Lithium-rich manganese based lithium ion battery cathode material and preparation method thereof

A technology of lithium-rich manganese-based lithium and positive electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor rate performance of positive electrode materials, large irreversible capacity loss, low Coulombic efficiency, etc., to reduce corrosion and improve Effects of the first Coulombic efficiency, enhanced rate performance and cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

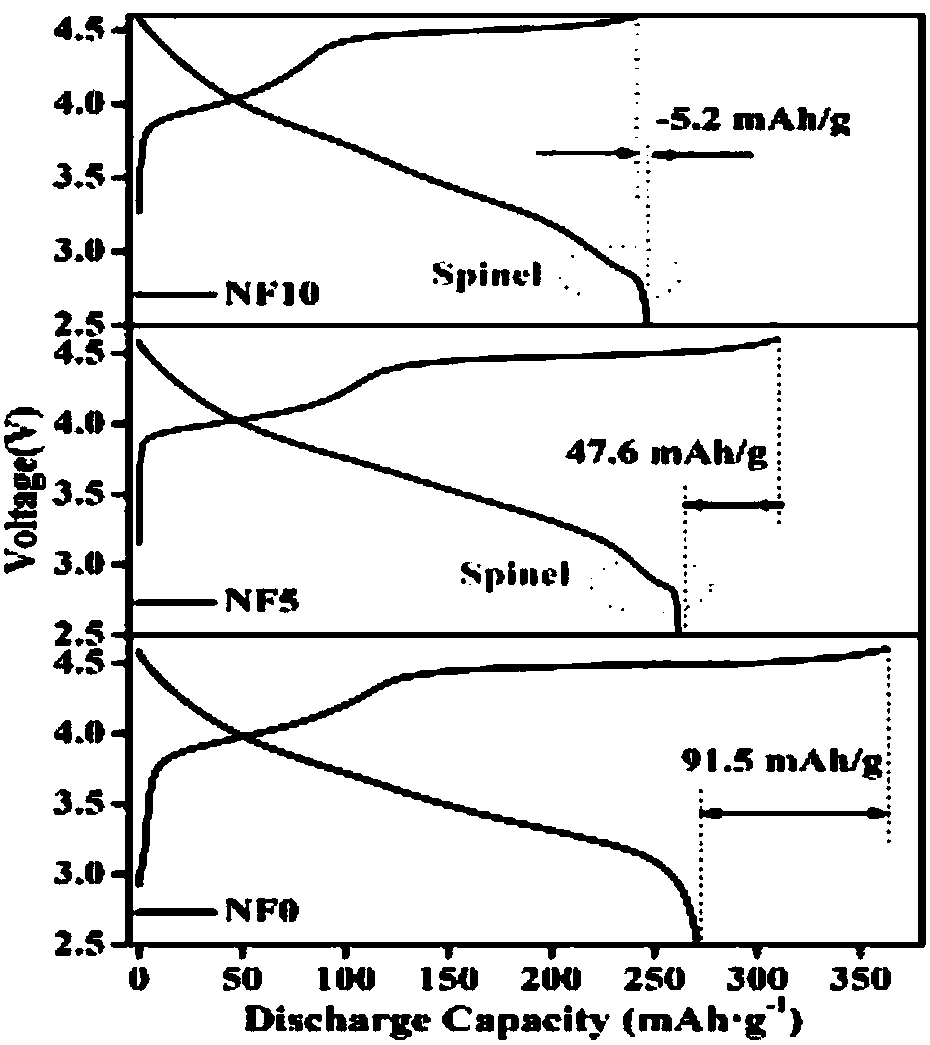

[0023] This embodiment provides a lithium-rich manganese-based positive electrode material for a lithium-ion battery, which includes a lithium-rich manganese-based positive electrode material, and also includes a spinel phase LiM formed on the surface of the lithium-rich manganese-based positive electrode material. 2 o 4 (M=Mn, Co, Ni, etc.), and a lithium fluoride coating layer coated on the lithium-rich manganese-based positive electrode material.

[0024] In this embodiment, a spinel phase LiM is formed on the surface of the lithium-rich manganese-based positive electrode material of the lithium-rich manganese-based lithium battery positive electrode material. 2 o 4 (M=Mn, Co, Ni, etc.), covered with a lithium fluoride coating layer; among them, the spinel phase LiM 2 o 4 The generation of LiM will lead to the shortening of the platform around 4.6V in the first charging process, that is, the charging capacity will be reduced, and the spinel phase LiM will be discharged d...

Embodiment 2

[0026] On the basis of Example 1, this example provides a method for preparing the lithium-rich manganese-based lithium-ion battery cathode material described in Example 1:

[0027] Step 1, adding ammonium fluoride and lithium carbonate in a certain mass ratio to the lithium-rich manganese-based positive electrode material, and then grinding and mixing uniformly to obtain a mixed powder;

[0028] Step 2. The mixed powder is subjected to low-temperature firing heat treatment under airtight conditions. The chemical reaction that occurs during the treatment process is:

[0029]

[0030]

[0031] Then obtain the required lithium-rich manganese-based lithium battery positive electrode material.

[0032] In this example, the NH 4 NH produced by F decomposition 3 The spinel phase LiM can be formed on the surface of lithium-rich manganese-based cathode materials 2 o 4 , HF and Li produced by the decomposition of NH4F 2 CO 3 Reaction in Li-rich manganese-based cathode mater...

Embodiment 3

[0036] On the basis of Example 2, this example provides a specific preparation method of a lithium-rich manganese-based lithium-ion battery positive electrode material, as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com