Patents

Literature

58results about How to "Precise size adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

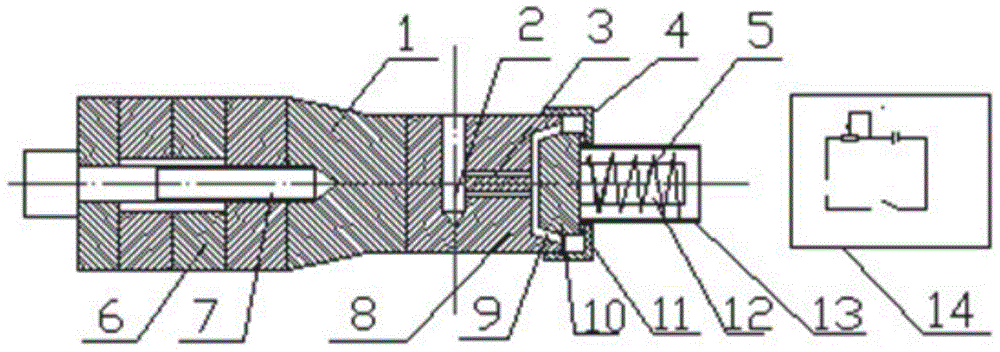

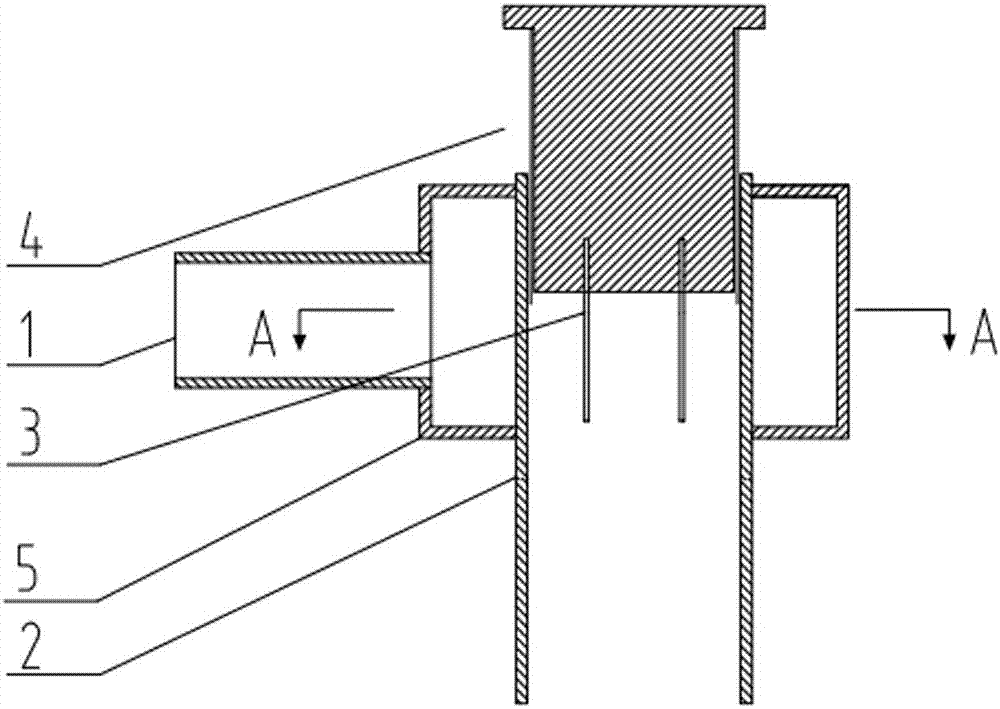

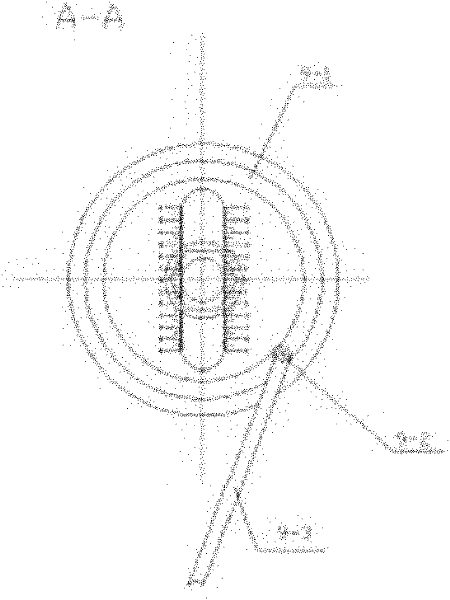

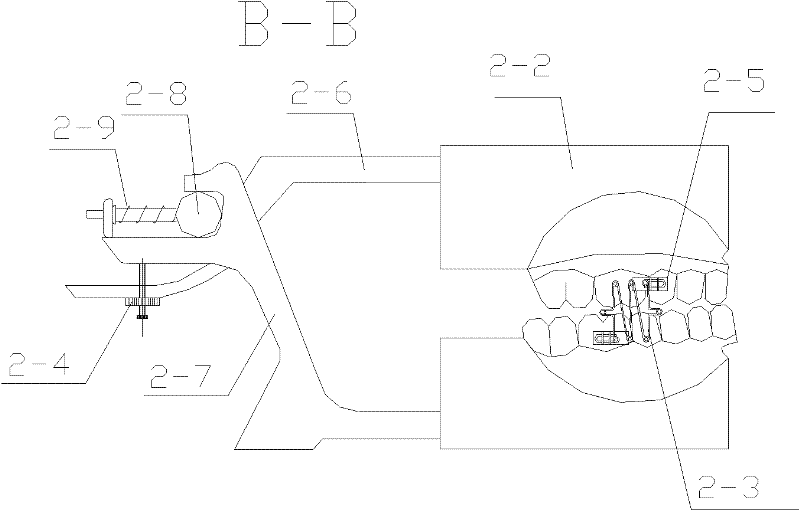

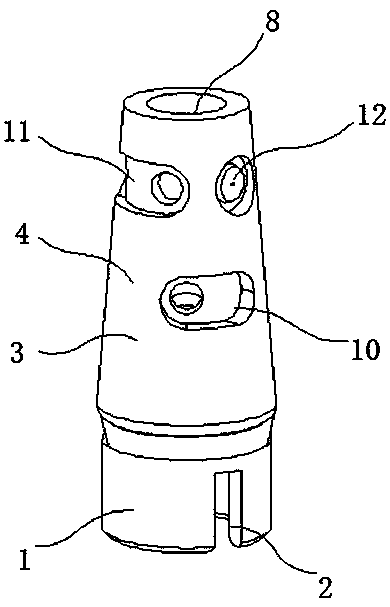

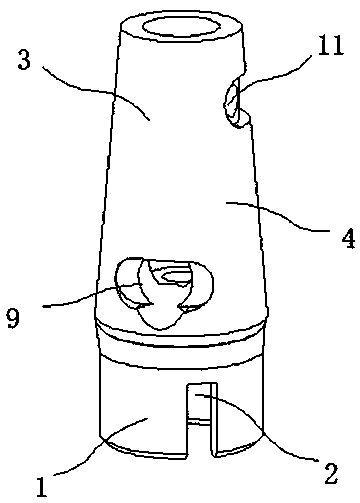

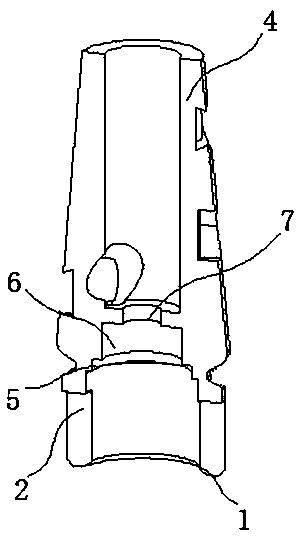

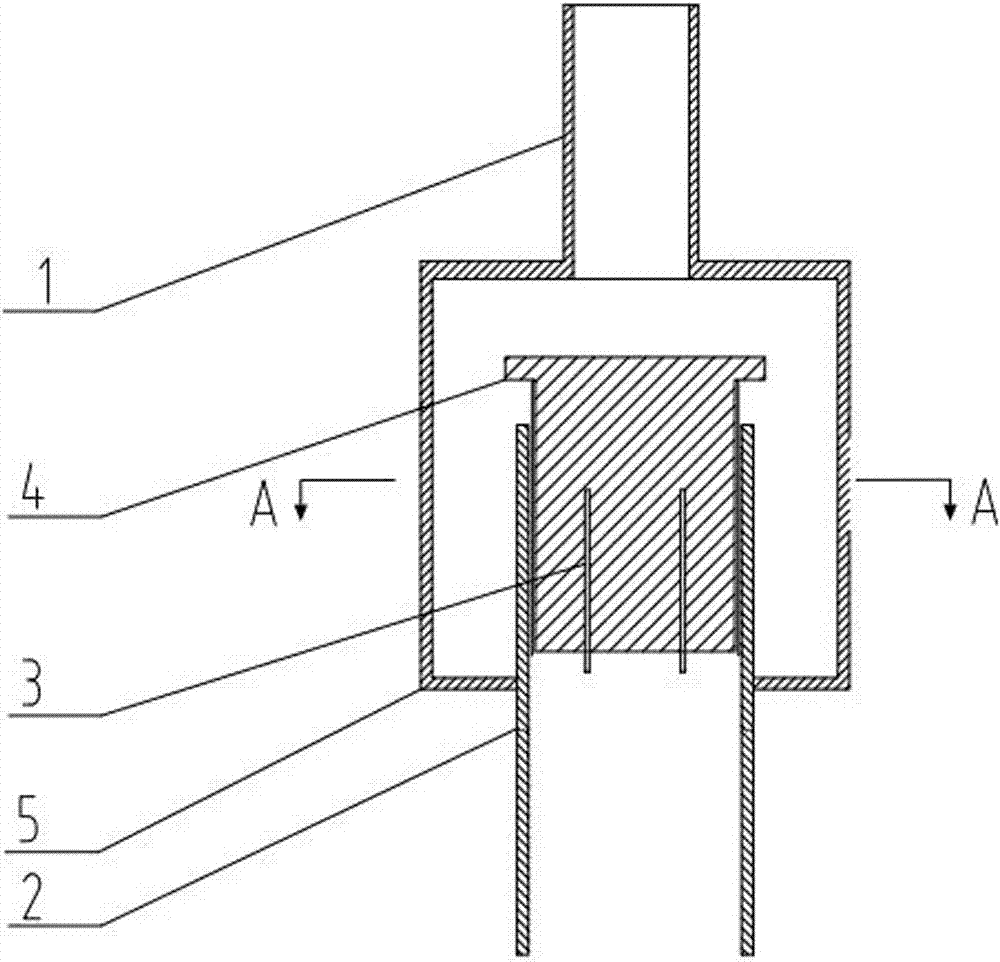

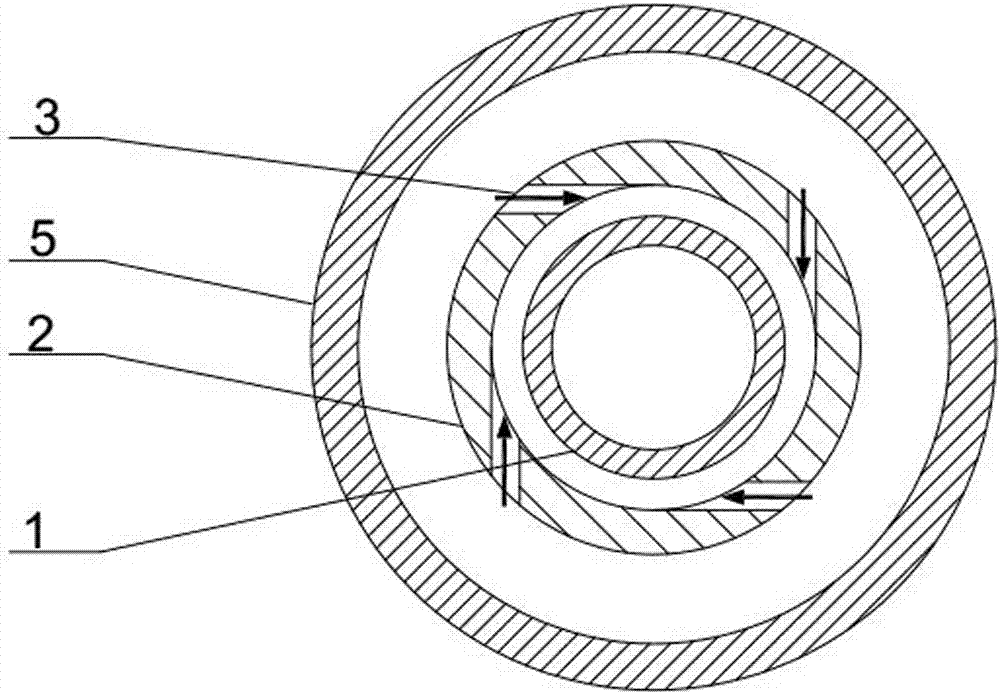

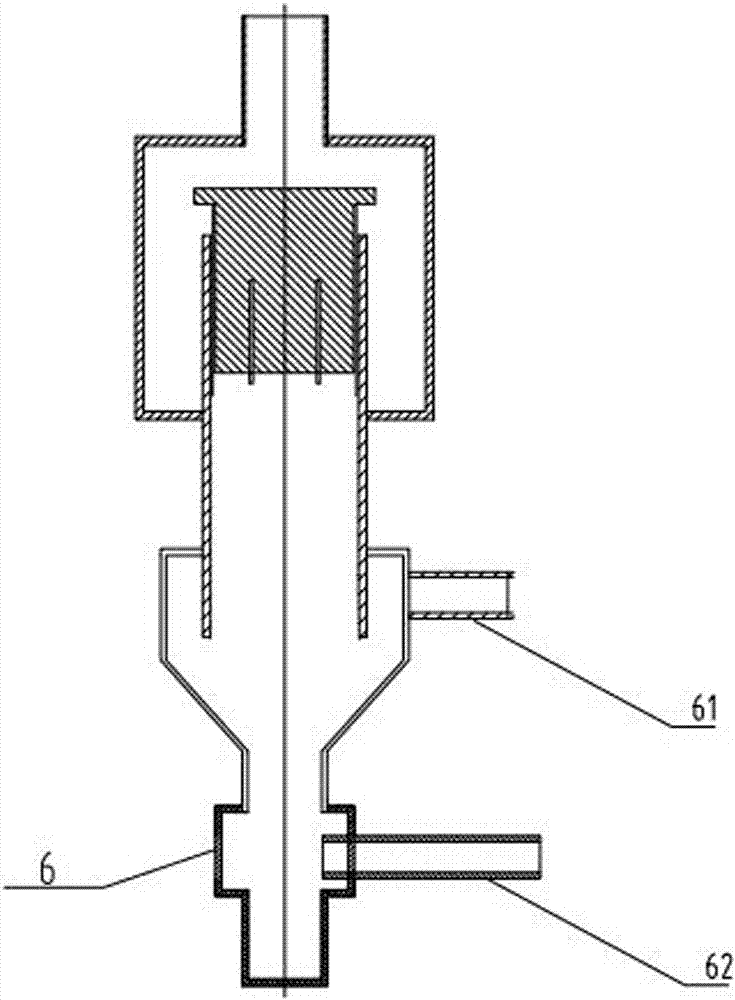

Low-frequency ultrasonic secondary atomizing spraying head controlled in electromagnetic mode

InactiveCN104874515APrecise size adjustmentPrecise Control of SpacingSpray nozzlesLiquid spraying apparatusLow frequencyElectromagnetic mode

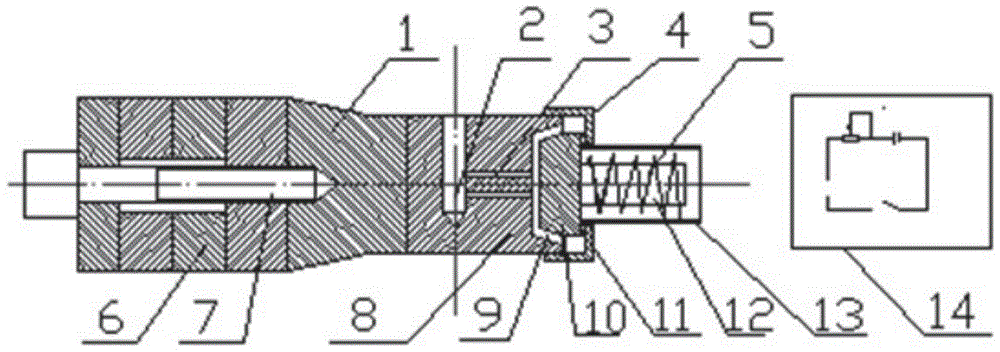

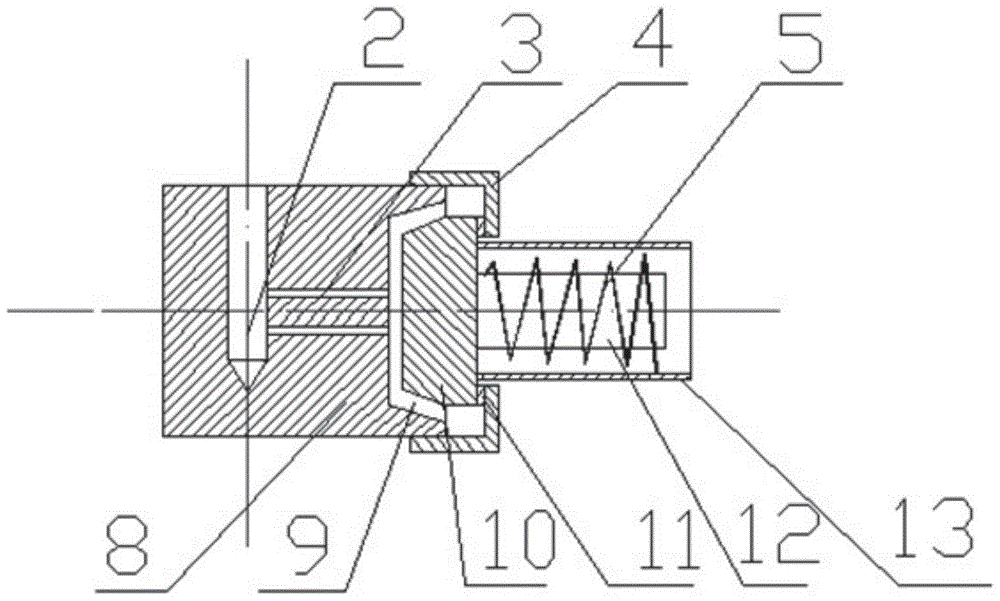

The invention discloses a low-frequency ultrasonic secondary atomizing spraying head controlled in an electromagnetic mode. The low-frequency ultrasonic secondary atomizing spraying head comprises a nozzle. A liquid inlet hole is formed in the nozzle and communicated with one end of a liquid outlet hole. A trapezoidal nozzle groove is formed in the tail end of the nozzle and provided with a trapezoidal secondary atomizing moving body. The other end of the liquid outlet hole is communicated with the trapezoidal nozzle groove. An iron core and the trapezoidal atomizing moving body are bonded together. A coil winds around the iron core which is covered with a protecting cover. The protecting cover and the trapezoidal secondary atomizing moving body are bonded. One end of a stop block supports the trapezoidal secondary atomizing moving body. A sponge is stuffed between the stop block and the trapezoidal secondary atomizing moving body and bonded to the stop block. The other end of the stop block is welded to the nozzle. Currents flowing into the coil are changed by adjusting a circuit, electromagnetic force can be adjusted accurately, the distance between the trapezoidal nozzle groove and the trapezoidal secondary atomizing moving body is controlled accurately, and therefore the size of generated mist drops can be accurately controlled.

