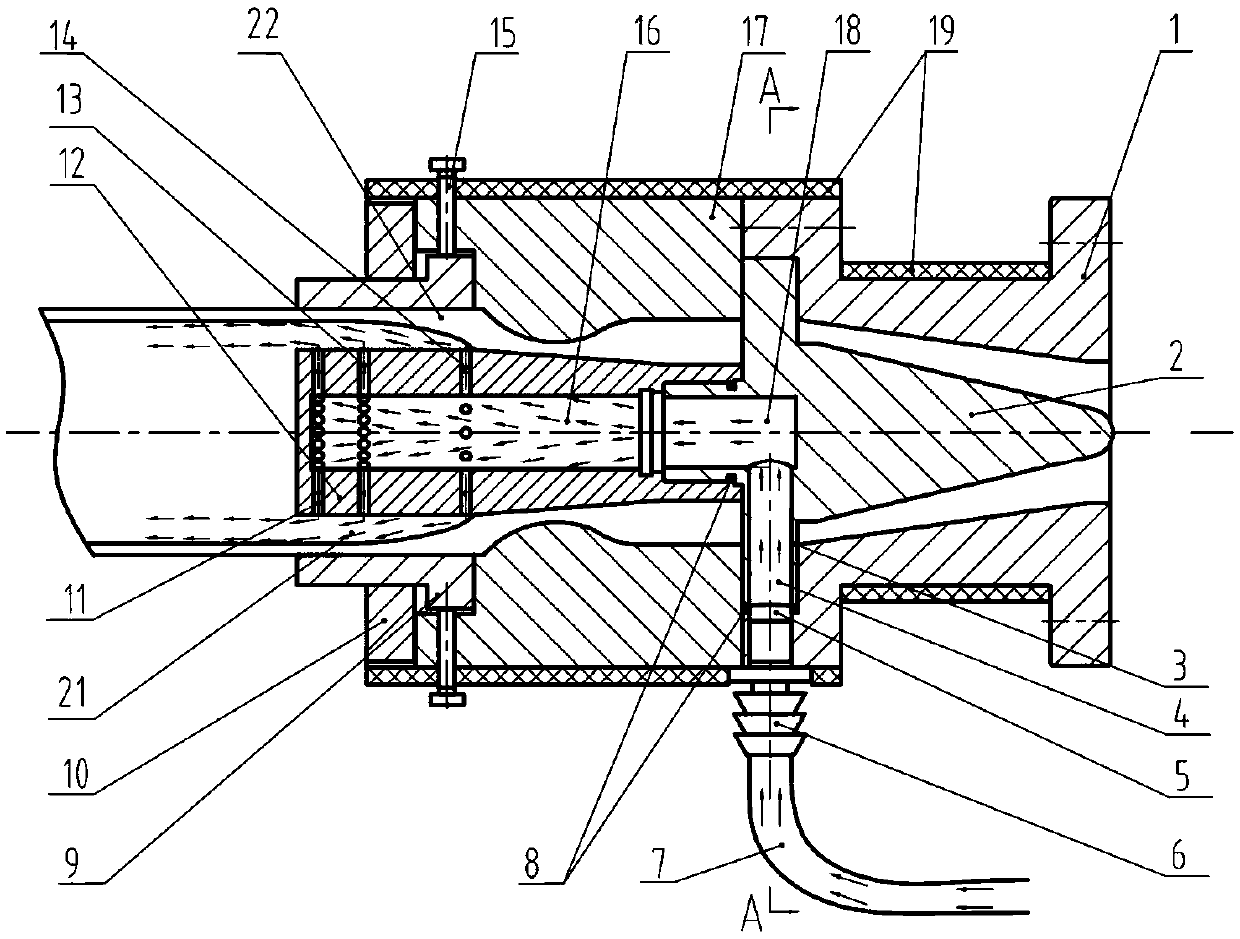

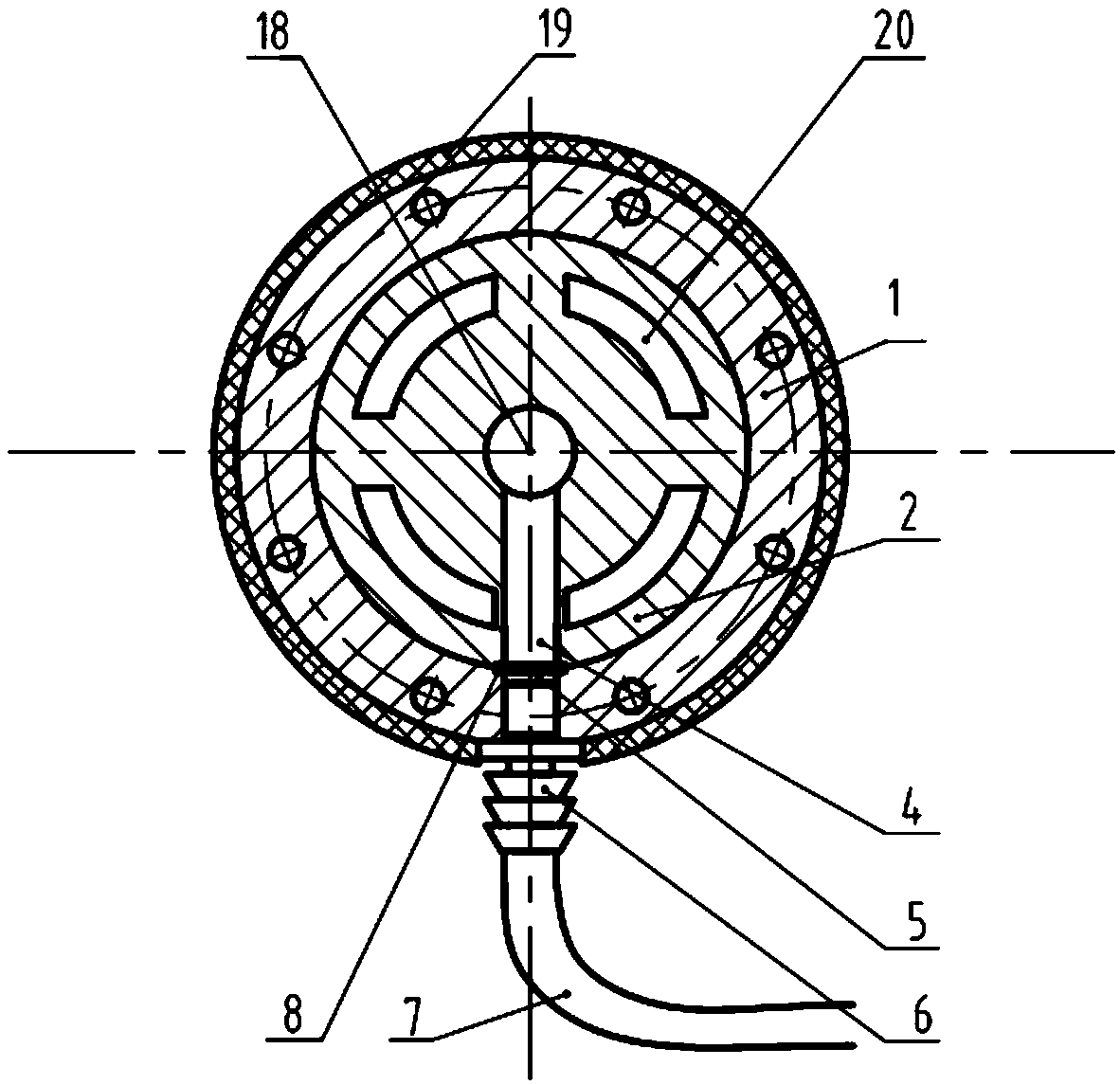

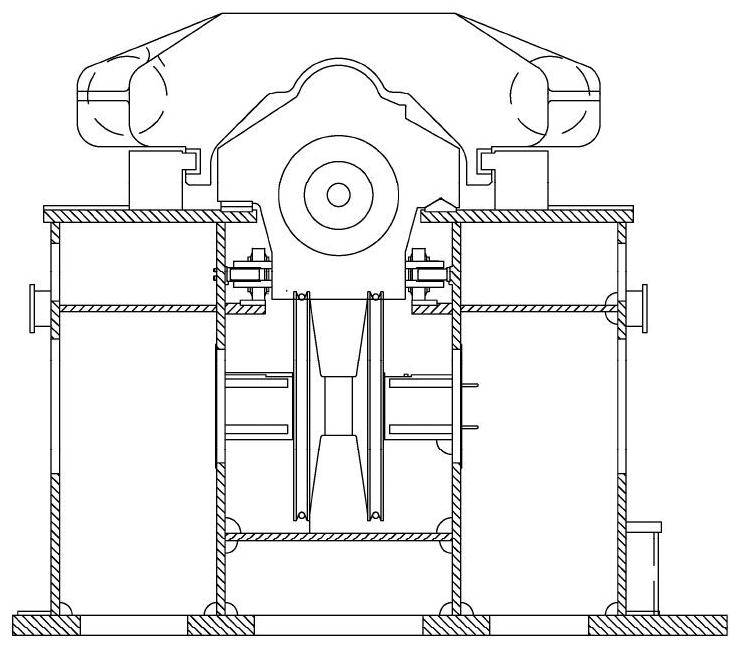

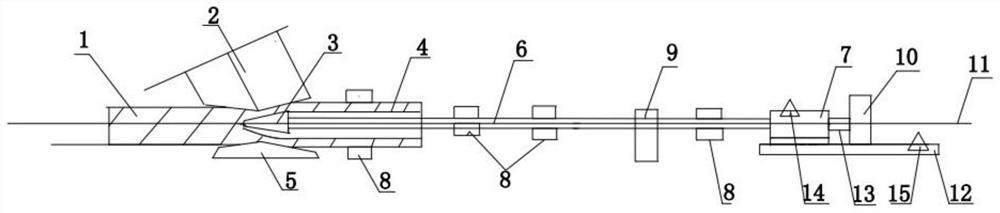

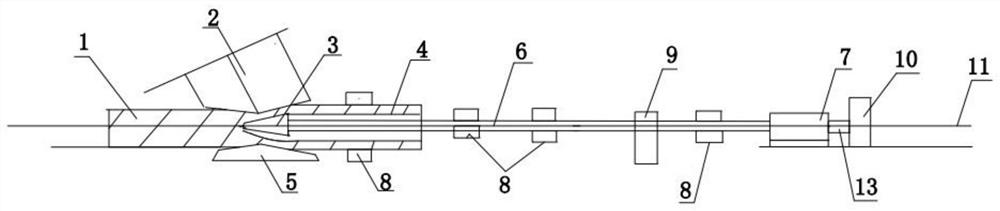

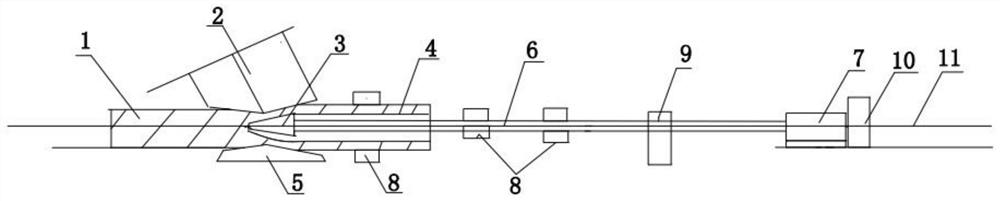

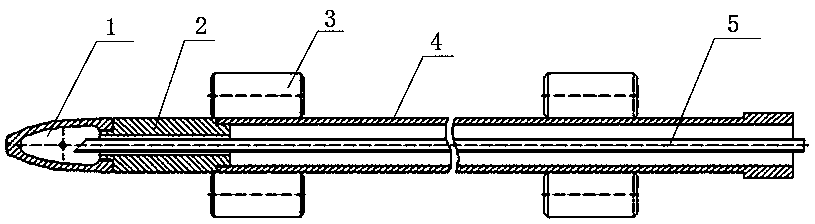

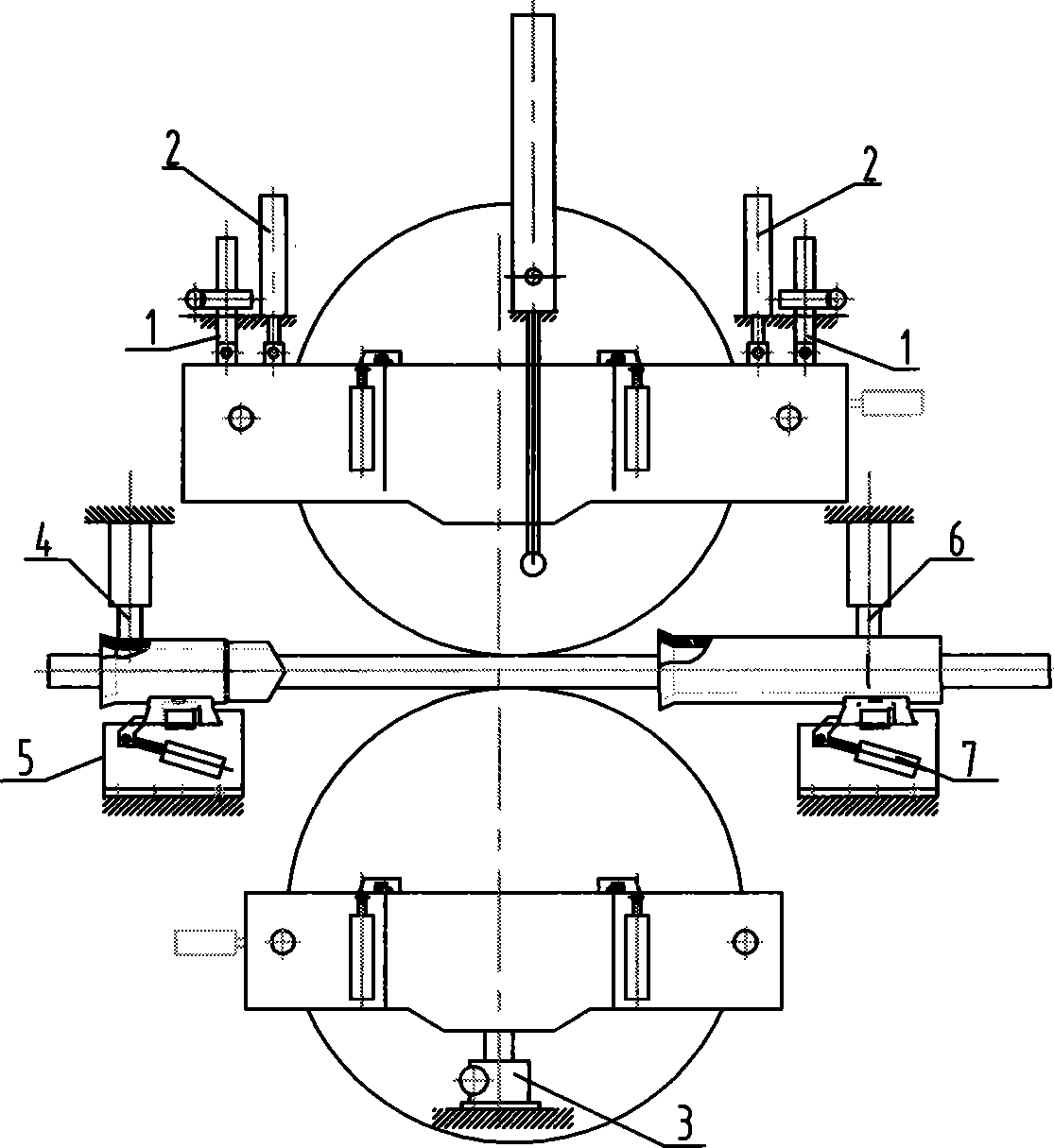

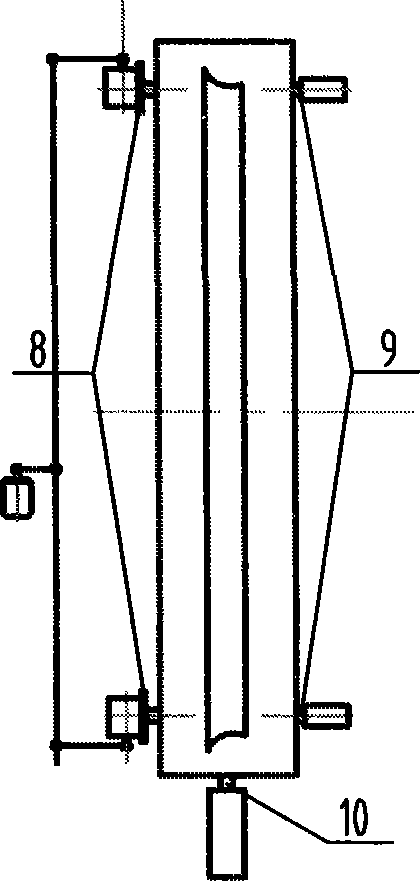

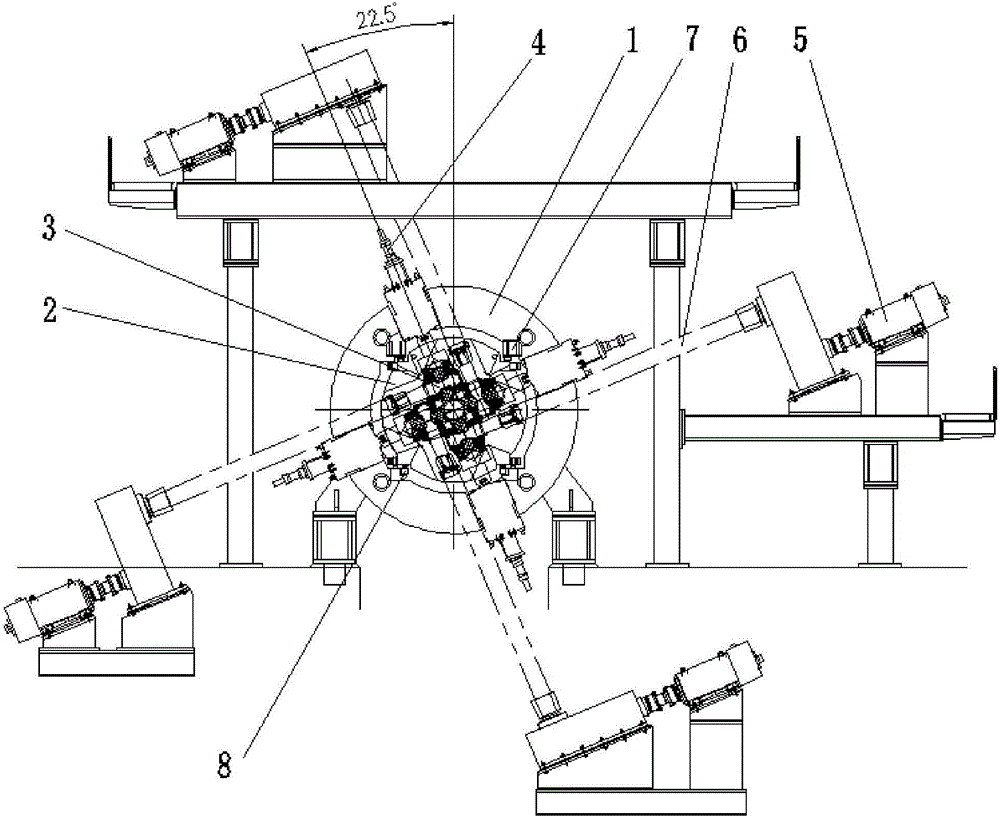

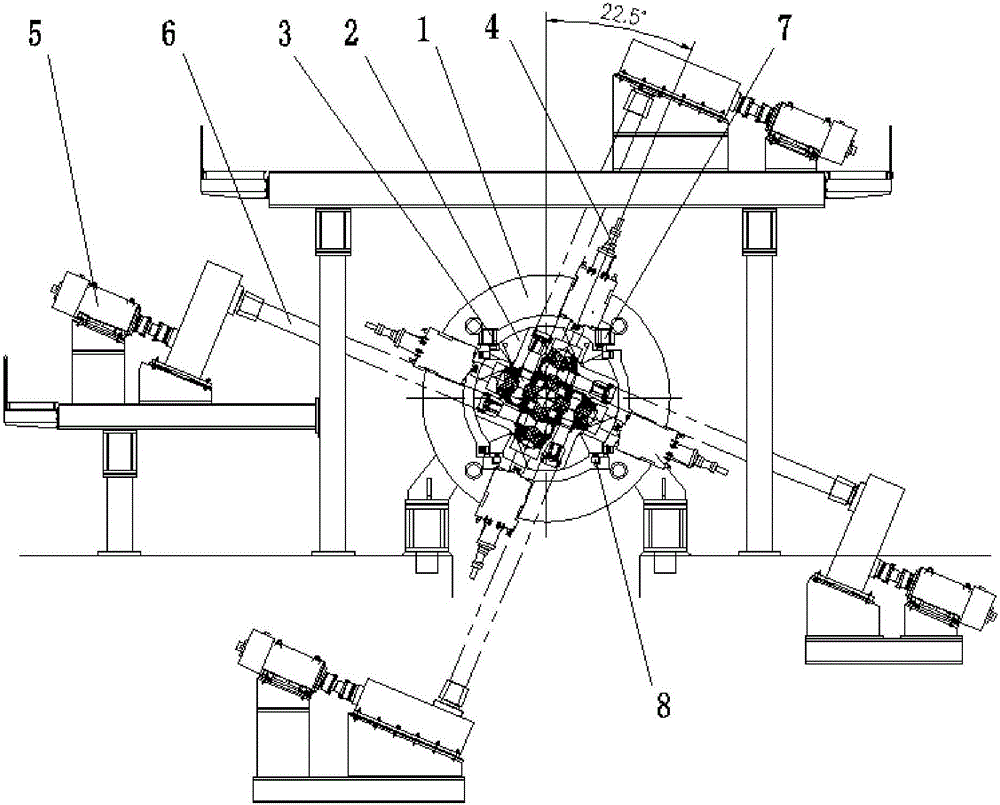

Hot-rolling seamless steel pipe slant mill foreground and background mandrel full-supporting rolling process, device and technology

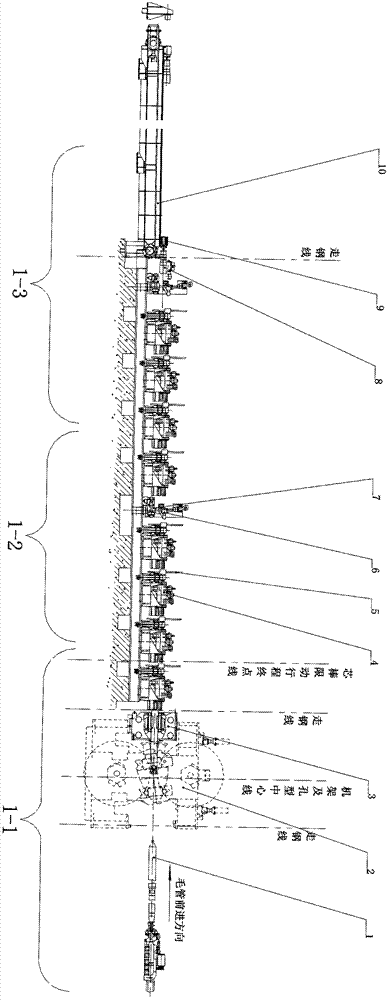

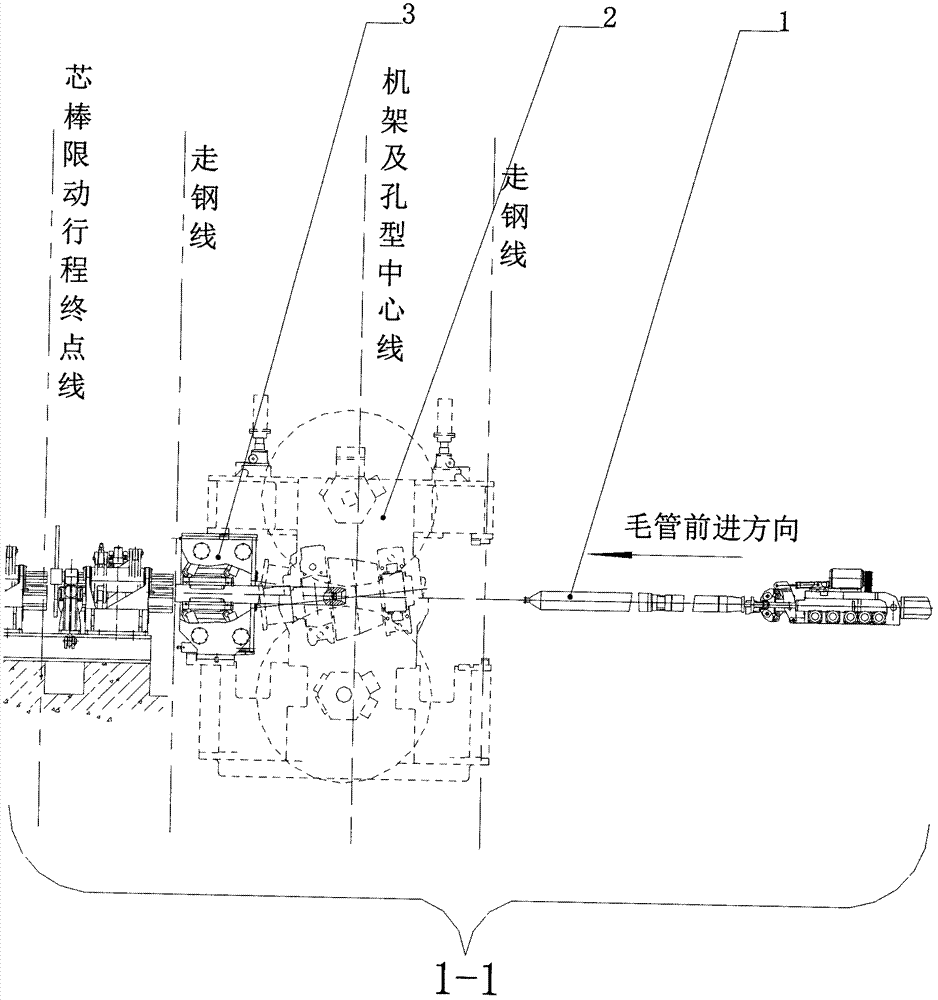

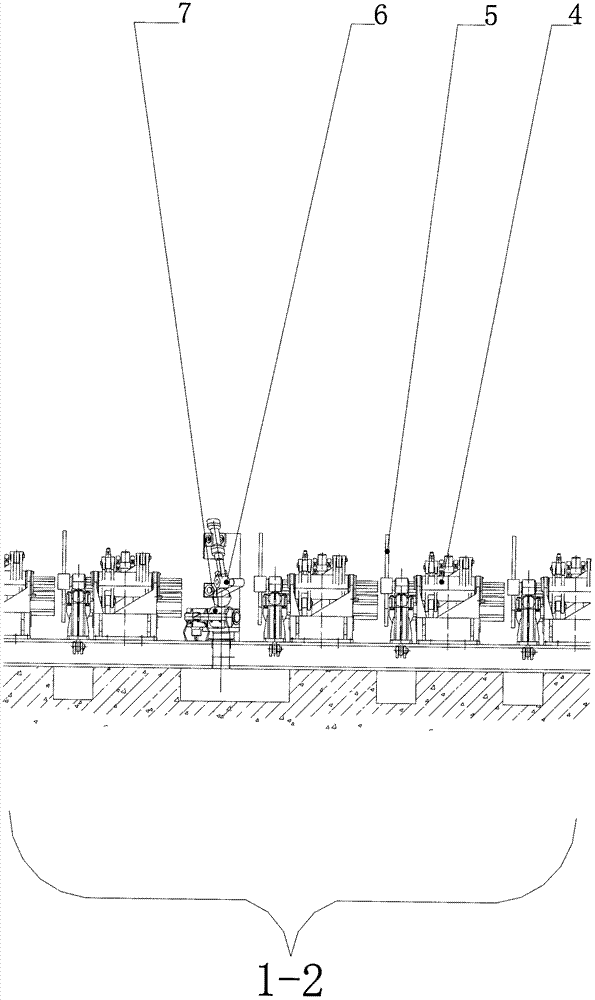

ActiveCN107159713AImprove rolling stabilityImproved Wall Thickness AccuracyMandrelsMetal rolling arrangementsSteel tubeMaterials science

The invention belongs to the technical field of metal press working (steel rolling), and relates to a steel rolling process for rolling deformation of a seamless steel pipe slant mill, so that a rolling deformation process is comprehensively improved, the deformation stability is improved, and problems in a skew-rolling seamless steel pipe production process are solved, that is, a rolling process method, equipment and technology are provided for overcoming quality defects of spiral ducts in the inner surface of a steel pipe and improving the quality. The core scheme is that a slant mill foreground and background mandrel adopts the full-supporting rolling process, equipment and technology. During skew-rolling deformation, the rolling mandrel is limited and clamped at an inlet of the slant mill and an outlet end at the same time in the rolling process, the mandrel is completely in a controlled and retrained state in the rolling process, and radial displacement of the mandrel in the skew-rolling process is reduced to the maximum extent. The effect of improving the rolling stability is achieved through cooperation of skew-rolling roller form design and rack novel structural design, the spiral ducts in the skew-rolling inner surface are eliminated or decreased to the maximum extent, and the quality of steel pipe products is improved. The skew-rolling process level of the seamless steel pipe is increased, and application and development of a skew-rolling process are promoted.

