Double-roll crusher with rollers with fixed shaft support structure

A technology of roller crusher and supporting structure, which is applied in the direction of grain processing, etc. It can solve the problems of inability to guarantee equipment safety, high crushing cost, and difficulty in accurately judging whether there is iron or not, so as to avoid insufficient system robustness and improve system robustness. Rodability, the effect of reducing crushing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

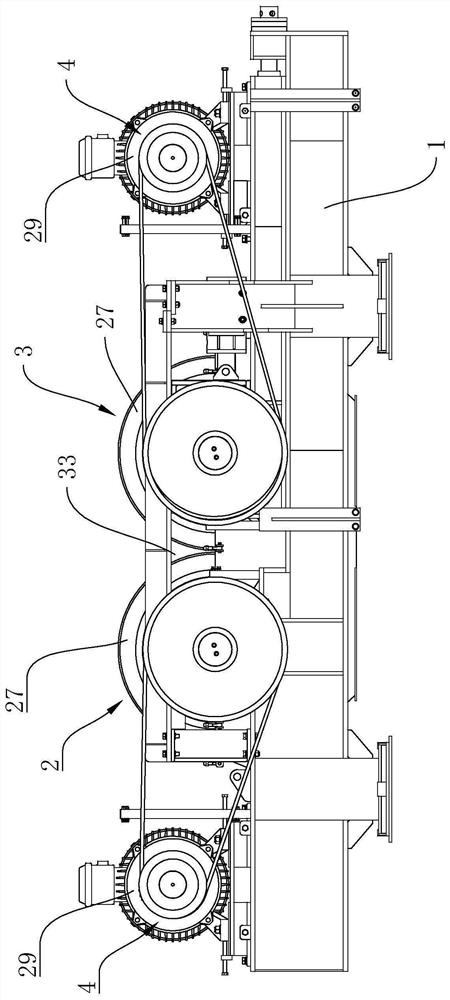

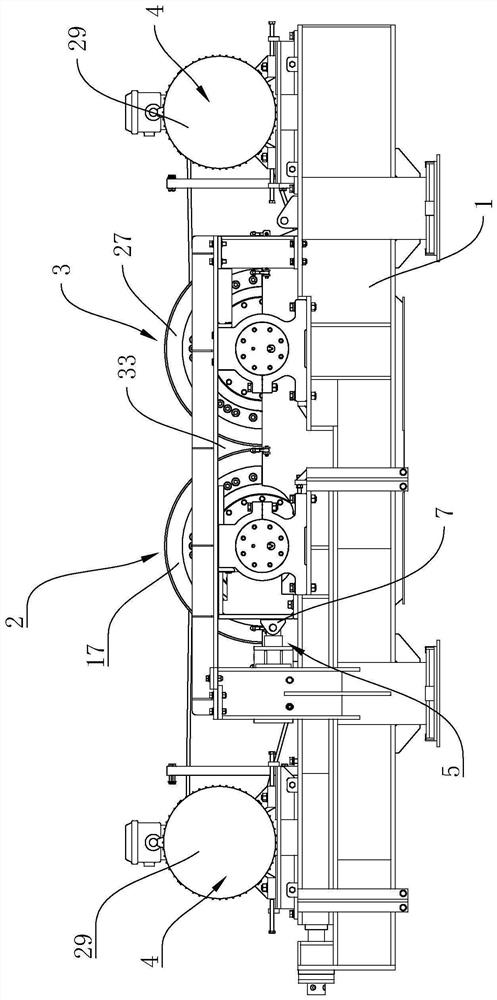

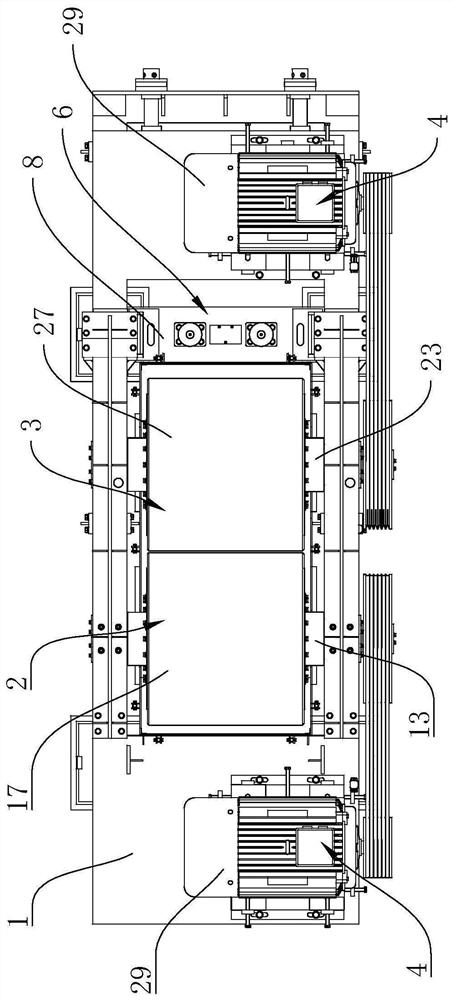

[0029] The present invention will be further described below with reference to the accompanying drawings.

[0030] like Figure 1-7 As shown in the figure, a pair of roller crushers with rollers with a fixed axis supporting structure includes a crusher frame 1, and the crusher frame 1 is provided with a fixed roller part 2 and a movable roller part 3. The fixed roller part A crushing discharge port 33 is formed between 2 and the moving roller part 3, the crusher frame 1 is provided with a driving part 4, the fixed roller part 2 and the moving roller part 3 are respectively connected with the driving part 4, and the The crusher frame 1 is also provided with a discharge port adjusting assembly 5 and an iron-passing adjusting member 6, and the discharge port adjusting assembly 5 is connected with the moving roller part 3, and the moving roller part 3 can be close to or away from the fixed position. One end of the roller portion 2 performs a reciprocating linear motion, and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com