Owner:JIANGSU UNIV

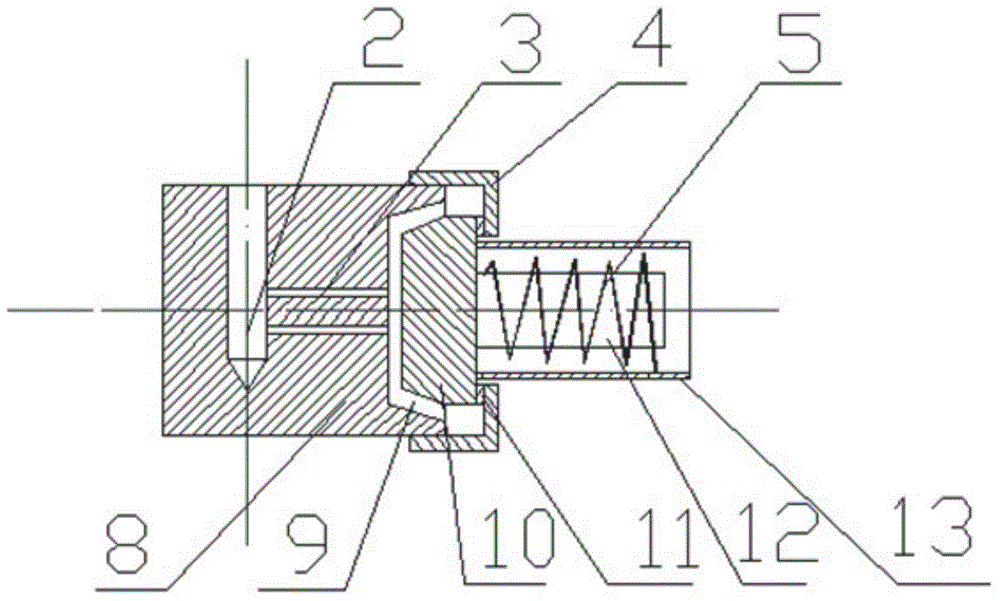

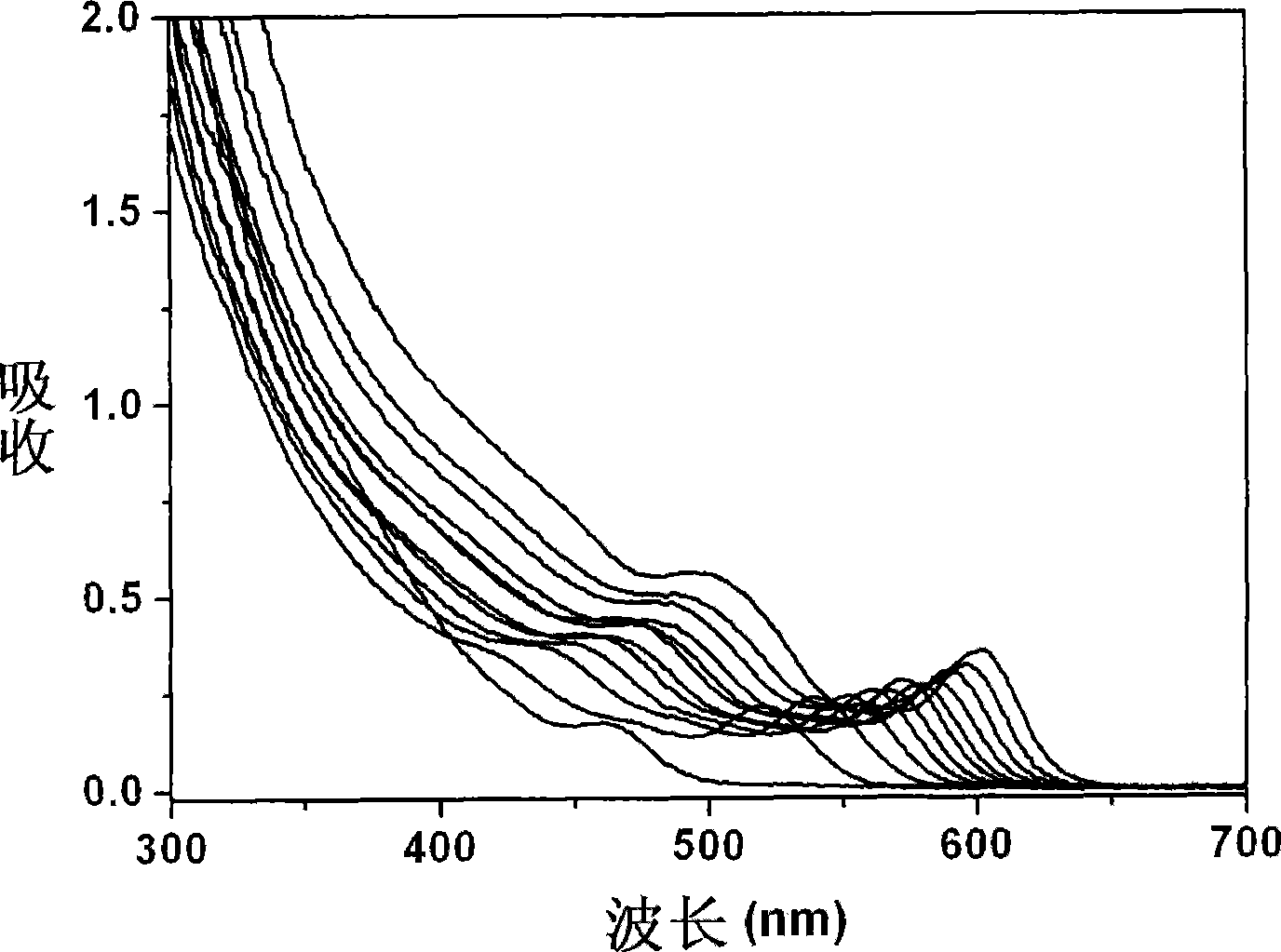

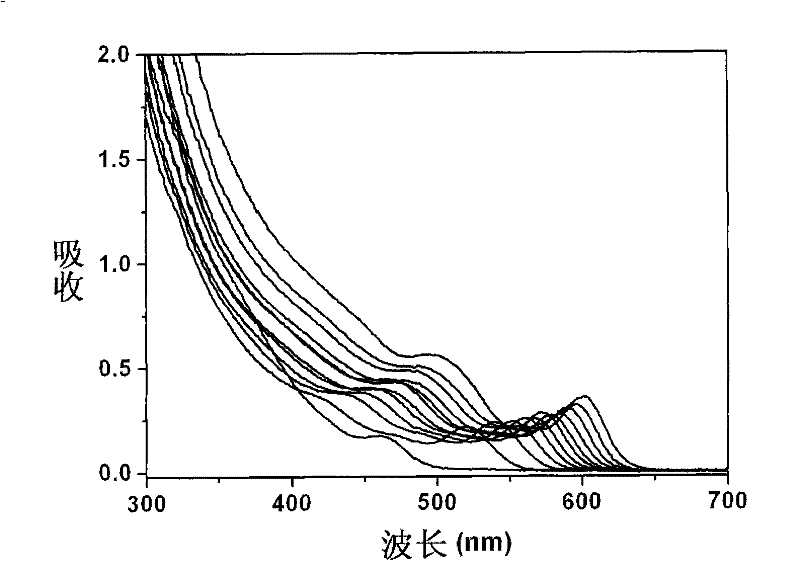

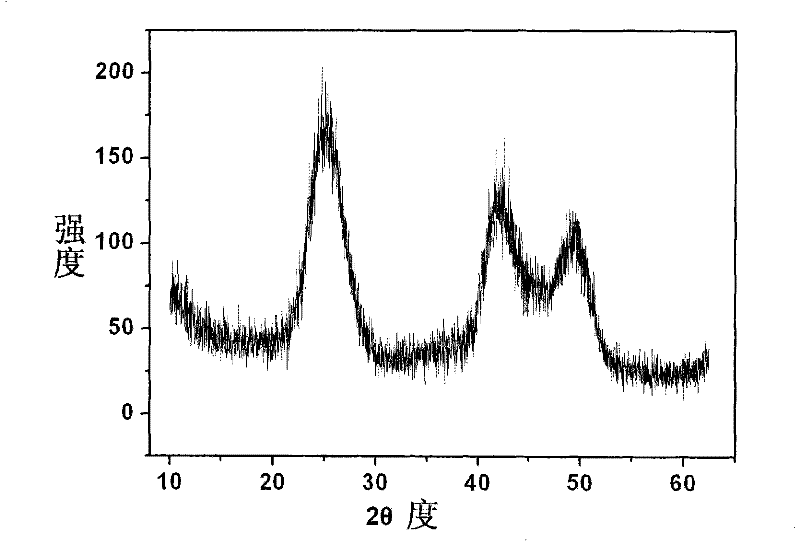

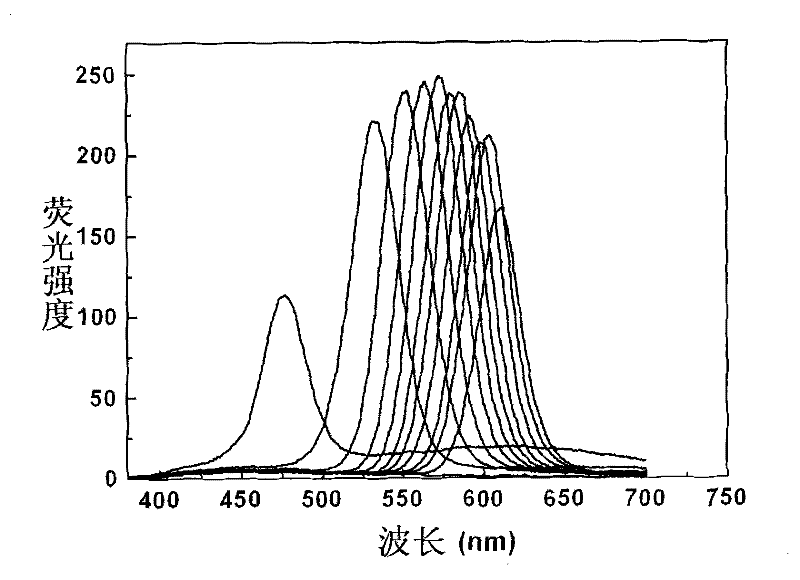

Green synthetic method of controllable dimension semi-conductor nano cluster and nanocrystalline

ActiveCN101457403AHigh crystallinityHigh fluorescence quantum efficiencyPolycrystalline material growthCadmium compoundsSolventNanoclusters

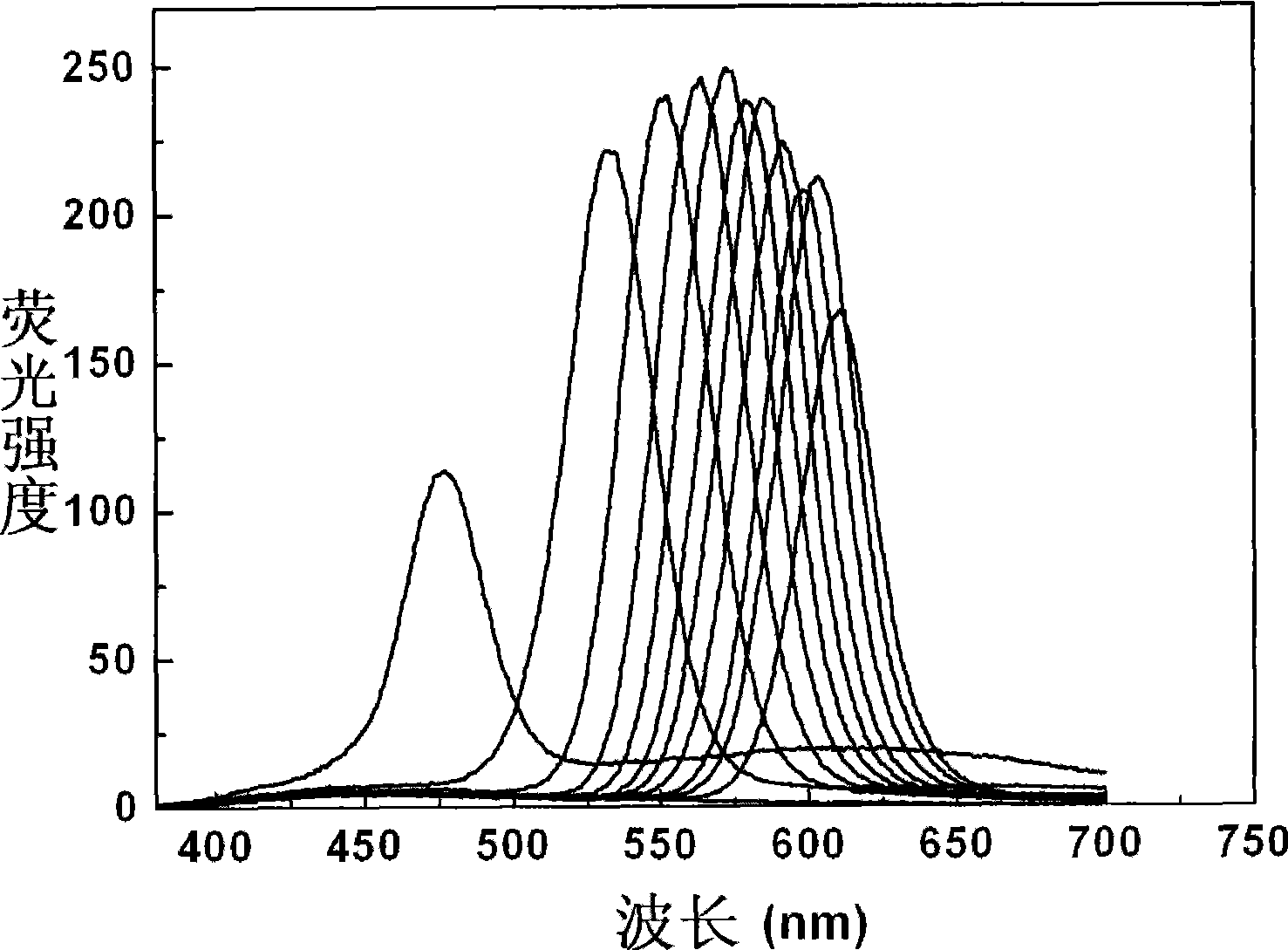

The invention provides a green synthesis method of a cadmium selenide nano-cluster and a cadmium selenide nanocrystal with controllable size. In the method, a series of low toxic / economical ligands are adopted, a selenium elementary substance and cadmium oxide dispersed in a non-ligand solvent are taken as precursors, and the cadmium selenide nano-cluster and the cadmium selenide nanocrystal are synthesized in the non-ligand solvent. The size can be adjusted within 0.7nm-13nm by adjusting the proportion of the ligands and the precursors. The obtained nanocrystal has high crystallinity and narrow size distribution fwhm which equals 25 plus or minus 2nm, relatively high fluorescence quantum efficiency which is 5%-38%, and a fluorescence emission spectrum can be adjusted within 450nm-690nm.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Active control current-limiting system for fault current and control method thereof

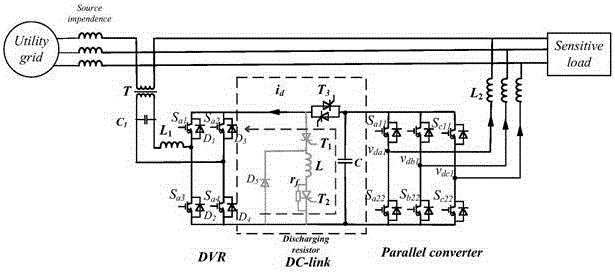

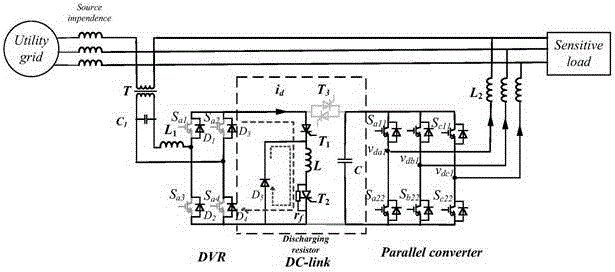

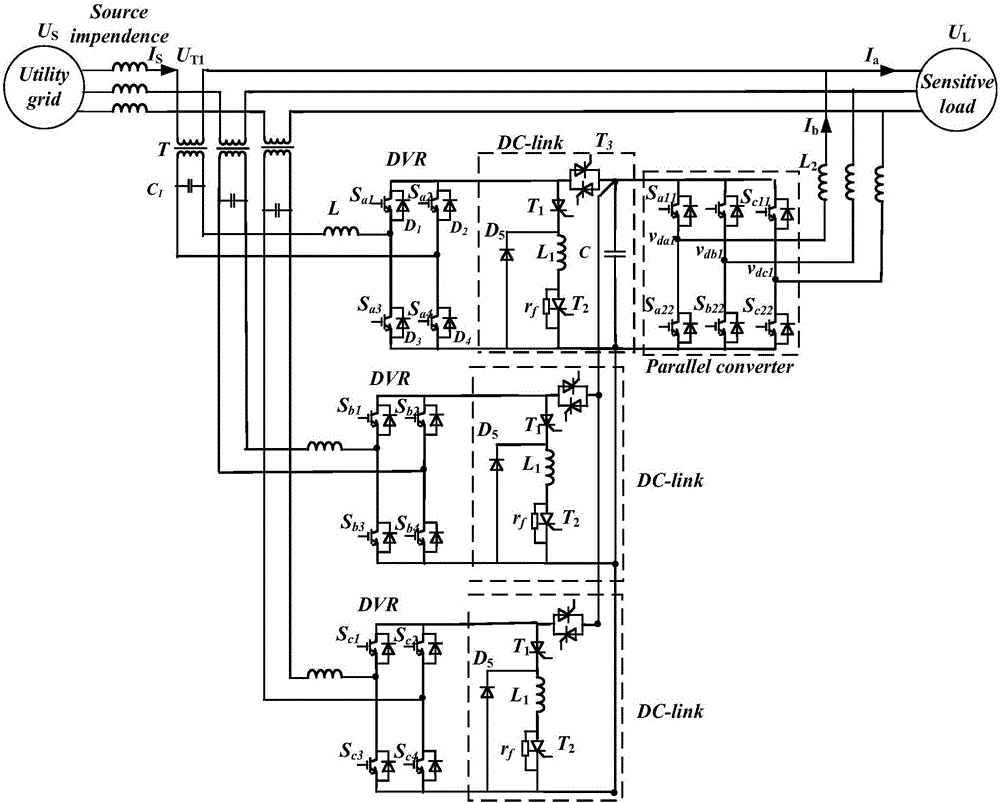

ActiveCN106786643AImprove the quality of supply voltageIncrease profitPolyphase network asymmetry elimination/reductionReactive power adjustment/elimination/compensationFull bridgeTransformer

The invention discloses an active control current-limiting system for fault current and a control method thereof. The active control current-limiting system comprises series DVR modules, DC-links and a parallel converter, wherein a series side is formed by a three-single-phase structure; each phase comprises an L, a C1 filter link, a series transformer T, one DVR module and one DC-link; an each DC-link comprises a current-limiting inductor L1, a bleeder resistor rf, a D5 and a bidirectional thyristor T3. LC filters are used for filtering out harmonic waves, and the input time of the bleeder resistors is controlled through regulating the duty ratios of controlled tubes T2, so that current is limited below a specific value. Stabilized capacitors C are connected between the three-single-phase series side and the PWM parallel converter in parallel; and the PWM parallel converter is formed by a three-phase full bridge. Improvement of the voltage quality of a power network system, governance of harmonic current and a short-circuit fault current limiting function can be achieved and the electric security is improved.

Owner:HUNAN UNIV

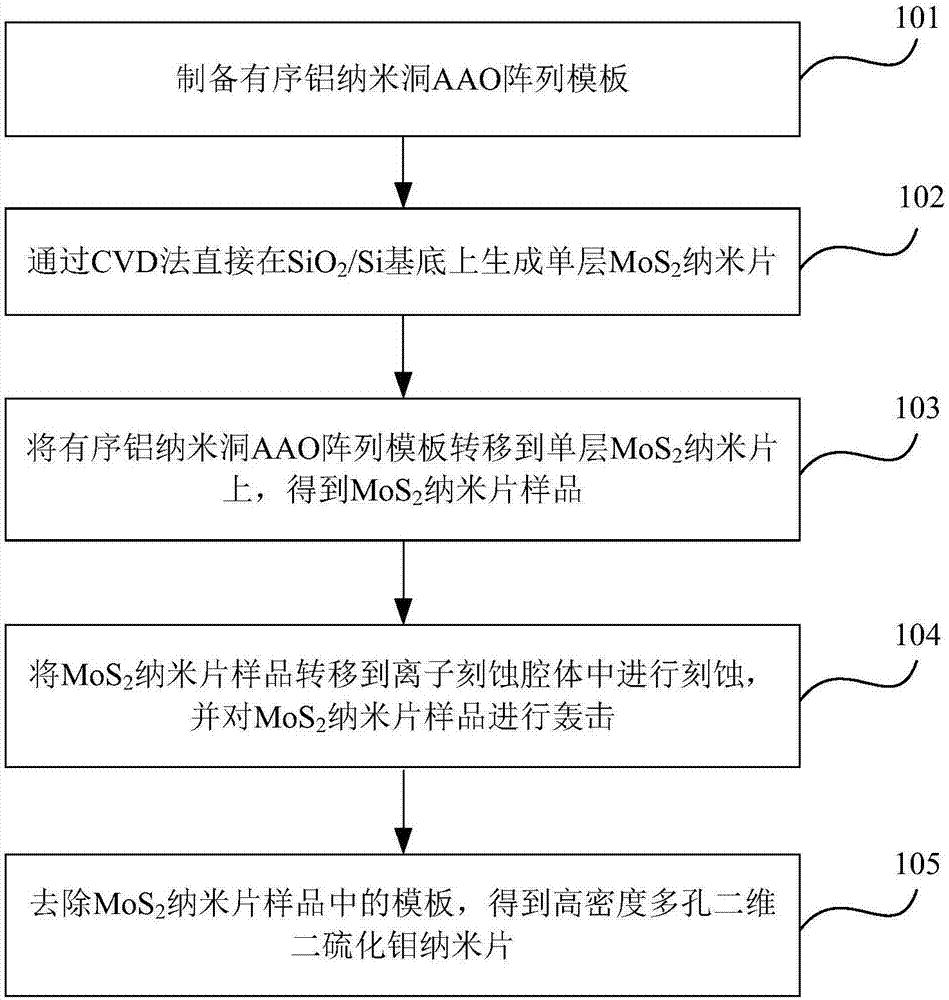

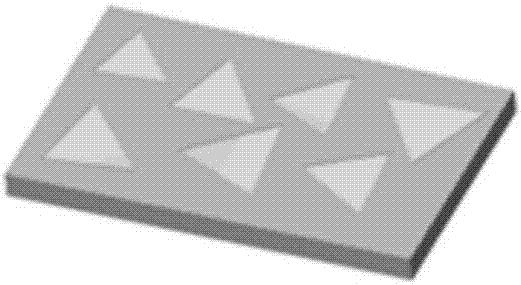

Method for preparing high density porous two-dimensional molybdenum disulfide nanosheet

ActiveCN106865616AAvoid lostOrderly porous structurePhysical/chemical process catalystsMolybdenum sulfidesHigh densityActive site

The invention relates to the technical field of nanomaterial preparation and particularly relates to a method for preparing a high density porous two-dimensional molybdenum disulfide nanosheet. The method comprises preparing an ordered aluminum nanometer hole AAO array template, directly forming a single layer of MoS2 nanosheets on a SiO2 / Si base through a CVD method, transferring the ordered aluminum nanometer hole AAO array template to the single layer of MoS2 nanosheets to obtain a MoS2 nanosheet sample, transferring the MoS2 nanosheet sample into an ion etching chamber, carrying out etching, bombarding the MoS2 nanosheet sample, and removing the template of the MoS2 nanosheet sample to obtain the high density porous two-dimensional molybdenum disulfide nanosheets. The method can introduce a boundary-like structure to the base surface of the two-dimensional MoS2 to increase the number of active sites, can directly form a single layer of MoS2 on the SiO2 / Si base, prevents MoS2 transferring and prevents a MoS2 loss during the transferring.