Owner:CHENGDU CHENGWU TUBE TECH LTD

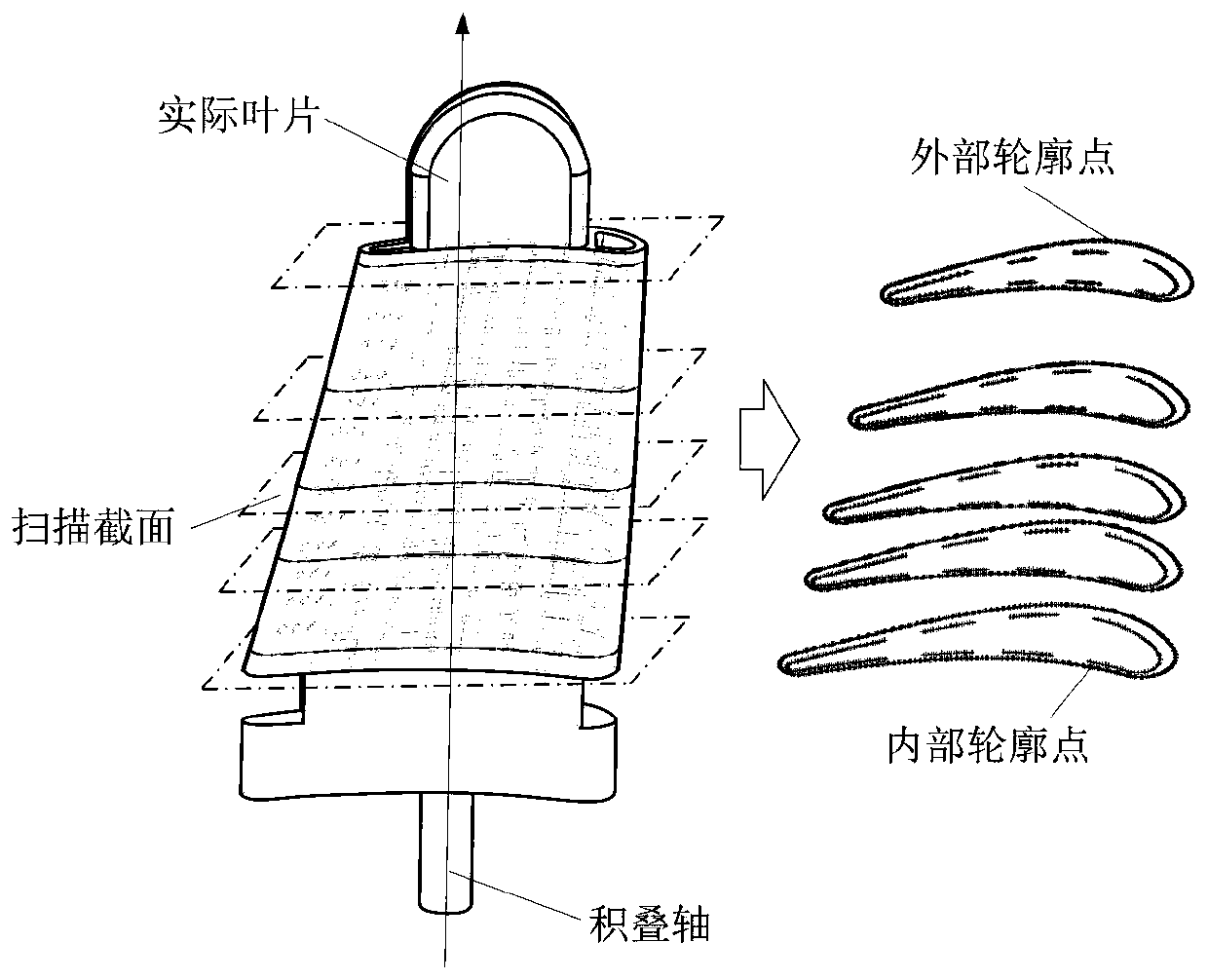

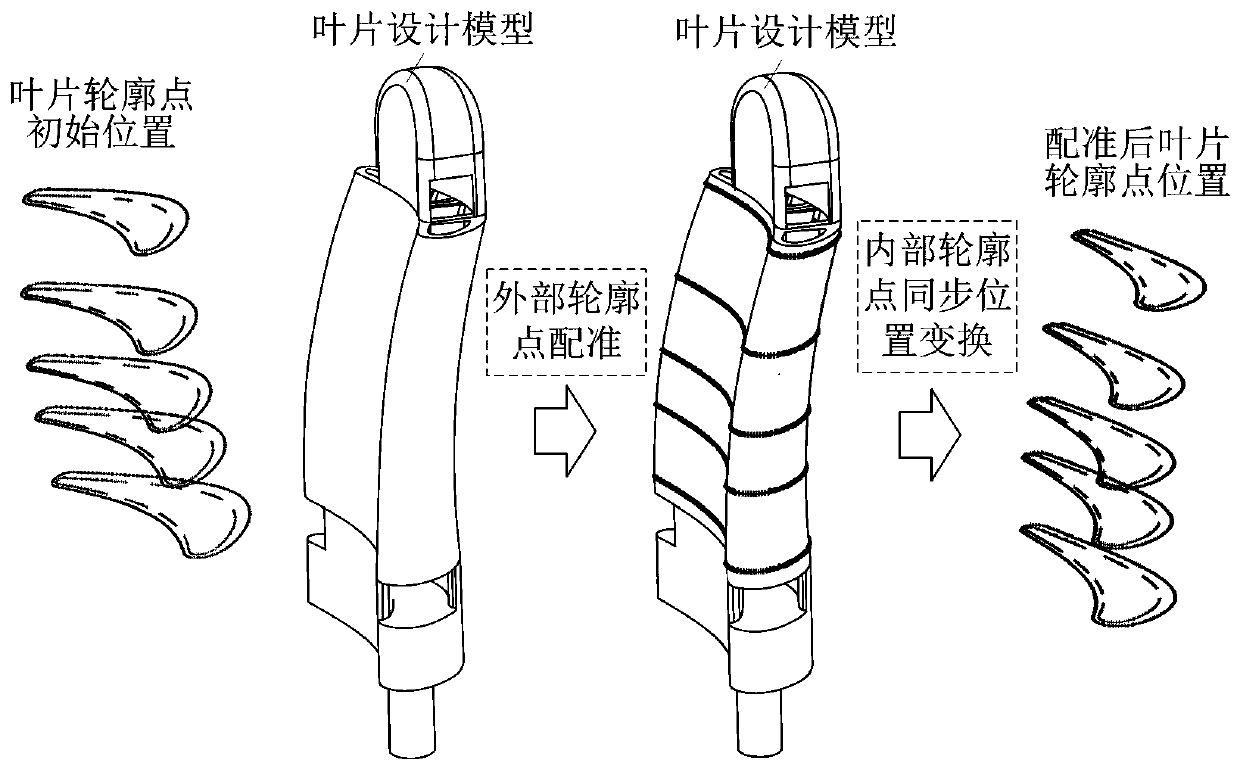

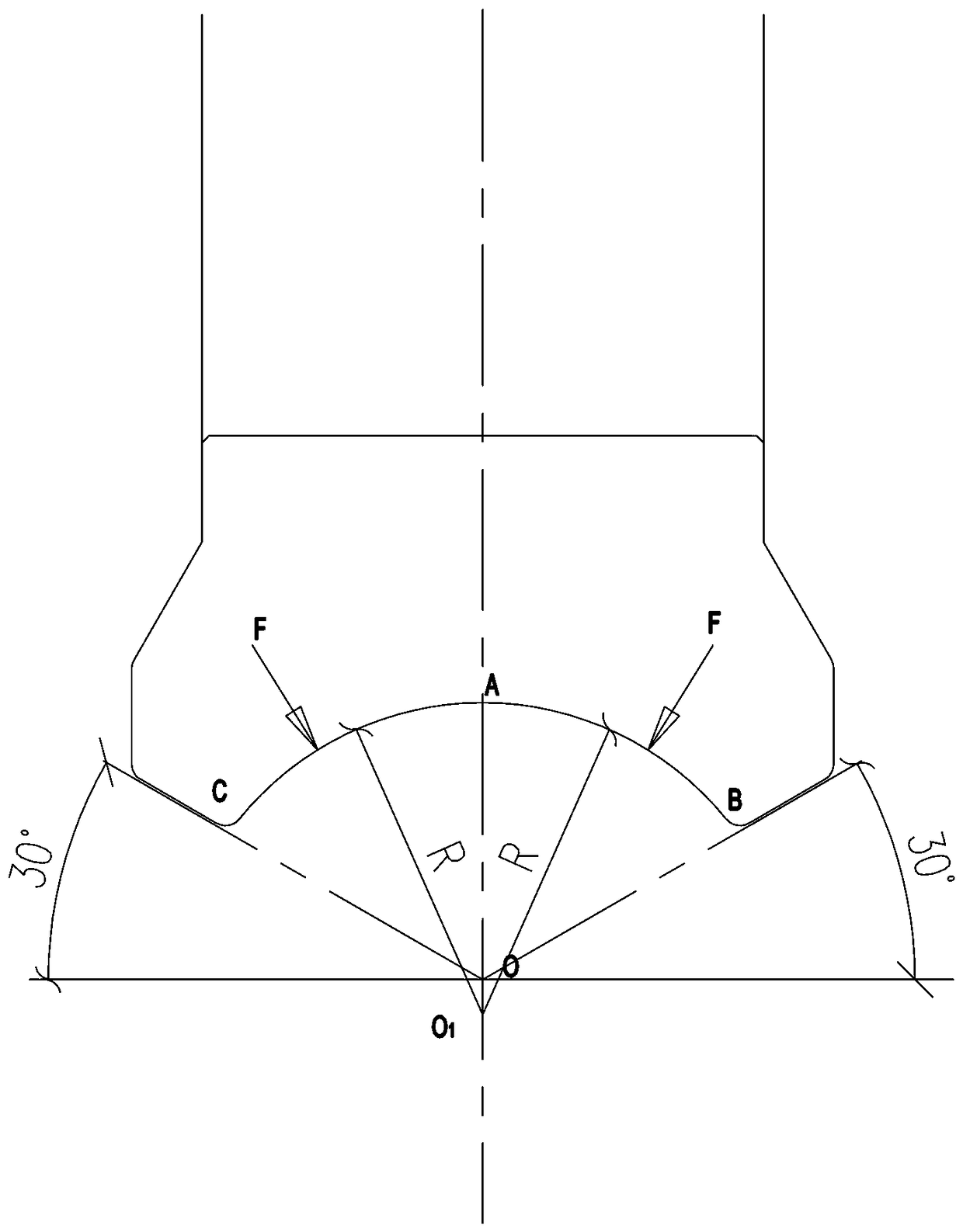

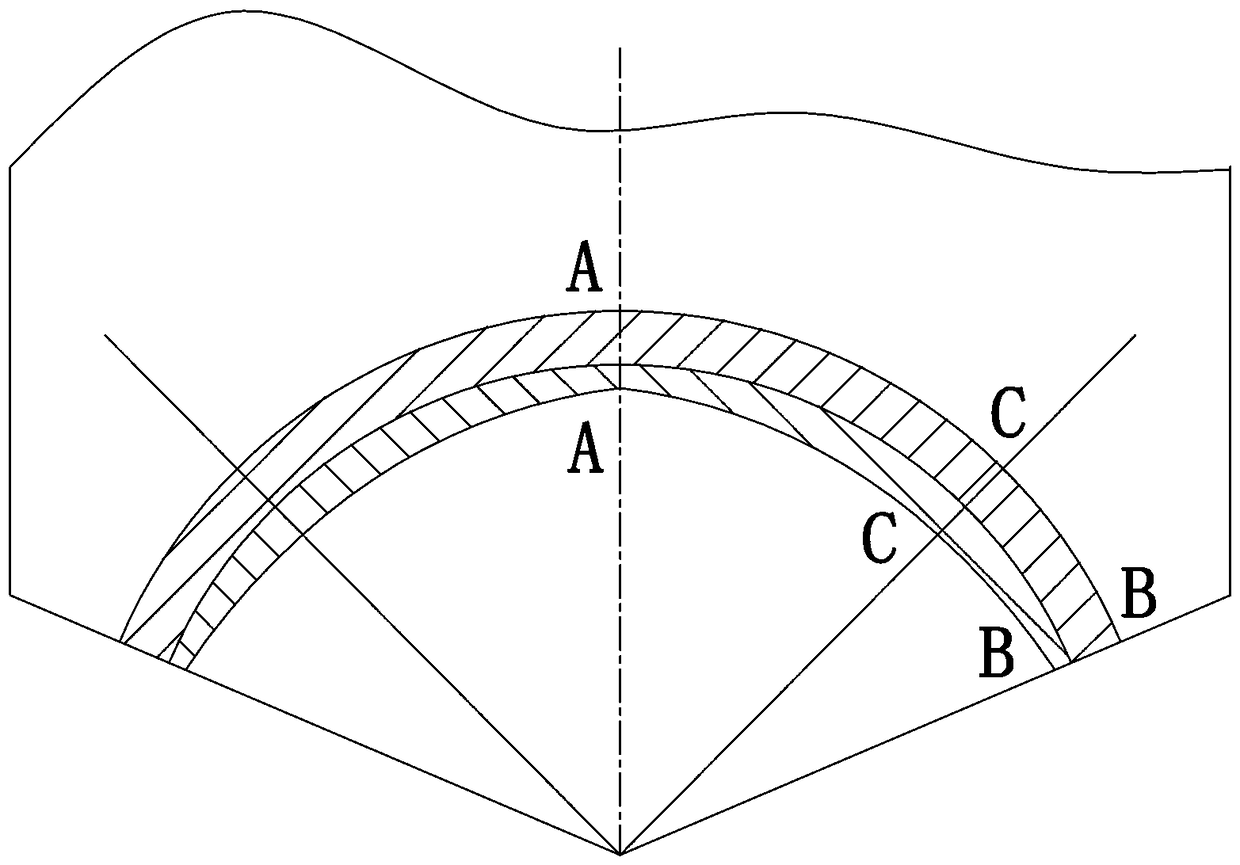

Hollow turbine blade wall thickness deviation reverse regulation and control method based on ceramic core positioning compensation

ActiveCN111259557APrecise control of wall thickness accuracyOptimize the matching relationshipGeometric CADHydro energy generationTurbine bladeCeramic

The invention belongs to the technical field of aeroengine hollow turbine blade investment precision casting, and particularly relates to a hollow turbine blade wall thickness deviation reverse regulation and control method based on ceramic core positioning compensation. The method comprises the following steps: 1) acquiring data of inner and outer contour points of an actual hollow turbine blade;2) carrying out three-dimensional iterative registration on the outline points of the blade and a design model; 3) calculating the pose drift amount of the ceramic core in the precision casting process; 4) calculating the reverse offset of the ceramic core; 5) reversely biasing the ceramic core design model; and 6) adjusting the size of the wax mold ceramic core positioning element. The problem that the wall thickness size of an existing aero-engine hollow turbine blade is out of tolerance seriously is solved. From the perspective of ceramic core pose regulation and control, the spatial poseof a ceramic core in a wax pattern is changed by adjusting the size of a ceramic core positioning element in the wax pattern mold, then a core shift wax pattern is formed, and finally the purposes ofimproving the position matching relation between a shell and the ceramic core and achieving accurate control over the wall thickness precision of the hollow turbine blade are achieved.

