Methanol electrooxidation catalyst and preparation method and application thereof

A catalyst and electro-oxidation technology, applied in circuits, electrical components, battery electrodes, etc., to achieve high activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

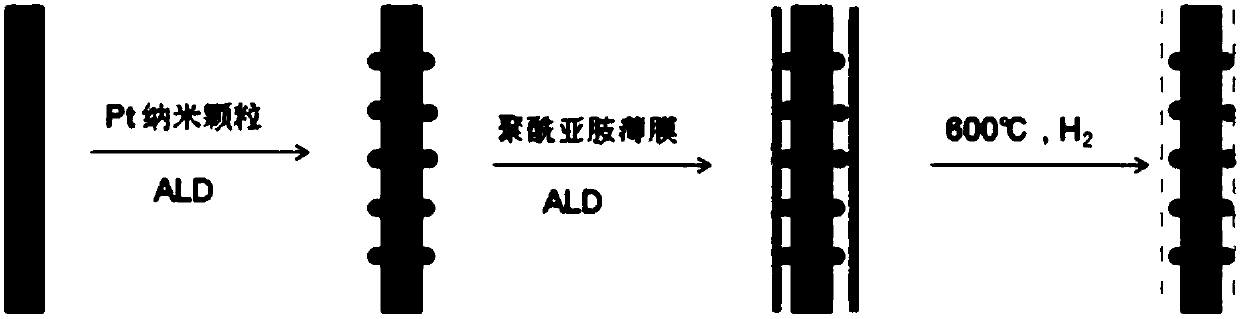

[0026] The invention provides a kind of preparation method of methanol electrooxidation catalyst, comprising the following steps:

[0027] (1) coating the dispersion of carbon nanomaterials on the surface of the substrate to obtain a template;

[0028] (2) depositing a nitrogen-containing organic polymer film and Pt nanoparticles on the surface of the template in the step (1) by atomic layer deposition to obtain a catalyst precursor;

[0029] (3) Under a protective atmosphere, the catalyst precursor in the step (2) is heat-treated to obtain a methanol electro-oxidation catalyst.

[0030] In the invention, the dispersion liquid of the carbon nanometer material is coated on the surface of the substrate to obtain a template. In the present invention, the carbon nanomaterial preferably includes carbon nanotubes, carbon fibers, carbon spheres or graphene. In the present invention, there is no special limitation on the source of the carbon nanomaterials, and commercially available...

Embodiment 1

[0052] 1) Coating the ethanol dispersion of carbon nanotubes with a concentration of 0.01g / mL on the surface of a glass sheet, and evaporating to dryness to obtain a template, the thickness of the cured film on the surface of the template is 1.0mm;

[0053] 2) Utilize atomic layer deposition to deposit Pt nanoparticles on the surface of the template:

[0054] The set deposition parameters are: the reaction temperature is 220°C, the pressure is 70Pa, the temperature of the reaction source trimethylcyclopentadiene platinum is 70°C, the oxygen temperature is 30°C, and the nitrogen flow rate is 50mL / min;

[0055] Pulse trimethylcyclopentadiene platinum vapor first, the pulse time is 0.5s, the hold time is 8s, and the purge time is 20s; then pulse oxygen, the pulse time is 1s, the hold time is 8s, and the purge time is 20s , thus completing one deposition cycle, repeating this process for 20 cycles to obtain a sample of carbon nanotube-loaded Pt nanoparticles, denoted as Pt / CNT;

...

Embodiment 2

[0067] The methanol electrooxidation catalyst was prepared according to the method of Example 1, wherein, when depositing Pt nanoparticles, the number of deposition cycles was 50 cycles.

[0068] According to the method of Example 1, the methanol electrooxidation activity and stability of the prepared methanol electrooxidation catalyst were tested, and the test results showed that the current density of methanol oxidation on C-Pt / CNT was 0.8A / mg Pt , respectively Pt / CNT (0.46A / mg Pt ), commercial Pt / C (0.28A / mg Pt ) of 1.7 and 2.8 times. After 3600s stability test, the current density of methanol oxidation on C-Pt / CNT is 0.16A / mg Pt , respectively Pt / CNT (0.012A / mg Pt ), commercial Pt / C (0.01A / mg Pt ) 13.3 times and 16 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com