Owner:山东天汇光年无人机科技有限公司

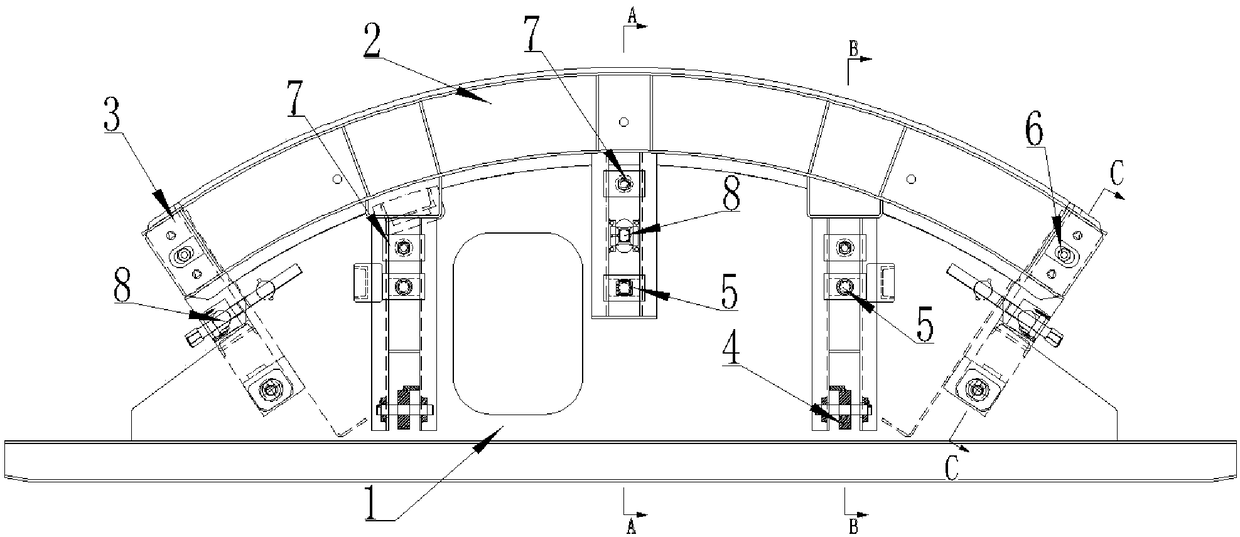

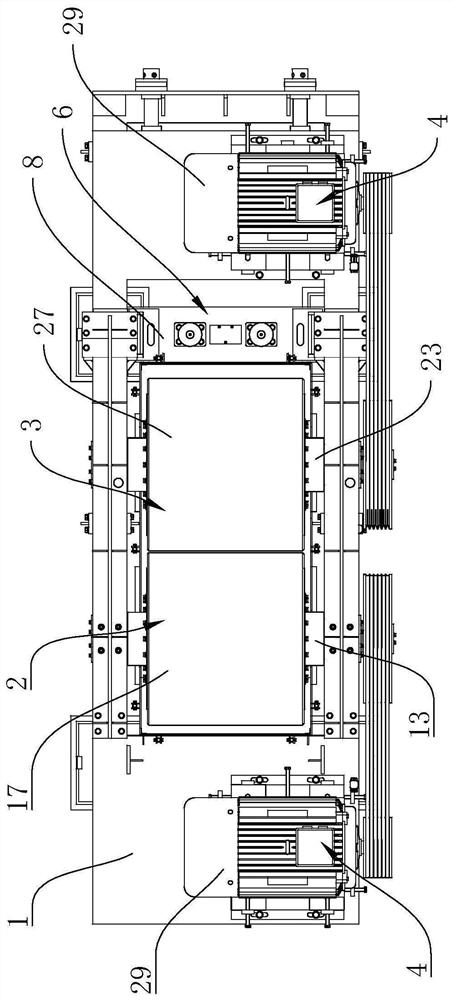

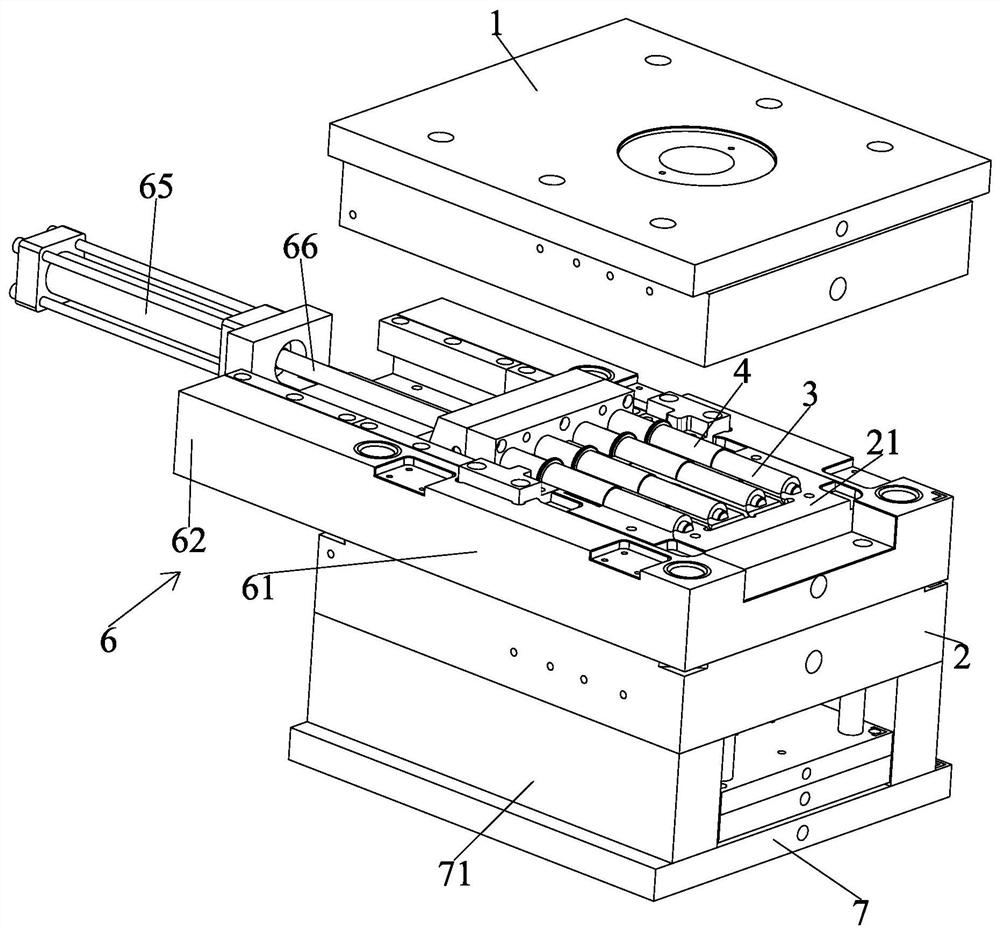

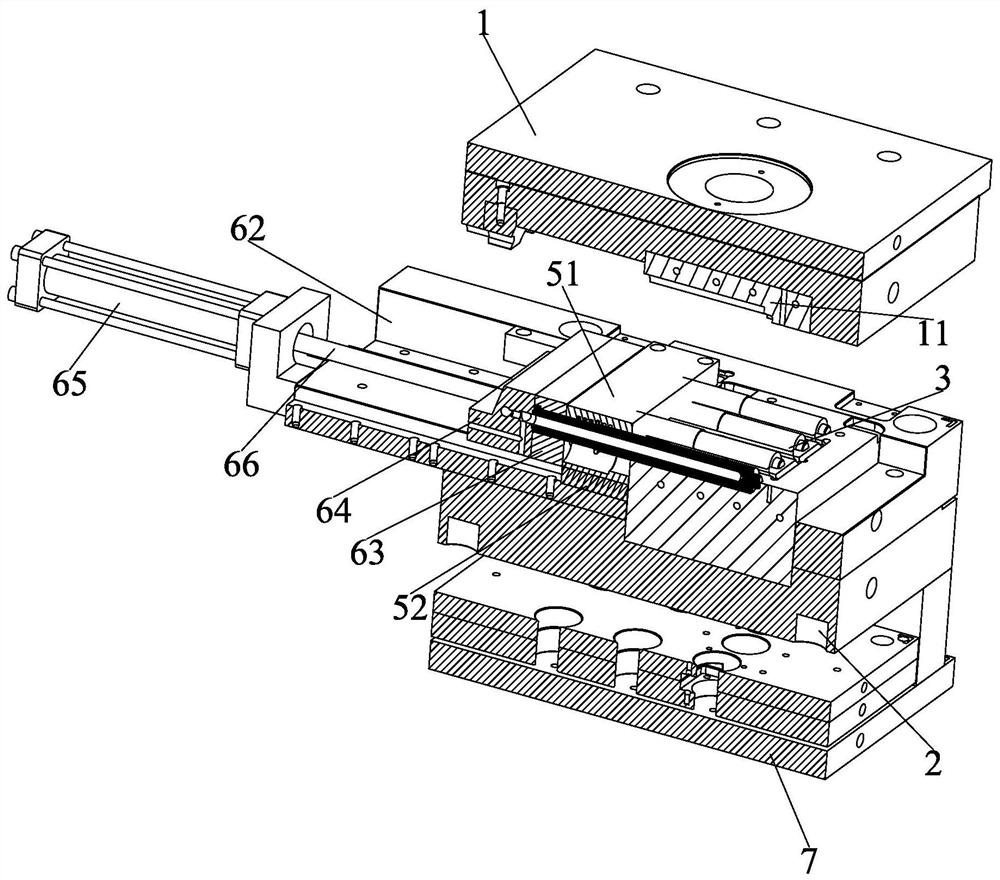

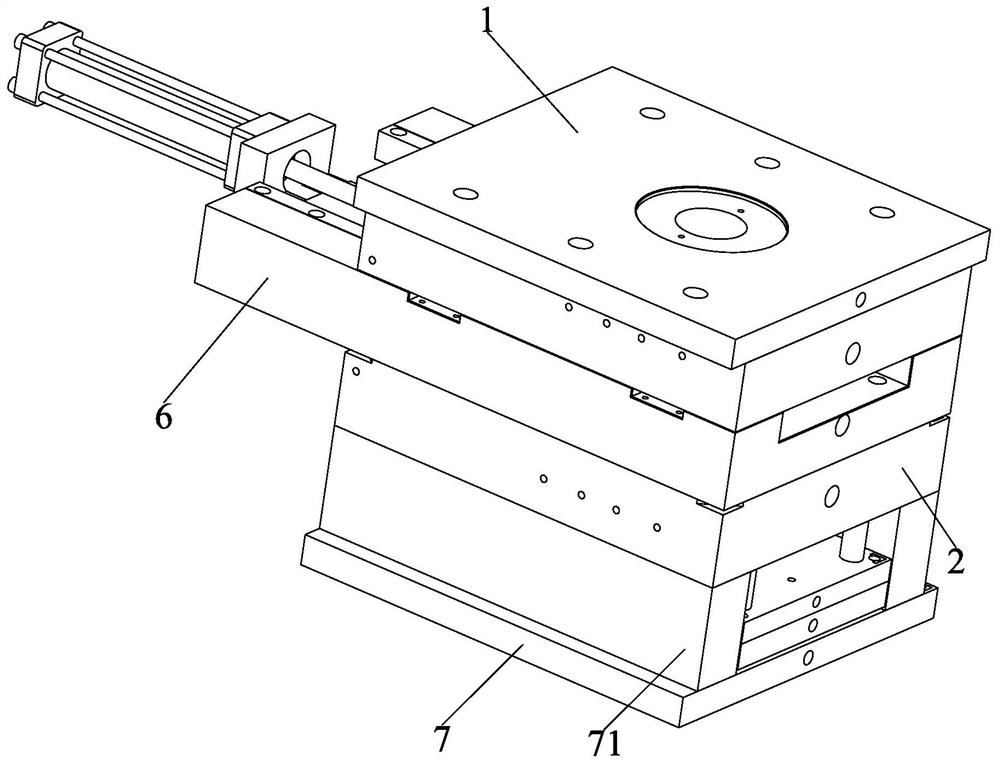

Novel tunnel lining segment mold

InactiveCN109227899AEasy to open and closeSmall sizeMouldsMould fastening meansLine segmentMaterials science