Owner:SHANXI UNIV

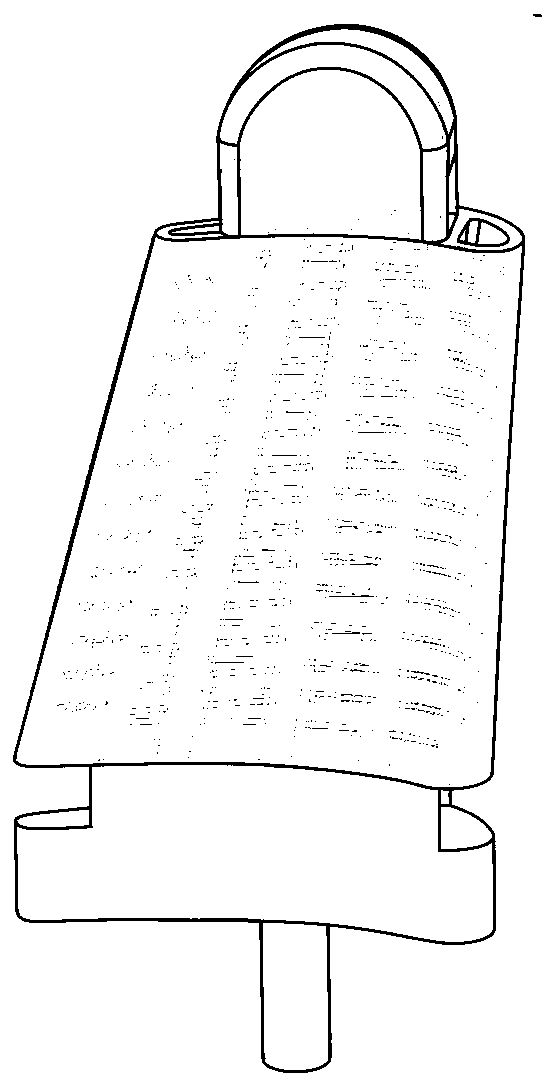

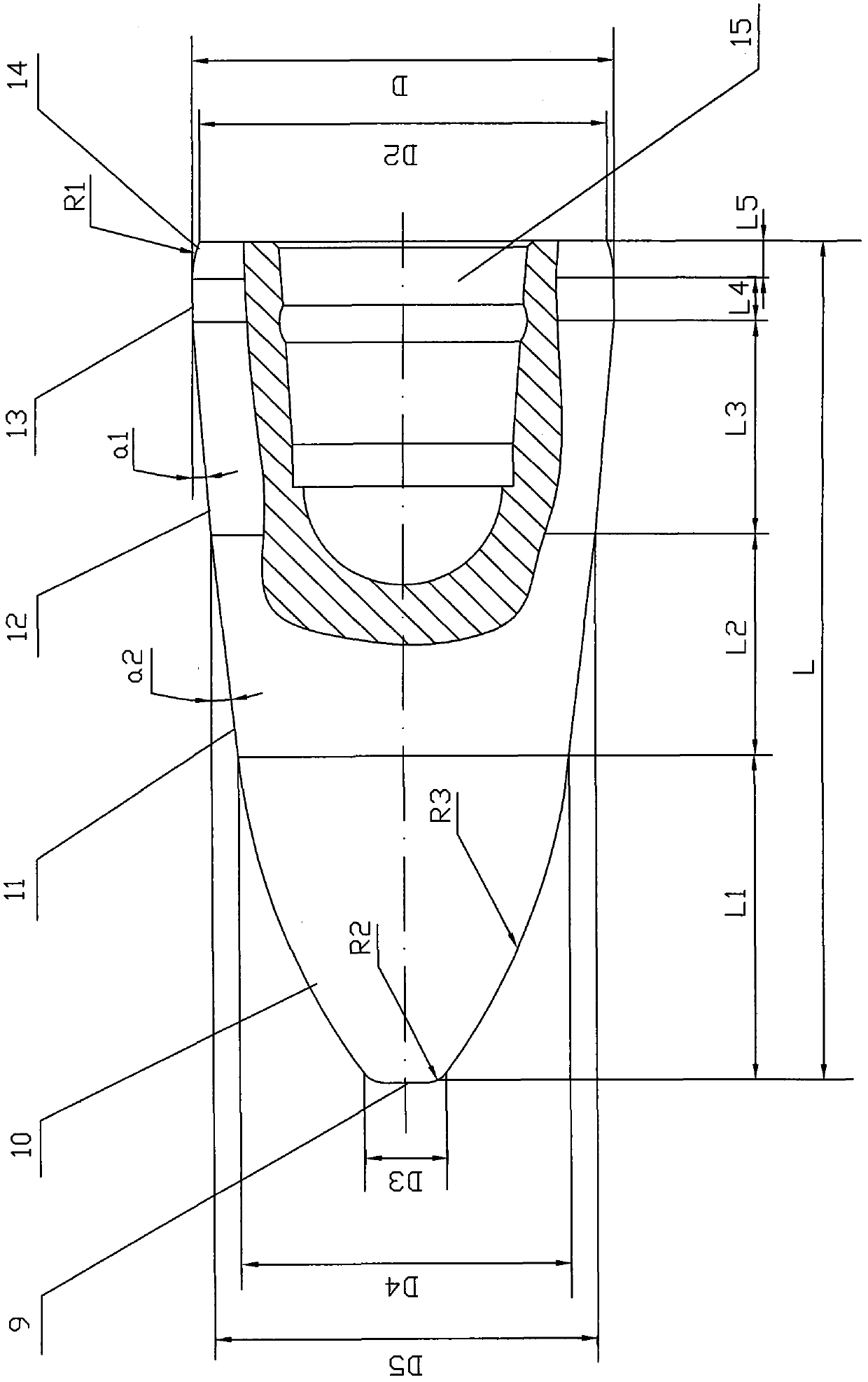

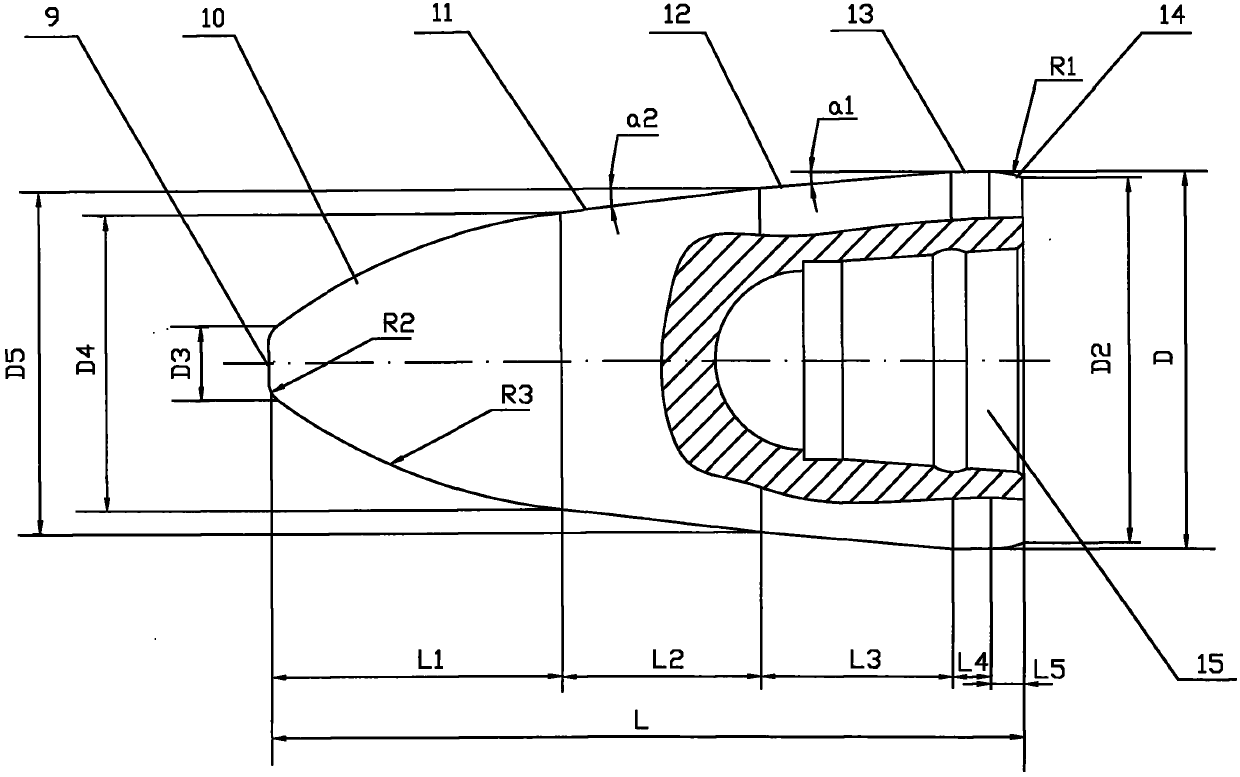

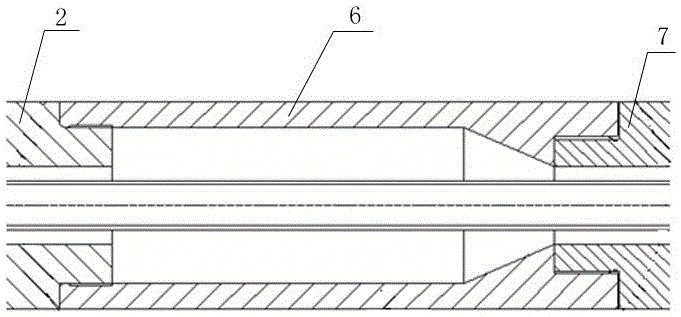

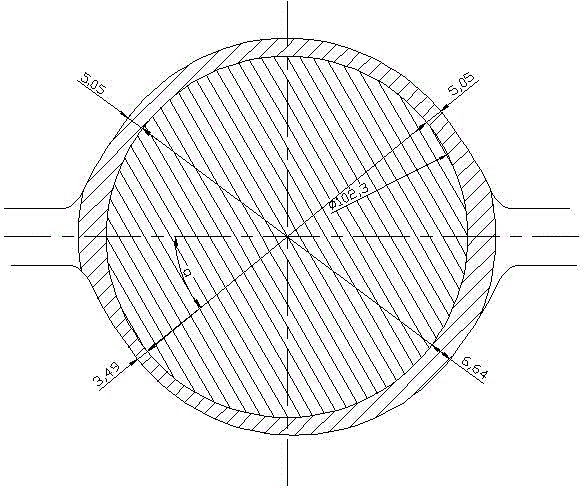

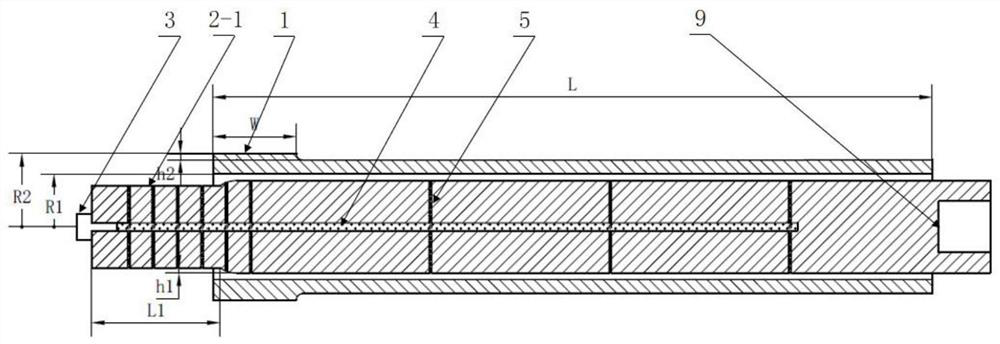

Plug for large-hole series medium- and thick-wall capillaries

InactiveCN101947551AImproved Wall Thickness AccuracyImprove straightnessMandrelsMetal rolling arrangementsPunchingThick wall

The invention relates to the field of steel pipe production, in particular to a plug for punching of large-hole series medium- and thick-wall capillaries. The outline of the plug consists of a punching section, an expanding section, a rolling section, a circling section and a reverse cone section. The front end surface of the plug adopts a flat head design, and a bar inserting hole is formed on the tail end of the plug; connection between the front end surface of the plug and the punching section is realized through arc transition, wherein the arc radius is R2, and the arc radius of the outline of the punching section is R3; the expanding section and the rolling section are cones, wherein the taper of the expanding section is a2, and the taper of the rolling section is a1; the outline of the reverse cone section is an arc of which the arc radius is R1; and the circling section is a cylinder.

Owner:HENGYANG VALIN STEEL TUBE

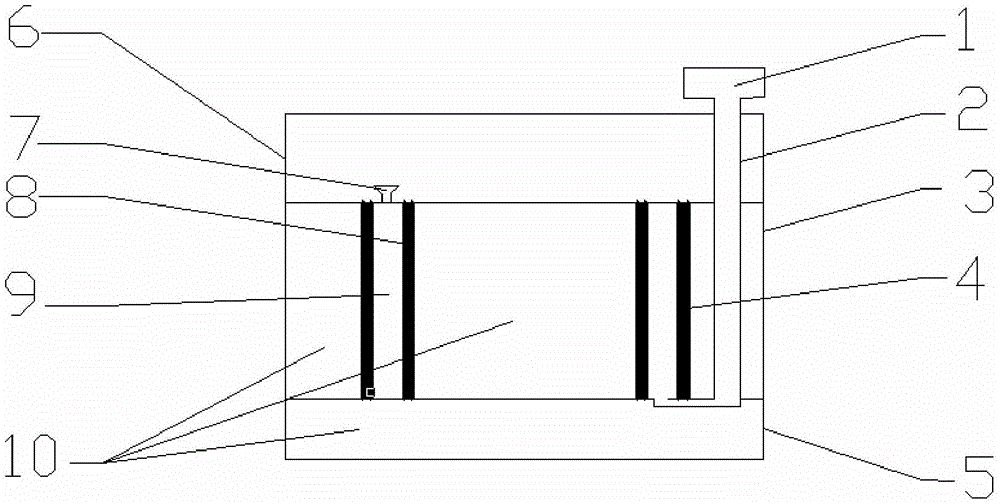

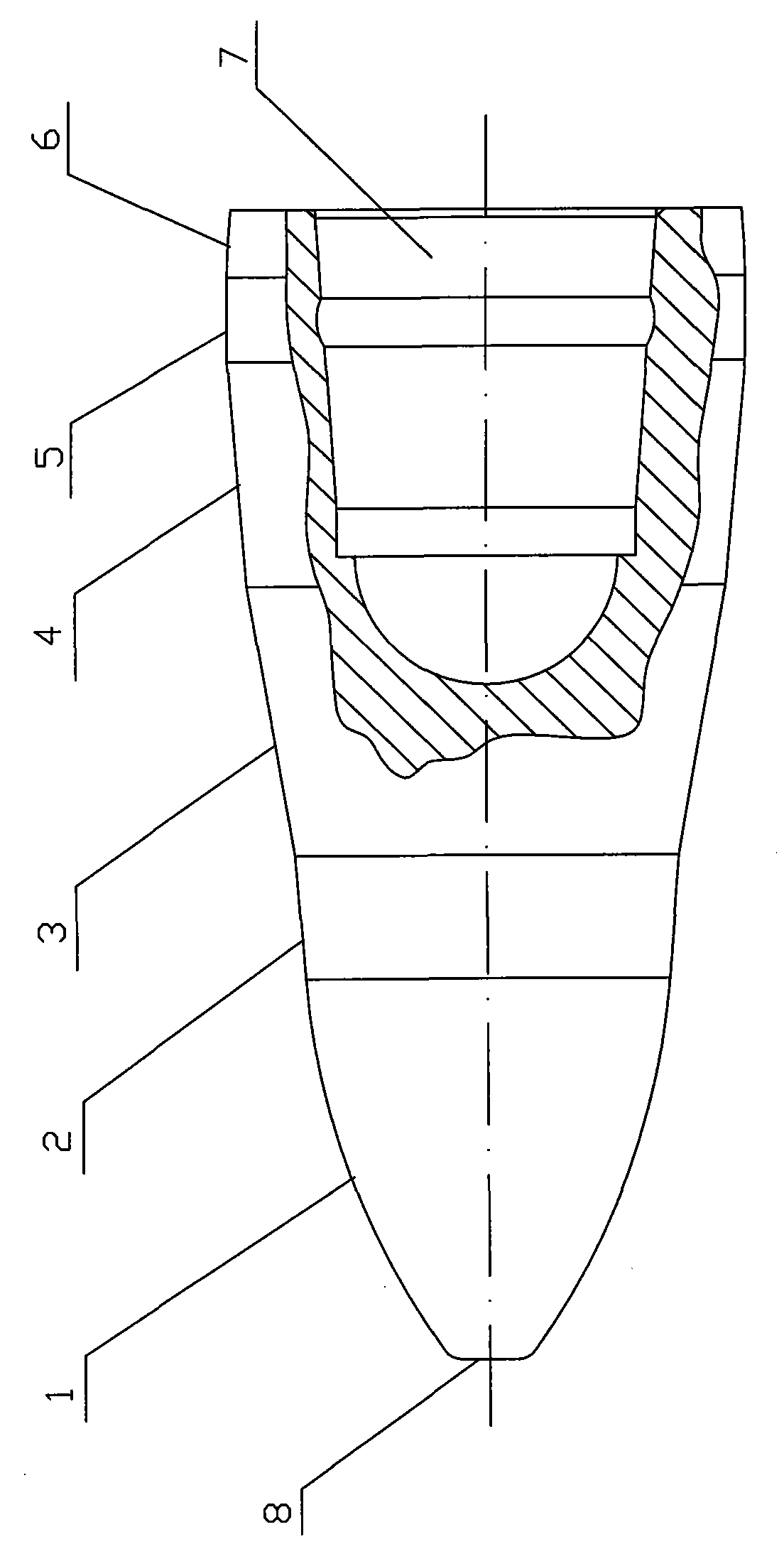

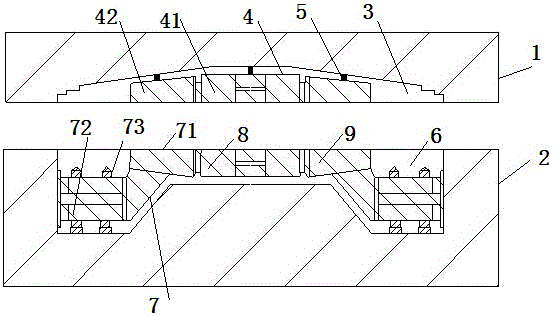

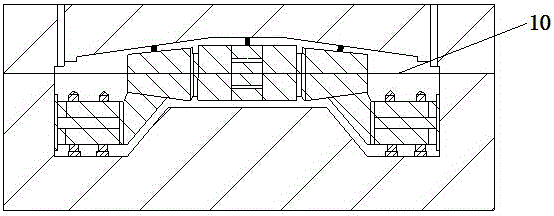

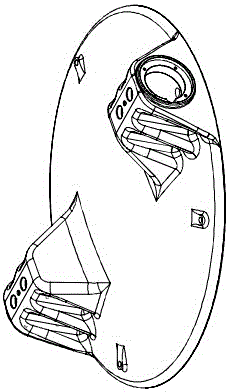

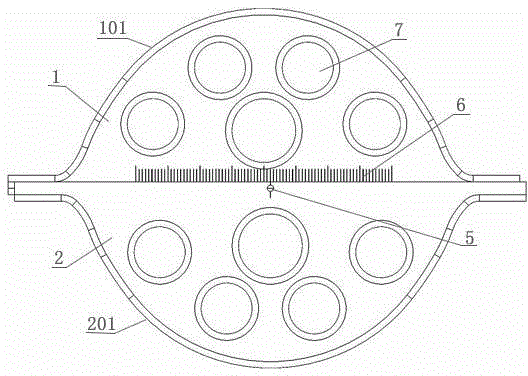

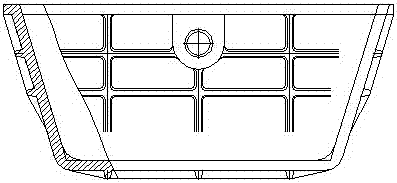

High-precision butterfly plate casting

ActiveCN106513591AReduce manufacturing costAvoid lostFoundry mouldsFoundry coresMaterials scienceCasting

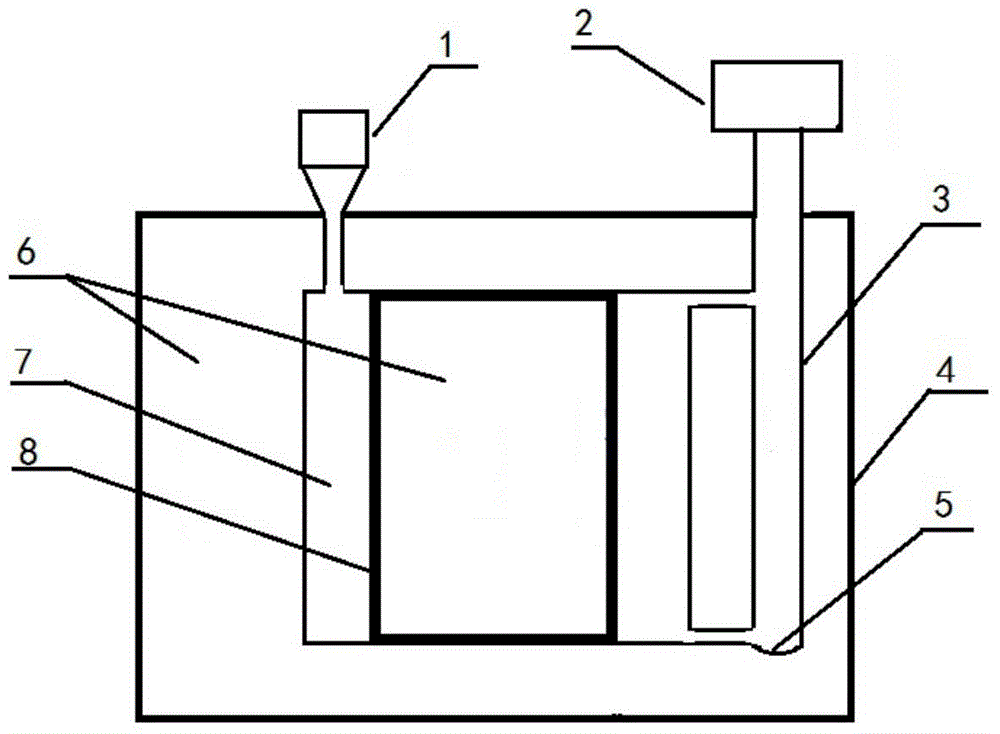

The invention discloses a high-precision butterfly plate casting. The high-precision butterfly plate casting comprises an upper moulding box (1) and a lower moulding box (2), wherein a butterfly plate upper cavity (3) is formed in the upper moulding box (1); an upper core (4) is arranged in the butterfly plate upper cavity (3); a group of technological supports (5) made of an iron material are arranged between the upper core (4) and the butterfly plate upper cavity (3); a butterfly plate lower cavity (6) is formed in the lower moulding box (2); a lower core (7) is arranged in the butterfly plate lower cavity (6) and comprises a first core (71); axle hole cores (72) are arranged at two sides of the first core (71) and positioned below and connected with the first core (71); and second cores (73) are arranged at the upper ends and the lower ends of the axle hole cores (72). The high-precision butterfly plate casting has the characteristics that the manufacturing precision and the qualification rate are high, the production cost is low, the sealing effect is improved, and the damage probability of a butterfly plate is reduced.

