Gradient doped cobaltosic oxide material and preparation method thereof

A technology of cobalt tetroxide and gradient doping, which is applied in the directions of cobalt oxide/cobalt hydroxide, electrical components, battery electrodes, etc., can solve the problems of reduced battery capacity and unstable structure, and achieves a simple preparation method, improved structural stability, and improved doping. high clutter effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention discloses a preparation method of a gradient doped cobalt tetroxide material, comprising the following steps:

[0032] Step 1, mixing the cobalt salt solution with a precipitant to prepare a preprecipitate A;

[0033] Step 2, adding a salt solution containing a doping element to the above reaction system to obtain a doping precipitate B;

[0034] Step 3, post-processing the doped precipitate B to obtain gradiently doped tricobalt tetroxide.

[0035] In step 1, add the cobalt salt solution and the precipitant solution into the reaction vessel, stir, and react at a set temperature to prepare the preprecipitate A.

[0036] In a preferred embodiment, the cobalt salt solution is an aqueous cobalt salt solution, and the cobalt salt is selected from any one or more of cobalt chloride, cobalt nitrate, cobalt sulfate and cobalt acetate;

[0037] The precipitation agent is mixed with the cobalt salt solution in the form of an aqueous solution, and the precipitatio...

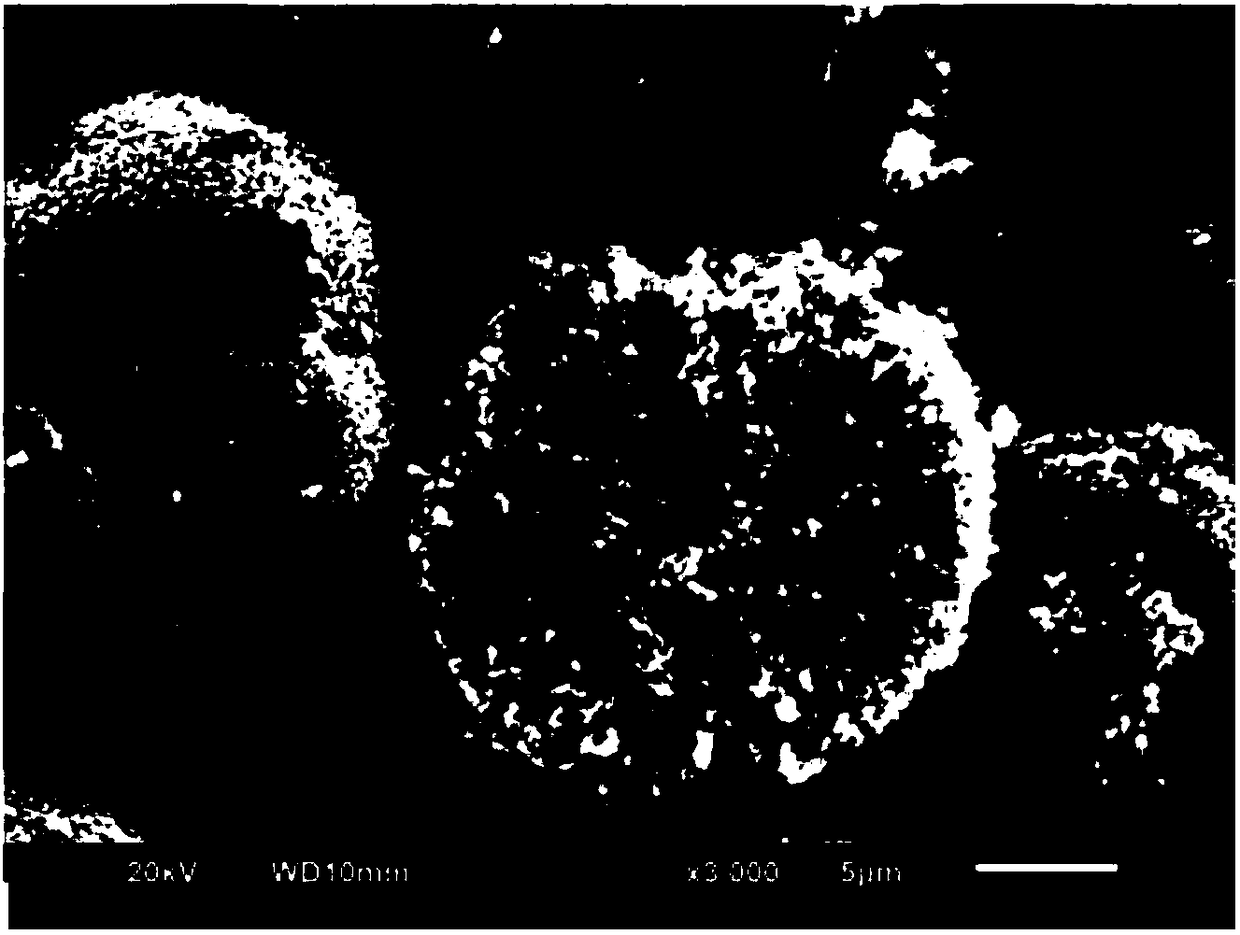

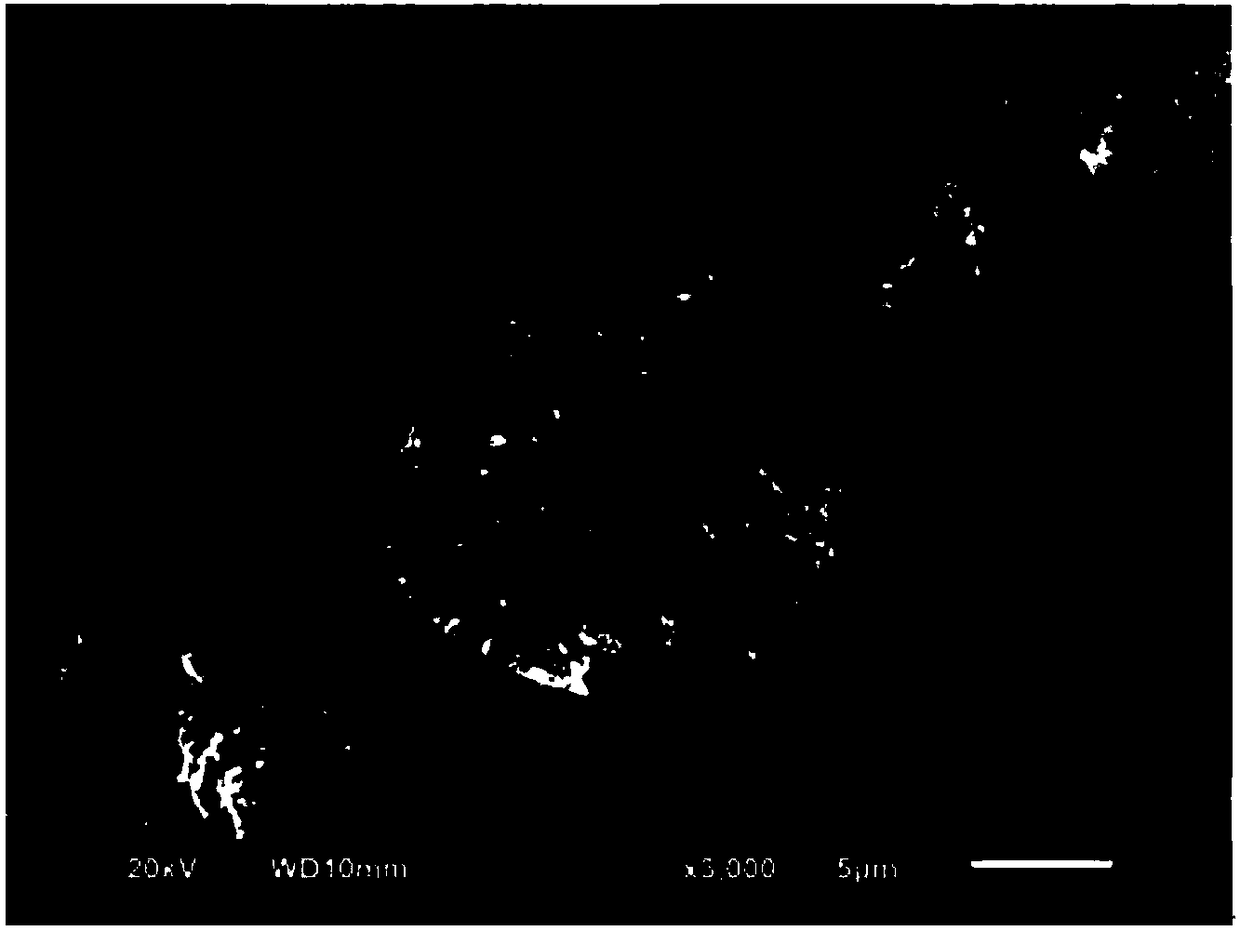

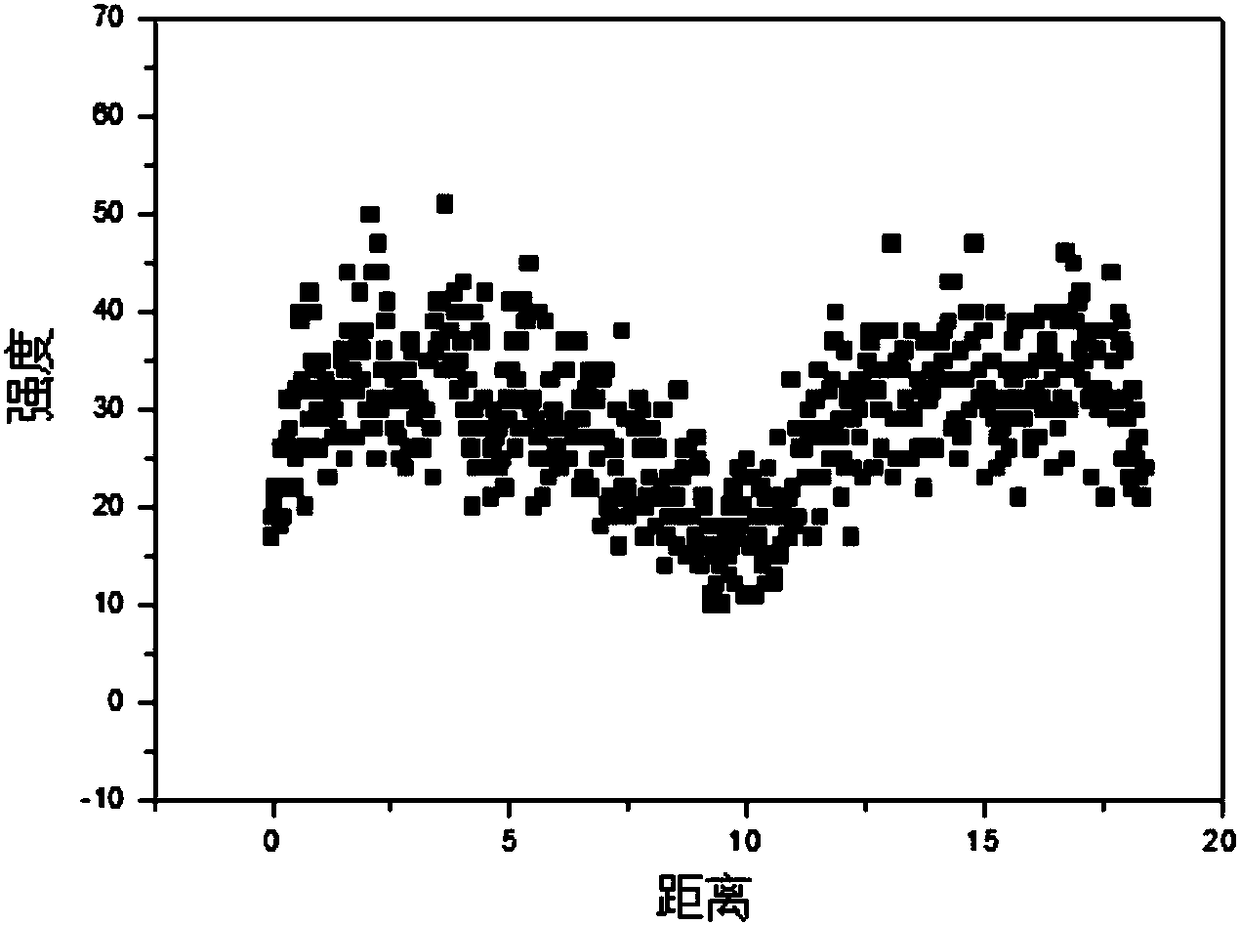

Embodiment 1

[0064] Prepare cobalt nitrate solution, the concentration of cobalt in the solution is 80g / L, ammoniacal liquor is added in sodium hydroxide solution to make precipitant solution, wherein the content of sodium hydroxide in the precipitant solution is 100g / L, ammoniacal liquor content is 25g / L ; The cobalt nitrate solution and the precipitant solution are added to the reaction vessel in a co-current manner to react, the co-current volume ratio of the cobalt nitrate solution and the precipitant solution is 1: (1.1~1.4), and the reaction pH value is 8.5~10.5 , the reaction temperature is 60°C, and the reaction time is 30h;

[0065] Prepare a salt solution containing doping element ions, the doping element Ni content is 0.15g / L, add the salt solution containing doping element ions into the reaction vessel for reaction, the reaction pH value is 8.5-10.5, and the reaction temperature is 60 °C, the reaction time is 10h;

[0066] The reaction product cobalt hydroxide precipitate was ...

Embodiment 2

[0069] Preparation of cobalt nitrate solution, the concentration of cobalt in the solution is 80g / L; ammoniacal liquor is added in the sodium hydroxide solution to make precipitant solution, wherein the content of sodium hydroxide in the precipitant solution is 100g / L, ammonia water content is 25g / L ; The cobalt nitrate solution and the precipitant solution are added to the reaction vessel in a co-current manner to react, the co-current volume ratio of the cobalt nitrate solution and the precipitant solution is 1: (1.1~1.4), and the reaction pH value is 8.5~10.5 , the reaction temperature is 60°C, and the reaction time is 30h;

[0070] Prepare a salt solution containing doping element ions, the doping element Al content is 0.15g / L; add the salt solution containing doping element ions into the reaction vessel for reaction, the reaction pH value is 8.5-10.5, and the reaction temperature is 60 °C, the reaction time is 10h;

[0071] The cobalt hydroxide precipitate obtained from ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com