Owner:江苏丰和隧道设备有限公司

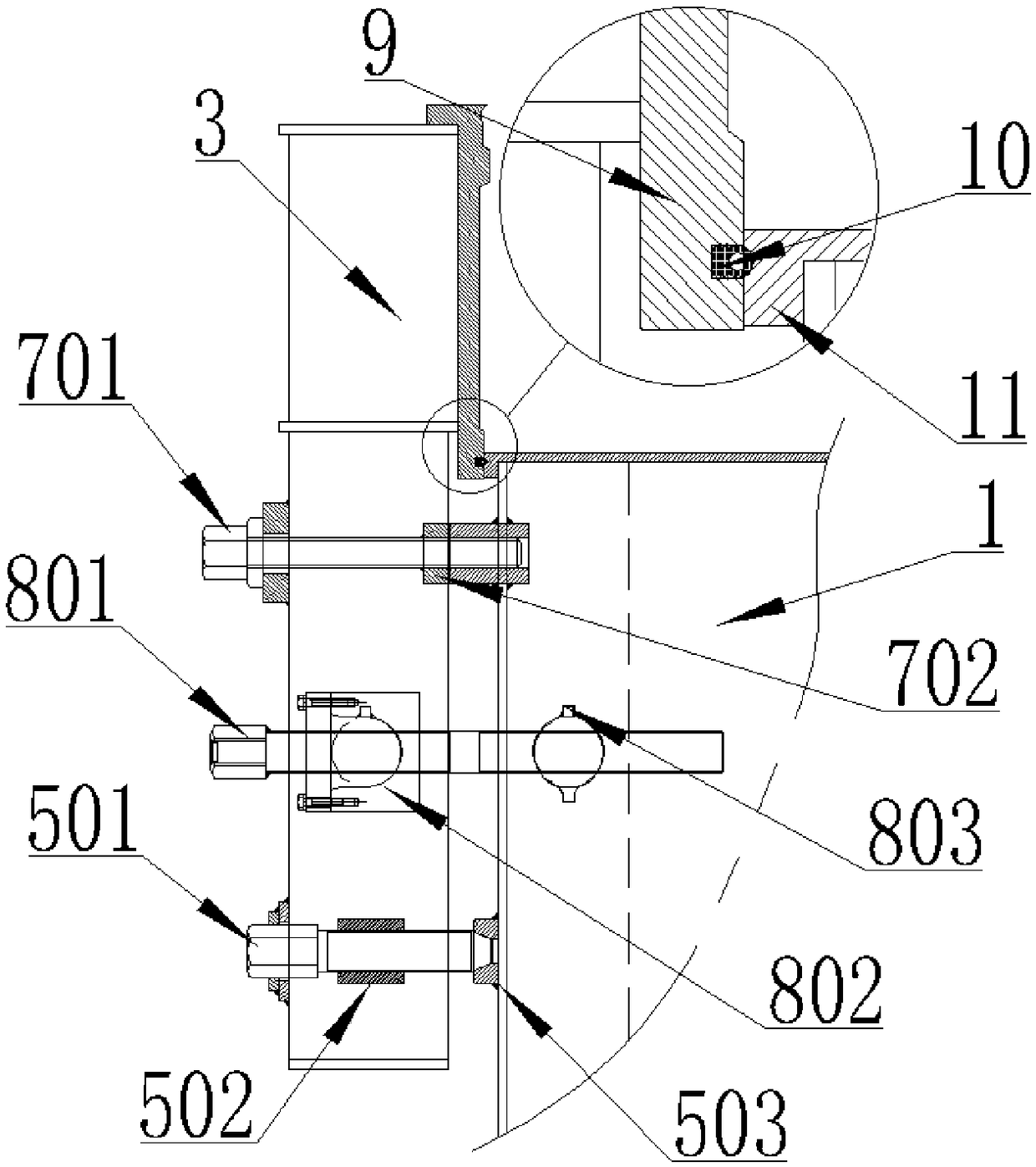

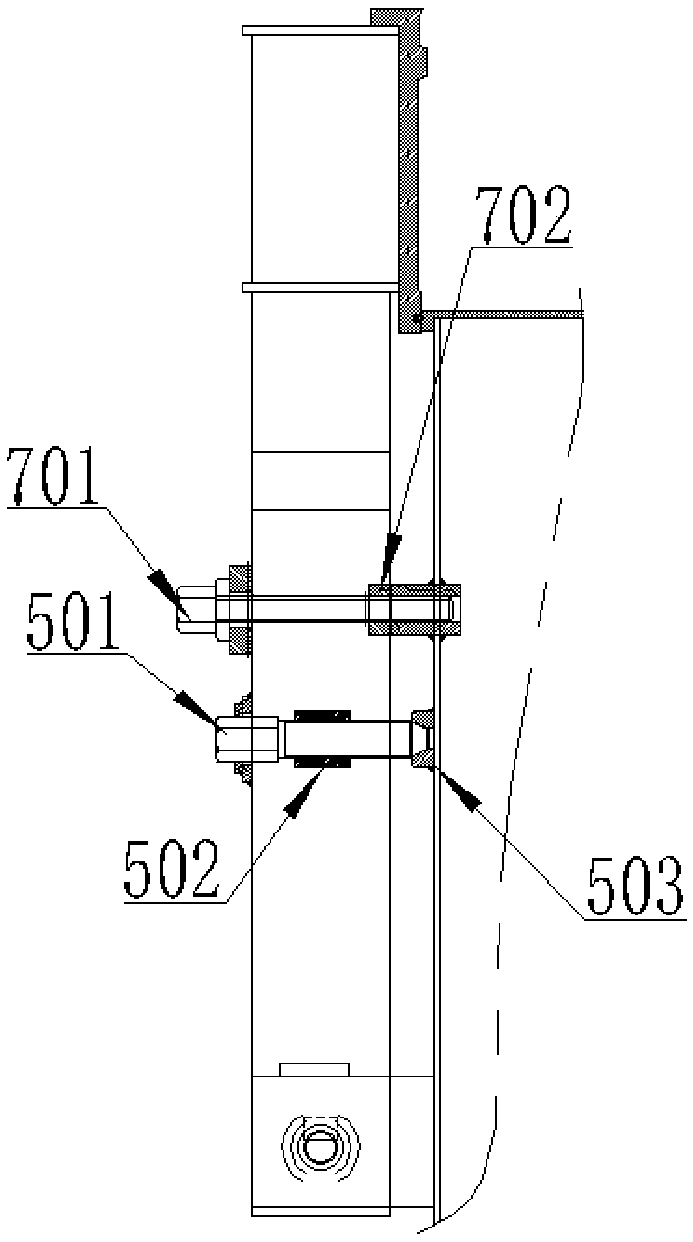

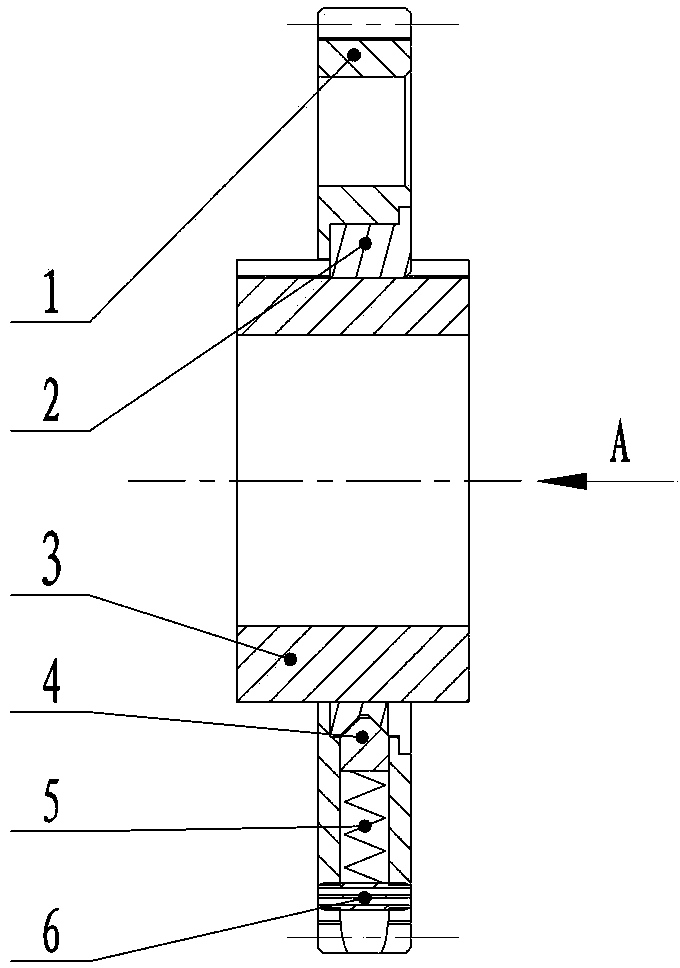

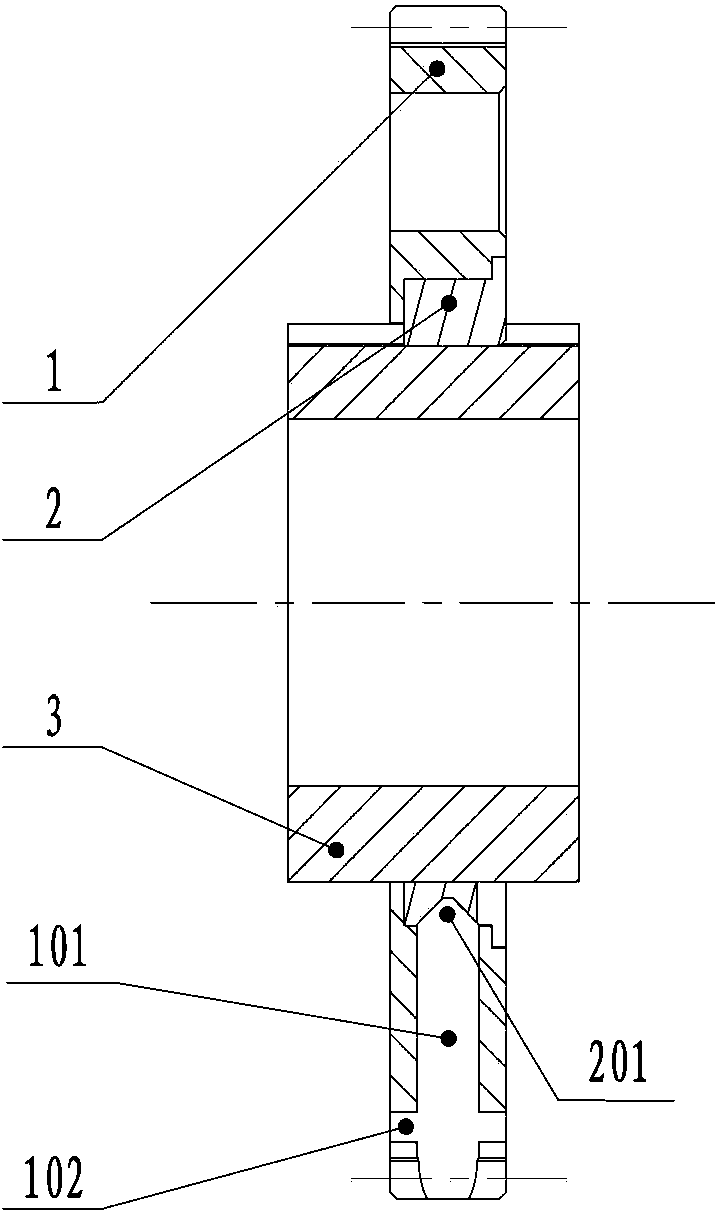

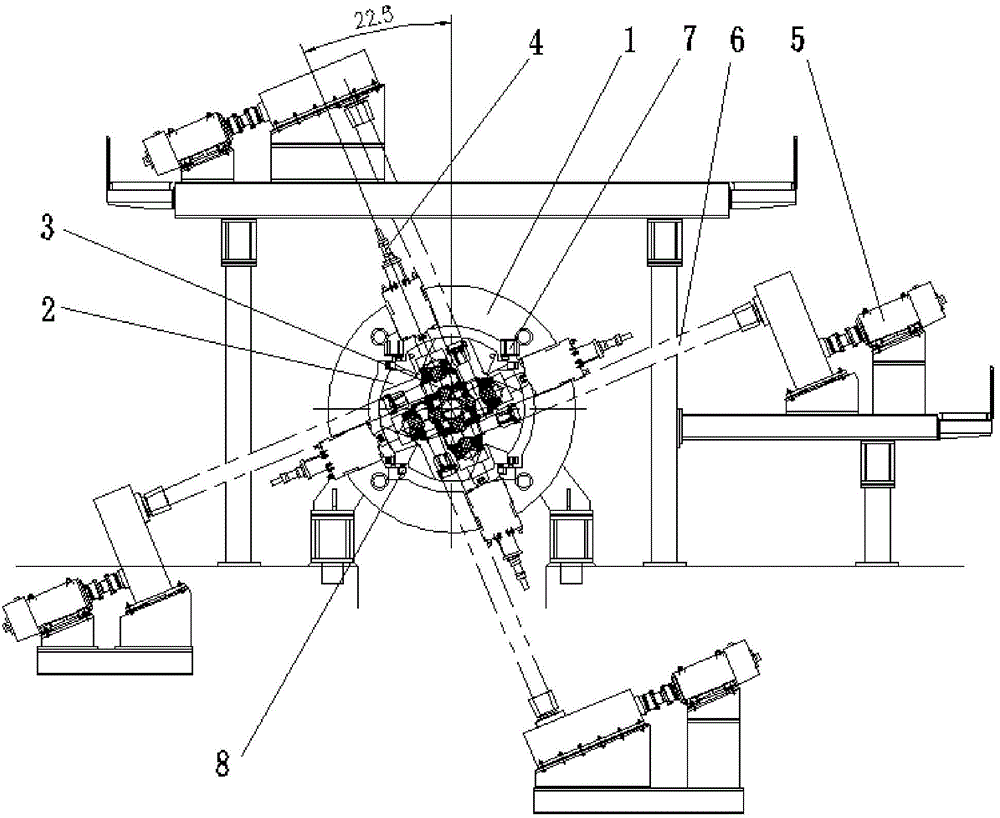

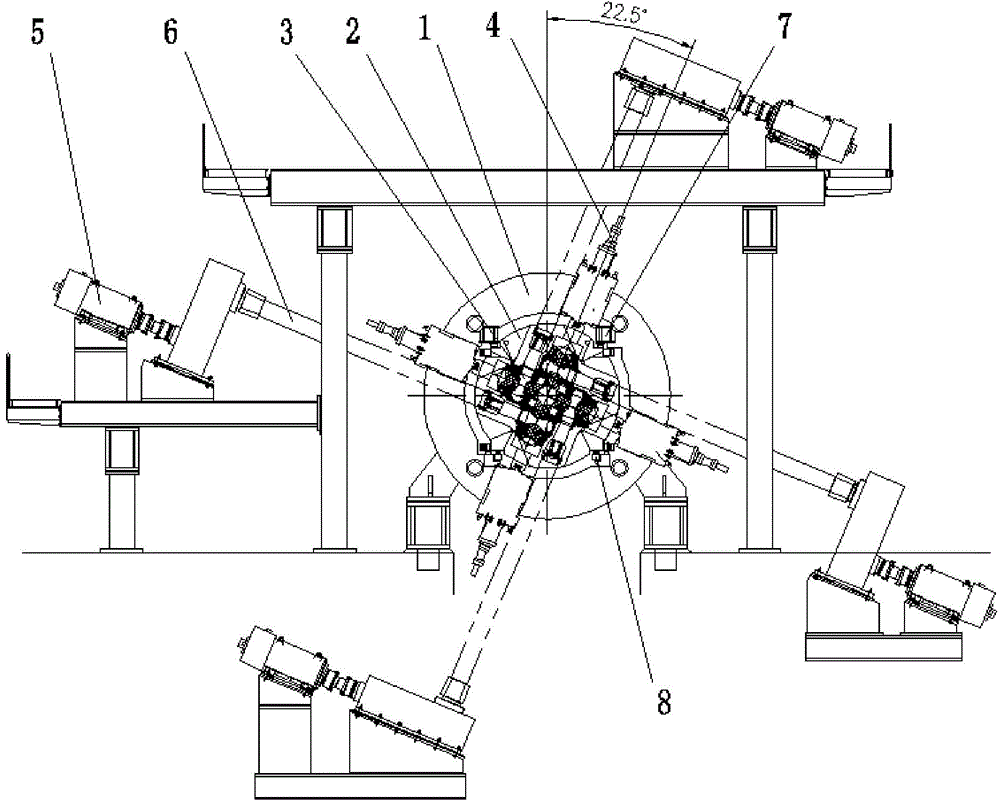

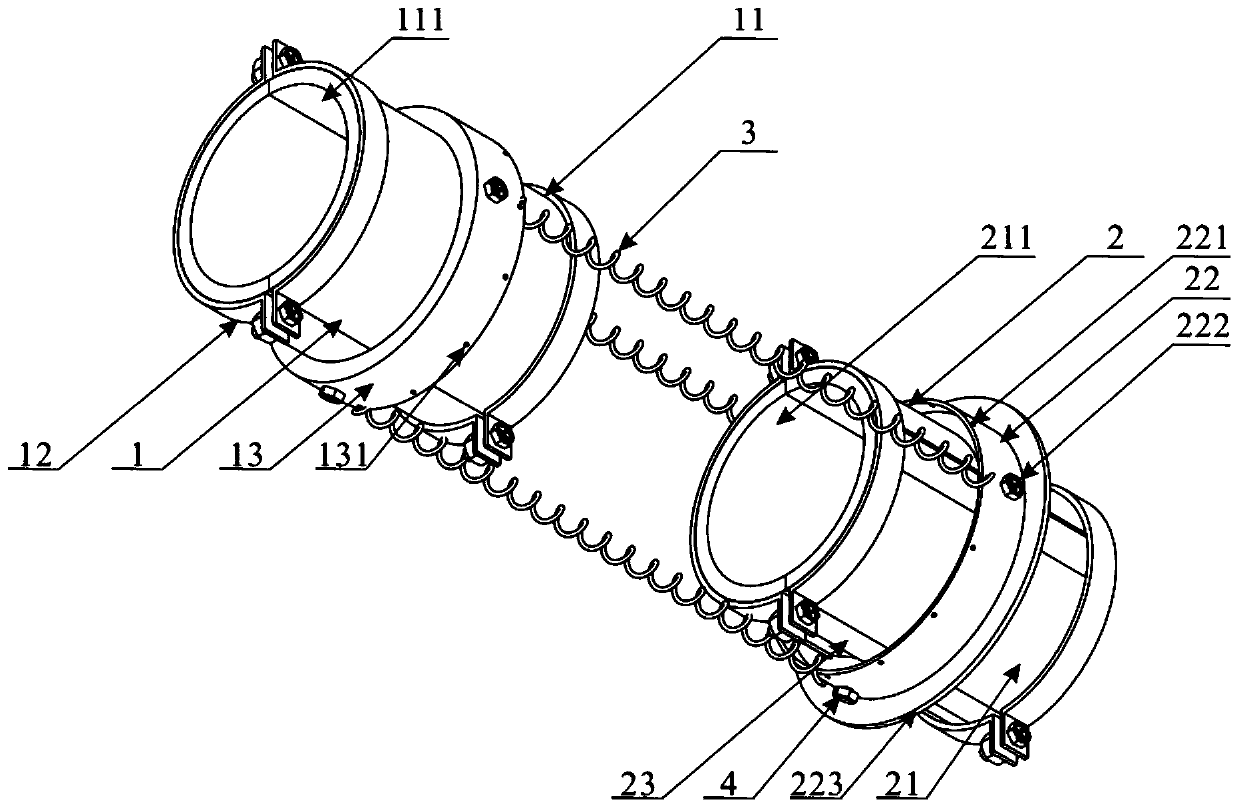

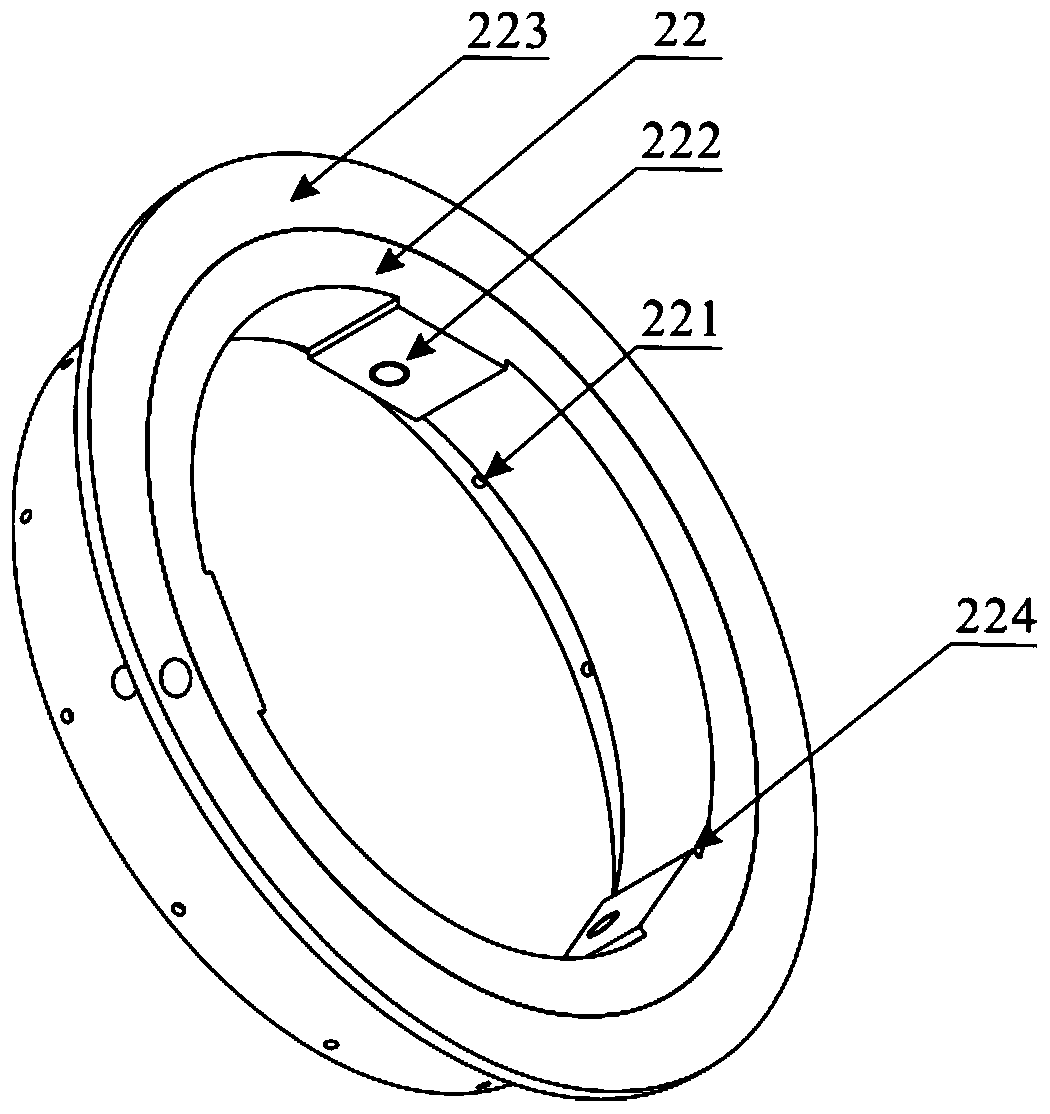

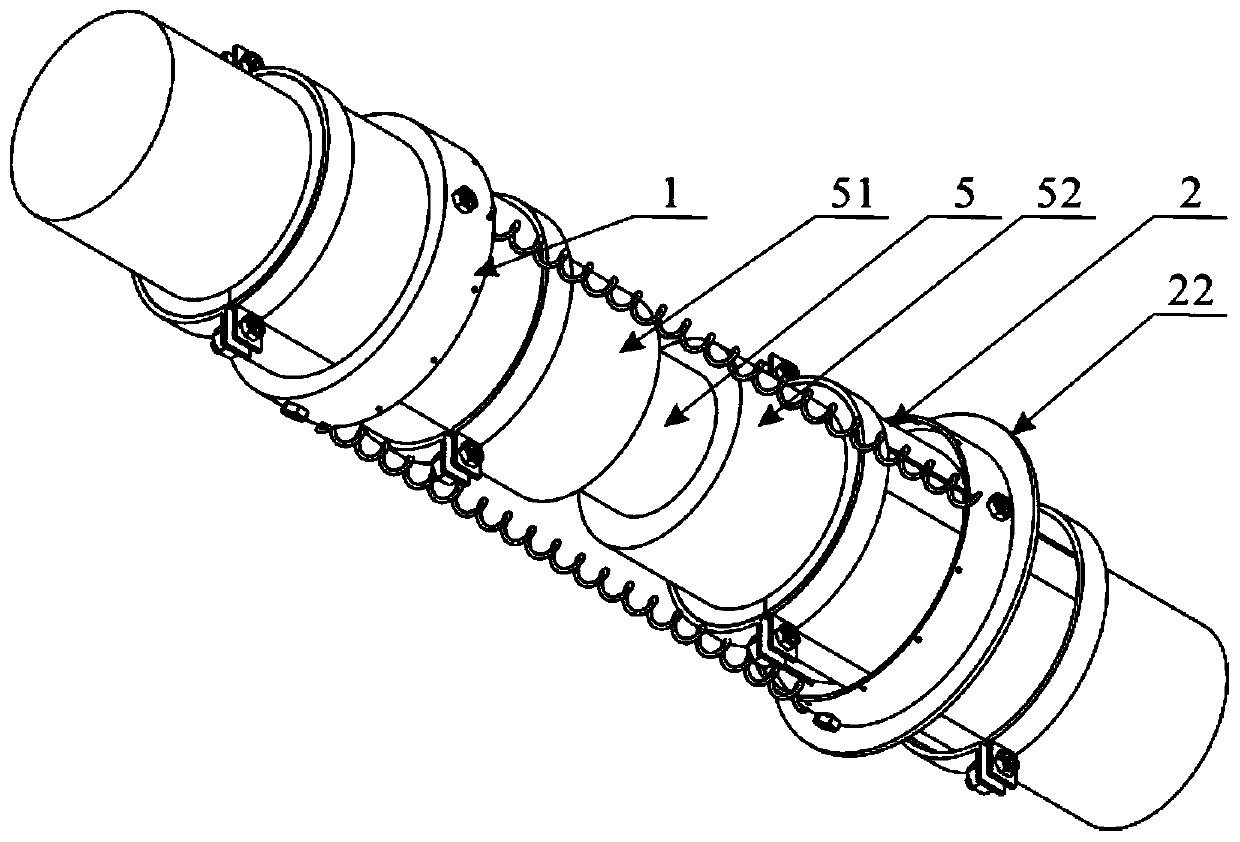

Test piece clamping device for large-diameter split Hopkinson pressure bar

ActiveCN108982209AStable clampingAdjustable sizeStrength propertiesEngineeringUltimate tensile strength

The invention discloses a test piece clamping device for a large-diameter split Hopkinson pressure bar. The test piece clamping device comprises a fixing end and a sliding end, wherein the fixing endcomprises a fixing sleeve; the fixing sleeve is sleeved with a fixing ferrule; the fixing ferrule is provided with a plurality of fixing holes; the sliding end comprises a sliding sleeve; the slidingsleeve is sleeved with a sliding ferrule through a plurality of sliding chutes which are formed uniformly; slide blocks which are matched with the sliding chutes are fixedly arranged on the inner wallof the sliding ferrule; the sliding ferrule is provided with positioning holes in a penetrating way at positions corresponding to the slide blocks; positioning parts are arranged in the positioning holes; the sliding ferrule is provided with a plurality of connection holes; the connection holes and the fixing holes are connected with the two ends of elastic elements respectively. By adopting thetest piece clamping device, the problems of insufficient support reliability and low positioning accuracy in a test piece clamping device in the prior art can be solved. The test piece clamping devicehas the advantages of high reliability, low randomness, high universality, easiness in disassembly and assembly, wider pre-clamping force adjusting range and high applicability, and can be flexibly adjusted and assembled according to the size and strength of a test piece.

Owner:SOUTHWEST JIAOTONG UNIV

Overload protection transmission gear

Owner:CHONGQING JIANSHE IND GRP

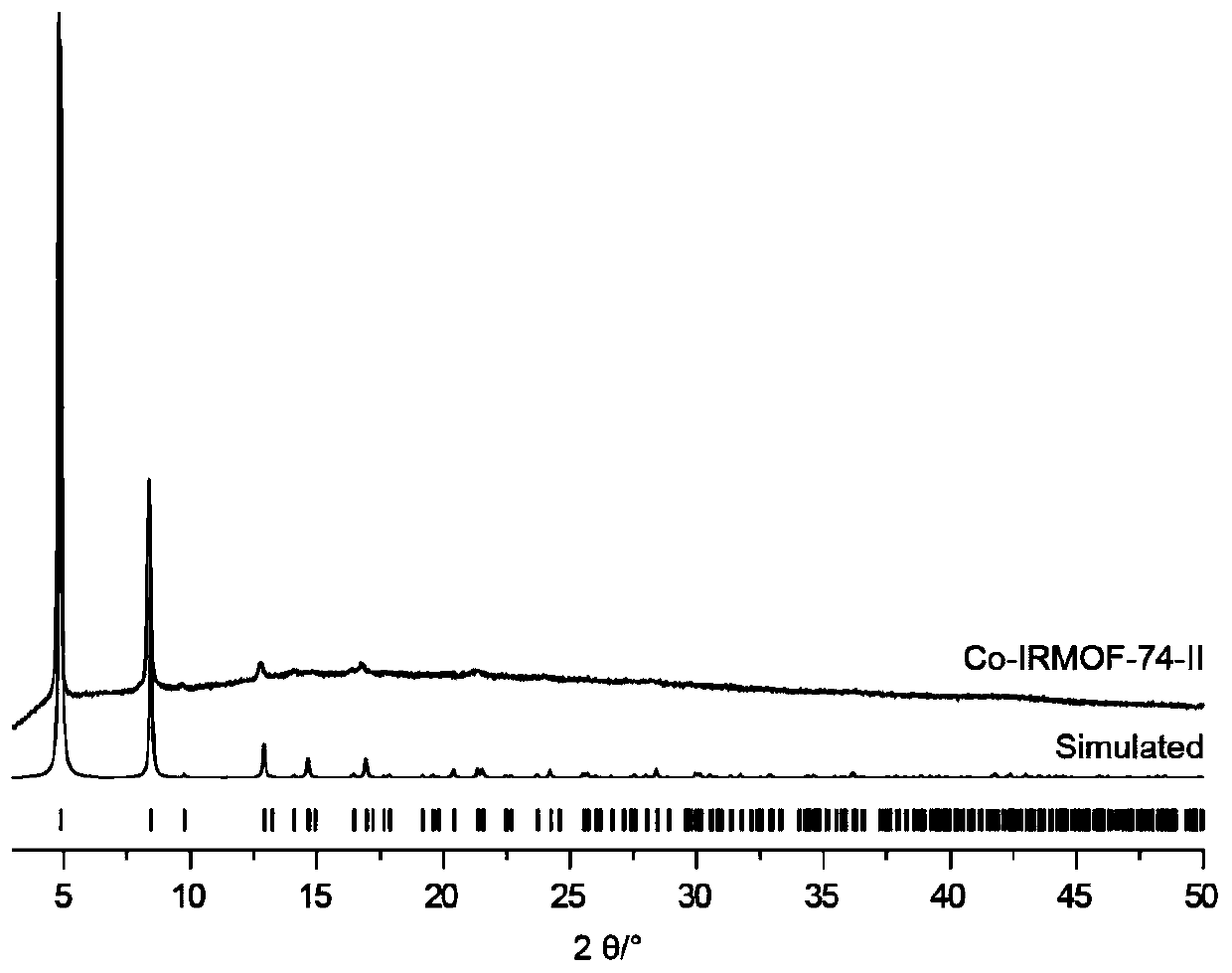

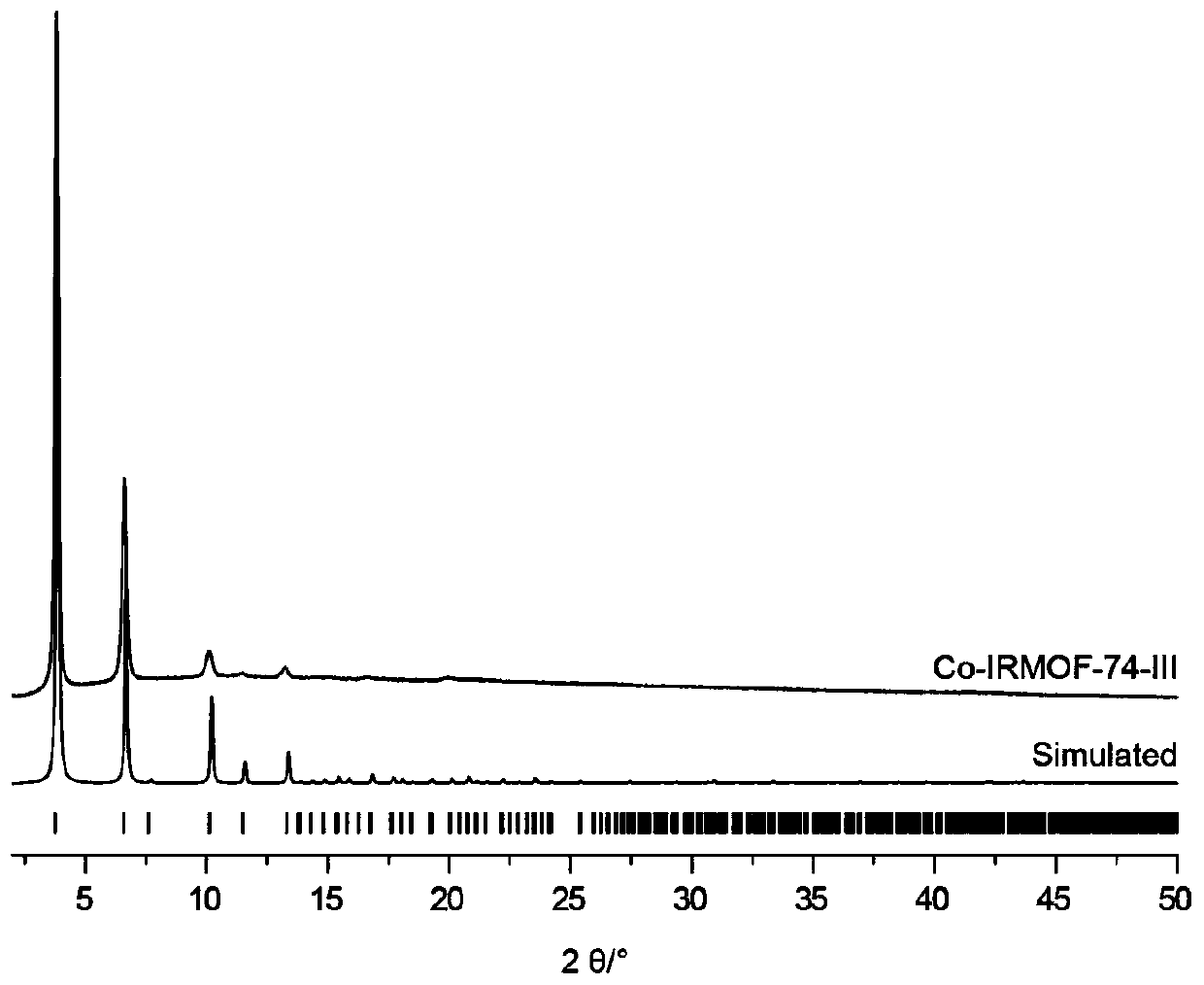

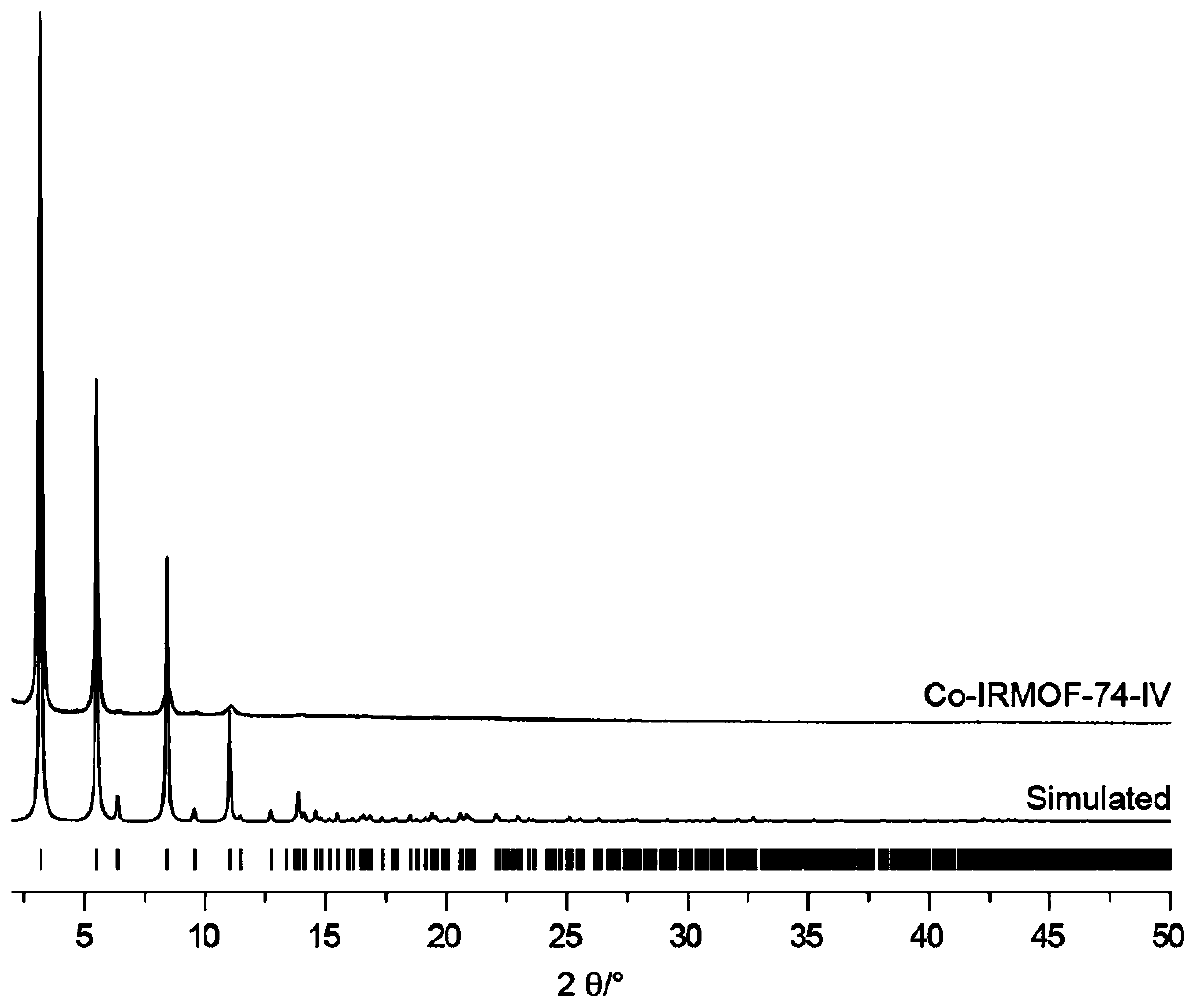

Synthesis method and application of pore-diameter-adjustable Co-based MOF material with nucleic acid screening function

ActiveCN111196876APrecisely adjust the lengthPrecise size adjustmentMicrobiological testing/measurementNucleic acid structurePhysical chemistry

The invention relates to a synthesis method and application of a pore-diameter-adjustable Co-based MOF material with a nucleic acid screening function. The synthesis method comprises the following steps of: (1) respectively synthesizing organic ligands II, III and IV of which the chain lengths are progressively increased as shown in the following formula, (2) respectively preparing the same topological structure by selecting metal Co and the organic ligands II, III and IV to obtain MOFs materials of which the pore diameters are progressively increased, and (3) activating the prepared MOFs material, so as to obtain a Co-based MOF material, namely Co-IRMOF-74-II, Co-IRMOF-74-III and Co-IRMOF-74-IV. The synthesized MOF material is suitable for rapid separation of various types of nucleic acidmolecules with secondary structures and has universality, and MOF materials with different pore sizes are selected according to different types of separated nucleic acid structures.

Owner:WUHAN UNIV

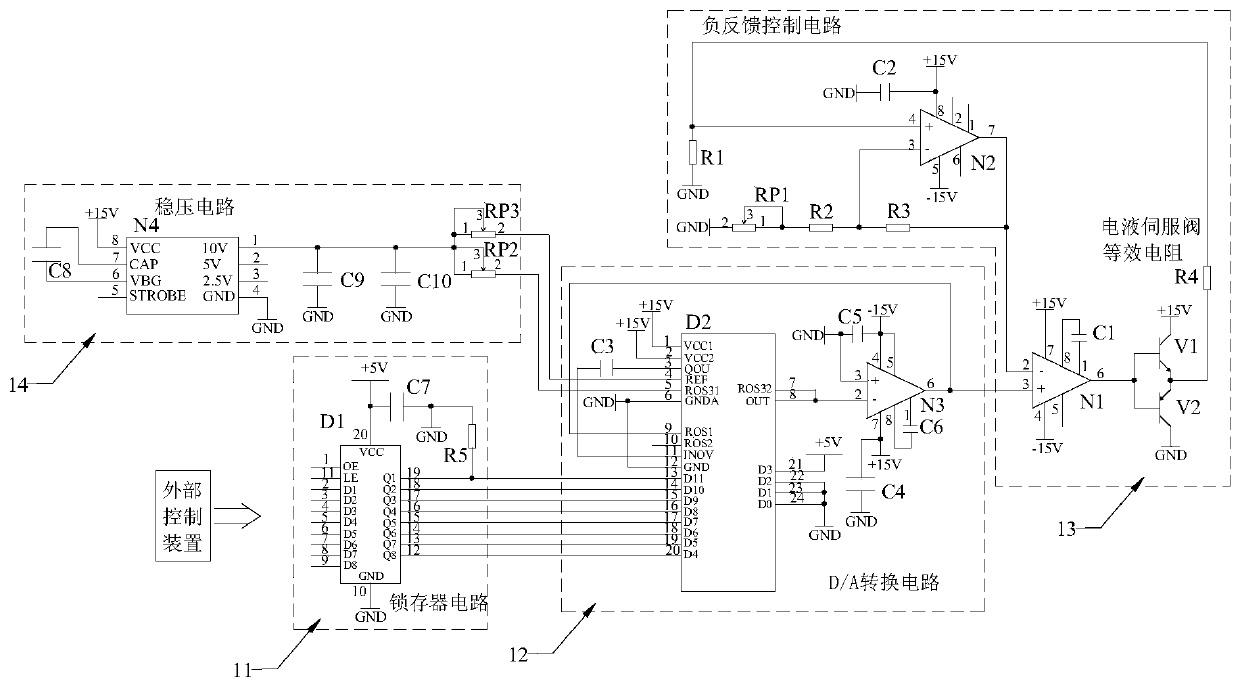

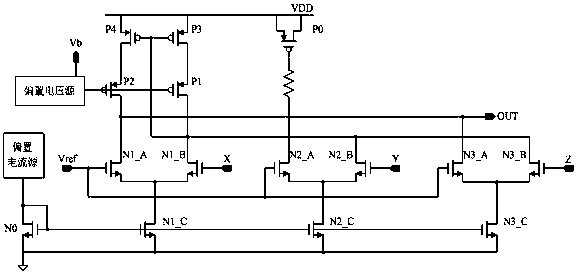

Precise control circuit of electro-hydraulic servo valve and gas turbine generator set

ActiveCN110159436AAccurate speed controlPrecise size adjustmentGas turbine plantsTurbine/propulsion fuel controlNegative feedbackPressure stabilization

The invention discloses a precise control circuit of an electro-hydraulic servo valve and a gas turbine generator set. According to the precise control circuit of the electro-hydraulic servo valve, alatch circuit is used for carrying out data latching on a control signal input by an external control device, then a D / A conversion circuit converts the digital quantity control signals input by the external control device into analog quantity control signals, finally a negative feedback control circuit receives the analog quantity control signals transmitted by the D / A conversion circuit and precisely adjusts the current input to the electro-hydraulic servo valve, so that the size of the opening of a valve is accurately adjusted so as to accurately control the amount of oil flowing into the generator set, and finally the purpose of accurately controlling the rotating speed of the generator set is achieved. According to the precise control circuit, the precise control circuit of the electro-hydraulic servo valve can accurately control the electro-hydraulic servo valve, so that the acceleration, deceleration and pressure stabilization operation of the generator set can be realized. In addition, the accurate control circuit of the electro-hydraulic servo valve is mainly applied to the gas turbine generator set.