Owner:ZHEJIANG OUYEDA MACHINE MFG

Process for improving wall thickness accuracy of medium-thick wall pipe

InactiveCN109092900AImproved Wall Thickness AccuracyEliminate gapsMandrelsMetal rolling arrangementsPunchingIngot

The invention discloses a process for improving the wall thickness accuracy of a medium-thick wall pipe, comprising the following steps: S1, steel pipe casting: selecting a suitable steel ingot and melting the steel ingot and pouring the melted ingot to produce a pipe blank; S2, piercing machine correction: setting a keyway of a connecting sleeve at the top of a piercing machine as a semicircularkeyway; S3, cold centering machine punching detection: detecting punching of a perforator; S4, coefficient modification: changing the frame speed and tension coefficient of the hole type to 0.05+ / -0.01; S5, centerline adjustment: ensuring that the rolling centerline of the piercing machine is consistent with the centerline of a piercing trolley, so that the force applied to the pipe blank during piercing is uniform. Through head technical modification, the system specification of the centering hole and the optimization of the tension coefficient of the sizing mill, the yield of the medium-thick wall pipe with the wall thickness of 16 to 35 of 273 pipes can be stabilized at 93 percent or more.

Owner:LINZHOU FENGBAO PIPE

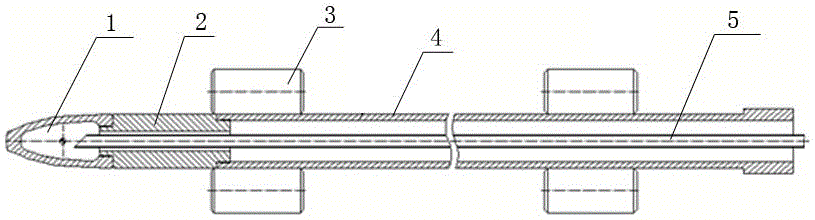

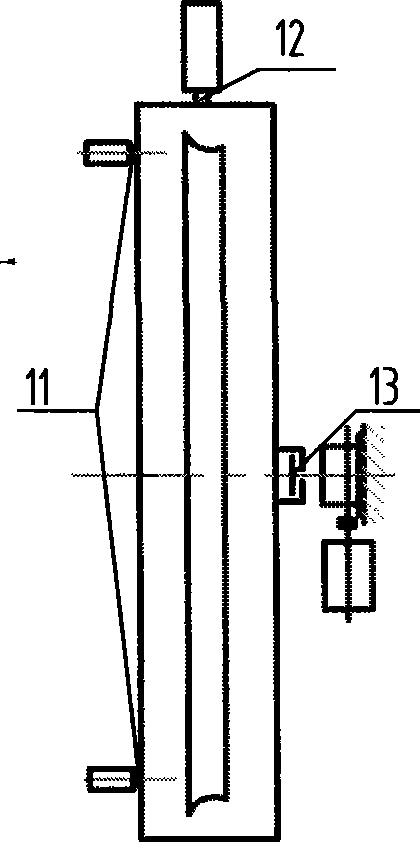

Ejector rod of seamless steel pipe perforating machine

InactiveCN106825051AResolving Dynamically Unstable ContactsExtend your lifeMandrelsMetal rolling arrangementsMaterial PerforationWater pipe

The invention relates to the technical field of seamless steel pipe perforation, in particular to an ejector rod of a seamless steel pipe perforating machine. The ejector rod comprises a hollow conical ejector head, a cylindrical connecting rod with an internal cylindrical hollow cavity, a connecting section, a three-roller guiding apparatus and a cooling water pipe, wherein the connecting rod is connected with the ejector head by virtue of a bolt, the connecting section is connected with the connecting rod by virtue of a bolt, the three-roller guiding apparatus is installed at the outer side of the connecting section, the connecting section consists of a first connecting section, a second connecting section, a combination of N third connecting sections and the second connecting section and a tail rod section, which are successively connected with one another. The connecting section of a traditional ejector rod is divided into a plurality of sections, a bearing is installed on the second connecting section, so that the second connecting section and the third connecting section can be increased according to a perforating length, and the dynamic unstable contact between the ejector rod and a guiding rod when in rolling can be effectively solved.

Owner:苏州容合易工业科技有限公司

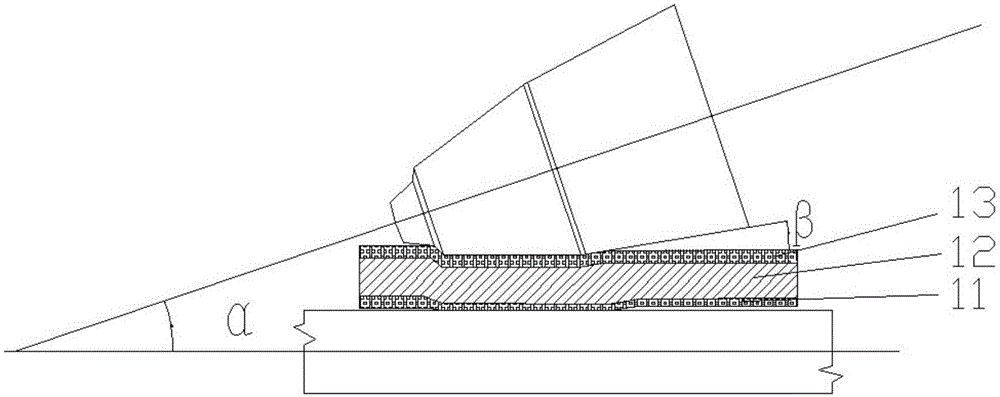

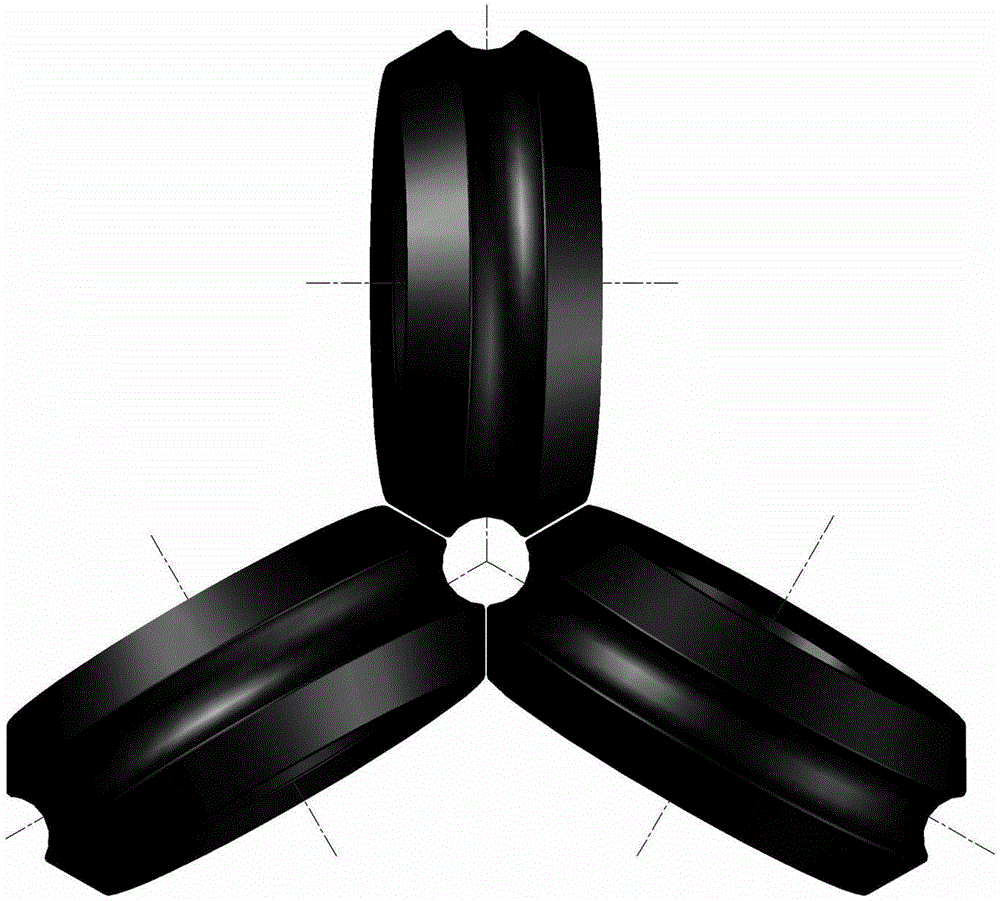

Fixed diameter reducing machine for eliminating inner squares of steel pipe

InactiveCN104353673AEliminate internal phenomenaImproved Wall Thickness AccuracyMetal rolling stand detailsMetal rolling arrangementsEngineeringThick wall

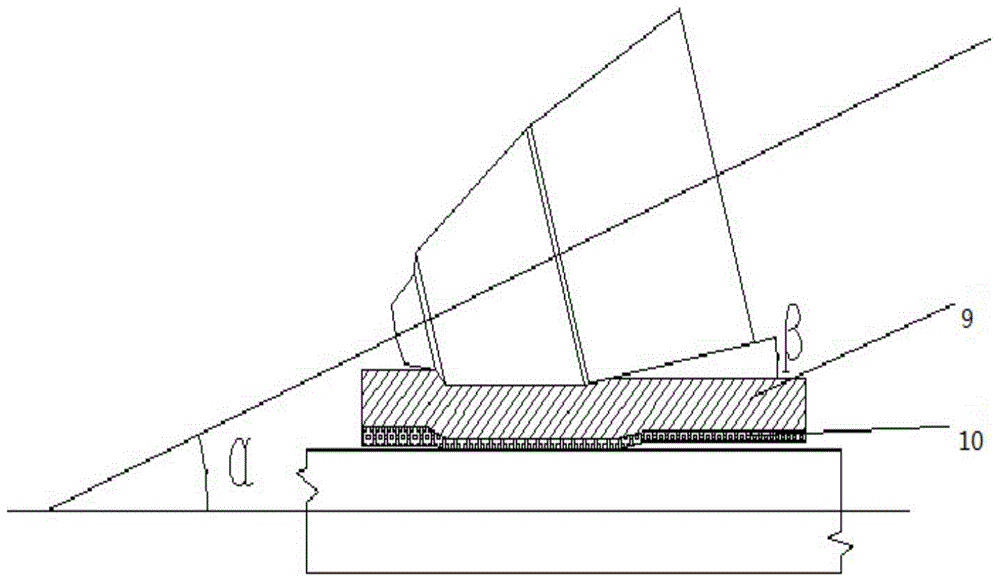

The invention belongs to the technical field of a hot milling seamless steel pipe, and particularly relates to a fixed diameter reducing machine for eliminating inner squares of a steel pipe. The fixed diameter reducing machine comprises a total assembling machine frame, a shaft, a bearing, a milling roller machine frame and milling rollers, wherein the milling rollers are arranged on the milling roller machine frame. The fixed diameter reducing machine is characterized in that the center line of each milling roller of the fixed diameter reducing machine forms an included angle alpha with a connecting line of a hole groove bottom center and a hole center of the milling roller, and in addition, the milling rollers are all in clockwise or anticlockwise direction arrangement. Each milling roller axial line of the original steel pipe fixed diameter reducing machine rotates an angle alpha by using the connecting line of the hole groove bottom center and the hole center of the corresponding milling roller as the axis, so that the steel pipe rotates in the milling process, the thickening sections of each machine frame are staggered, the lamination effect of the thickening sections of the machine frame in the same region is avoided, and the inner square phenomenon of the steel pipe is eliminated. The fixed diameter reducing machine has the advantages that the operation is simple and reliable, the wall thickness precision of the steel pipe can be greatly improved, and particularly, the inner square problem of thick wall pipes can be solved.

Owner:辽宁天丰特殊工具制造股份有限公司

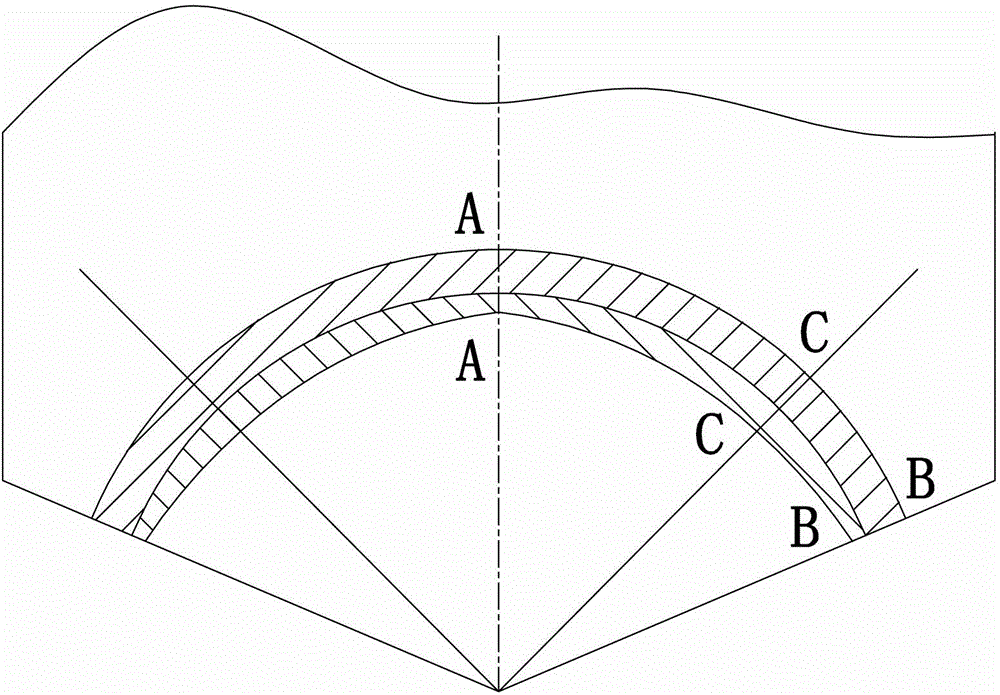

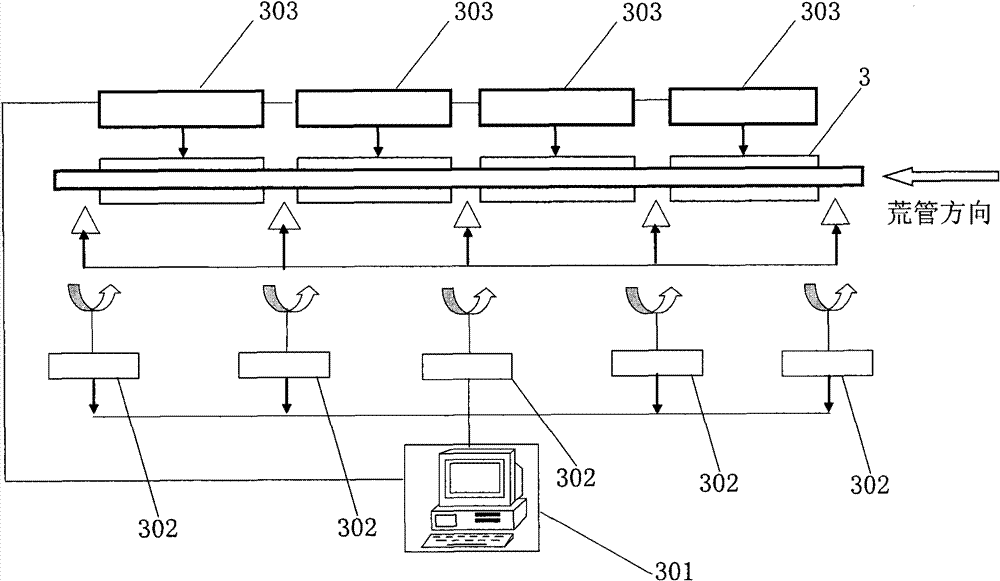

Online continuous roller hole pattern misplacement detection instrument and method

InactiveCN104690095ASimple structureThe detection method is simple and reliableMeasuring devicesMetal rolling arrangementsEngineeringNumeric Value

The invention relates to an online continuous roller hole pattern misplacement detection instrument and method. The online continuous roller hole pattern misplacement detection instrument comprises an upper hole pattern template and a lower hole pattern template which are provided with part cambered surfaces corresponding to continuous roller hole patterns and jointly form the continuous roller hole patterns. The instrument is characterized in that contact faces of the upper hole pattern template and the lower hole pattern template adopt a form that a slider is matched with a slideway, a zero position mark is arranged at the center of one of the hole pattern templates, the other hole pattern template is provided with a reference graduated ruler mark corresponding to the zero position mark, and multiple through holes convenient for hand-holding are distributed in faces of the upper hole pattern template and the lower hole pattern template. The instrument is simple in structure, reliable in use and simple to operate; hole pattern misplacement is adjusted and eliminated according to measured misplacement numeric value, so that the problem that existing continuous roller hole pattern misplacement is less prone to being timely found and dealt is solved, wall thickness accuracy of continuously rolled steel pipes is improved greatly, defective product rate is lowered remarkably, and production cost is saved.

