Functional fiber and microfluidic spinning device and fiber preparing method thereof

A spinning device and microfluidic control technology, applied in stretch spinning, fiber treatment, fiber chemical characteristics, etc., can solve the problems of high requirements for equipment and production environment, long time consumption in the transfer process, and difficulty in realizing fiber design, etc. , to achieve the effect of easy promotion, easy integration and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

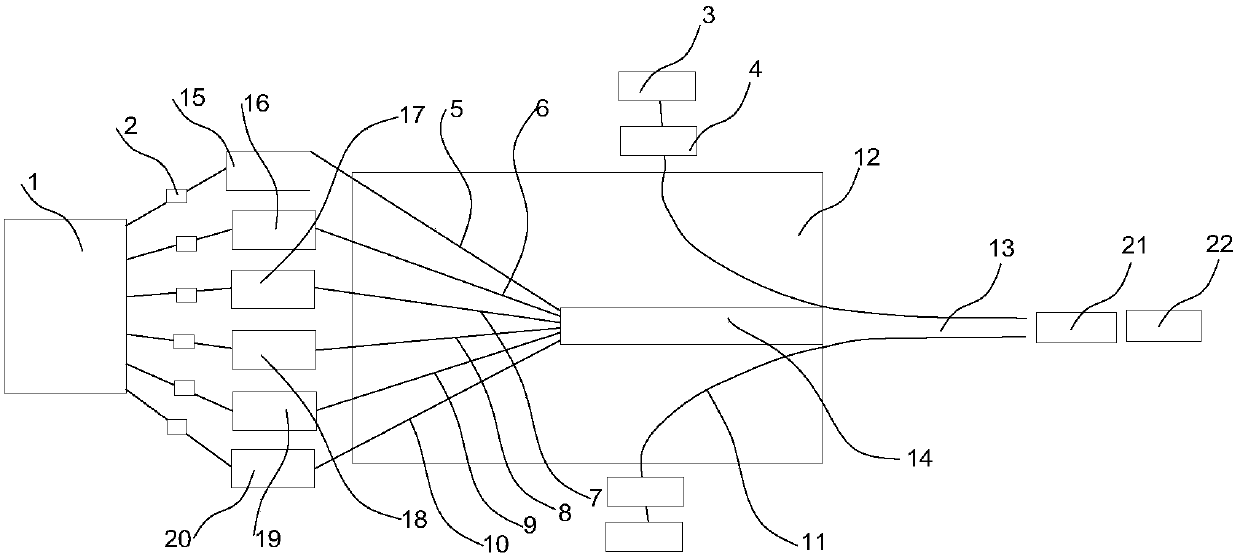

[0040] A microfluidic spinning preparation method of a structure controllable function designable fiber of the present invention comprises the following steps:

[0041] (1) The spinning solution or coagulation solution with a mass fraction of 0.1-30% is poured into the spinning tank sequentially, and left to stand for degassing for 0.5-3 hours to obtain the spinning solution or coagulation solution for microfluidic spinning;

[0042] (2) The computer 1 controls the propeller of the spinning pot through the solenoid valve 2, and the speed of the propeller is 0.05-100mm / min, so as to realize the design of the fiber components online;

[0043] (3) The spinning solution or coagulation solution enters the microfluidic spinning chip through the spinning solution pipeline at a flow rate of 0.1-100mL / min, and converges in the common spinning solution pipeline 14 to form nascent fibers;

[0044] (4) The as-spun fibers are drawn through the airflow gathering drafting zone 13, and after ...

Embodiment 1

[0051] See attached figure 1 , a microfluidic spinning preparation method of a structure controllable function designable fiber of the present invention, comprising the following steps:

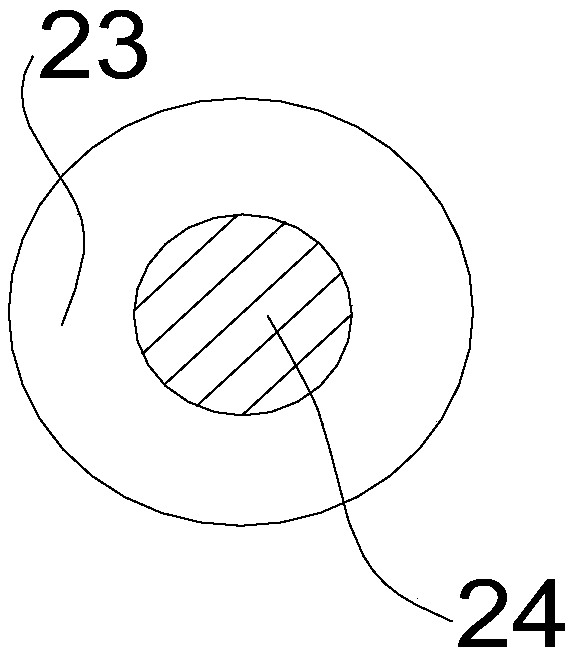

[0052] 1) According to the structure of the designed functional fiber, the microfluidic chip 12 is taken, and the microfluidic chip 12 has six spinning solution pipelines, which are respectively the first spinning solution pipeline 5, the second spinning solution pipeline 6, and the third spinning solution pipeline. The spinning solution pipeline 7, the fourth spinning solution pipeline 8, the fifth spinning solution pipeline 9, and the sixth spinning solution pipeline 10, these six spinning solution pipelines are all connected with the common spinning solution pipeline 14;

[0053] The six spinning liquid pipelines of the microfluidic chip 12 are all provided with corresponding spinning pots and propellers connected with the spinning pots, which are respectively the first propeller and the s...

Embodiment 2

[0065] On the basis of Example 1, the components of the spinning solution, the mass concentration, the speed of the propeller, the flow rate of the spinning solution and the flow through the pipeline were adjusted.

[0066] In this embodiment, the spinning solution includes spinning solution A and spinning solution B, and the spinning solution A is a chitosan solution with a mass concentration of 2%, and its preparation method is: take chitosan, dissolve in 5% In the acetic acid aqueous solution, stand defoaming to obtain chitosan solution; the spinning solution B is a graphene solution with a mass fraction of 0.1%, and its preparation method is: take a certain amount of self-made graphene and dissolve it in water, and ultrasonically disperse it for 10 minutes to obtain graphene solution.

[0067] In the present embodiment, in the present embodiment, the spinning solution A is packed into the second propeller and the spinning tank in the spinning tank 16 and the third propelle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com