Width dynamically adjustable conveying device

A technology of conveying device and angle adjusting device, applied in conveyor control device, conveyor, storage device, etc., can solve the problems of equipment docking and conveying safety hazards, few solutions for packages, and reduced conveying efficiency, etc., to save labor The effect of cost, infinite adjustment of opening and closing angle, and short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

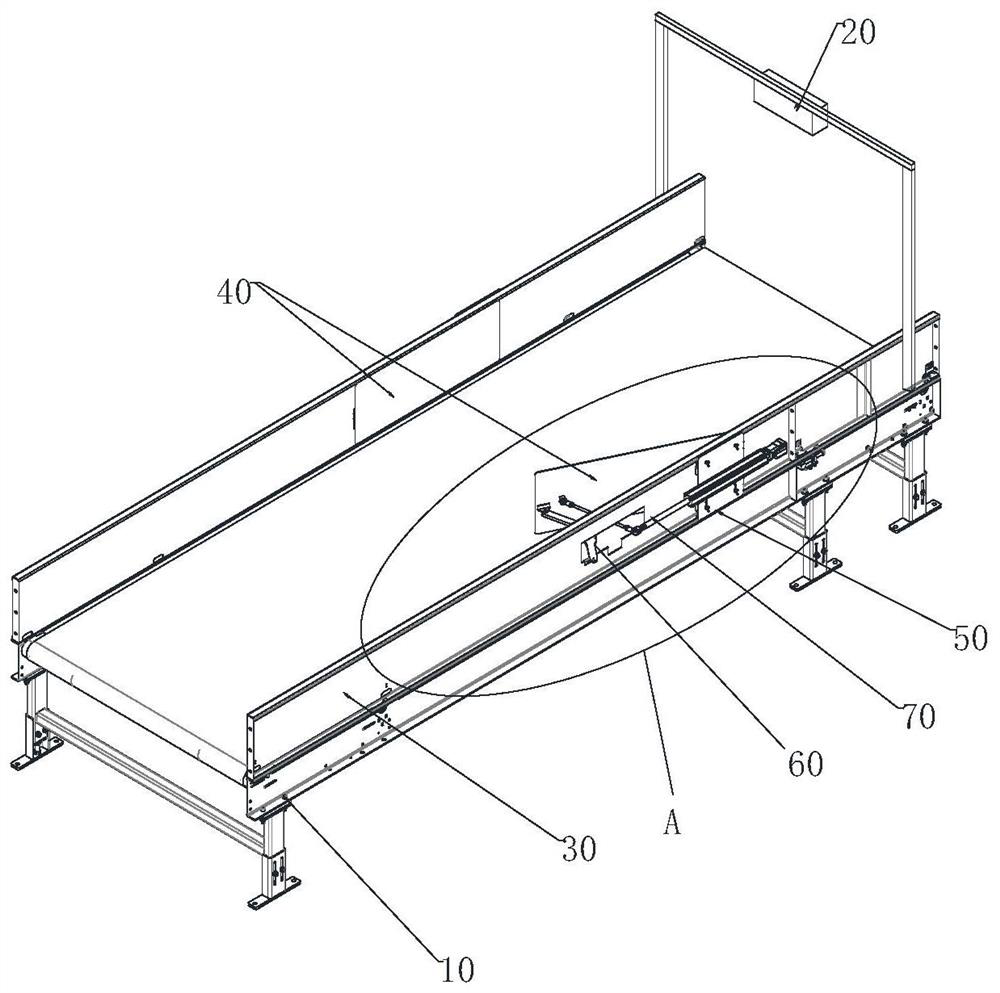

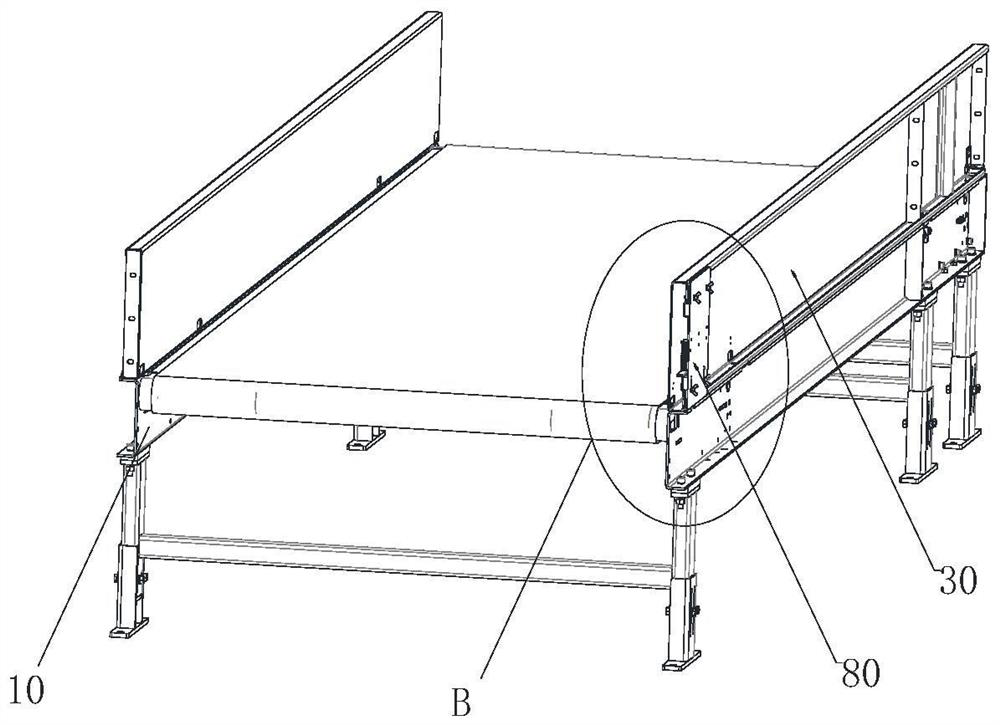

[0036] Example 1, as Figure 1 to Figure 10 As shown, the width dynamically adjustable conveying device described in this application includes a frame 10 and a visual recognition device 20 arranged vertically above the frame 10;

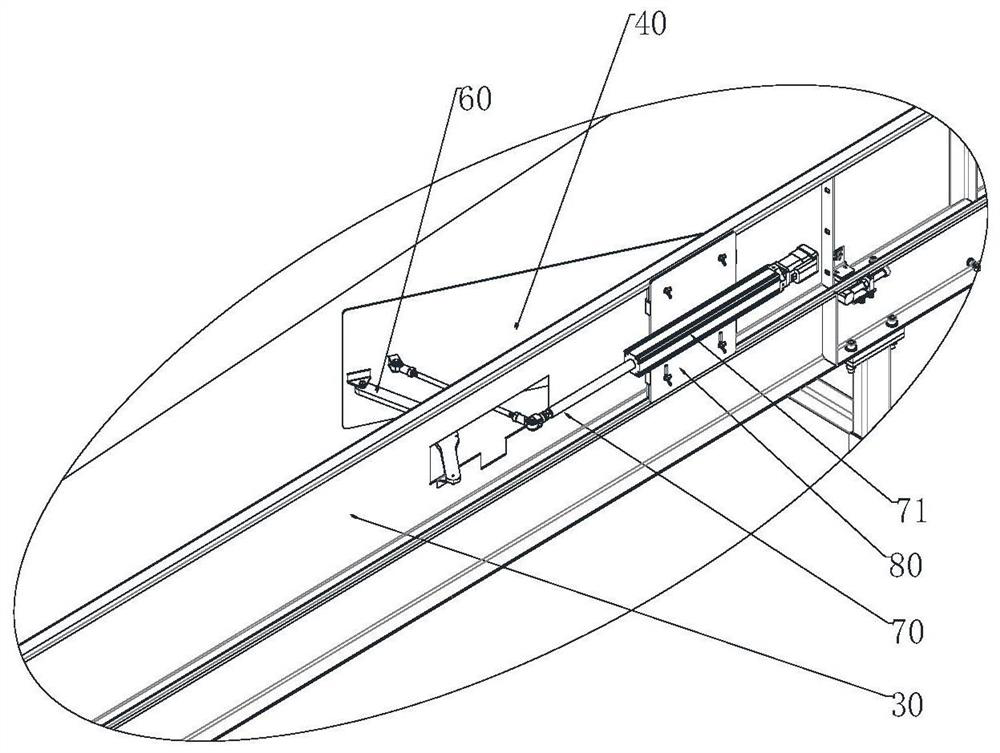

[0037] Adjustment baffles 40 are movably provided on both side baffles 30 of the frame 10 and are driven and connected by an angle adjustment device 50 .

[0038] In order to realize the conveyance of packaged goods, the said width dynamically adjustable conveying device can be a roller conveyor, a belt conveyor or a balance wheel conveyor;

[0039] Along the package conveying direction, the visual recognition device 20 is arranged at the front end of the adjustment baffle 40, so as to adjust the opening and closing angle of the adjustment baffle 40 in real time through the angle adjustment device 50 according to the package size data and position information obtained by real-time detection. The conveying width is changed accordingly, so as to guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com