Owner:辽宁天丰特殊工具制造股份有限公司

A seamless thin-wall tube drawing die for integrated circuits

Owner:浙江义腾特种钢管有限公司

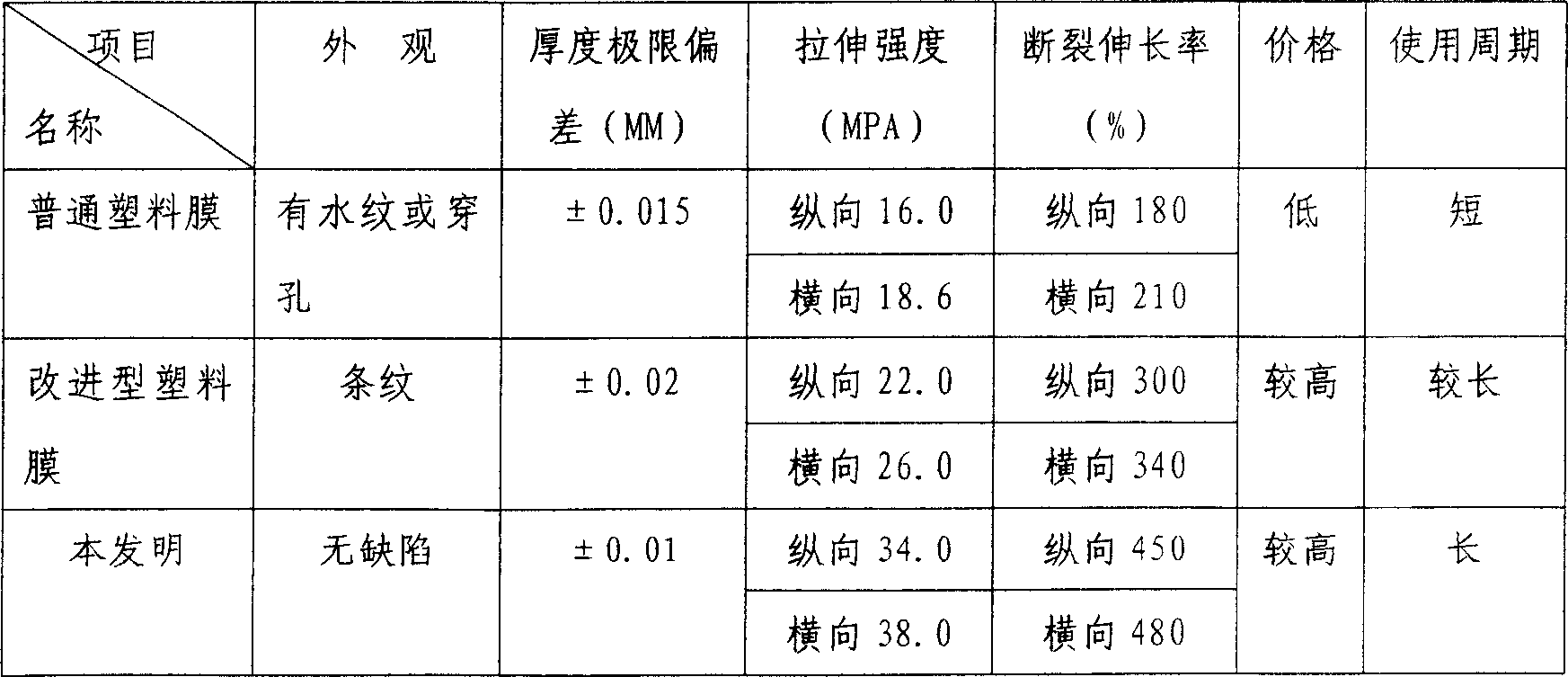

Modified polyethylene film and its production technology

A modified polyethylene film comprising the constituents (by weight proportion) of chlorinated polyethylene 55-65%, low density polyethylene 30-40%, carbon black 2-4%, anti-oxidant 0.1%, epoxy soya-bean oil 2%. The preparation process comprises the steps of extrusion and blowing film. The advantages of the present invention are ageing-proof, chemical-resistance, low-temperature resistance, and less temperature distortion.

Owner:孔少云

A metallurgical slag basin modelless casting method

ActiveCN105170904BLow costAvoid uneven wall thicknessFoundry mouldsFoundry coresMetallurgical slagTransdermal patch

The invention provides a metallurgical slag basin modelless casting method, which comprises the following steps: using a corner core box to make sand cores at the four corner ends of the slag basin, obtaining the outer contours of the four corner ends of the casting slag basin, and molding the slag basin by means of a scraper, Form the sand mold of the outer contour of the slag basin casting; mend the skin: use multi-layer boards or molding sand to fill and assemble the cavity part of the mold to form the outline of the slag basin sand mold; lower the sand to form a sand core box; lower the core and close the box, compared The original method of casting by making molds. In this method, the length, width and wall thickness of the slag basin can be adjusted arbitrarily, so the slag basin of any size can be made, replacing multiple sets of molds, which can be reused and greatly reduces the At the same time, the problem of uneven wall thickness of castings is avoided, and the wall thickness accuracy of slag basin castings is improved.

Owner:山东瑞浩重型机械有限公司

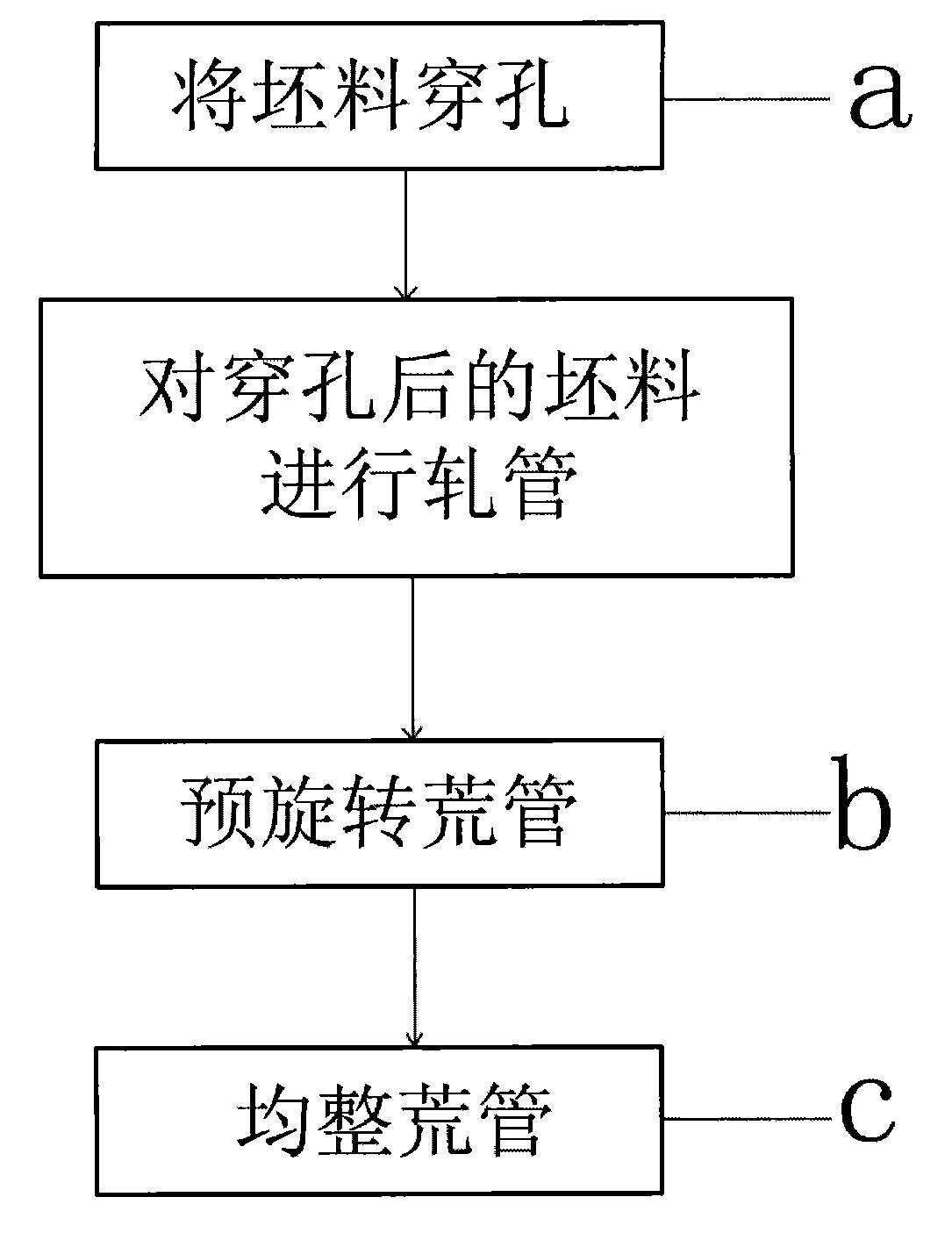

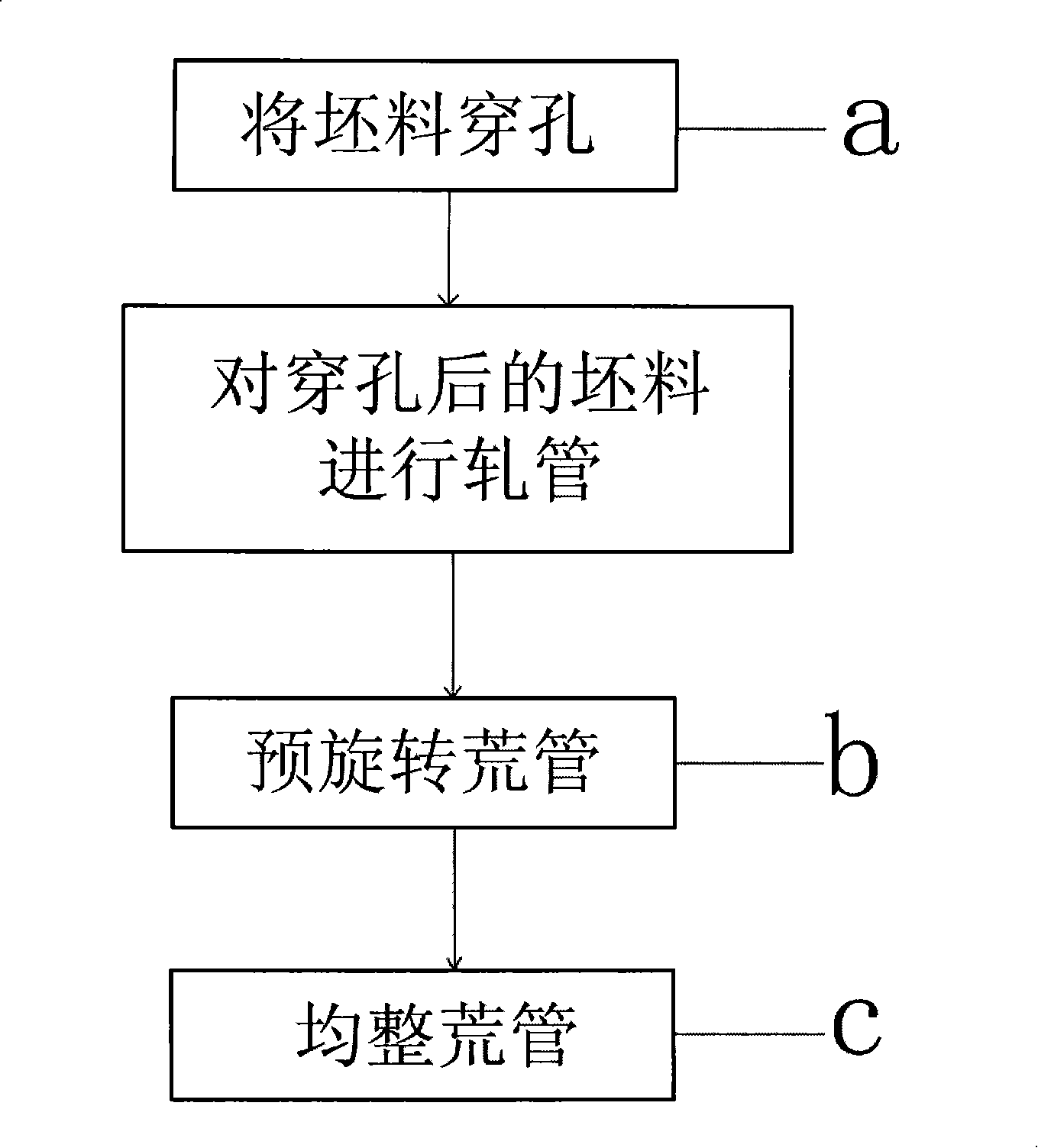

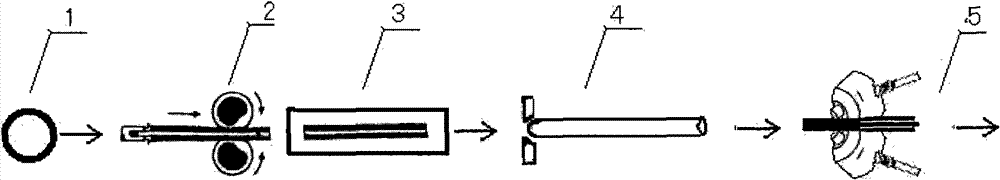

Precision rolling process for heavy-caliber skew rolling reeling weldless steel tube

ActiveCN101318200BRolling Process to Solve BitingImproved Wall Thickness AccuracyMetal rolling arrangementsMaterials scienceSteel tube

The invention provides a finish rolling technique for a large diameter skew rolling reeling seamless steel tube, and the technique is carried out under a temperature being higher than 900 DEG C. The finish rolling technique includes the following processes: a. a blank is perforated by a piercer; b. the blank after being perforated in the above process is subject to tube rolling by a tube mill to form a crude tube; c. the crude tube formed in the above process is evenly reeled by a reeling mill, wherein, between the process b and the process c, the process of pre-rotating the crude tube is carried out, and in the process, the crude tube is pre-rotated at a speed lower than a rolling speed by a pre-rotating device, thus leading the crude tube to move toward the direction of the reeling millwhile pre-rotating, and meanwhile, the crude tube is pushed into the reeling mill by a pushing device; thus perfectly solving the rolling process of crude tube biting, fully exerting reeling function, raising the wall thickness accuracy to minus or plus 1-3 percent, saving 5 percent of energy; and increasing metal yield by 2 percent.

Owner:BERIS ENG & RES CORP

A surface-enhanced inner step shaft inner hole precision forming process

ActiveCN113118353BImprove processing efficiencyReduce processing timeMetal-working apparatusMotor speedLubricant

Owner:XI AN JIAOTONG UNIV +1

Hot-rolled seamless steel pipe cross-rolling mill front and back mandrel fully supported rolling equipment

ActiveCN107159713BImprove rolling stabilityImproved Wall Thickness AccuracyMandrelsMetal rolling arrangementsStrip millMetal

The invention belongs to the technical field of metal press working (steel rolling), and relates to a steel rolling process for rolling deformation of a seamless steel pipe slant mill, so that a rolling deformation process is comprehensively improved, the deformation stability is improved, and problems in a skew-rolling seamless steel pipe production process are solved, that is, a rolling process method, equipment and technology are provided for overcoming quality defects of spiral ducts in the inner surface of a steel pipe and improving the quality. The core scheme is that a slant mill foreground and background mandrel adopts the full-supporting rolling process, equipment and technology. During skew-rolling deformation, the rolling mandrel is limited and clamped at an inlet of the slant mill and an outlet end at the same time in the rolling process, the mandrel is completely in a controlled and retrained state in the rolling process, and radial displacement of the mandrel in the skew-rolling process is reduced to the maximum extent. The effect of improving the rolling stability is achieved through cooperation of skew-rolling roller form design and rack novel structural design, the spiral ducts in the skew-rolling inner surface are eliminated or decreased to the maximum extent, and the quality of steel pipe products is improved. The skew-rolling process level of the seamless steel pipe is increased, and application and development of a skew-rolling process are promoted.

