Test piece clamping device for large-diameter split Hopkinson pressure bar

A Hopkinson pressure rod, separated technology, applied in the field of specimen clamping device of large diameter separated Hopkinson pressure rod, can solve the problems of low positioning accuracy, insufficient support reliability of specimen clamping device, etc. , to achieve the effect of stable clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

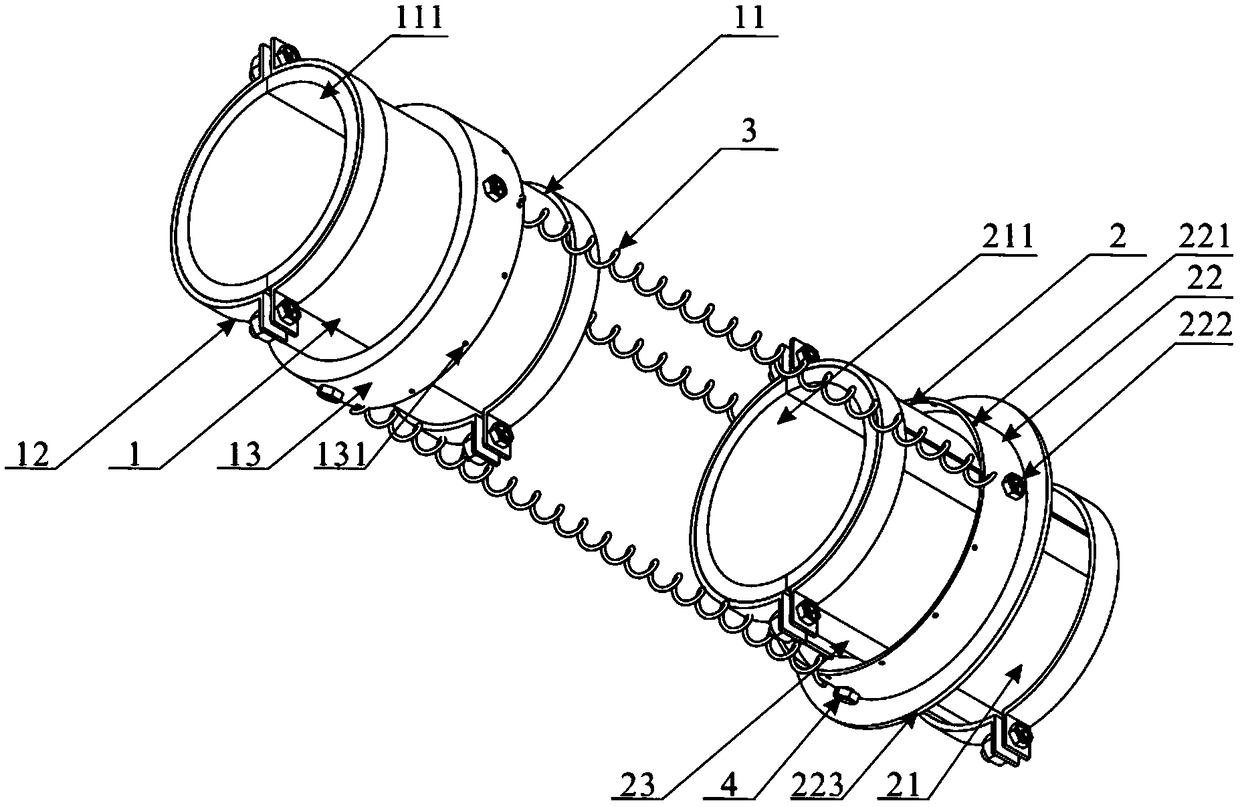

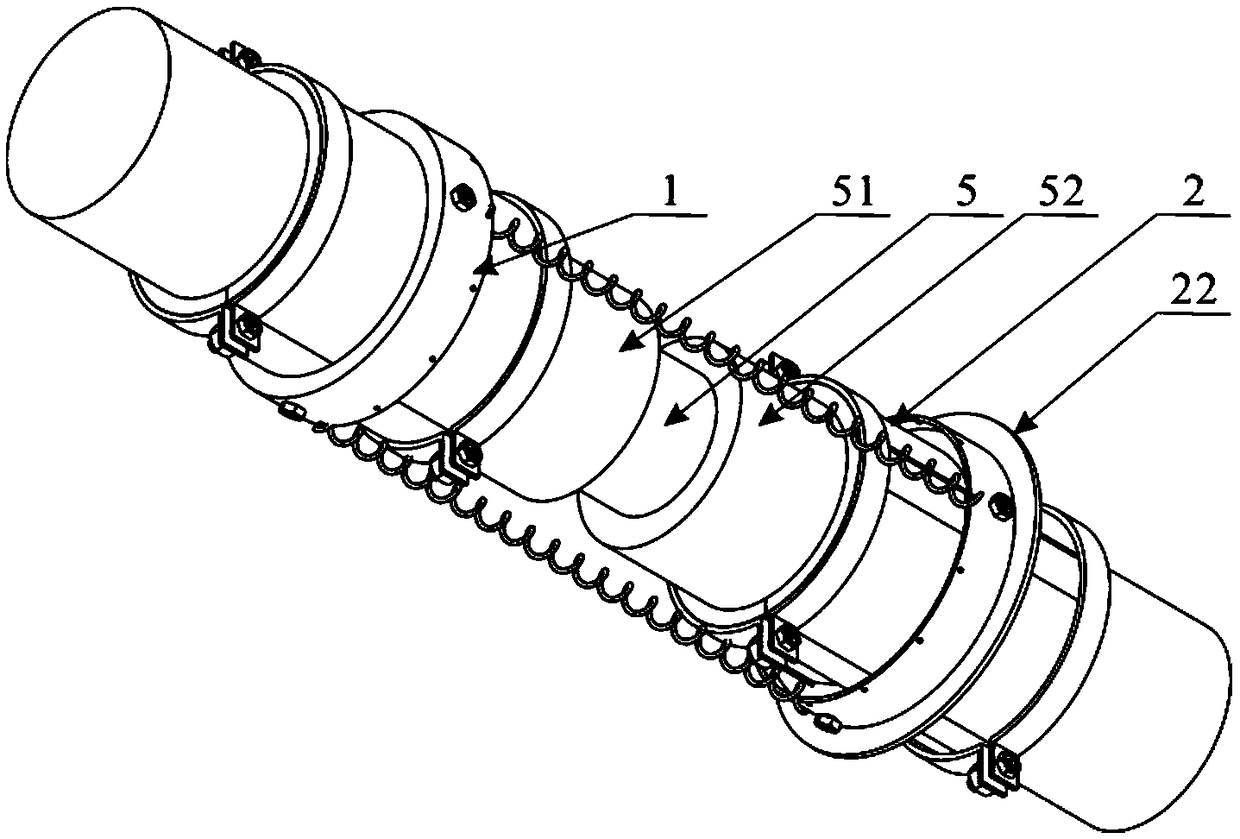

[0027] Such as figure 1 As shown in , it is a schematic structural diagram of the specimen clamping device of the large-diameter split Hopkinson compression bar.

[0028] The specimen clamping device of the large-diameter separated Hopkinson compression bar of the present invention includes a fixed end 1 and a sliding end 2, the fixed end 1 includes a fixed sleeve 11, and a fixed collar 13 is sleeved on the fixed sleeve 11. A number of fixing holes 131 are evenly distributed on the collar 13; the fixing sleeve 11 is composed of two semicircular fixing sleeve plates 111 spliced together.

