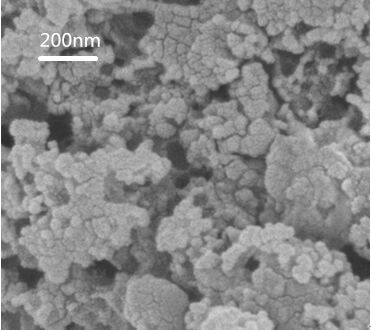

A kind of two-stage porous carbon material and its synthesis method

A synthesis method and technology of carbon materials, applied in the preparation/purification of carbon, crystalline aluminosilicate zeolite, nanotechnology, etc., can solve the problems of uneven distribution of material pores, long time-consuming template assembly, difficult industrial production, etc., to achieve Uniform pore size distribution, low production cost and high reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

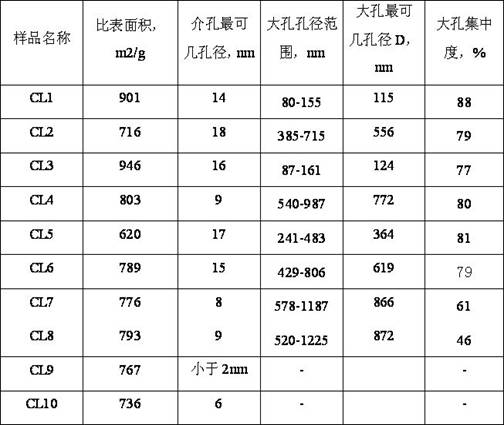

Embodiment 1

[0043] (1) Dissolve 0.43 g of sodium hydroxide in 40 mL of 25wt% TEAOH and 20 mL of distilled water, and stir for 30 min. Then add 0.7 g of sodium aluminate and stir for 30 min. Add 12 g of white carbon black slowly and stir for 30 min. Then put it into a closed reactor and crystallize in an oven at 140°C for 50 h. Then the obtained product was washed with distilled water until neutral, and then dried at 120° C. for 12 hours to obtain a Beta molecular sieve.

[0044] (2) Put the Beta molecular sieve obtained in step (1) into 50 mL of 50wt% propylene glycol solution and allow it to settle naturally. When the molecular sieve has just settled to the bottom, take out 1 / 3 of the solution in the middle of the entire solution and filter it. Dry at 120°C for 10h.

[0045] (3) Mix the Beta molecular sieve obtained in step (2) with 5mL of 10wt% sodium benzoate solution, sonicate for 20min, the frequency of the ultrasonic wave is 0.01MHz, and the power is 20W / L according to the volume...

Embodiment 2

[0051] (1) Dissolve 0.14 g of sodium hydroxide in 23 mL of 25 wt% TEAOH and 20 mL of distilled water, and stir for 30 min. Then add 0.7 g of sodium aluminate and stir for 30 min. Add 12 g of white carbon black slowly and stir for 30 min. Then put it into a closed reactor and crystallize in an oven at 160°C for 20 h. Then the obtained product was washed with distilled water until neutral, and then dried at 120° C. for 12 hours to obtain a Beta molecular sieve.

[0052] (2) Put the Beta molecular sieve obtained in step (1) into 50 mL of 70wt% propylene glycol solution and allow it to settle naturally. When the molecular sieve has just settled to the bottom, take out 1 / 5 of the solution in the middle of the entire solution and filter it. Dry at 120°C for 10h.

[0053] (3) Mix the Beta molecular sieve obtained in step (2) with 6mL of 18wt% sodium benzoate solution, ultrasonically treat for 20min, the frequency of ultrasonic is 0.88MHz, and the power is 100W / L according to the v...

Embodiment 3

[0059] (1) Dissolve 1.32 g of sodium hydroxide in 30 mL of 25% TEAOH and 15 mL of distilled water, and stir for 30 min. Then add 1 g of sodium aluminate and stir for 30 min. Then slowly add 10g of white carbon black and stir for 30 min. Then put it into a closed reactor and crystallize in an oven at 105°C for 50 h. Then the obtained product was washed with distilled water until neutral, and then dried at 120° C. for 12 hours to obtain a Beta molecular sieve.

[0060] (2) Put the Beta molecular sieve obtained in step (1) into 80mL of 10wt% propylene glycol solution, and let it settle naturally. When the molecular sieve has just settled to the bottom, take out 1 / 7 of the solution in the middle of the whole solution, filter it, and keep it at 120°C Dry for 10h.

[0061] (3) Mix the Beta molecular sieve obtained in step (2) with 5mL of 10wt% sodium benzoate solution, ultrasonically treat for 20min, the frequency of ultrasonic is 0.92MHz, and the power is 50W / L according to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com