Owner:CHENGDU CHENGWU TUBE TECH LTD

A large and wide aluminum alloy ribbed plate and its production method and extrusion perforating needle

ActiveCN112547831BInhibition of recrystallizationImprove solid solubilityFurnace typesHeat treatment furnacesIngotMaterials processing

A large-width aluminum alloy ribbed plate, a production method thereof and an extrusion perforating needle belong to the field of aluminum alloy material processing. In the production method of the large-width aluminum alloy ribbed plate, casting, preheating, and extrusion are made into an aluminum alloy ribbed pipe material, which is cut and flattened after quenching, and then heat-treated to obtain an ultra-wide and high-strength pipe that meets the requirements of the hull. 1. A large and wide aluminum alloy ribbed plate with high corrosion resistance; and an extrusion perforation needle is provided for extrusion, and the performance can be further improved compared with the aluminum alloy solid ingot extrusion. This production method can avoid the welding passes of friction stir welding used in the existing process in order to realize the mass production of large and wide aluminum alloy ship plates, reduce the number of welds, greatly improve the overall strength and sealing of ships, reduce production costs, and improve production efficiency.

Owner:NORTHEASTERN UNIV LIAONING

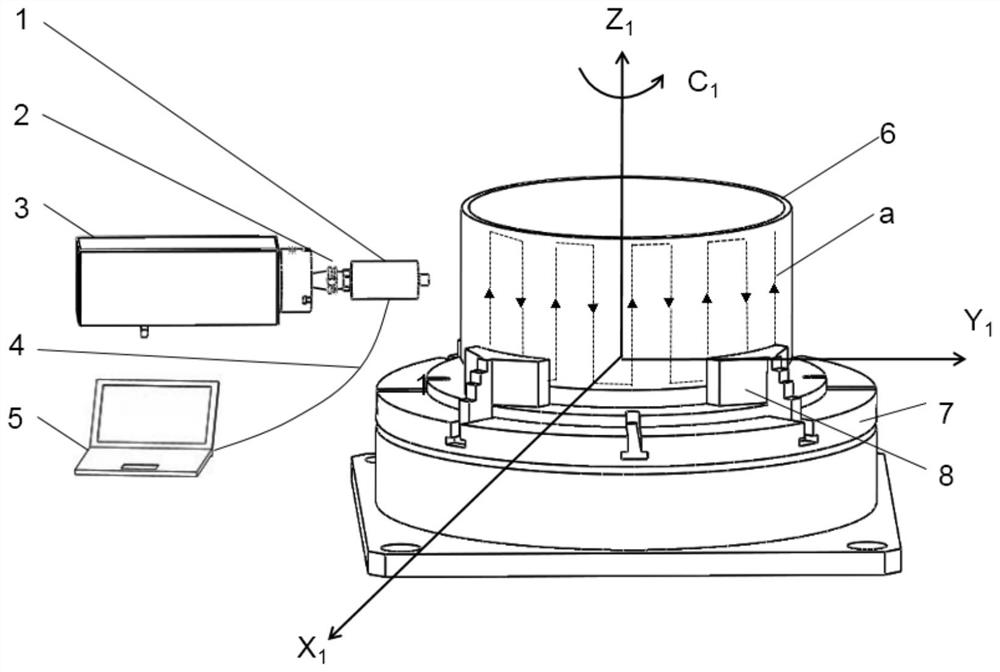

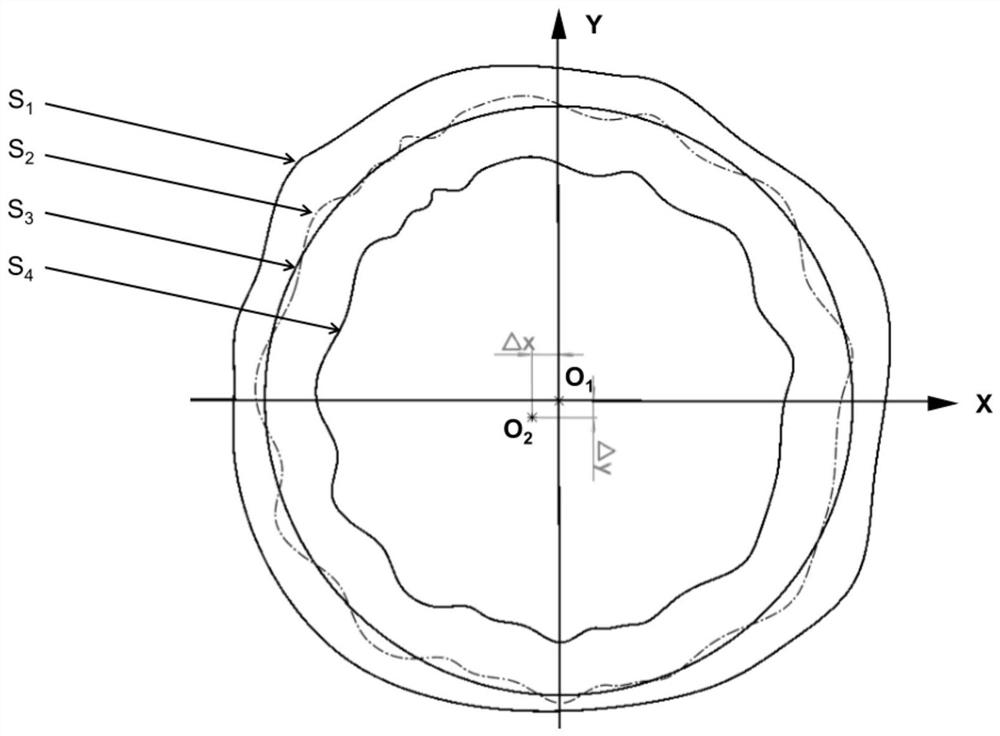

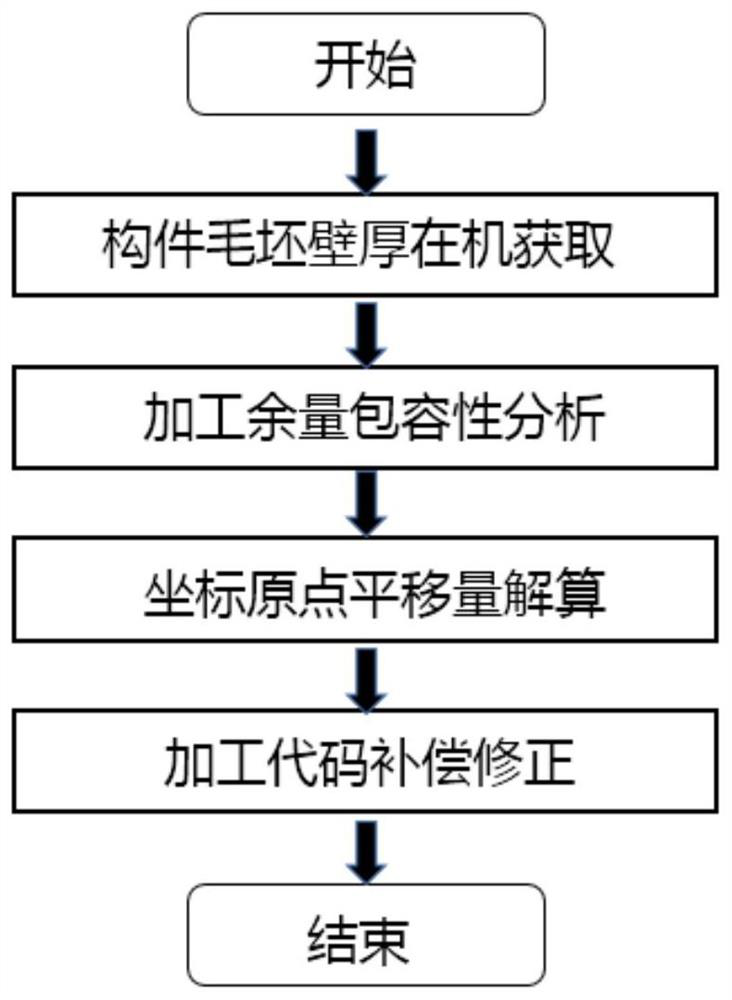

Complex component machining residual wall thickness self-adaptive compensation method based on coordinate origin translation

ActiveCN114001683AGuaranteed profileGuaranteed accuracyUsing wave/particle radiation meansNumerical controlControl engineering

The invention discloses a complex component machining residual wall thickness self-adaptive compensation method based on coordinate origin translation, and belongs to the technical field of measurement-machining integration. According to the method, on an open type numerical control platform, wall thickness data of a component is measured through an ultrasonic thickness measuring device, a machining target curved surface related to the residual wall thickness is reestablished, inclusiveness analysis is completed, coordinate origin translation amount calculation is conducted, and machining compensation is completed through machining code origin correction. According to the method, the defects of an existing residual wall thickness compensation method are overcome, the machining requirement that the residual wall thickness and the profile tolerance of the complex component are restrained at the same time is met, the machining precision is improved, the labor intensity is reduced, and self-adaptive compensation of the machining residual wall thickness of the complex component is achieved.

Owner:DALIAN UNIV OF TECH

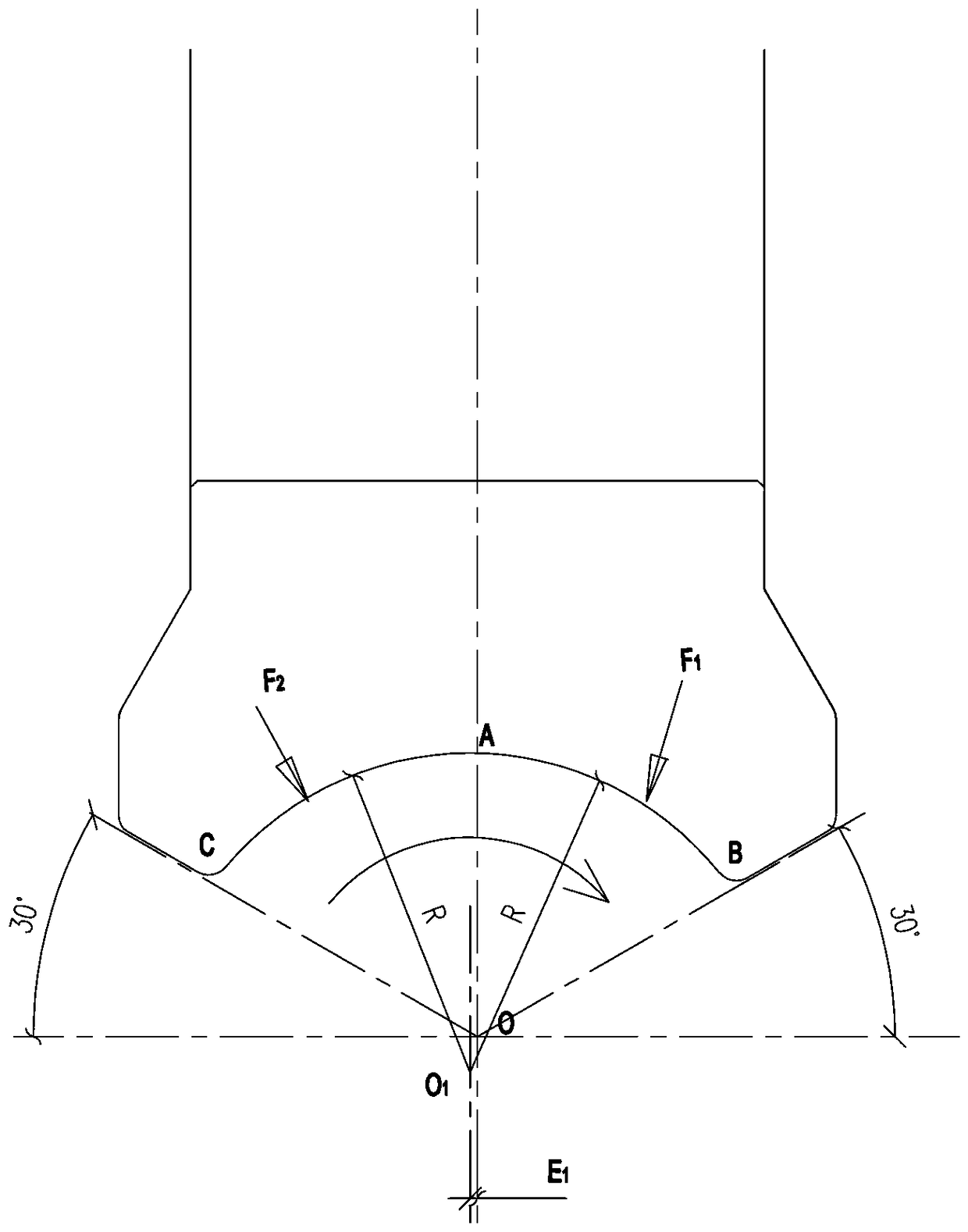

Asymmetric roller for sizing and reducing machine

PendingCN108356078AEliminate internal phenomenaImproved Wall Thickness AccuracyRollsMetal rolling arrangementsBilateral asymmetryEllipse

The invention belongs to the technical field of hot-rolled seamless steel pipes, and particularly relates to an asymmetric roller for a sizing and reducing machine. The asymmetric roller comprises oval rollers, and is characterized in that the oval hole type center lines of the oval rollers do not coincide with the center axis of the roller, and the oval hole type center lines of all the oval rollers deviate towards one side of the center axis of the roller by the distance E1. According to the asymmetric roller, on the premise that an original longitudinal rolling sizing and reducing unit is not changed, the traditional symmetric roller hole type design is changed, and through the bilateral asymmetry on the hole type design, a steel pipe bears a couple function in the sizing and reducing process; and the couples applied by all the rollers to the steel pipe are all in the clockwise direction or all in the anticlockwise direction, the steel pipe slightly rotates in the sizing and reducing process, the thickened segments of racks are staggered, the effect that the thickened segments of the racks are stacked in the same area is avoided, the inner square phenomenon of the steel pipe iseliminated, and the wall thickness precision of the steel pipe is greatly improved.

Owner:辽宁天丰特殊工具制造股份有限公司

Extrusion molding method and device for rapidly and steplessly adjusting pipe wall thickness

The invention discloses an extrusion moulding method and an extrusion moulding device capable of quickly regulating the wall thickness of a pipe in a stepless manner. According to the device, a mandrel and a flow dividing cone are coaxially arranged in the inner cavities of a die head body and a transition die head body; a first ventilating hole is radially formed in the outer ring of a supporting frame; a second ventilating hole is radially formed in the transition die head body; a third ventilating hole is axially formed in the bottom of the flow dividing cone; a fourth ventilating hole is axially formed in the centre of the mandrel; the second ventilating hole is connected with an air compressor through a ventilating hole; high-pressure compressed air enters the outer surface of the mandrel and the inner surface of a material blank through above ventilating channels in sequence to form a high-pressure air cushion, and the thickness of the high-pressure air cushion is changed by changing the pressure and the flow of the high-pressure compressed air, so that quick stepless regulation of the wall thickness of an extruded pipe is realized. According to the extrusion moulding method and the extrusion moulding device capable of quickly regulating the wall thickness of the pipe in the stepless manner, the wall thickness of the extruded pipe can be regulated quickly in the stepless manner without replacing the mandrel; quick, real-time and stepless regulation of the wall thickness of the extruded pipe can be realized; meanwhile, the wall thickness precision and the finish degree of an inner wall of the extruded pipe can be improved effectively; circumferential mechanical properties of the pipe are enhanced.

