Four-roll continuous pipe mill

A technology of continuous rolling and tube mills, which is applied in the direction of metal rolling stands, metal rolling mill stands, and driving devices for metal rolling mills, and can solve problems such as inability to achieve roll gap adjustment, strict market demand, and inability to apply , to achieve the effects of good control accuracy consistency, expanded specification range, and convenient roll replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

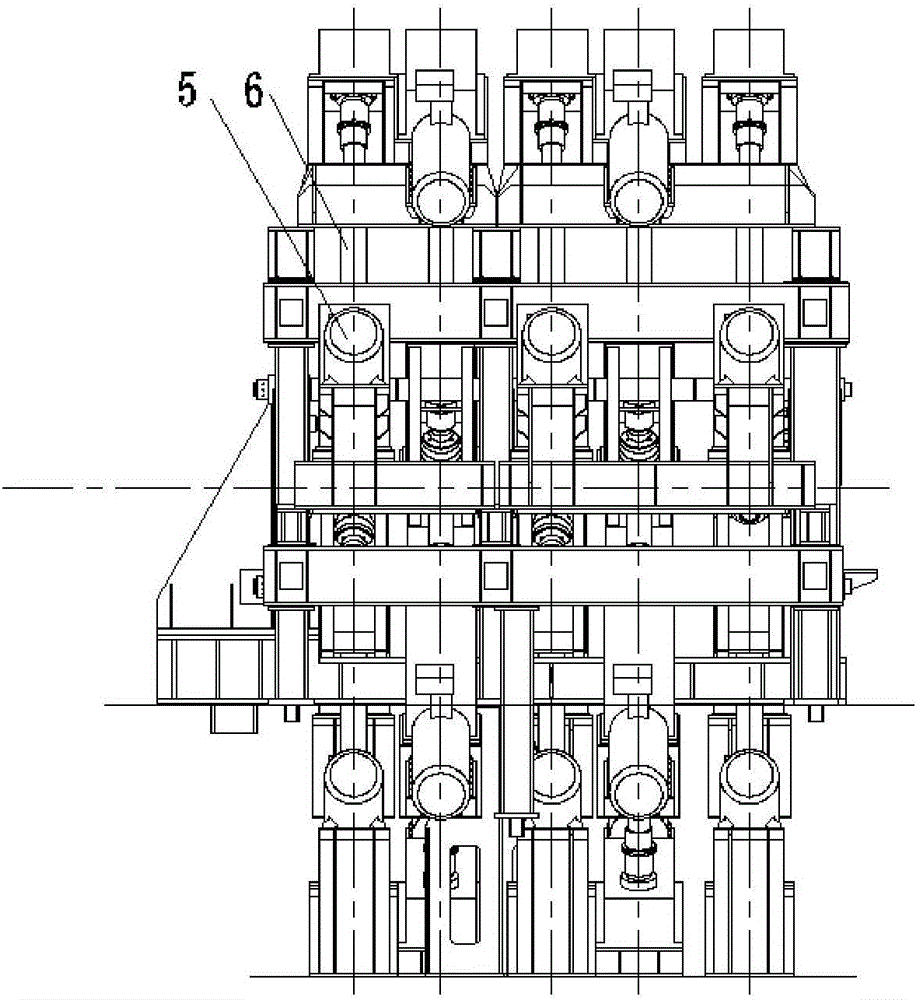

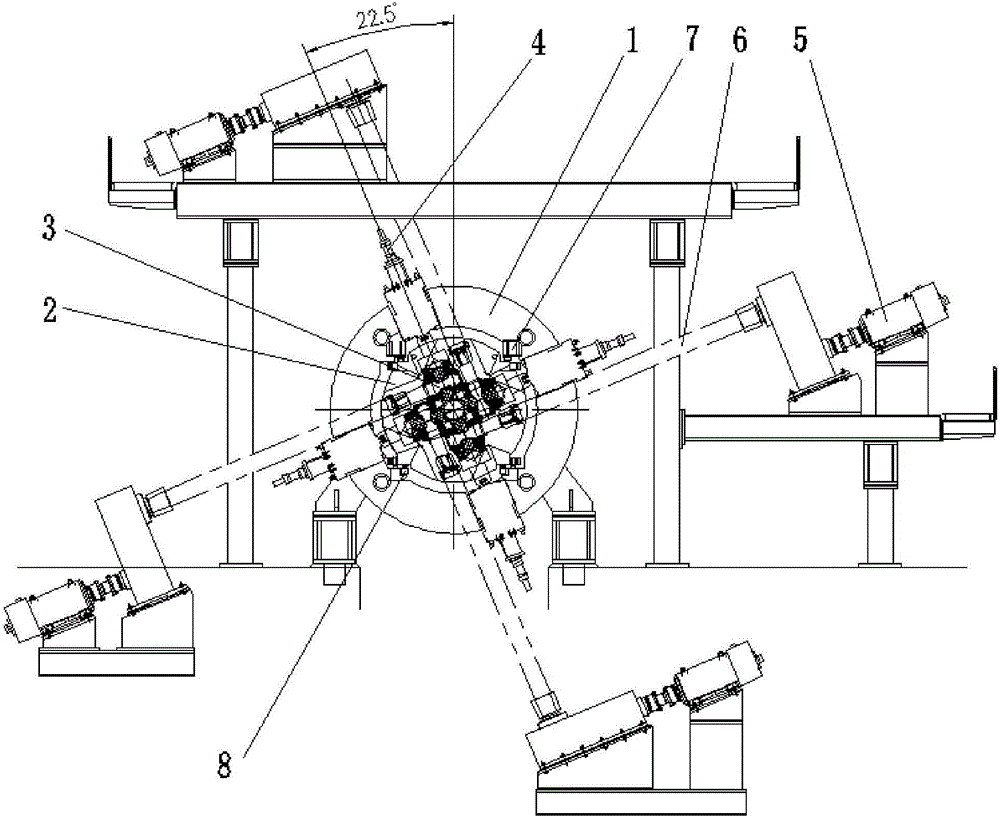

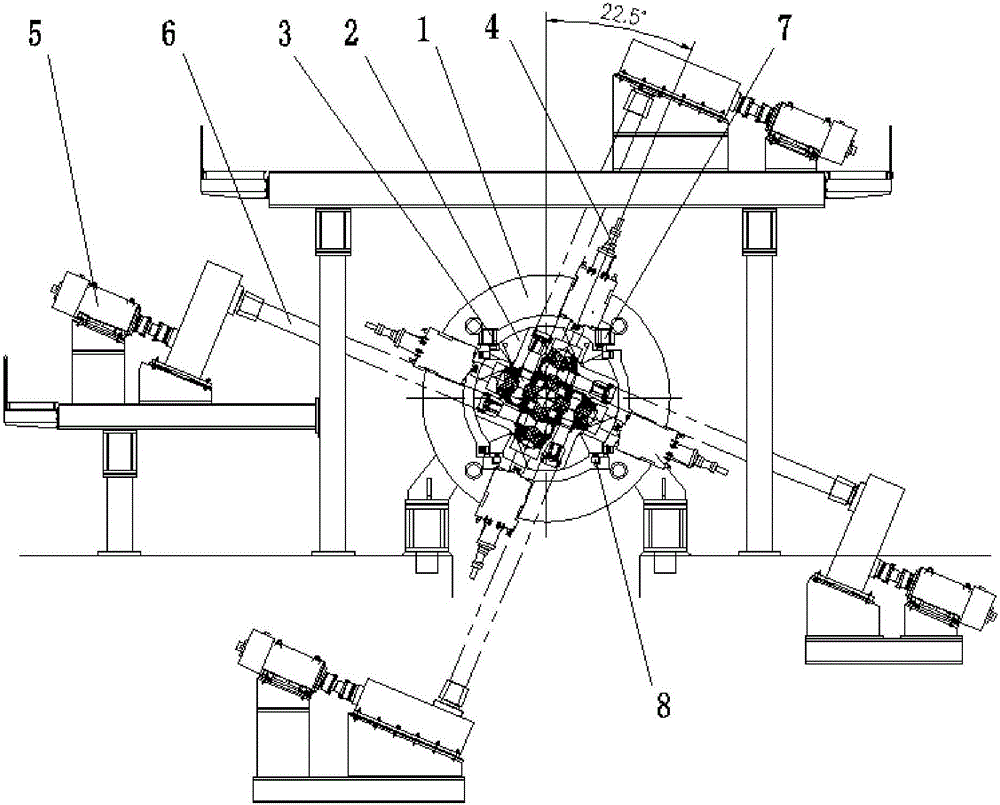

[0017] As shown in the figure, the four-roll continuous pipe rolling mill described in this embodiment includes a tunnel-type archway 1 and multiple groups of rolling stands 2 arranged sequentially along the central axis of the tunnel-type archway 1, and each group of rolling stands 2 There are four sets of roll assemblies 3, and each roll assembly 3 is respectively connected to a set of roll gap adjustment devices 4 for adjusting the roll gap between the roll assemblies 3, and the rolling stand 2 is also provided with a rolling stand 2 A roll changing device that moves back and forth along the central axis of the tunnel-type archway 1; wherein the roll gap adjustment device 4 is fixed on the tunnel-type archway 1, so that the roll gap adjustment device 4 has consistent rigidity in the radial direction of the tunnel-type archway 1, The rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com