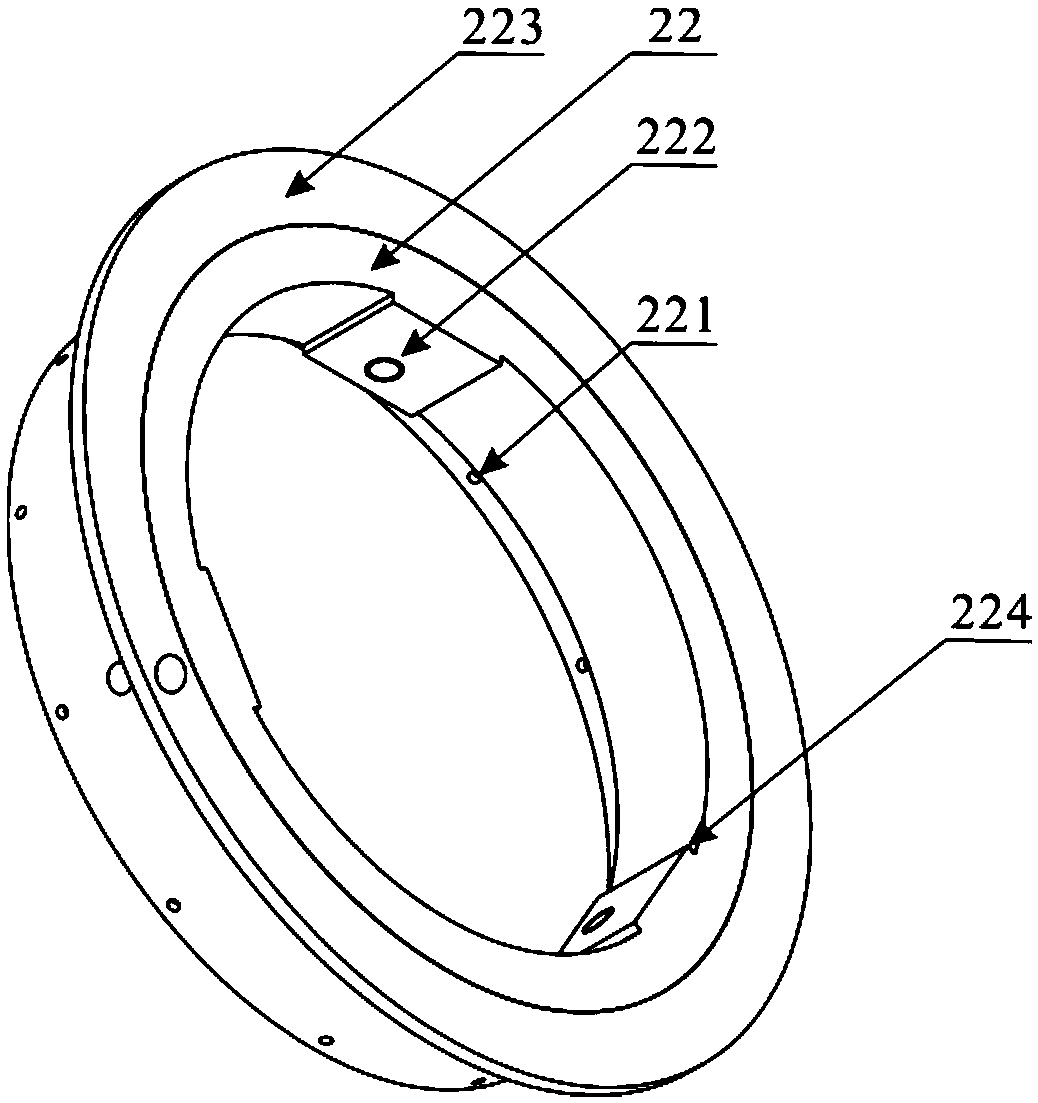

[0029] The sliding end 2 includes a sliding sleeve 21 , and the sliding sleeve 21 is formed by splicing two semicircular sliding sleeve plates 211 . Both ends of the fixed sleeve 11 and the sliding sleeve 21 are respectively sleeved with snap rings 12, and the snap rings 12 are formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com