Owner:CHINA HANGFA SOUTH IND CO LTD

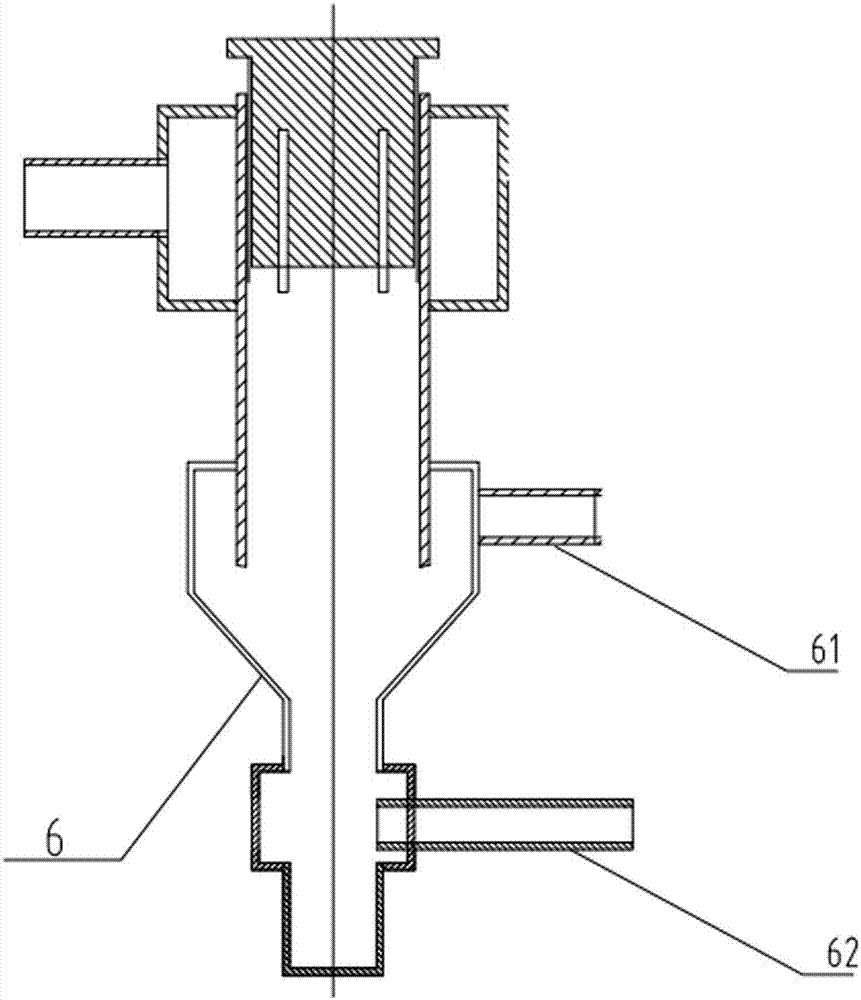

Lateral feeding-type hydrocyclone

InactiveCN107199128AOptimize or intensify mixing actionEnhanced mixingReversed direction vortexCycloneChemical reaction

The invention discloses a side-feed type cyclone which can precisely adjust and control the flow velocity of the liquid-phase swirl on the outside. The sealing cavity formed between the jacket and the swirl tube; the upper section of the swirl tube is provided with an internal thread to match the external thread of the flow rate regulating valve and seal the top end, and the middle section is tangential to the inside of the outer jacket and the wall of the swirl tube. On its inner circle, a number of rectangular slits are evenly arranged, and the lower section extends to the outside of the outer jacket; the flow rate regulating valve and part of the swirl tube are arranged outside the outer jacket, and the front section of the flow velocity regulating valve is a cylinder, and the rear section is provided with external threads, respectively. The inner circle of the swirl tube is matched with the inner thread; the size of the tangential slit of the swirl is adjusted through the rotary flow rate regulating valve to realize the adjustment and control of the liquid phase swirl flow rate and the residence time in the swirl tube, which is suitable for solid / liquid cyclone separators Solid and liquid separation of different properties in applications and physical and chemical reactions of different properties in tubular reactor applications.

Owner:李尽善

Jaw frame type bionic movement mechanism fatigue test device

InactiveCN102183424BAccurate measurement of fatigue cyclesTimely brakingMaterial strength using repeated/pulsating forcesReducerEngineering

The invention aims at providing a jaw frame type bionic movement mechanism fatigue test device. The jaw frame type bionic movement mechanism fatigue test device comprises a jaw frame type bionic movement mechanism, a motor, a speed reducer, a groove-cam mechanism and a base, wherein the jaw frame type bionic movement mechanism, the motor, the speed reducer and the groove-cam mechanism are arranged on the base; the speed reducer is connected with the motor and the groove-cam mechanism respectively; and the jaw frame type bionic movement mechanism is connected with the groove-cam mechanism. Thejaw frame type bionic movement mechanism fatigue test device has a simple structure, is practical, convenient to carry, intelligent to control and accurate to test, can precisely adjust the size according to various opening requirements of the activity of a multi-bending spring on the cheek side, precisely measure a fatigue period of the multi-bending spring and immediately brake when the multi-bending spring is broken, and is applied to fatigue performance test of the multi-bending spring effectively.

Owner:HARBIN ENG UNIV

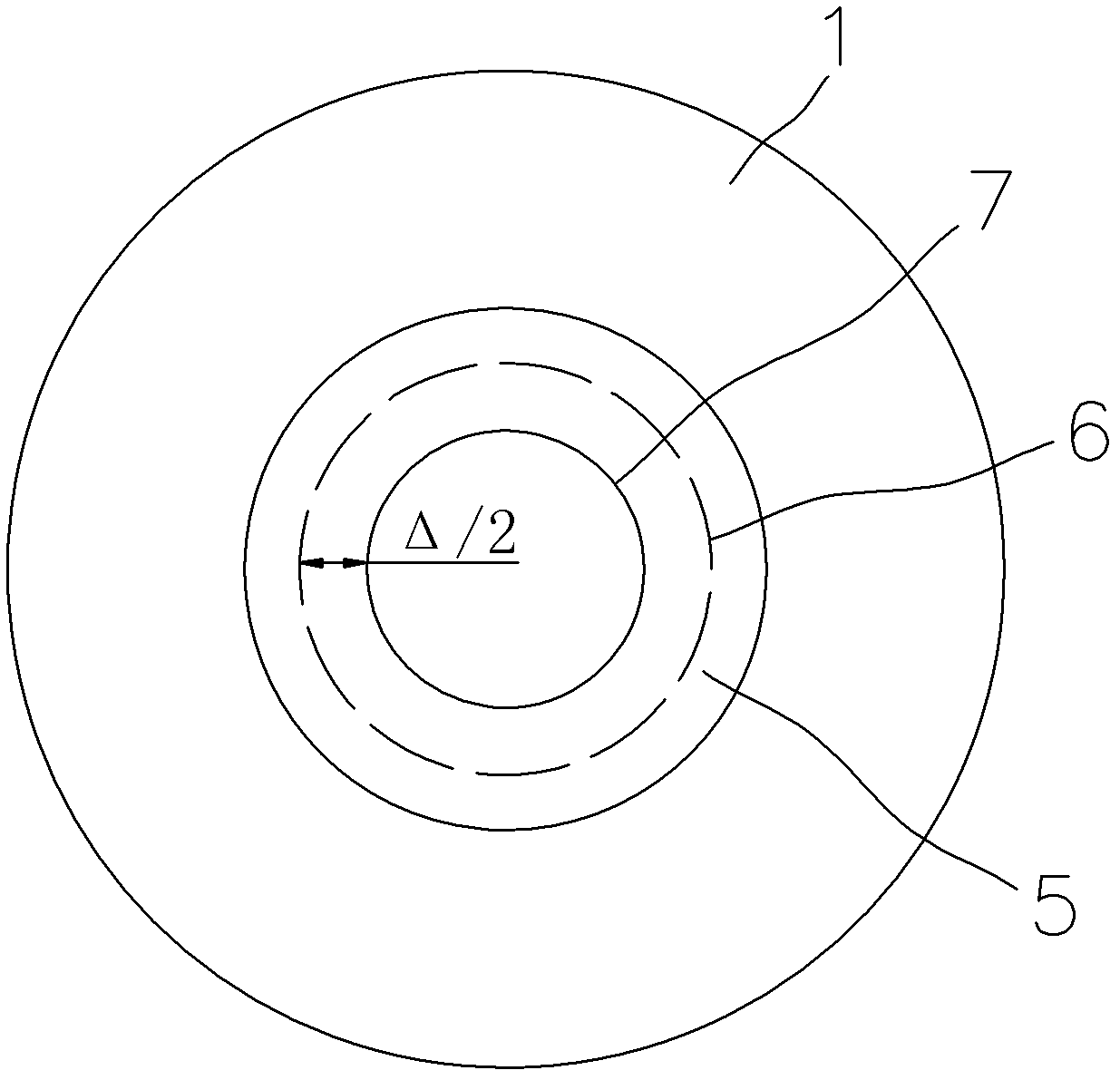

Method for adjusting diameter of silicon nanometer hole

ActiveCN102583230APrecise size adjustmentImprove design requirementsDecorative surface effectsChemical vapor deposition coatingHydrofluoric acidPore diameter

The invention belongs to the technical field of processing and preparation of silicon nanometer holes, and particularly relates to a method for adjusting diameter of a silicon nanometer hole. The method comprises the steps as follows: measuring the diameter of the silicon nanometer hole; and calculating the difference delta of the diameter and an expected value, if the diameter is greater than the expected value, a device provided with the silicon nanometer hole is heated and oxidized to ensure that the thickness r of silicon that is oxidized equals to (delta / 2)*(44 / 56), then detection is carried out to ensure that whether the diameter of the silicon nanometer hole reaches the expected value or not until the a hole with an expected diameter is obtained, however, if the diameter is smaller than the expected value, the device provided with the silicon nanometer hole is heated and oxidized to ensure that the thickness of silicon that is oxidized equals to delta / 2, then a generated silicon dioxide layer is corroded by hydrofluoric acid solution, and finally then detection is carried out to ensure that whether the diameter of the silicon nanometer hole reaches the expected value or not until the a hole with an expected diameter is obtained. By adopting the method, the size of the silicon nanometer hole can be adjusted accurately, and repeated adjustment can be realized, so that design requirements can be met conveniently.

Owner:UNITED MICROELECTRONICS CENT CO LTD

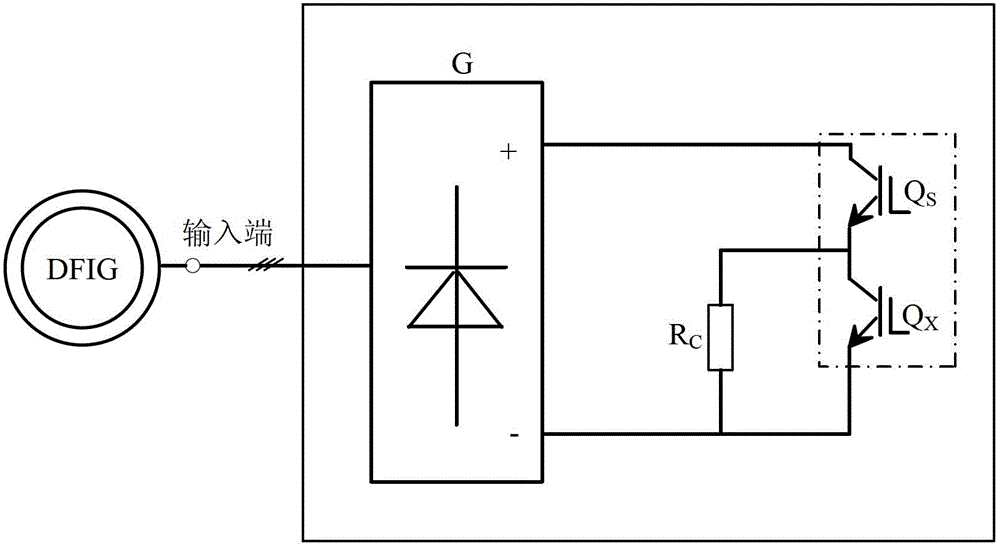

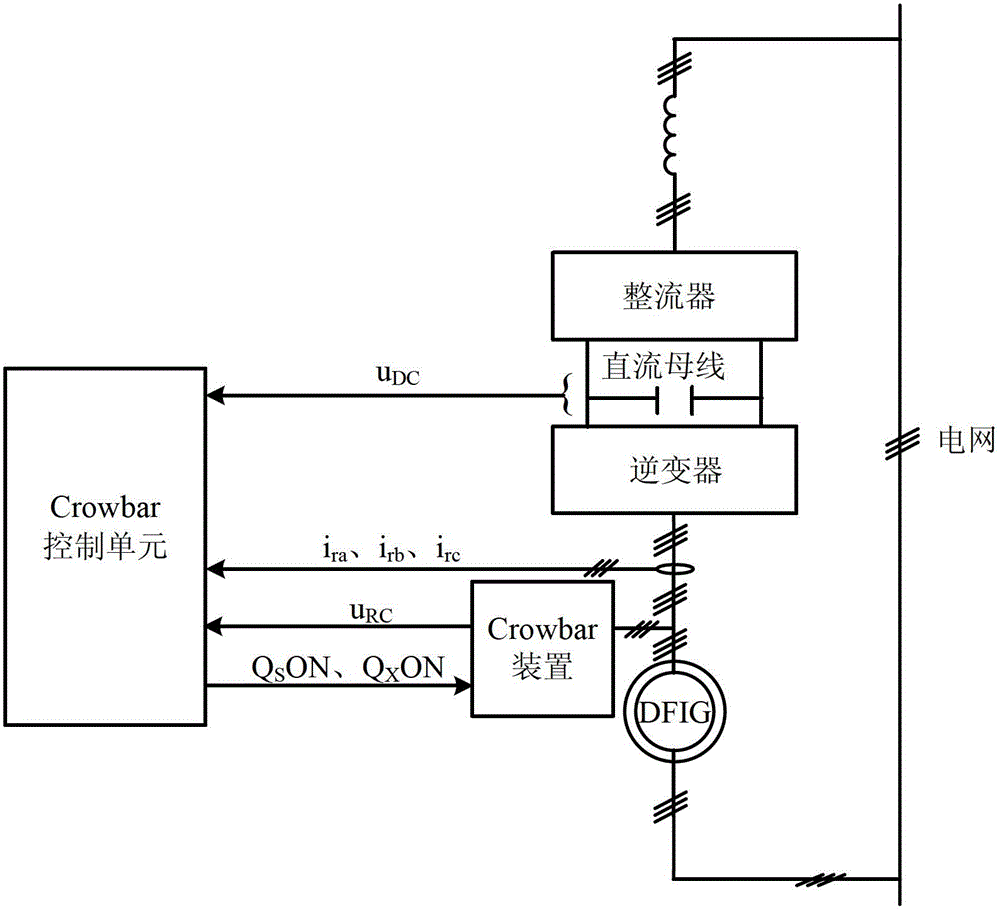

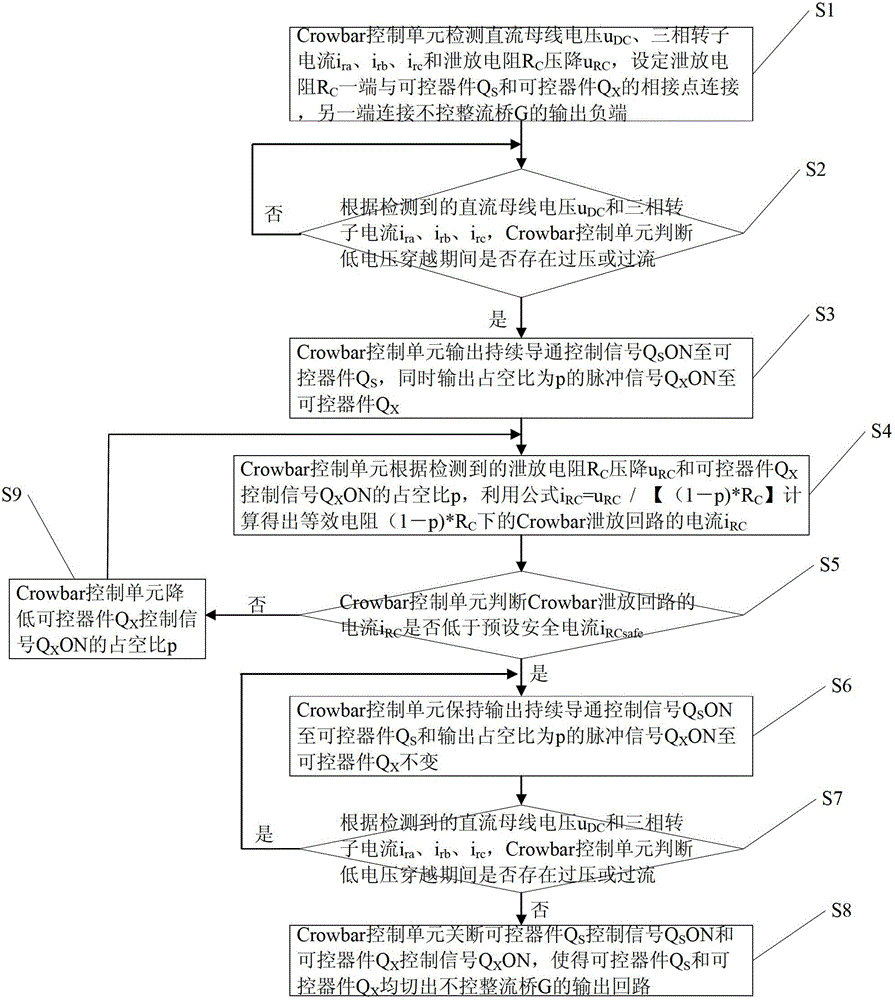

Crowbar device for low voltage ride-through of wind generator set and control method of device

InactiveCN102983592APrecise size adjustmentLow costSingle network parallel feeding arrangementsElectric generator controlElectricityElectrical resistance and conductance

The invention discloses a Crowbar device for low voltage ride-through of a wind generator set and a control method of the device. The device comprises an uncontrolled rectifier bridge G, a controllable component QS, a controllable component QX and a bleeder resistor RC, wherein an input end of the uncontrolled rectifier bridge G is connected with A, B and C phases on a rotor side of a double-fed asynchronous generator; the controllable component QS and the controllable component QX are connected with an output end of the uncontrolled rectifier bridge G in series; one end of the bleeder resistor RC is connected with a connection point of the controllable component QS and the controllable component QX; and the other end of the bleeder resistor RC is connected with a positive output end or a negative output end of the uncontrolled rectifier bridge G; The device is simple in structure and lower in cost, and solves the problems that the existing Crowbar is complicated in structure and higher in cost.

Owner:DALIAN GUOTONG ELECTRIC

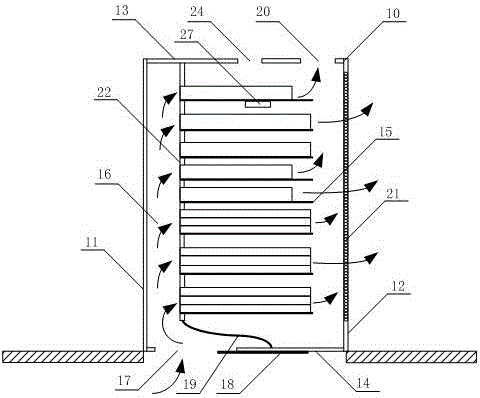

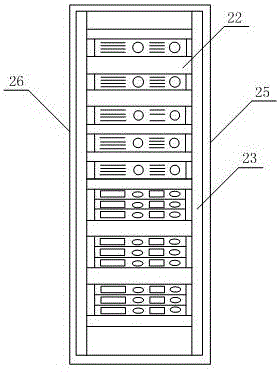

Interactive training curriculum management system

InactiveCN106061216AEffective coolingMonitor temperature in real timeCooling/ventilation/heating modificationsCold airEngineering

The invention discloses an interactive training curriculum management system which comprises an intelligent terminal, a data server, a network server and a cabinet. The cabinet comprises a cabinet body, at least two separating plates, an air inlet, a flow deflector, an air outlet, air outgoing holes and at least one wireless temperature sensor, wherein the cabinet body comprises a front door plate, a rear door plate, a top plate, a bottom plate, a left side plate and a right side plate; the separating plates are arranged in the cabinet body horizontally, and are separated from the front door plate for certain distance to form a cold air cavity; the air inlet is arranged in the base plate and communicates with the cold air cavity correspondingly, and is provided with a sliding cover plate; the flow deflector is arranged over the air inlet, one end of the flow deflector is connected to the side, close to the front door plate, of the bottommost separating plate, and the other end of the flow deflector is connected to the side, close to the rear door plate, of the air inlet; the air outlet is arranged in the top plate; the air outgoing holes are arranged in the rear door plate; and the wireless temperature sensor is mounted in the bottom side of the separating plate. According to the interactive training curriculum management system of the invention, the cabinet realizes cooling in a downward blowing manner, and the energy utilization efficiency can be improved effectively.

Owner:成都攒道管理咨询有限公司

Three-ring fire valve core

InactiveCN109488790AImprove reliabilityImprove sealingPlug valvesMultiple way valvesGas conditioningFuel gas

The invention discloses a three-ring fire valve core and relates to the technical field of gas stove adjusting valves. Specifically, the three-ring fire valve core comprises a fixing base and a conical vent valve core. A clamping and installing groove is formed in the middle of the fixing base. A sealing outer edge face is arranged on the outer surface of the conical vent valve core. The conical vent valve core is located above the fixing base. A connecting flange is arranged on the inner side of the conical vent valve core. A clamping flange is arranged above the connecting flange. A connecting hole is formed above the clamping flange. A gas inlet is connected above the connecting hole. A valve core lower portion gas outlet is formed in the middle of the conical vent valve core. Accordingto the three-ring fire valve core, total supply of fuel gas is achieved through the gas inlet, the whole device is installed on the fuel gas adjusting valve through the fixing base, fuel gas is supplied through the gas inlet in the bottom of the fixing base, the gas inlet is connected with the connecting hole in a communicating manner, meanwhile, the gas inlet and the fixing base are located on the same vertical line, and passing and supply efficiency of the fuel gas can be kept conveniently.