Owner:SOUTH CHINA UNIV OF TECH

Control system of ejector trolley mechanism

ActiveCN111167863BEasy to controlImproved Wall Thickness AccuracyServomotor componentsRoll mill control devicesHydraulic cylinderControl system

Owner:TAIYUAN HEAVY IND

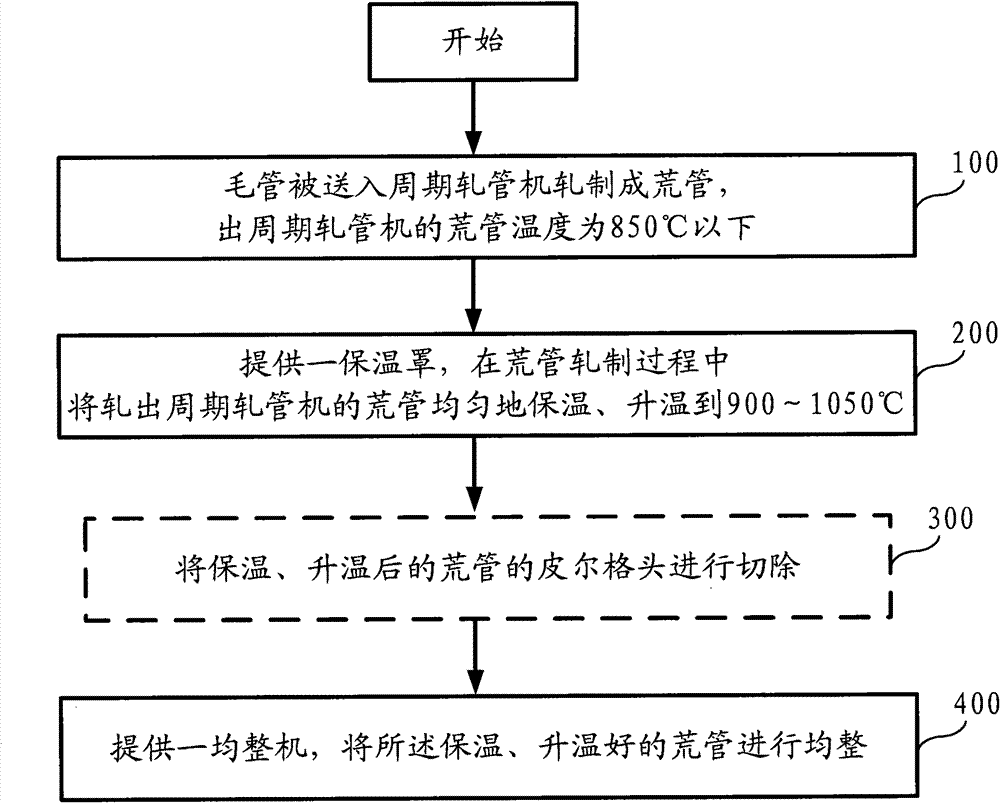

Method for producing seamless steel tube with heat preservation cover of pilger mill

ActiveCN101745537BHigh yieldImprove surface qualityTemperature control deviceMetal rolling arrangementsProcess engineeringSteel tube

The invention provides a method for producing a seamless steel tube with a heat preservation cover of a pilger mill, which comprises the following steps sequentially: conveying a blank tube to the pilger mill to produce a crude tube; providing the heat preservation cover to carry out heat preservation and temperature rise on the crude tube in the process of rolling the crude tube; cutting off a leather head of the crude tube which is subjected to heat preservation and temperature rise; and providing a reeling mill to carry out reeling on the crude tube the leather head of which is cut off. Due to the characteristics of the pilger mill and the combination allocation of the pilger mill and the reeling mill, the method for producing the seamless steel tube of the invention utilizes the heat preservation cover to carry out random rolling, heat preservation and temperature rise on the crude tube, can solve the oxidation problem of the inner surface, saves energy, reduces consumption and reduces investment.

Owner:BERIS ENG & RES CORP

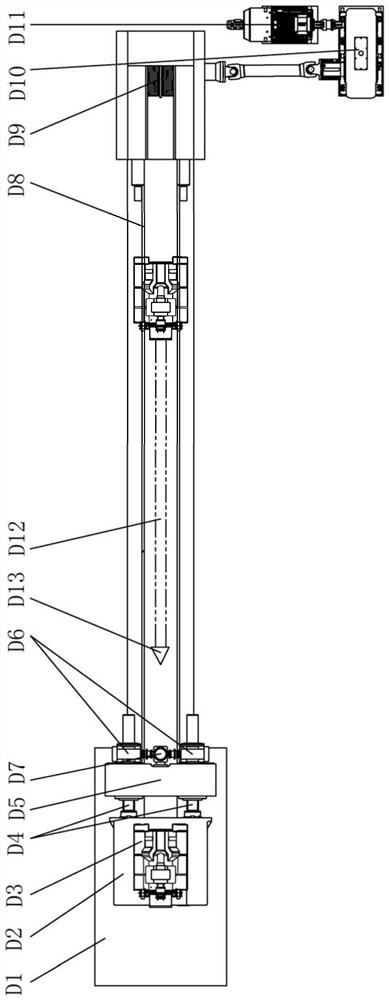

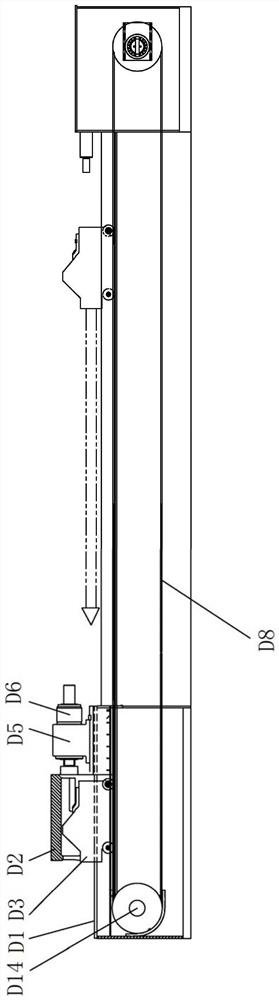

A piercing machine rolling high-precision capillary equipment and method

ActiveCN110860560BImproved Wall Thickness AccuracySolve the problem of wall thickness deviationMandrelsMetal rolling arrangementsHydraulic cylinderStructural engineering

The invention discloses a high-accuracy tubular billet rolling device and method through a piercing mill. The high-accuracy tubular billet rolling device comprises a skew-rolling piercing mill and anassembly accessory; the assembly accessory is an ejector rod centering accessory or a trolley telescopic mechanism or a trolley heightening mechanism or a combined assembly of any kinds of the ejectorrod centering accessory, the trolley telescopic mechanism and the trolley heightening mechanism; the ejector rod centering accessory is a centering roller; and the centering roller is disposed between a pipe stop apparatus and a trolley of the skew-rolling piercing mill and always embraces an ejector rod of the skew-rolling piercing mill. The trolley telescopic mechanism is a hydraulic cylinder,an ejector column of the hydraulic cylinder is connected with the trolley of the skew-rolling piercing mill, and a cylinder barrel of the hydraulic cylinder is connected with an antithrust seat of theskew-rolling piercing mill. The trolley heightening mechanism comprises a reference block and a sliding seat; the upper surface of the sliding seat is a zero-point horizon reference, and the reference block is disposed on the trolley of the skew-rolling piercing mill. The corresponding improvement measures are taken on an existing skew-rolling piercing mill, the wall-thickness accuracy of a tubular billet is improved, and the problem of the wall thickness deviation of the tail of a thin-wall tubular billet is solved.

Owner:XINPENGYUAN INTELLIGENT EQUIP GRP

A method of manufacturing a cylinder barrel for a hydraulic cylinder

The invention discloses a method for manufacturing a cylinder barrel for a hydraulic cylinder, which uses a hot-rolled coil as a raw material and undergoes the following steps in order to obtain it: (1) cutting the coil into strip steel; (2) cutting the coil into strip steel; ERW welding to form welded pipes; (3) Quenching and tempering heat treatment for welded pipes; (4) Cold reduction for welded pipes; (5) Precision straightening for welded pipes; (6) Non-destructive testing for welded pipes; Cut to length; (8) Finish the inner and outer surfaces of the welded pipe. This method makes full use of the high precision of the outer diameter and wall thickness of the ERW welded pipe, the high strength and high toughness of the quenched and tempered heat-treated material, the high precision of the cold reduction diameter, the high surface finish and high efficiency, and the precision straightening to improve the straightness and roundness of the steel pipe without damage. The detection improves the reliability of the cylinder. When used as a multi-stage cylinder, the machining allowance of the outer circle is small and the efficiency is high. The high concentricity of the welded pipe and the machining allowance of the scraping and rolling of the inner hole are small, high-precision and high-efficiency.

Owner:潘克云

A seamless steel pipe piercing machine ejector

InactiveCN106825051BResolving Dynamically Unstable ContactsExtend your lifeMandrelsMetal rolling arrangementsEngineeringMaterial Perforation

The invention relates to the technical field of seamless steel pipe perforation, in particular to an ejector rod of a seamless steel pipe perforating machine. The ejector rod comprises a hollow conical ejector head, a cylindrical connecting rod with an internal cylindrical hollow cavity, a connecting section, a three-roller guiding apparatus and a cooling water pipe, wherein the connecting rod is connected with the ejector head by virtue of a bolt, the connecting section is connected with the connecting rod by virtue of a bolt, the three-roller guiding apparatus is installed at the outer side of the connecting section, the connecting section consists of a first connecting section, a second connecting section, a combination of N third connecting sections and the second connecting section and a tail rod section, which are successively connected with one another. The connecting section of a traditional ejector rod is divided into a plurality of sections, a bearing is installed on the second connecting section, so that the second connecting section and the third connecting section can be increased according to a perforating length, and the dynamic unstable contact between the ejector rod and a guiding rod when in rolling can be effectively solved.

Owner:苏州容合易工业科技有限公司

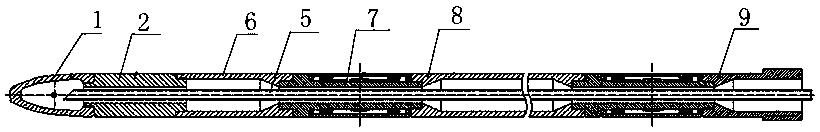

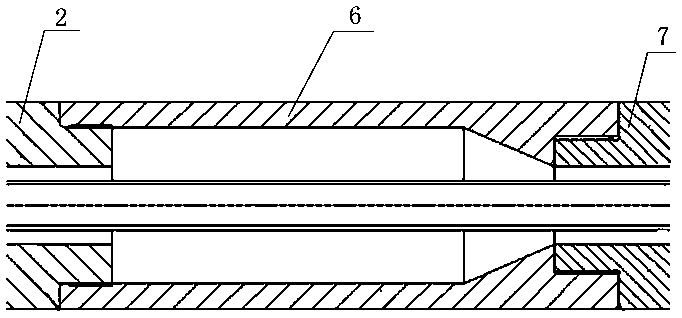

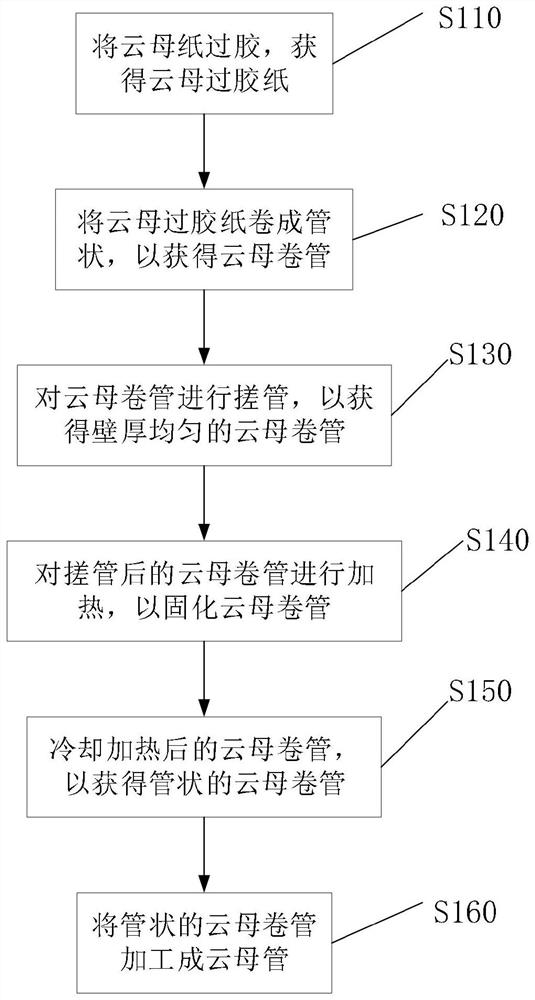

Mica pipe manufacturing method

PendingCN113096901AEasy to processThere are no unqualified issuesInsulating bodiesIndustrial engineeringComposite material

The invention provides a mica pipe manufacturing method which comprises the following steps: gluing mica paper to obtain mica glued paper; rolling the mica glued paper into a tubular shape to obtain a mica reel pipe; rubbing the mica reel pipe to obtain the mica reel pipe with uniform wall thickness; heating the mica reel pipe obtained after rubbing so that the mica reel pipe can be cured; cooling the heated mica reel pipe to obtain a tubular mica reel pipe; and processing the tubular mica reel pipe into the mica pipe. According to the mica pipe manufacturing method, the production difficulty of the mica pipe can be reduced.

Owner:PAMICA TECH CORP

All direction multifunctional adjustment disc extending machine

InactiveCN101104179BIncrease the elongation factorImproved Wall Thickness AccuracyMetal rolling stand detailsGuiding/positioning/aligning arrangementsHydraulic cylinderCircular disc

The invention relates to an omnidirectional multi-functional disk type elongating mill, the diameters of an upper and a lower guide disk are increased; the lifting of the upper guide disk adopts a turbine, a worm and a leading screw device; the lifting of the lower guide disk adopts a standard spiral elevator; and the axial direction adjustment is realized by the standard spiral elevator; the positive direction location, lateral direction location and upper and lower direction location are realized by a hydraulic cylinder. The axial direction adjustment of the roller is realized by the standard spiral elevator; the radial direction is adjusted by the combination of a non-standard spiral elevator and the hydraulic cylinder; the locking device adopts the hydraulic cylinder and an adjusting wedge mechanism. Guide bushes of an outlet and an inlet port adopt the upper-pressing and lower-locking of the hydraulic cylinder. The reliability is increased by adopting the hydraulic system; the enlarged diameters of guide disks can improve the locking condition of the roller, the elongation coefficient is increased, screw threads in the steel tube are reduced after rolling, and the variety of products is enlarged; gaps of the axial direction and radial direction of the guide disks and the roller are reduced, and the stability of the rolling is strengthened; the structure of the side pressure oil cylinder of the roller is simple, and the running is reliable; the guide bushes of the outlet and inlet port adopt the upper-pressing and lower-locking device to realize the double-assurance.

Owner:ANGANG STEEL CO LTD

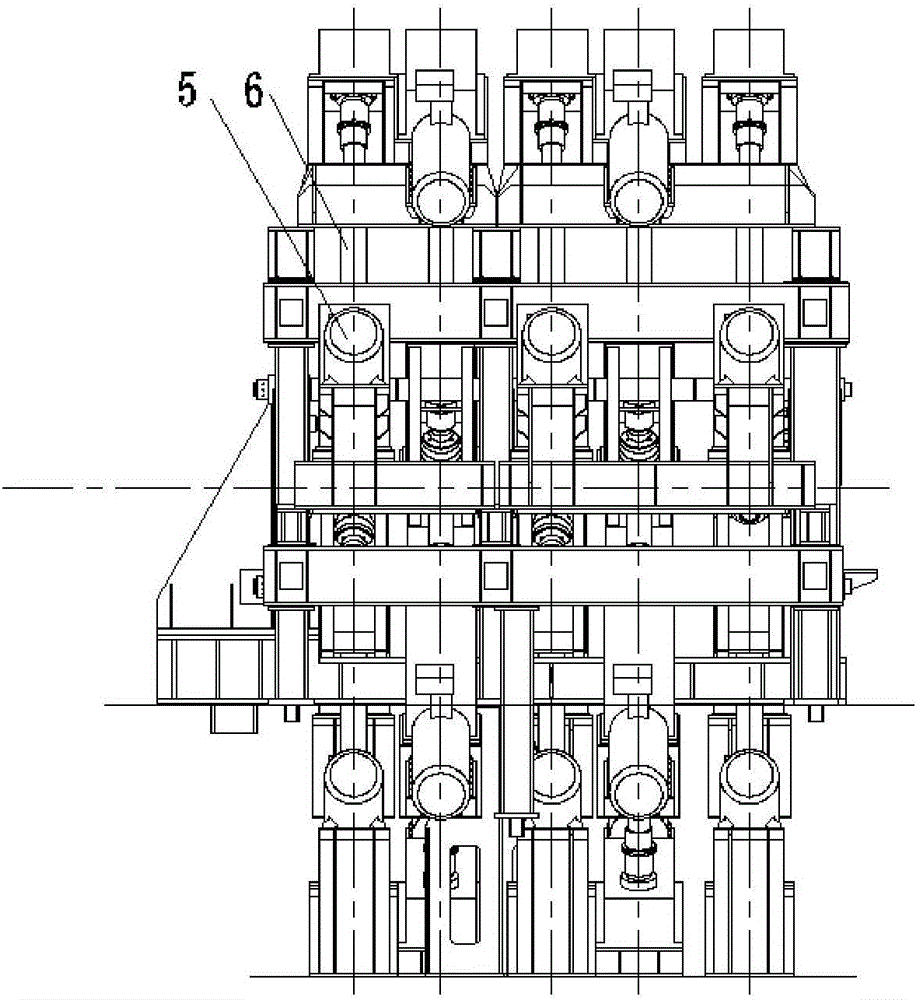

Four-roll continuous pipe mill

ActiveCN103599938BGood speed consistency in the circumferential directionUniform deformationMetal rolling stand detailsRolling mill drivesEngineeringMechanical engineering

Owner:CISDI ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com