Economical concrete carbonization test box

A technology of carbonization test chamber and concrete, which is applied in the field of test chambers, can solve the problems of increasing the air pressure in the chamber, large loss of carbon dioxide, complex structure of the chamber, etc., and achieves small loss of carbon dioxide, small loss of carbon dioxide, and good gas uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

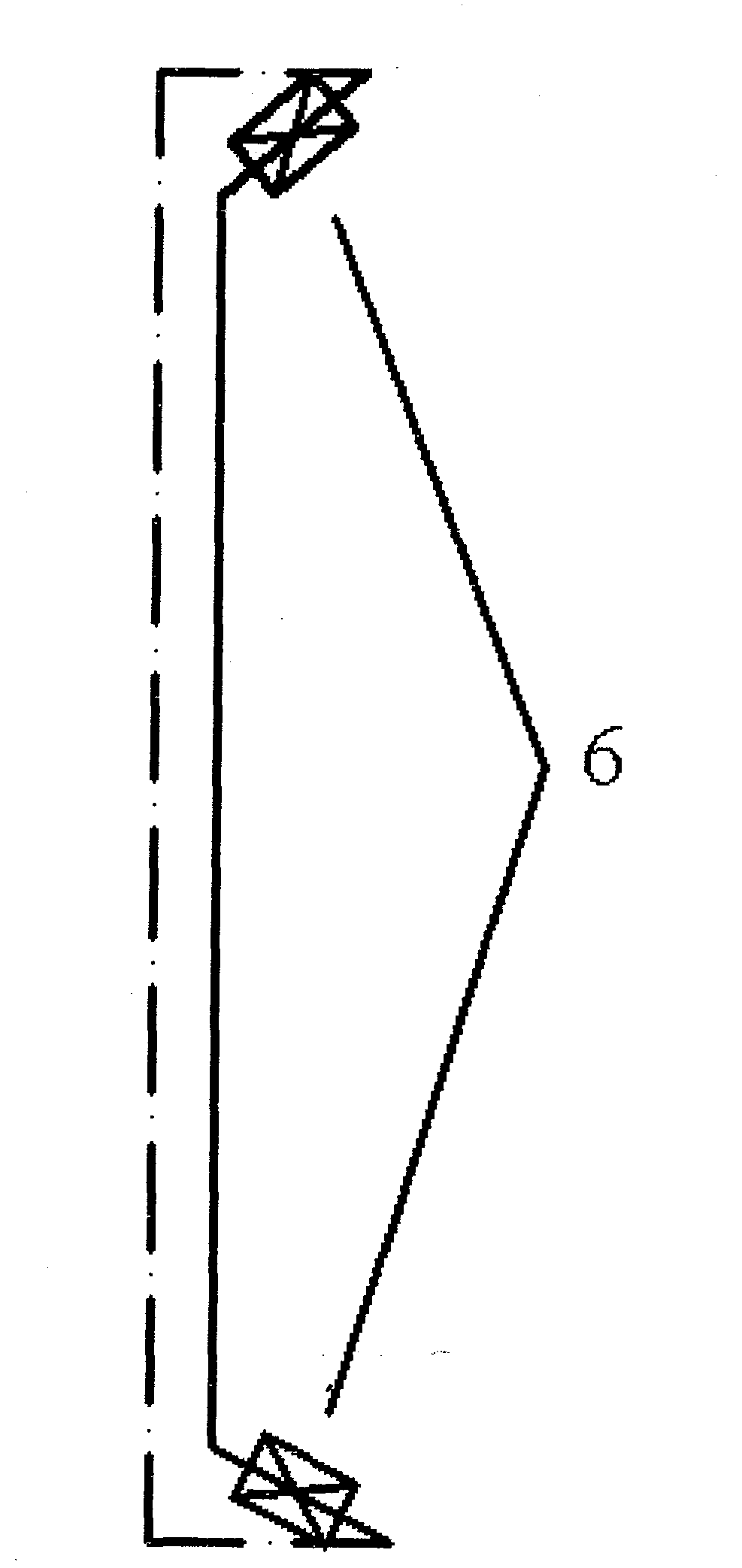

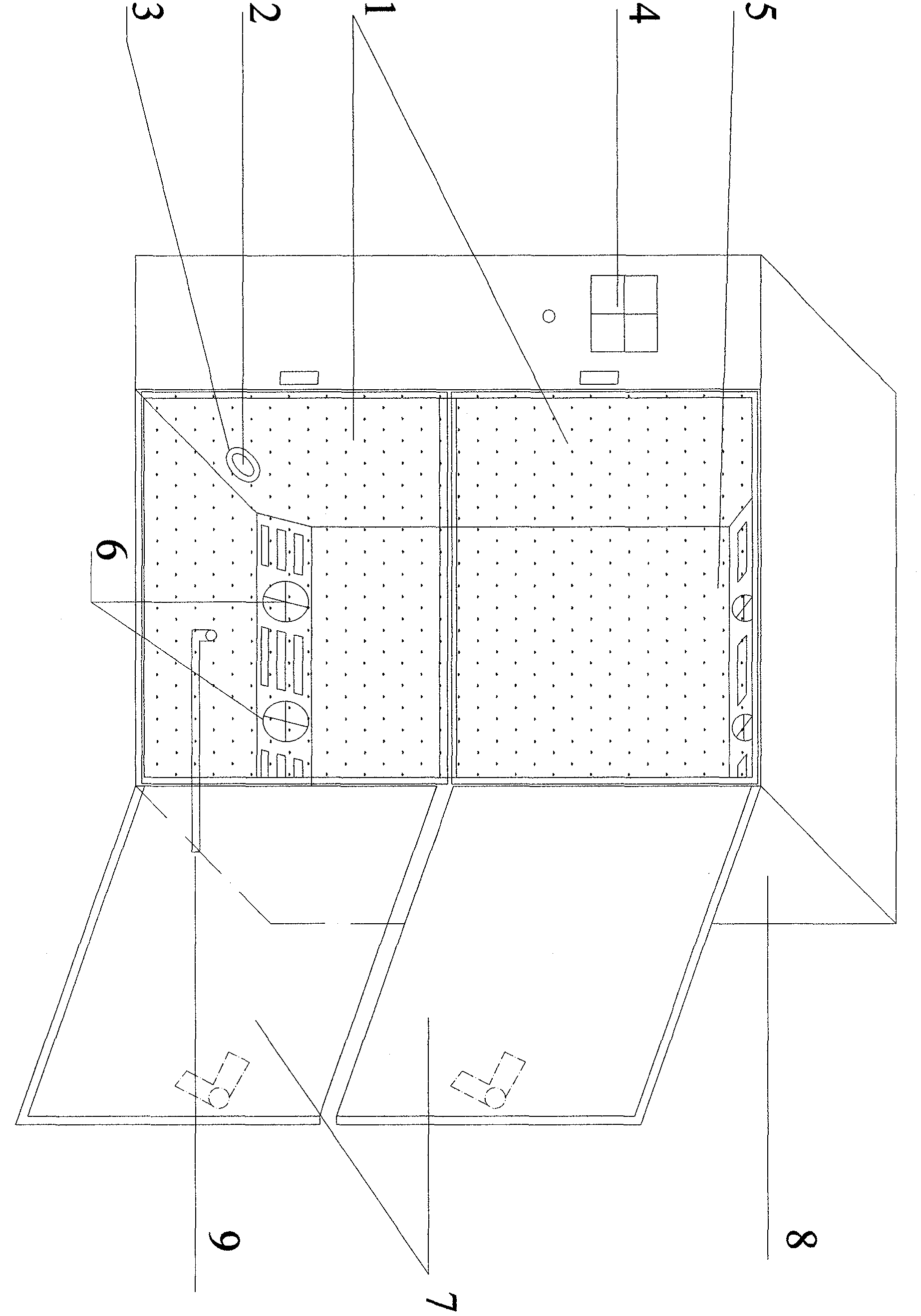

[0016] see figure 1 , an economical concrete carbonation test chamber, mainly includes a temperature and humidity control system, a carbon dioxide concentration control system and a chamber. Since the temperature and humidity control system and the carbon dioxide concentration control system are the same as those of the prior art, they are not shown in the accompanying drawings, and will not be repeated here. Described box body is made up of box door 7 and box cabinet 8, and described box body is provided with controller 4, and described box body is provided with gas circulation device 5, and described box body is provided with exhaust fan 2 and The valve 3 is provided with a switchable drain 9 at the bottom, and a door curtain 1 is provided outside the door frame of the cabinet 8 . The gas circulation device 5 is provided with an auxiliary fan 6 . The exhaust fan 2 , the valve 3 and the auxiliary fan 6 are connected with the control system 4 .

[0017] First, the door 7 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com