Owner:佛山市宇煜五金有限公司

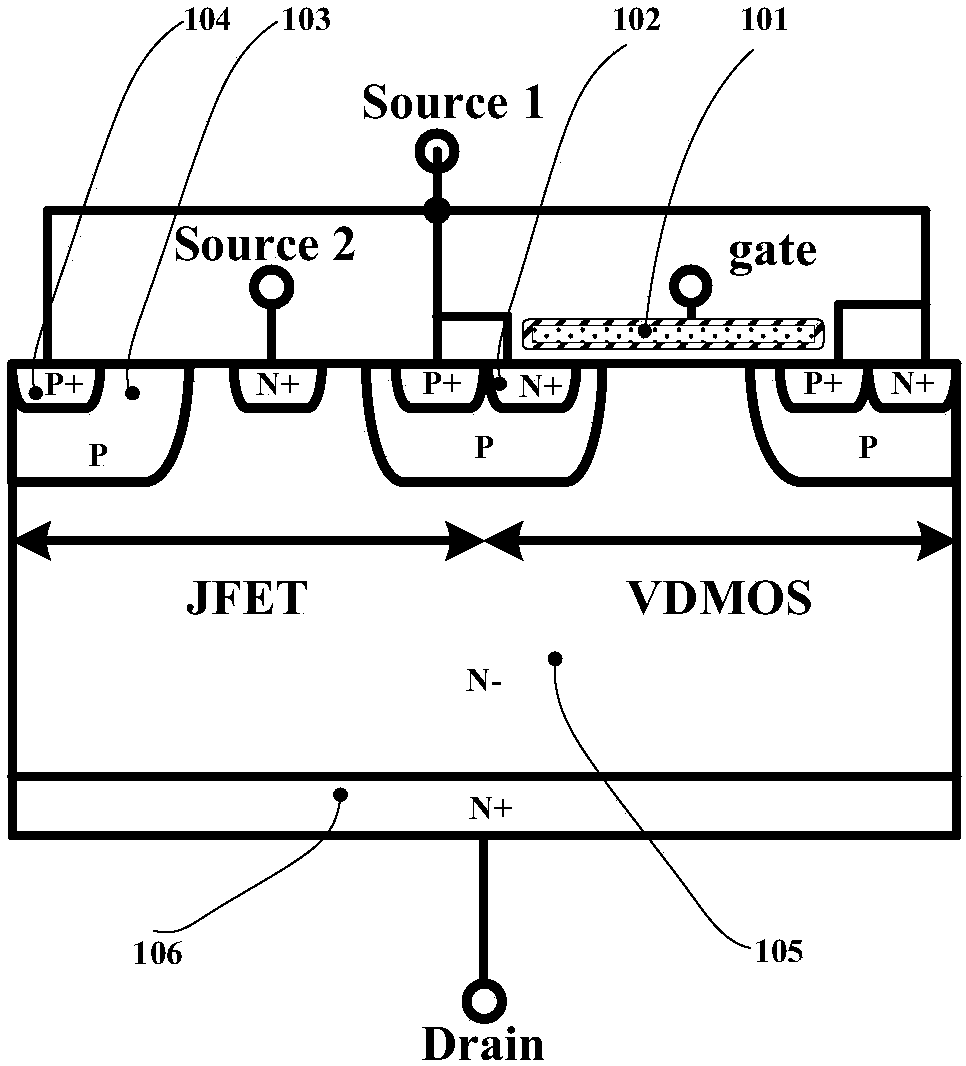

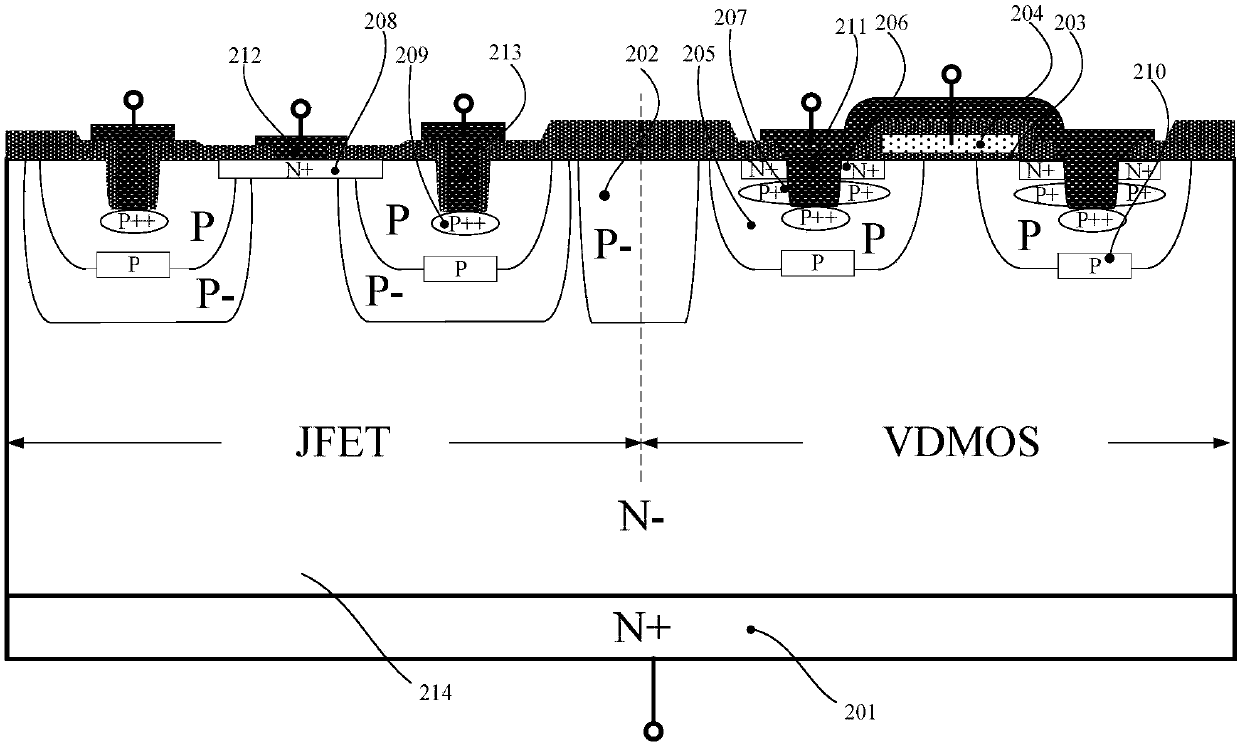

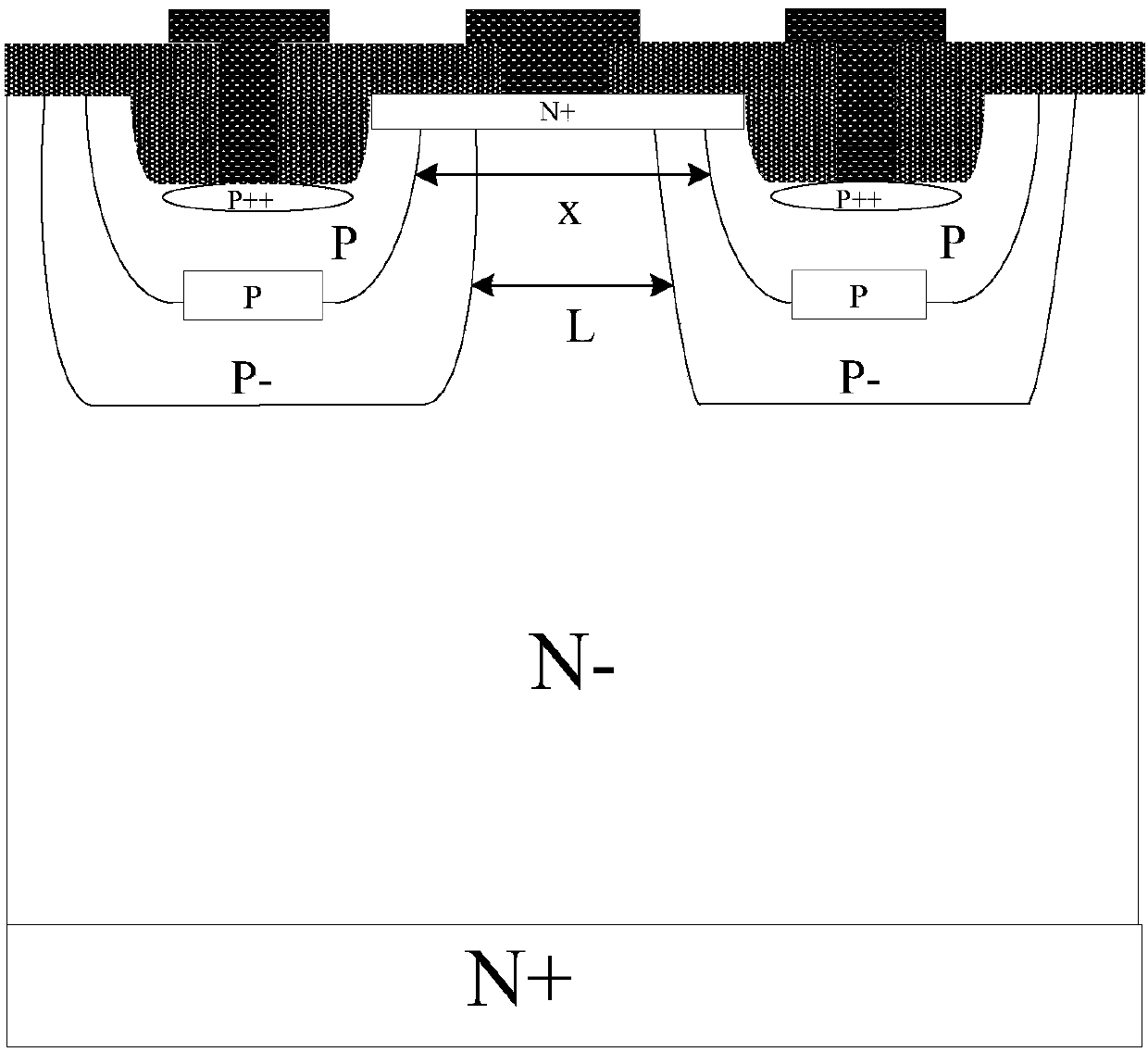

Device integrated with junction field effect transistor and manufacturing method thereof

ActiveCN107785365AEnhanced depletion abilityImprove stabilitySolid-state devicesSemiconductor devicesComposite channelLateral extension

The invention relates to a device integrated with a junction field effect transistor and a manufacturing method thereof. The JFET region of the device comprises: a JFET source, a metal electrode of the JFET source, composite well region structures and a JFET metal gate, wherein the JFET source is of a first conductive type; the metal electrode is formed on the JFET source and is in contact with the JFET source; each composite well region structure is of a second conductive type, is arranged within a first conductive type region and comprises a first well and a second well in the first well, the ion concentration of the second well is greater than that of the first well, the composite well region structure is formed on each of two sides of the JFET source, and the JFET source extends transversely into the first well and the second well; and the JFET metal gate is arranged on the composite well region structures on two sides of the JFET source. By using a composite channel formed by a composite well region consisting of the first well and the second well, the channel depletion capability is enhanced, and the pinch-off voltage stability is strengthened. At the same time, the pinch-offvoltage can be accurately adjusted by adjusting the distance between the composite channels to meet different circuit application occasions.

Owner:CSMC TECH FAB2 CO LTD

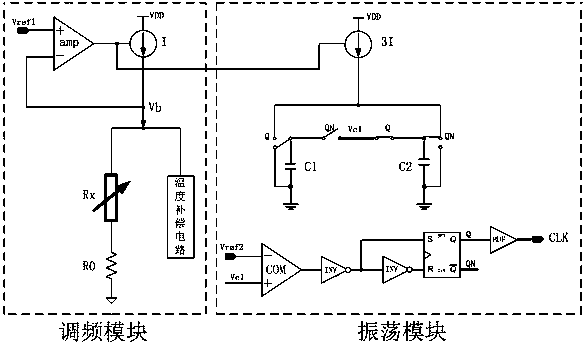

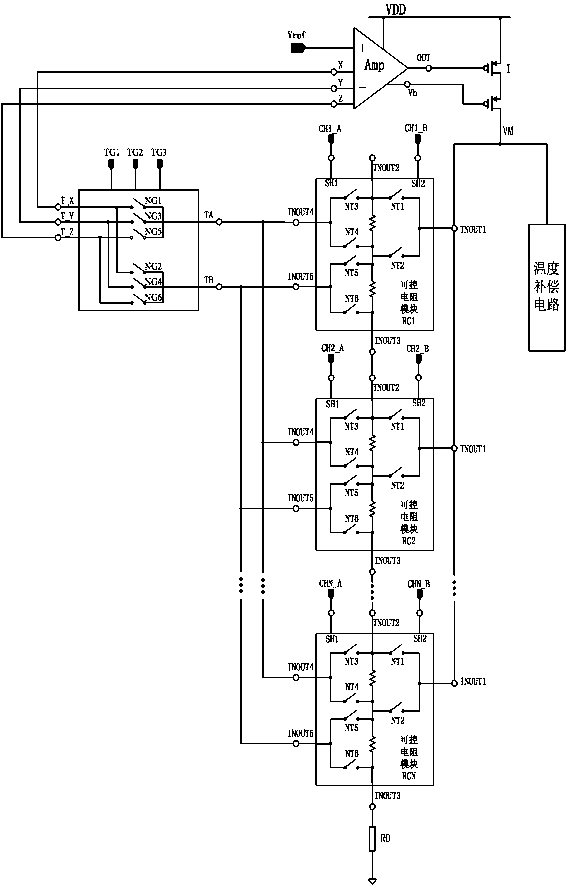

Circuit which is applied to relaxation oscillator and is capable of realizing precise frequency modulation

ActiveCN107896092APrecise size adjustmentSimple structureAngle modulation detailsFrequency modulationRelaxation oscillator

The invention discloses a circuit which is applied to a relaxation oscillator and is capable of realizing precise frequency modulation. Compared with a traditional frequency modulation of the relaxation oscillator, the circuit has the advantages that through utilization of errors imported by multiway feedback voltages, the problem that a structure of the relaxation oscillator is difficult to realize precise frequency modulation is skillfully solved, and a relaxation structured oscillator, instead of a crystal oscillator, can even be applied to some circuits having relatively harsh frequency precision demands.

Owner:CHANGSHA JINGJIA MICROELECTRONICS

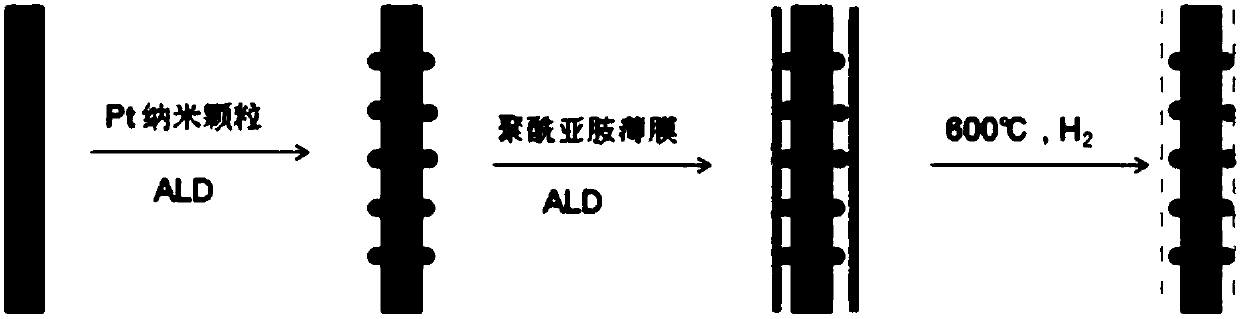

Methanol electrooxidation catalyst and preparation method and application thereof

ActiveCN107858661AThe preparation method is simple and controllablePrecise adjustment of component contentCell electrodesChemical vapor deposition coatingCarbon filmPtru catalyst

The invention provides a methanol electrooxidation catalyst preparation method. The preparation method comprises the steps that dispersion liquid of carbon nano-material is coated on the surface of asubstrate to obtain a template, a nitrogen-containing organic polymer film and a Pt nano-particle are deposited on the surface of the template by using an atomic layer deposition method so as to obtain a catalyst precursor, and the catalyst precursor is subjected to heat treatment under a protective atmosphere to obtain a methanol electrooxidation catalyst. According to the methanol electrooxidation catalyst preparation method, the nitrogen-containing organic polymer film and the Pt nano-particle are deposited on a carbon carrier by using the atomic layer deposition method, the nitrogen-containing organic polymer film is carbonized into a conductive nitrogen-containing carbon film after being subjected to heat treatment, and compared with a pure Pt catalyst, the methanol electrooxidation catalyst shows higher activity and stability in the methanol electrocatalytic oxidation process; and meanwhile, the methanol electrooxidation catalyst preparation method is simple and controllable, content and sizes of all components are convenient to accurately adjust, product preparation uniformity is good, and repeatability is high.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Double-roll crusher with rollers with fixed shaft support structure

ActiveCN112473818BPrecise size adjustmentReduce work intensityGrain treatmentsStructural engineeringCrusher

Owner:ZHEJIANG MEIANPU MINE MACHINERY CO LTD

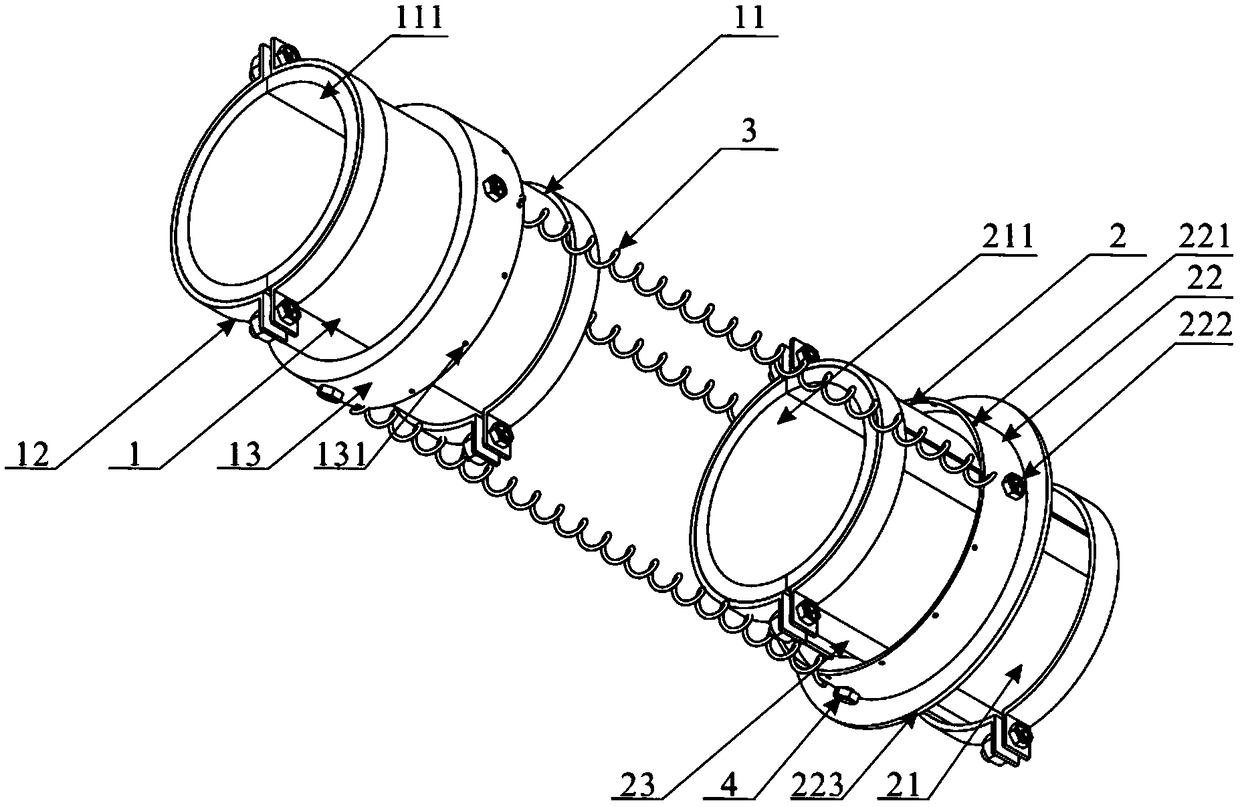

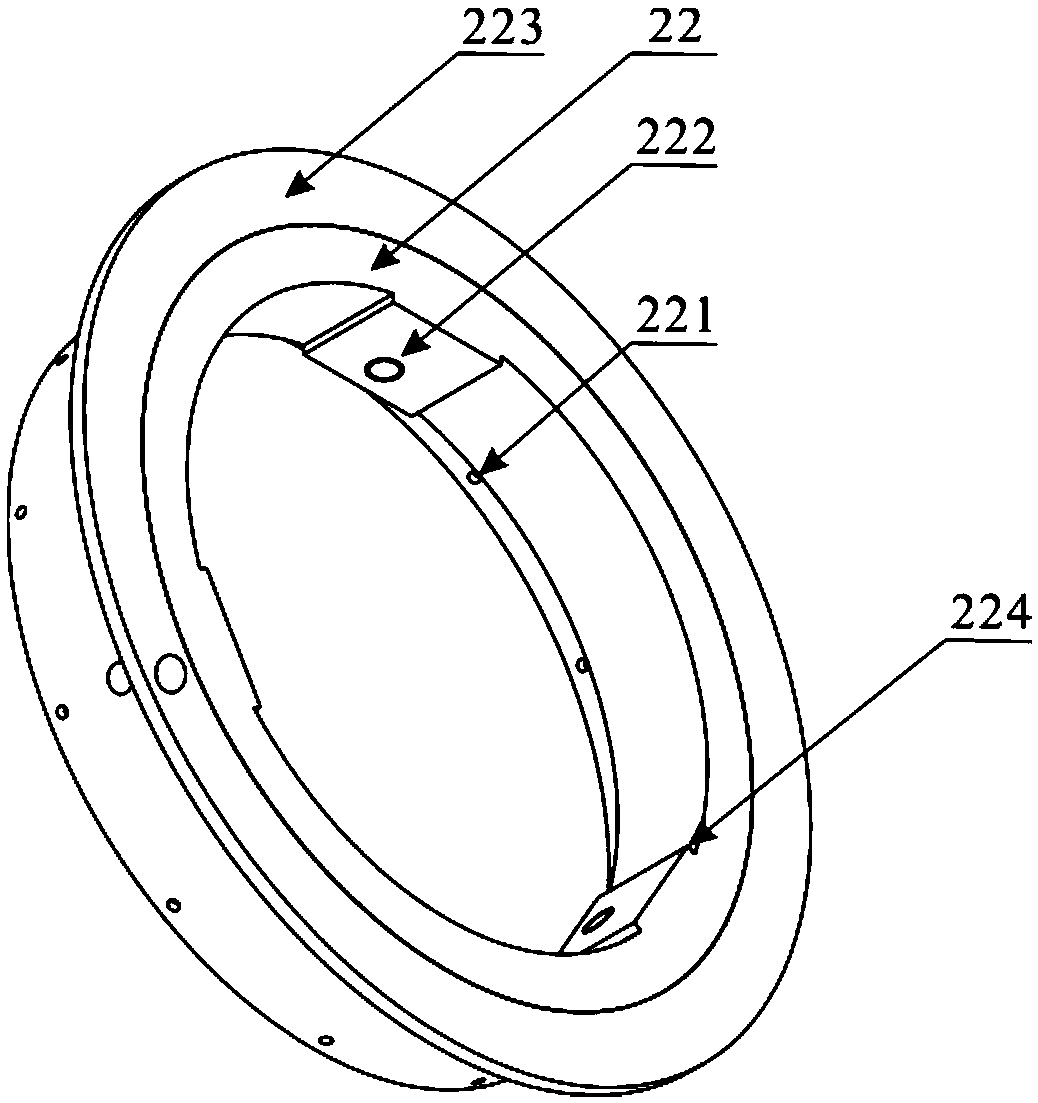

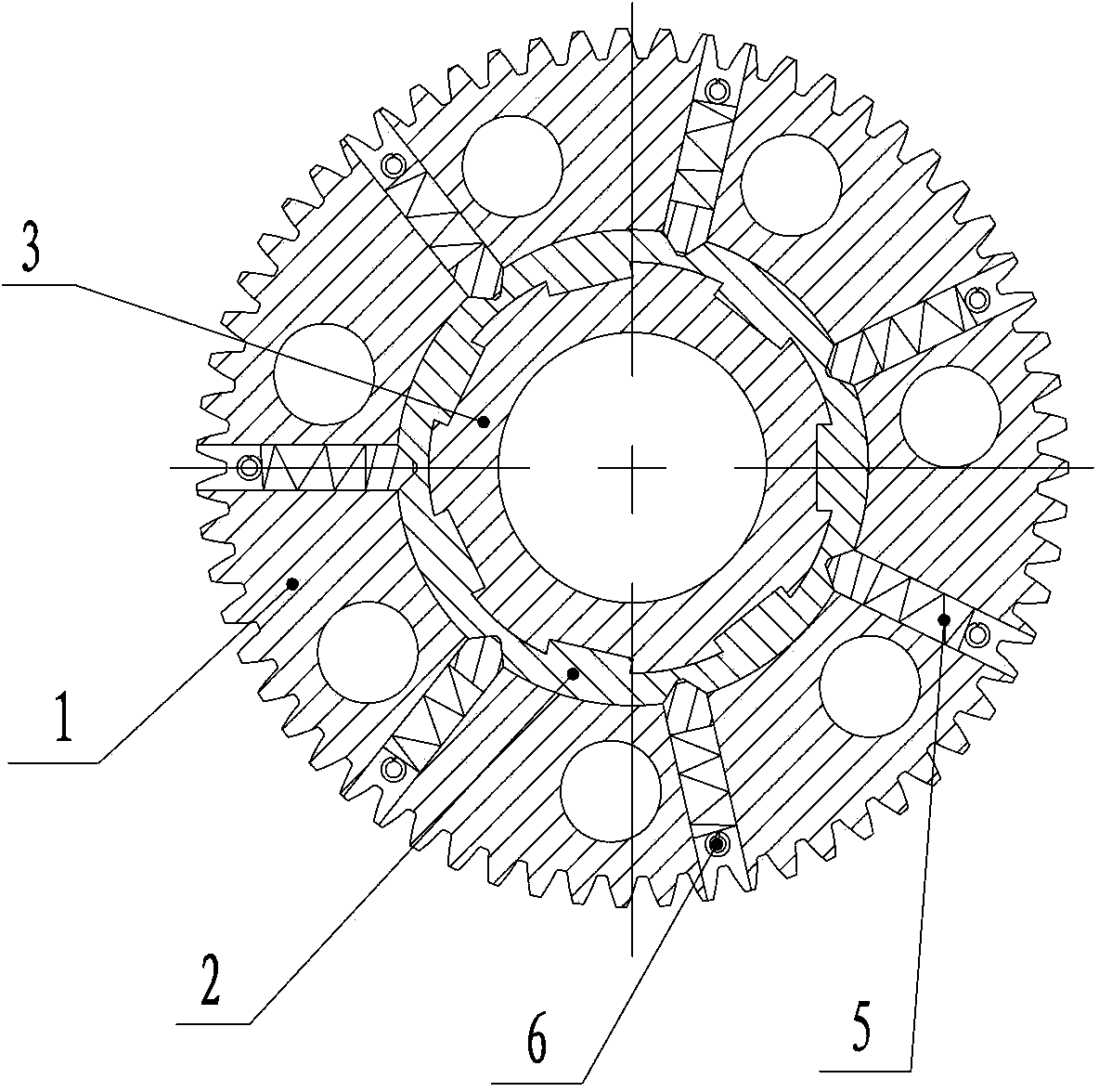

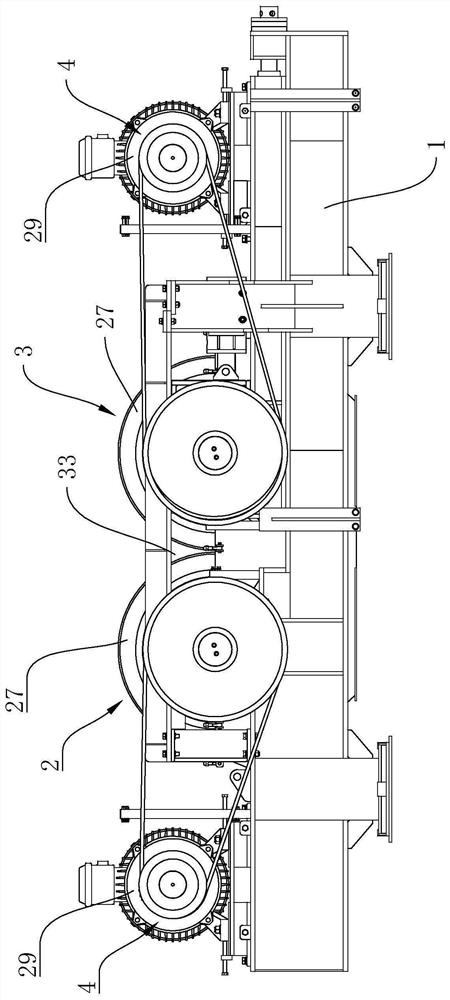

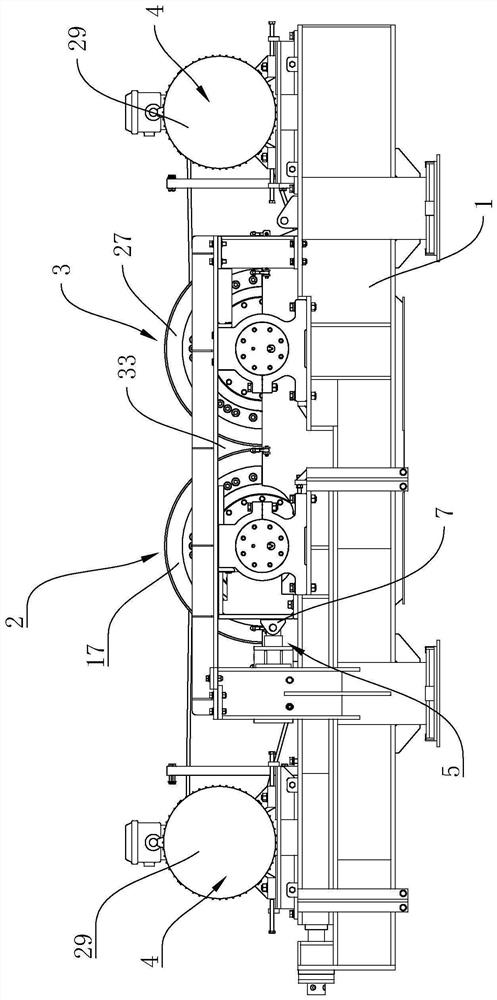

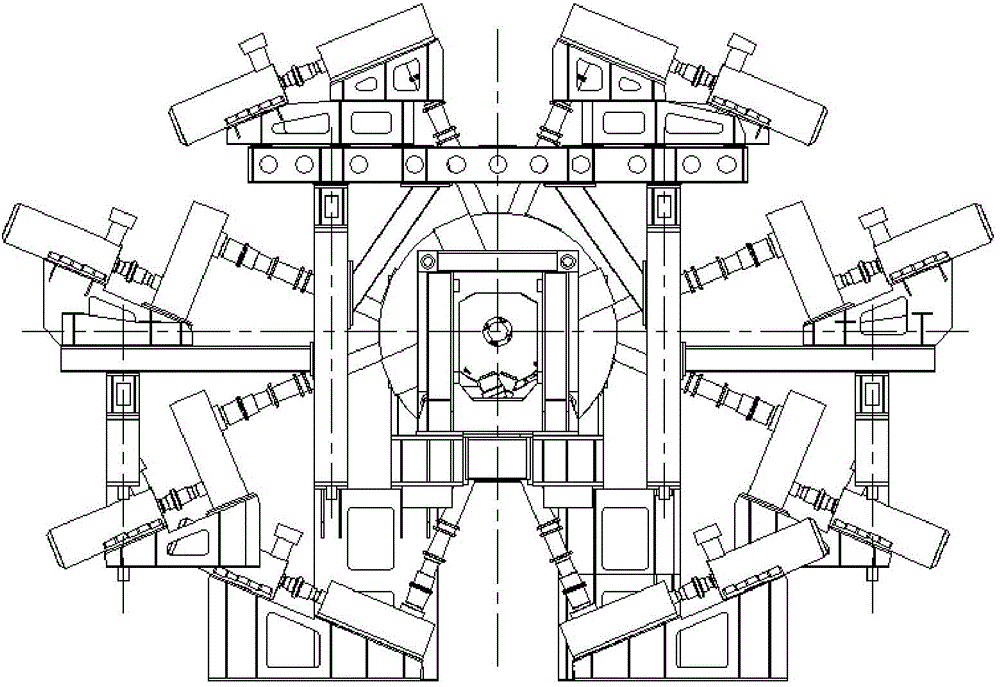

Four-roller mandrel pipe mill

ActiveCN103599938AGood speed consistencyUniform deformationMetal rolling stand detailsRolling mill drivesSteel tubeTransmission system

