Lateral feeding-type hydrocyclone

A technology of side feed and cyclone, which is applied in the direction of swirl devices and devices in which the axial direction of the swirl can be reversed, etc., can solve the problem of increasing equipment investment and operating costs, mixing intensity cannot be adjusted at any time, and is difficult to predict, etc. problem, achieve the effect of optimizing reaction residence time, reducing energy consumption and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

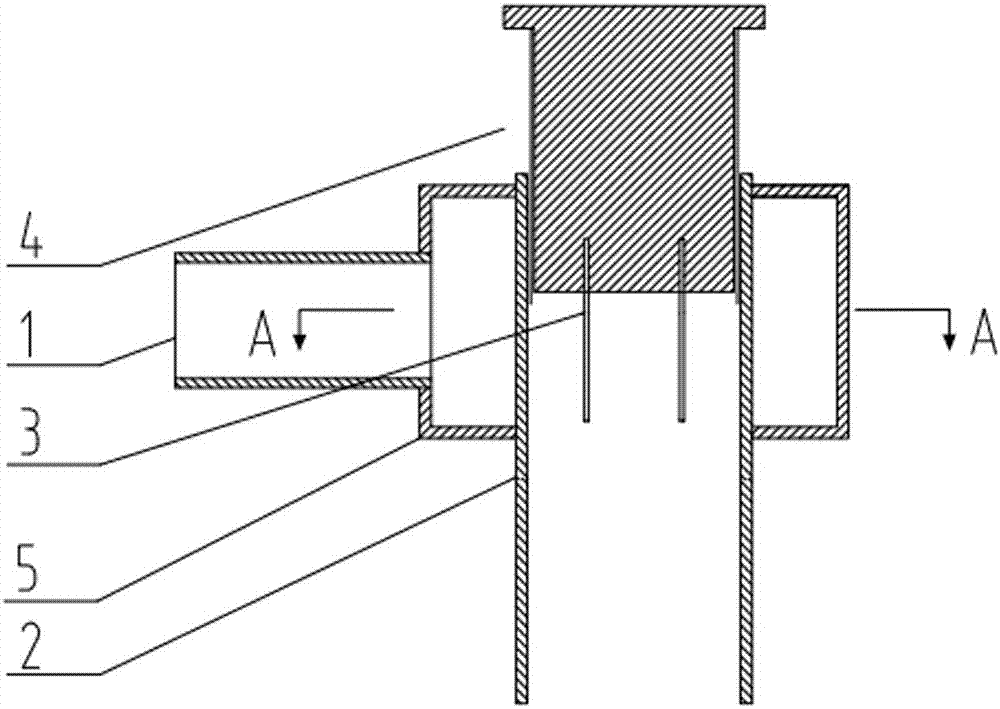

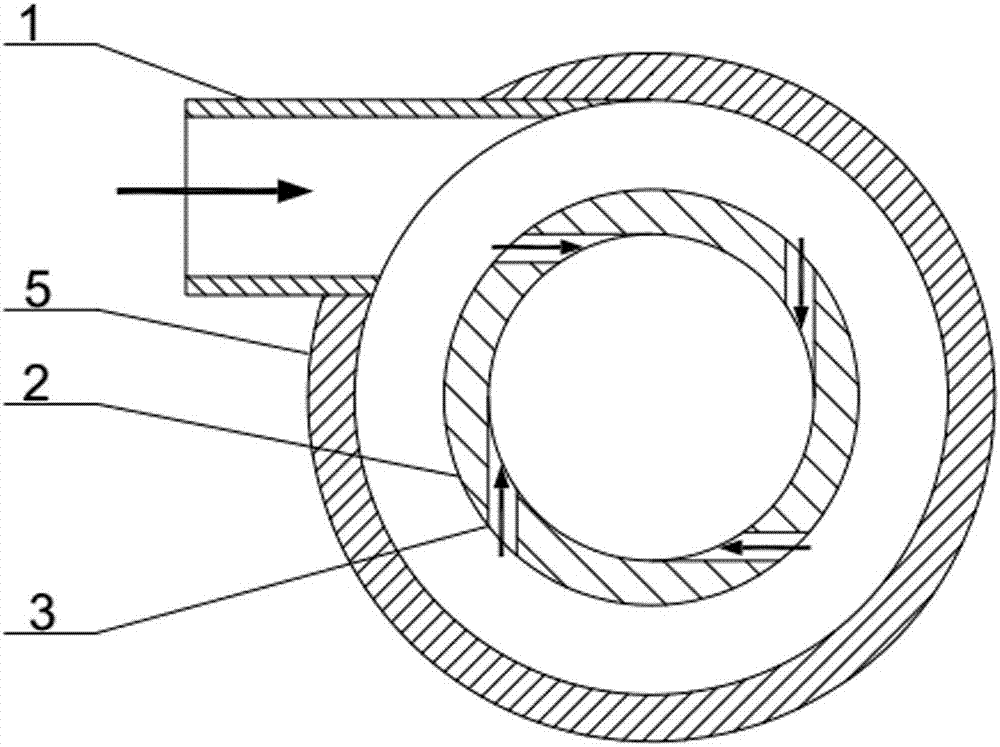

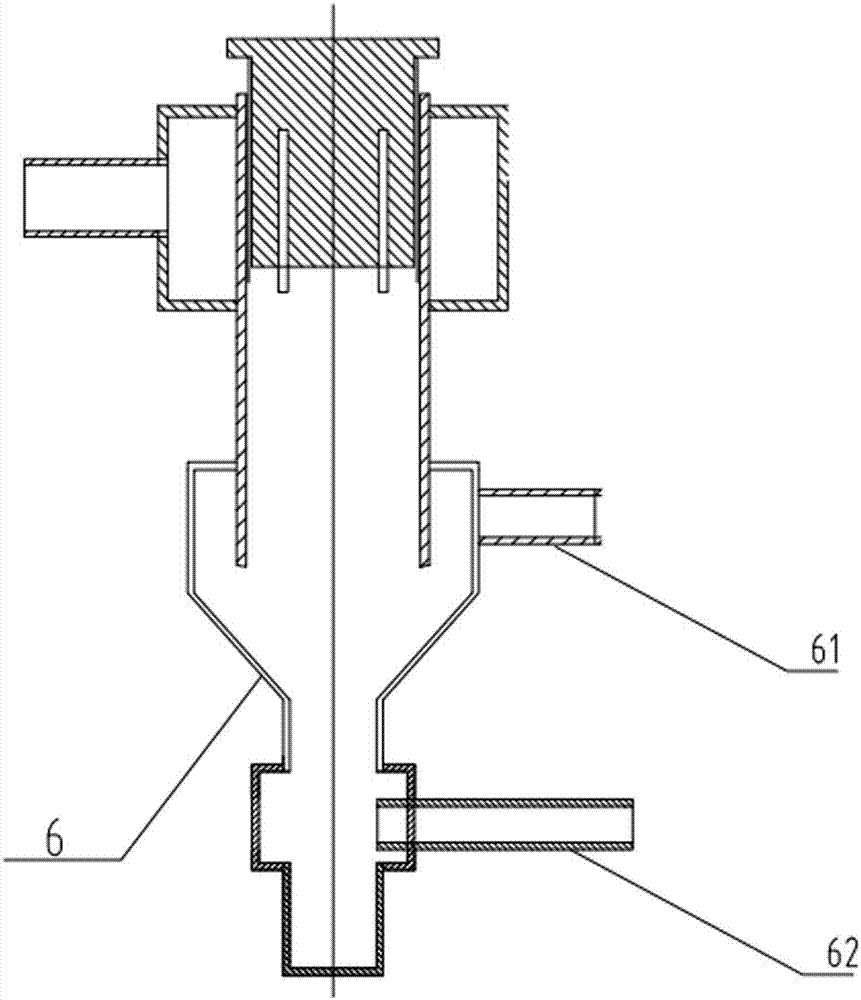

[0022] Such as figure 1 , figure 2 As shown, the side feed type cyclone includes a feed pipe 1 , a swirl pipe 2 , a flow rate regulating valve 4 and an outer jacket 5 . Wherein, the outer jacket 5 is sleeved on the outside of the swirl tube 2, and the upper and lower ends of the outer jacket 5 are sealed with the outer wall of the swirl tube 2; the flow rate regulating valve 4 is arranged on the swirl tube 2 The upper end and the outside of the outer jacket, and cooperate with the swirl tube 2, the feed tube 1 is horizontally arranged in the middle of the outer jacket 5, and the swirl tangential direction is set in the middle of the swirl tube 2 inside the outer jacket 5 Slit 3.

[0023] Further, the outer jacket 5 is composed of an outer jacket tube, an upper annular sealing cover and a lower annular sealing cover, the outer jacket tube and the upper and lower annular sealing covers are connected by flanges, screws or welding, and the upper part of the outer jacket 1. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com