Injection mold capable of adjusting length of pipe fitting

An injection mold and adjustable technology, which is applied to household appliances, tubular objects, and other household appliances, etc., can solve the problems of complicated adjustment methods, achieve the effects of convenient disassembly, reduction of processing procedures, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

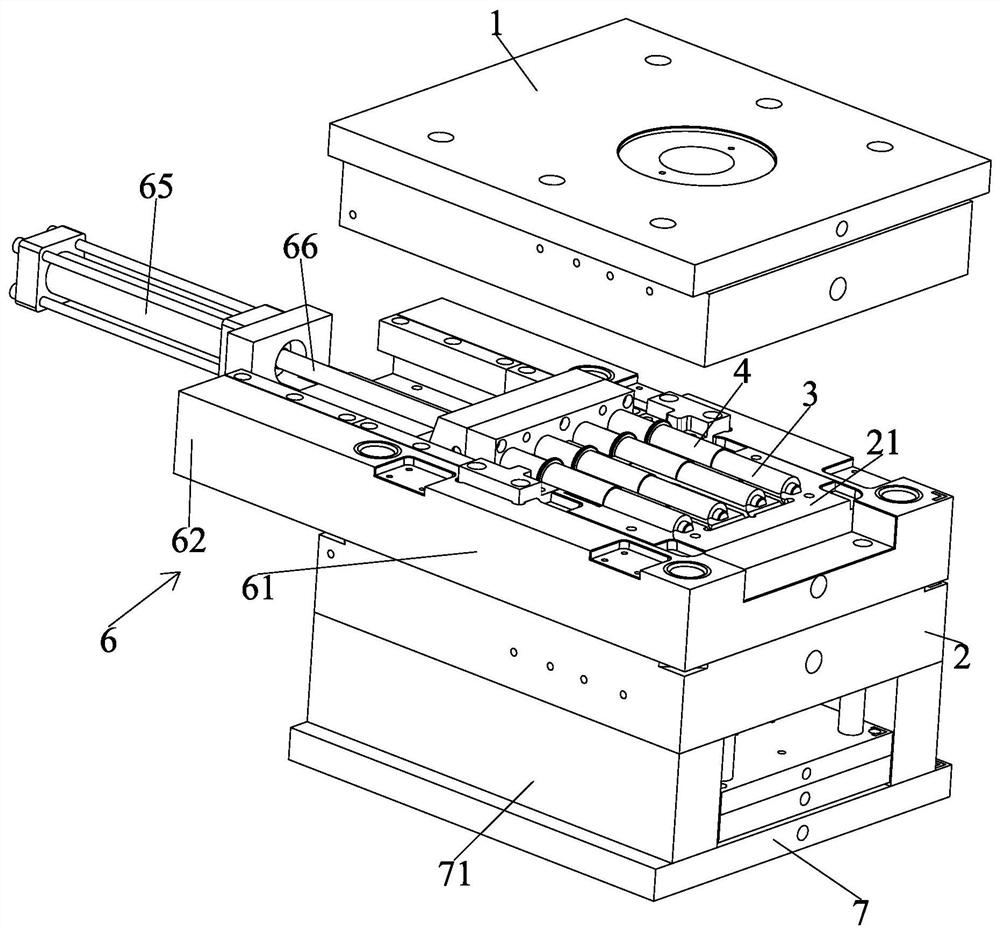

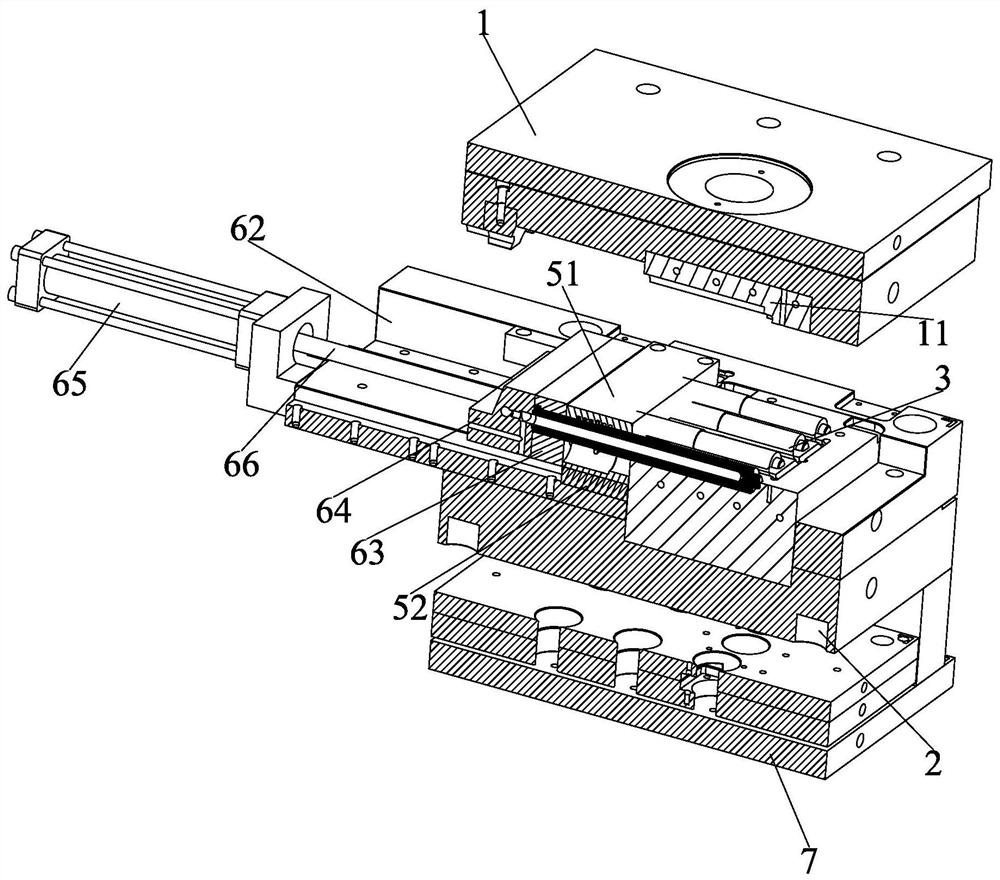

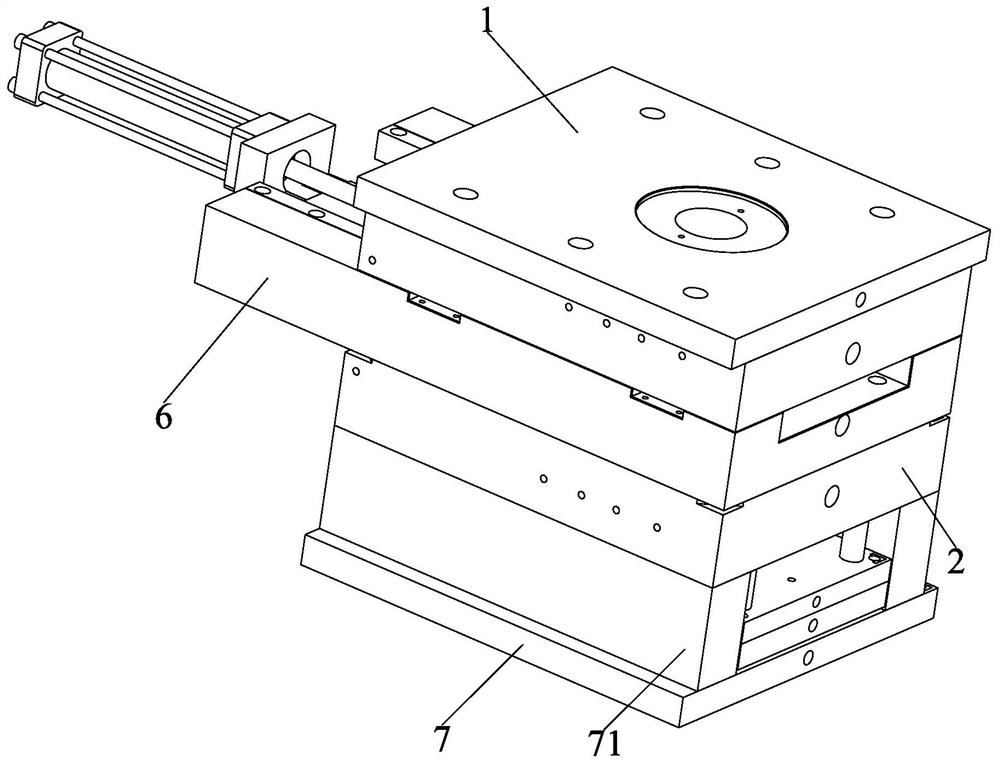

[0037] Such as Figure 1-13 As shown, the present invention provides a kind of injection mold that can adjust the length of pipe fittings, comprises fixed template 1, movable template 2 and core 3, and described fixed template 1 is provided with first cavity block 11, and described movable template 2 is provided with The second cavity block 21, the first cavity block 11 and the second cavity block 21 form a tubular cavity with an opening, and the core 3 is core-pulled from the opening and placed inside the tubular cavity, so The outer wall of the core 3, the inner wall of the first cavity block 11, and the inner wall of the second cavity block 21 form a tubular forming cavity,

[0038] The core 3 is sleeved with an adjustment sleeve 4, and the inner end of the adjustment sleeve 4 extends into the tubular forming cavity; the opening of the tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com