The invention discloses a four-roller mandrel pipe mill which comprises a tunnel type memorial archway, rolling racks arranged along the central axis of the tunnel type memorial archway in sequence, roller fittings located inside the rolling racks and a transmission system used for driving all the roller fittings to rotate. Each mill rack is provided with four sets of roller fittings, all the roller fittings are respectively connected to a set of roller clearance adjusting device used for adjusting the roller clearance, the roller clearance adjusting device is fixed on the tunnel type memorial archway, and each rolling rack is further provided with a rolling changing device used for allowing the corresponding rolling rack to move back and forth in the central axis direction of the tunnel type memorial archway. Four rollers are driven independently, the speeds in the peripheral direction of steel pipes are good in consistency, deformation is even, a hole pattern is sealed better, the wall thickness precision of products is improved, rolling defects are reduced, and the specification range of products capable of being rolled is enlarged.

Owner:CISDI ENG CO LTD

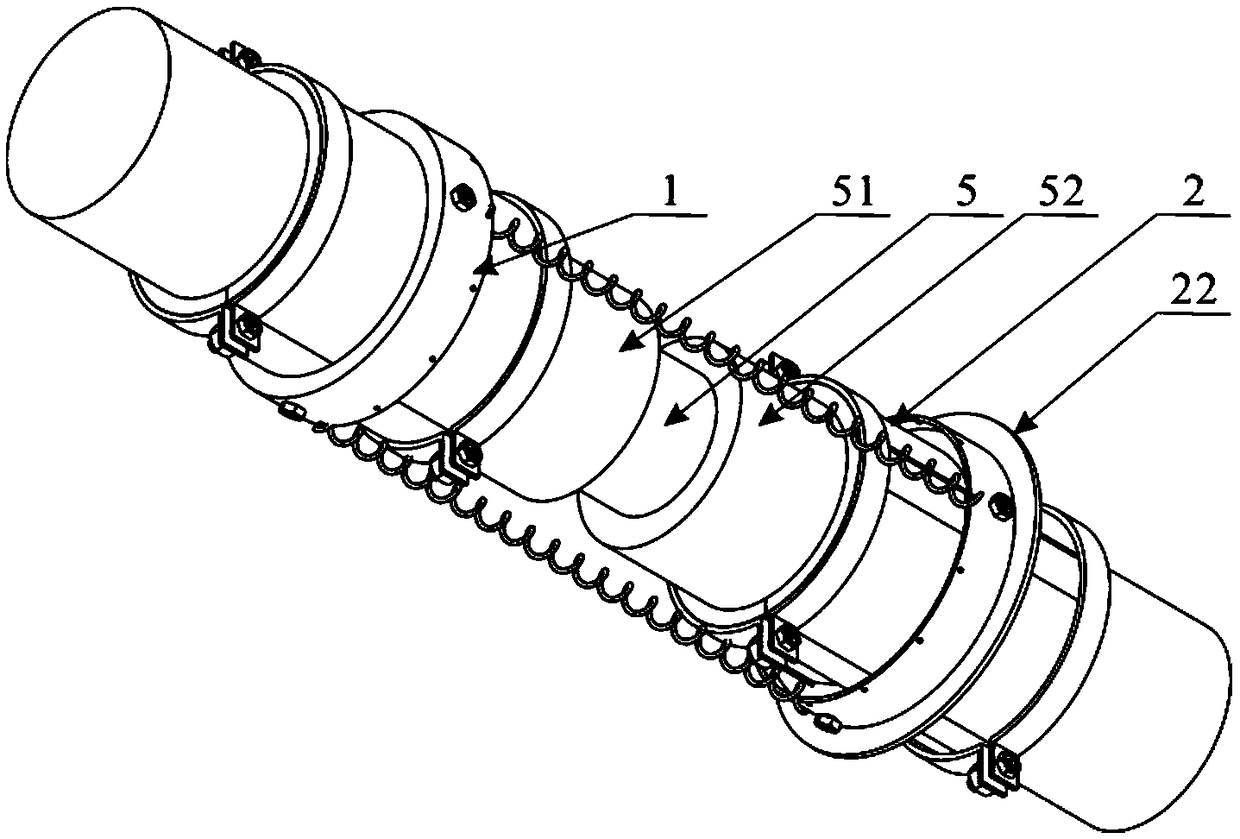

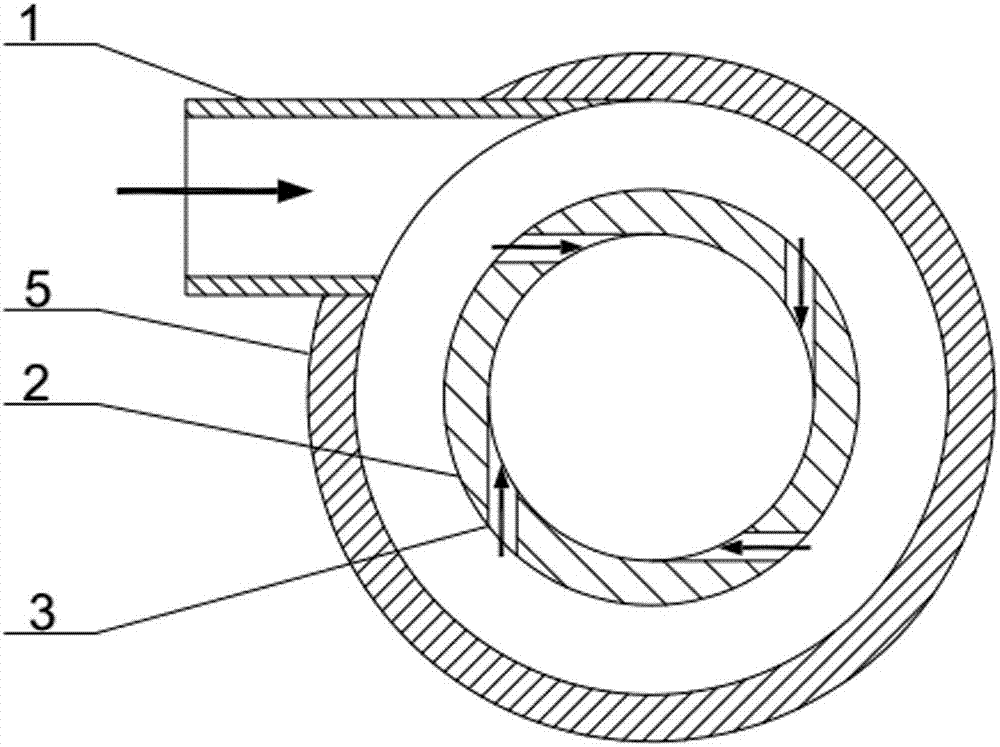

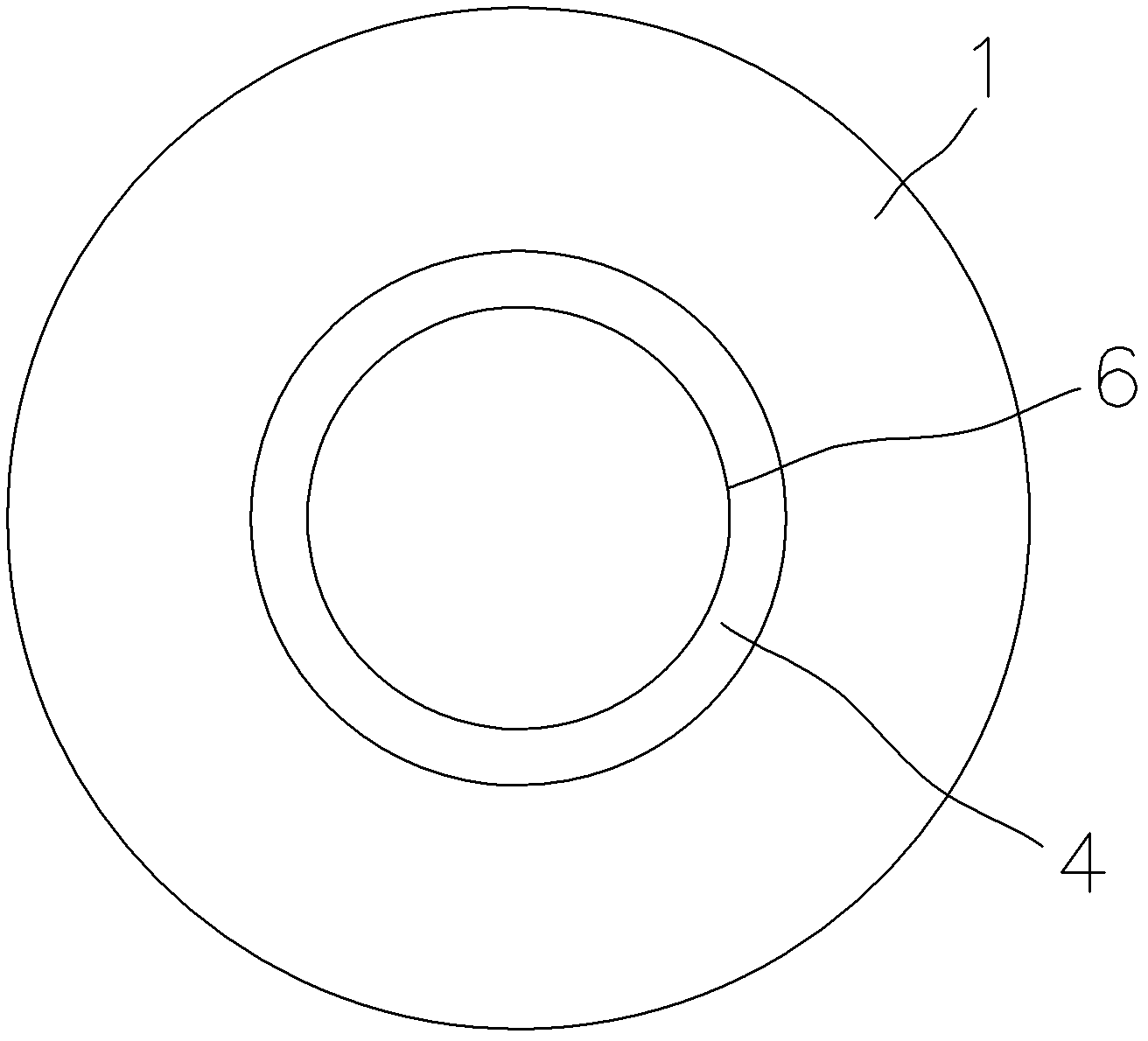

Axial feeding type swirler

InactiveCN107234009APrecise size adjustmentEasy to adjustReversed direction vortexCycloneEngineering

The invention discloses a multipurpose axial feeding type swirler capable of precisely adjusting and controlling a liquid phase vortex flow speed. The axial feeding type swirler is composed of a feeding pipe, a cyclone pipe, a cyclone tangential slit, a flow speed adjusting valve and an outer jacket. The feeding pipe is arranged on the center of an upper sealing cover of the outer jacket and connected with a cavity which is formed by the outer jacket and the cyclone pipe. An upper segment of the cyclone pipe is provided with an internal thread which is matched with an external thread of the flow speed adjusting valve, a middle segment or a liquid phase feeding position is provided with the cyclone tangential slit, and a lower segment extends to the exterior of the outer jacket. The flow speed adjusting valve is a cylinder, the diameter of a front segment of the flow speed adjusting valve is same as or is matched with the inner diameter of the cyclone pipe, and a rear segment of the flow speed adjusting valve is provided with an external thread. According to the core technology, the upper and lower positions of the flow speed adjusting valve are adjusted by rotating the flow speed adjusting valve, the liquid phase cyclone flow speed and the dwell time of a liquid phase in the cyclone pipe are conveniently and precisely adjusted, requirements on cyclone flow speeds, mixing degrees and reaction time of different systems are met, and the axial feeding type swirler can be used for industries of chemical engineering, metallurgy, materials, waste water treatment, medicament and the like.

Owner:李尽善

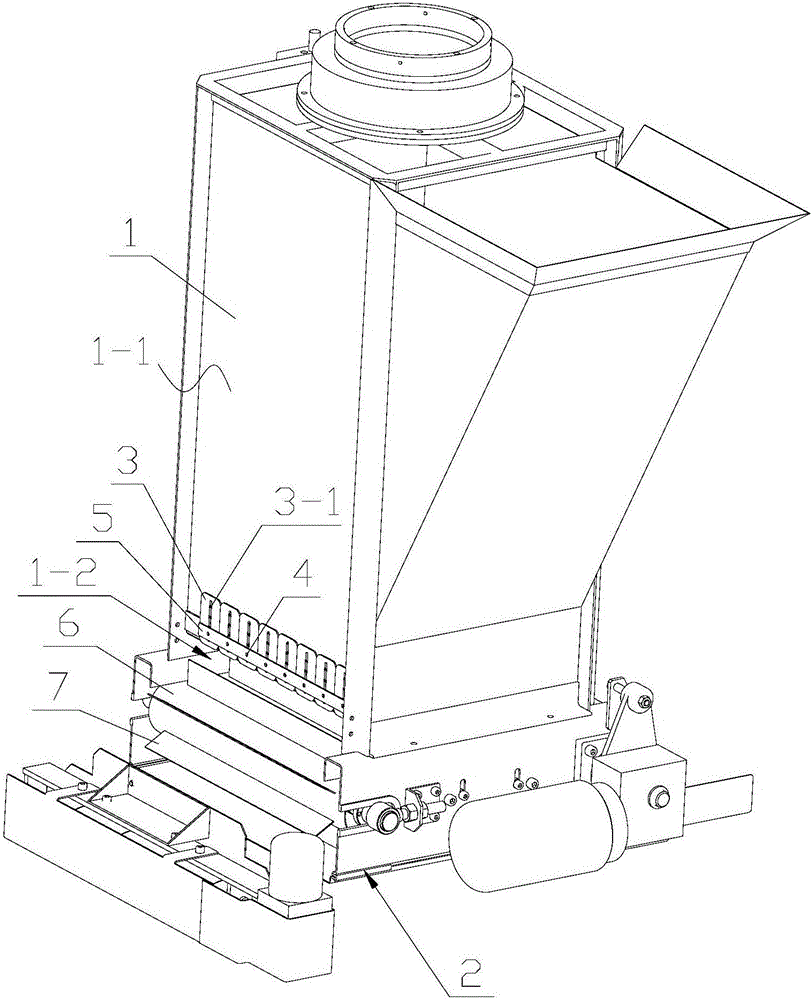

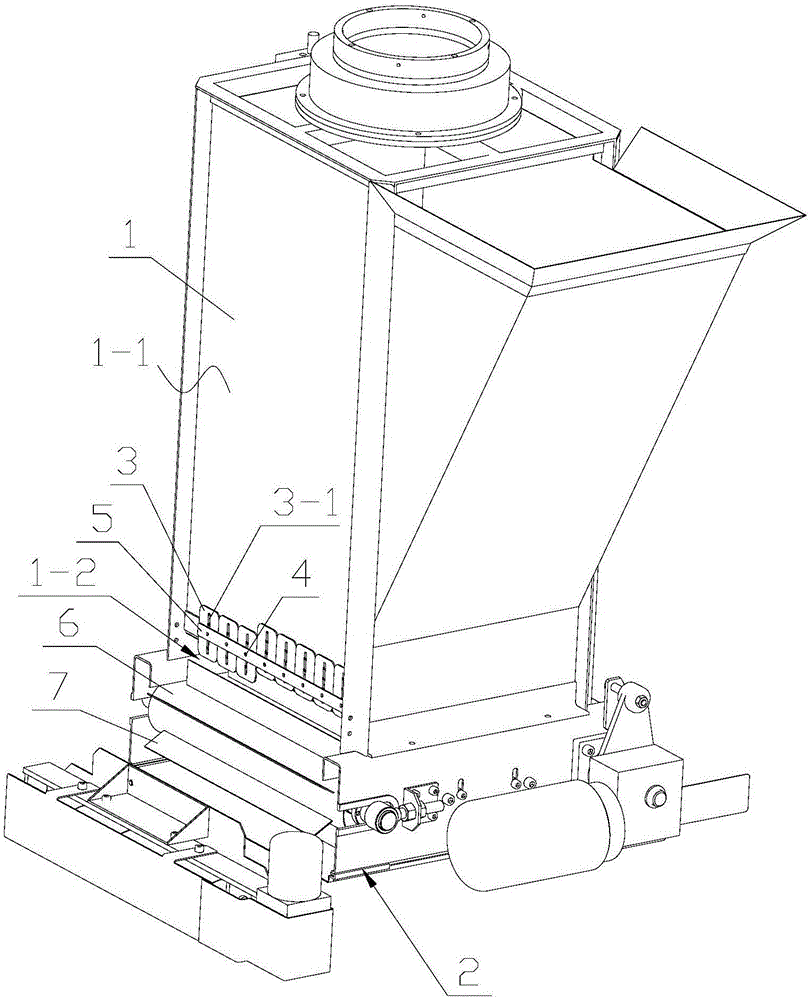

Discharging mechanism for steaming robot

InactiveCN106276309AAdjustable sizePrecise size adjustmentAlcoholic beverage preparationLoading/unloadingEngineeringMaterial distribution

The invention relates to a discharging mechanism for a steaming robot. The discharging mechanism comprises a stock bin and a distributor, wherein the distributor is located under the stock bin; the stock bin is equipped with a discharging port; the discharging port is shielded by a plurality of shielding sheets; the size of the discharging port can be adjusted by changing the size of the area of the discharging port shielded by one, two or more shielding sheets. According to the discharging mechanism for the steam-filling robot provided by the invention, a plurality of shielding sheets are arranged at the discharging port and the size of the discharging port can be adjusted by vertically drawing the shielding sheets, so that the fine adjustment can be realized, the area of the discharging port shielded by each shielding sheet can be adjusted and the function of finely adjusting the size of the discharging port can be achieved; the discharging ports on different parts can be differently arranged according to the requirement of the steam-filling material distribution, so that the different discharging volumes can be controlled; for example, the part close to the inner wall of the steam barrel can discharge more materials than the interior of the steam barrel, so that the lower inner and higher outer of the material distribution surface can be realized; the steaming effect can be promoted; the quality of the white spirit can be further increased.

Owner:CHANGZHOU MINGSEAL ROBOT TECH CO LTD

Green synthetic method of controllable dimension semi-conductor nano cluster and nanocrystalline

ActiveCN101457403BHigh crystallinityHigh fluorescence quantum efficiencyPolycrystalline material growthCadmium compoundsFluorescenceSynthesis methods

The invention provides a green synthesis method of a cadmium selenide nano-cluster and a cadmium selenide nanocrystal with controllable size. In the method, a series of low toxic / economical ligands are adopted, a selenium elementary substance and cadmium oxide dispersed in a non-ligand solvent are taken as precursors, and the cadmium selenide nano-cluster and the cadmium selenide nanocrystal are synthesized in the non-ligand solvent. The size can be adjusted within 0.7nm-13nm by adjusting the proportion of the ligands and the precursors. The obtained nanocrystal has high crystallinity and narrow size distribution fwhm which equals 25 plus or minus 2nm, relatively high fluorescence quantum efficiency which is 5%-38%, and a fluorescence emission spectrum can be adjusted within 450nm-690nm.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

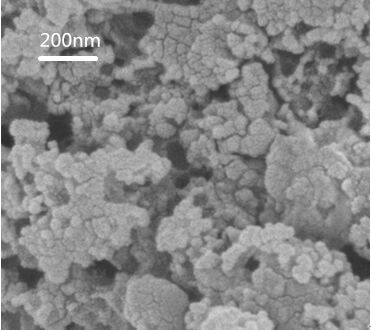

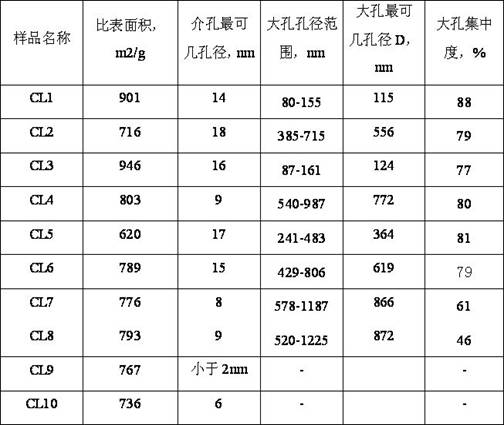

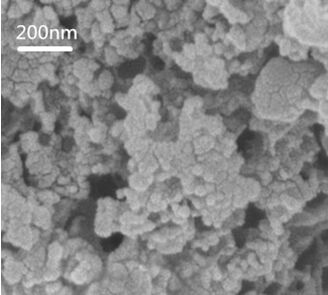

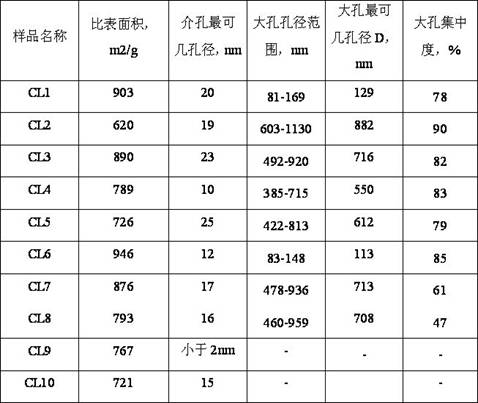

A kind of two-stage porous carbon material and its synthesis method

ActiveCN109928380BPrecise size adjustmentGood repeatabilityNanotechnologyCarbon preparation/purificationMolecular sievePhysical chemistry

The invention provides a carbon material with two-level pore channels, and a synthesis method thereof, wherein the carbon material comprises amorphous carbon, and has two-level pore channels. The synthesis method comprises: screening a Beta molecular sieve; placing the Beta molecular sieve in a sodium benzoate solution, and treating; mixing the Beta molecular sieve, saccharide, an auxiliary agentand water, and carrying out stirring ultrasonic treatment; carrying out drying treatment and high temperature treatment; and finally treating in an alkali solution to obtain the macroporous carbon material. According to the present invention, with the method, the expensive organic additives are not used, and the prepared macroporous carbon material has uniform pore size distribution.

Owner:CHINA PETROLEUM & CHEM CORP +1

A Specimen Clamping Device for Large Diameter Split Hopkinson Pressure Bars

ActiveCN108982209BStable clampingAdjustable sizeStrength propertiesUltimate tensile strengthSplit-Hopkinson pressure bar

Owner:SOUTHWEST JIAOTONG UNIV

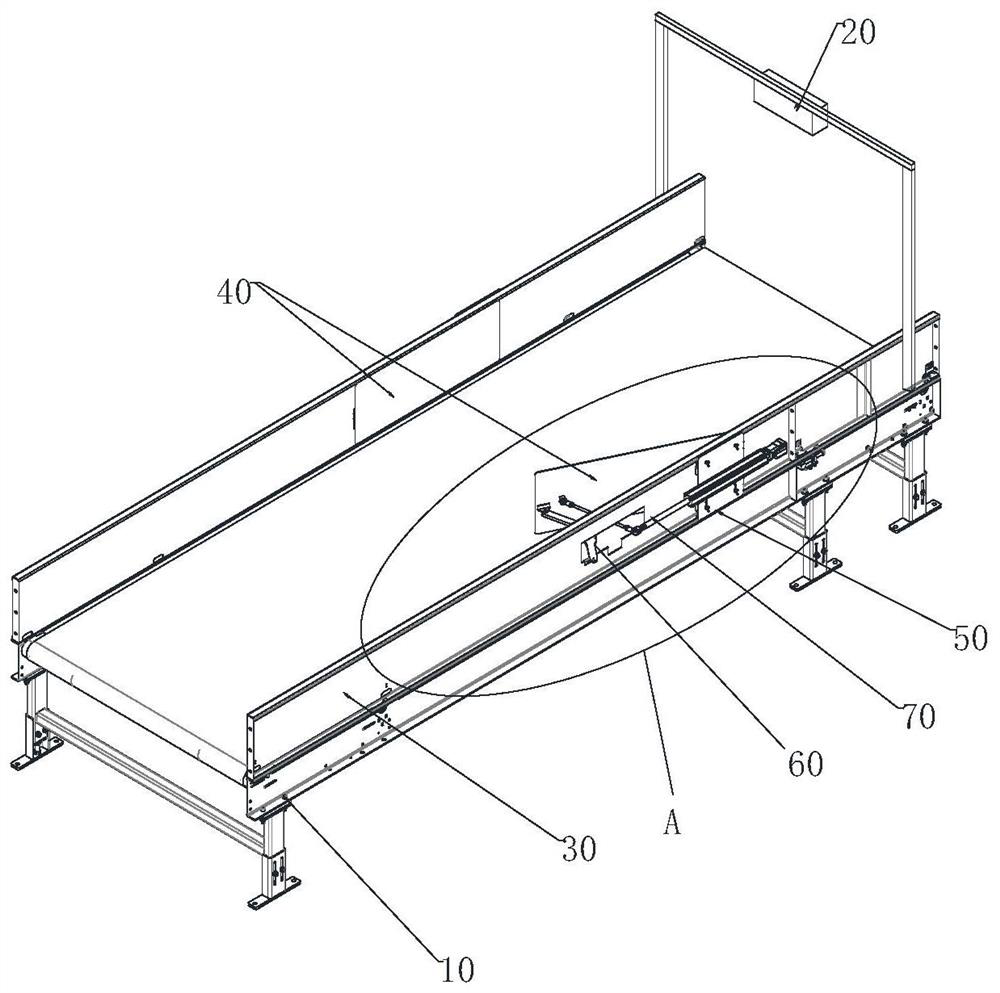

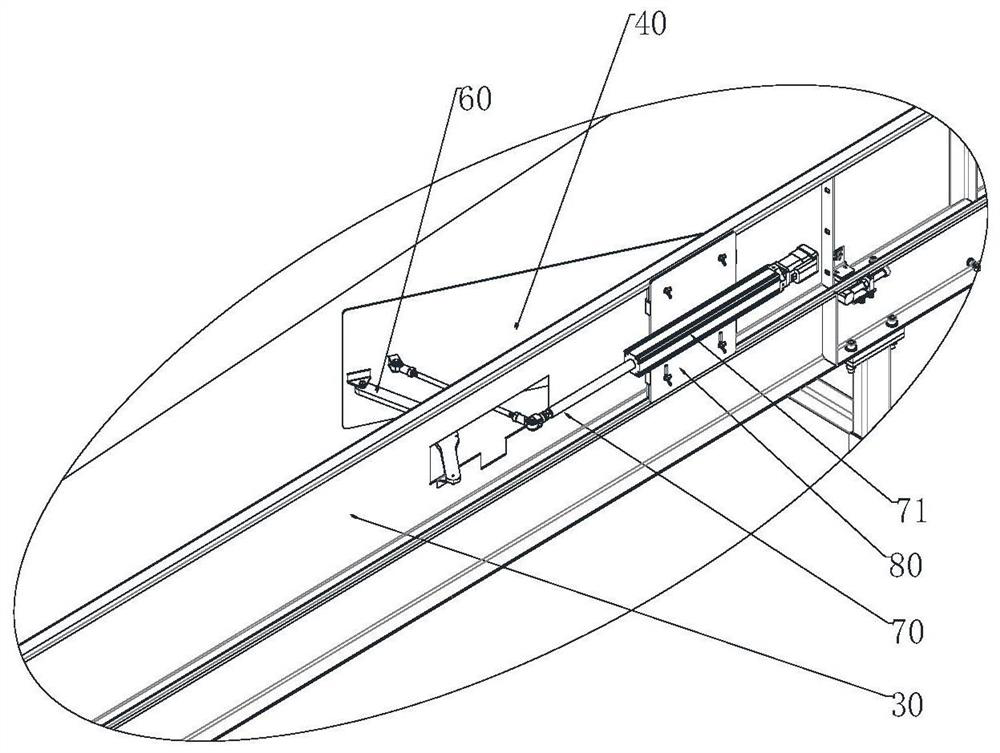

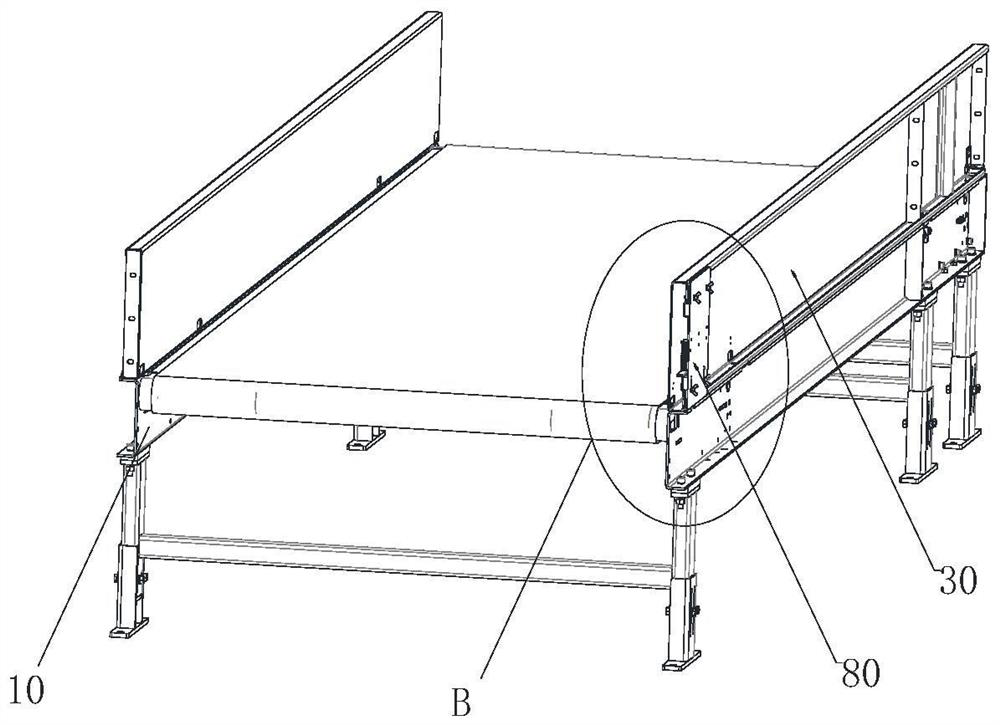

Width dynamically adjustable conveying device

ActiveCN113264306BPrecise size adjustmentAccurate and efficient guidanceConveyorsControl devices for conveyorsStructural engineeringVisual recognition

The width dynamically adjustable conveying device of the present invention is to solve the above-mentioned problems existing in the prior art and obtain the specific shape size and position of the current package based on visual recognition technology, and adopt the method of randomly adjusting the side baffles of the conveying device The opening and closing angle is expected to realize dynamic adjustment of the conveying width at any time and is suitable for fully automatic directional conveying and tallying of multi-standard parcels, so as to realize unimpeded passage of parcels, improve conveying efficiency and prevent congestion. It includes a frame and a visual recognition device arranged vertically above the frame; at least on the baffle on one side of the frame, there is an adjustable baffle driven and connected by an angle adjustment device; the angle adjustment device has a support A rod assembly and a push rod assembly, the push rod assembly includes an electric cylinder installed on the baffle, the output shaft of the electric cylinder is connected to one end of the connecting rod through a connecting fork and a joint bearing, and the other end of the connecting rod is connected to the adjustment baffle through a joint bearing; Connect the support rod assembly between the frame and the adjustment baffle.

Owner:QINGDAO KENGIC AUTOMATION EQUIP CO LTD

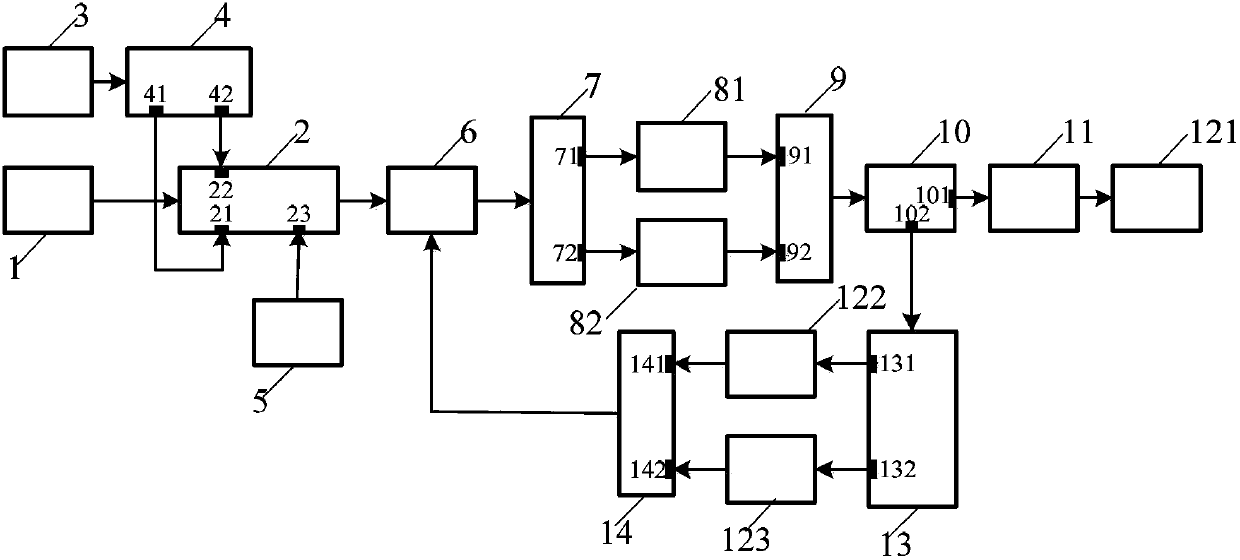

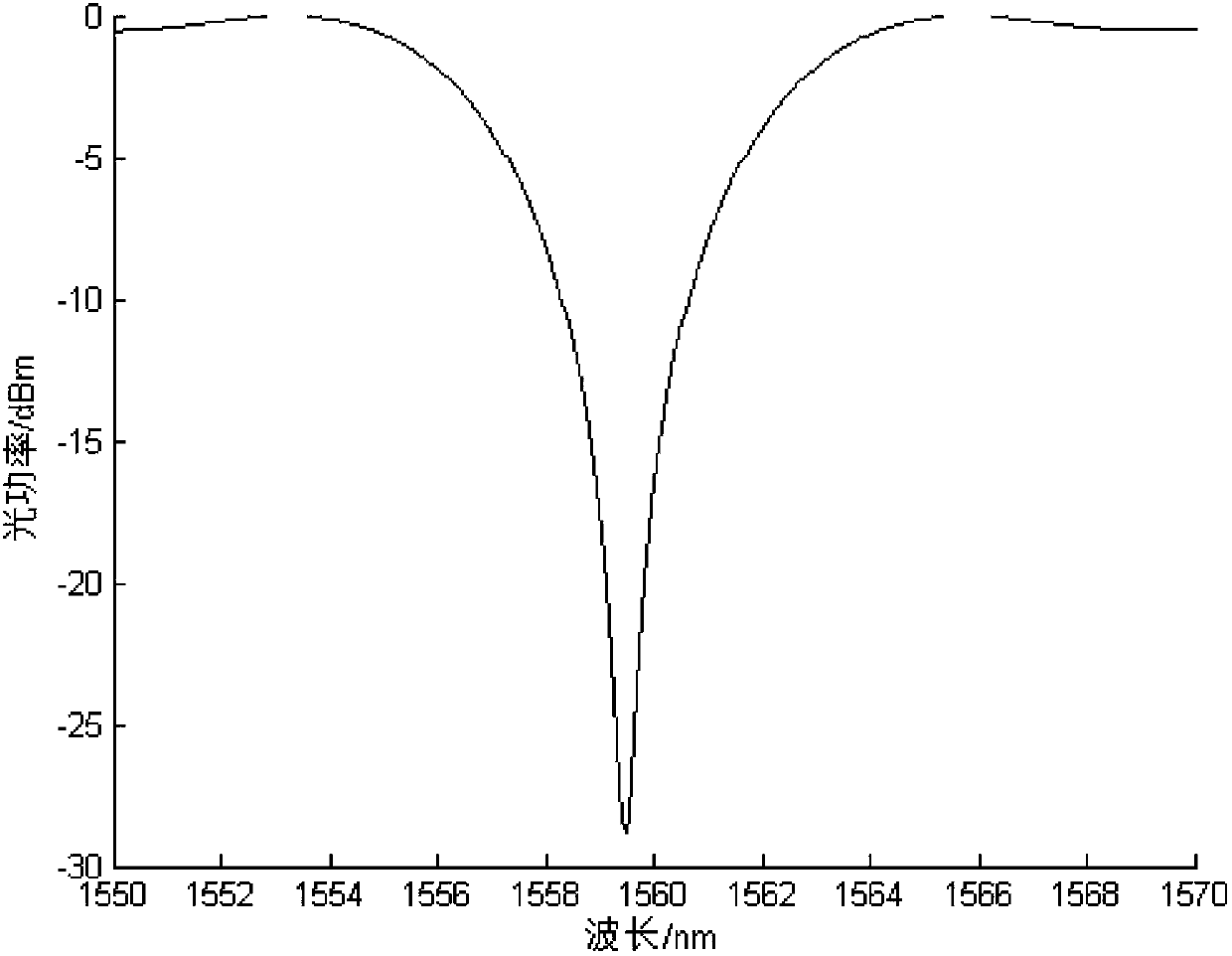

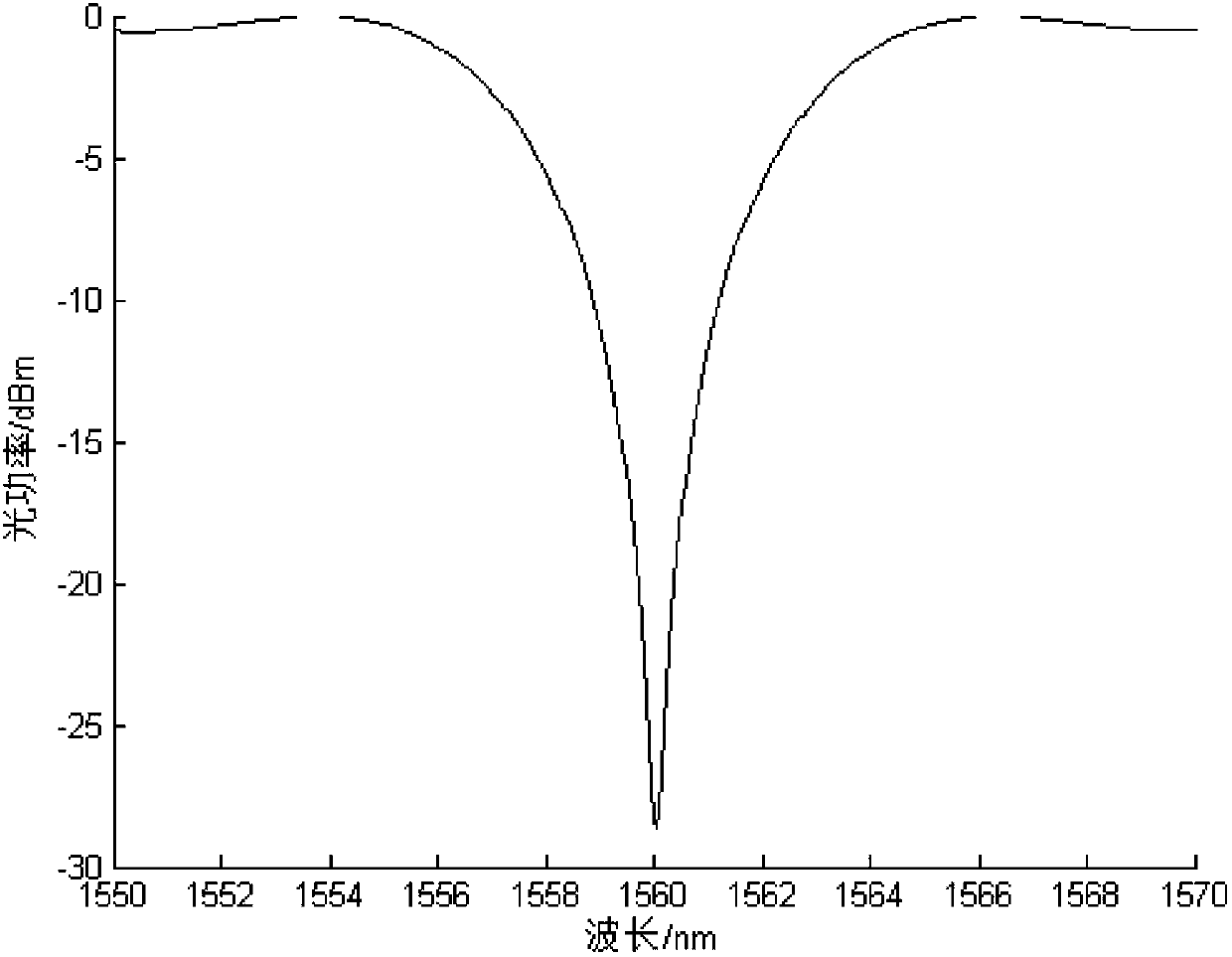

Fiber-optic wireless SSB modulation system with self-adaptive optical carrier ratio

InactiveCN103078682BPrecise size adjustmentEasy to makeElectromagnetic transmissionLong-period fiber gratingGrating

Optical fiber wireless single sideband modulation system with self-adaptive optical load side ratio, involving optical fiber communication, long-period fiber grating, microwave photon technology, the system includes: continuous wave laser (1), two-electrode Mach-Zehnder modulator (2 ), sine wave local oscillator (3), 90-degree power splitter (4), bias voltage regulator (5), dynamic polarization controller (6), polarization beam splitter (7), first long-period optical fiber Grating (81), second long-period fiber grating (82), polarization beam combiner (9), Y splitter (10), optical fiber (11), first photodetector (121), optical interleaver (13) , a second photodetector (122), a third photodetector (123), and a current comparator (14). The above devices are connected sequentially. The invention can make the change of the optical load side ratio of the single sideband modulation signal adaptive to system parameters, and keep it at 0dB all the time, so as to maintain the system performance in the optimal state.

Owner:QINGDAO AGRI UNIV

An electromagnetically controlled low-frequency ultrasonic secondary atomization nozzle

InactiveCN104874515BAvoid collisionReduce noiseSpray nozzlesLiquid spraying apparatusLow frequency ultrasoundPhysics

Owner:JIANGSU UNIV

A kind of carbon material and its synthesis method

ActiveCN109928382BPrecise size adjustmentGood repeatabilityCarbon preparation/purificationMolecular sievePhysical chemistry

The present invention provides a carbon material and a synthesis method thereof, wherein the carbon material comprises amorphous carbon, and has two-level pore channels. The synthesis method comprises: screening a Beta molecular sieve; placing the Beta molecular sieve in a sodium benzoate solution, and treating; mixing the Beta molecular sieve, saccharide, a silica sol and water, and carrying outstirring ultrasonic treatment; carrying out drying treatment and high temperature treatment; and finally treating in an alkali solution to obtain the macroporous carbon material. According to the present invention, with the method, the expensive organic additives are not used, and the prepared macroporous carbon material has uniform pore size distribution.

Owner:CHINA PETROLEUM & CHEM CORP +1

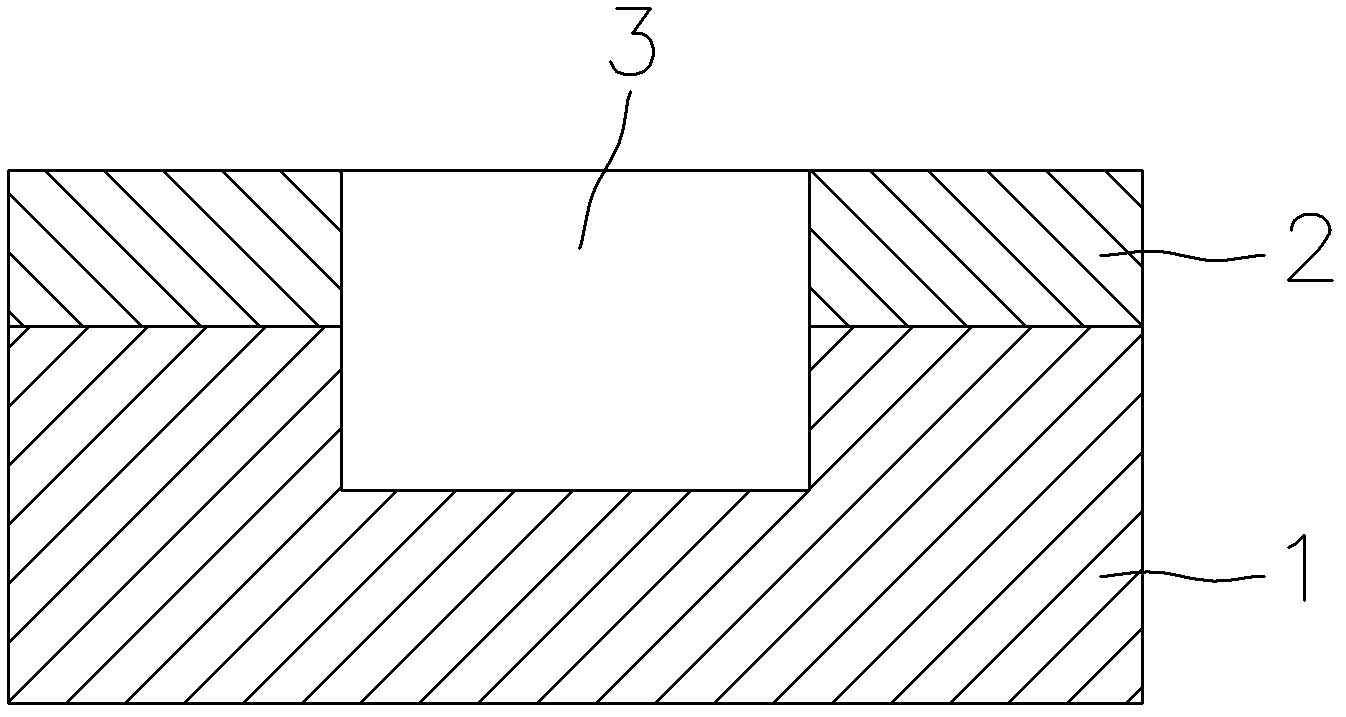

Injection mold capable of adjusting length of pipe fitting

PendingCN112109283AEasy to assemble and disassembleEasy to adjustTubular articlesPhysicsPipe fitting

The invention discloses an injection mold capable of adjusting the length of a pipe fitting. The injection mold comprises a fixed mold plate, a movable mold plate and a mold core. A first cavity blockis arranged on the fixed mold plate, a second cavity block is arranged on the movable mold plate, and the first cavity block and the second cavity block form a tubular cavity with an opening. The mold core is arranged in the tubular cavity in a core pulling manner from the opening, the outer wall of the mold core, the inner wall of the first cavity block and the inner wall of the second cavity block form a tubular forming cavity, the mold core is sleeved with an adjusting sleeve, and the inner end of the adjusting sleeve stretches into the tubular forming cavity. An axial adjusting and fixingdevice is arranged at the opening of the tubular cavity. After the adjusting sleeve slides to a required position on the mold core, the adjusting sleeve is fixed to the axial adjusting and fixing device so as to change the length of the tubular forming cavity. According to the scheme, adjustment is convenient, direct operation can be conducted on a machine table, size adjustment is accurate, andformed products do not need to be cut.

Owner:BESTTER XIAMEN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com