Composite positive electrode of lithium sulfur battery, preparation method of composite positive electrode and lithium sulfur battery

A composite positive electrode and lithium-sulfur battery technology, which is applied in the direction of battery electrodes, electrode carriers/current collectors, non-aqueous electrolyte battery electrodes, etc., can solve the problems of reducing ion conductance and electron conductance, increasing interface resistance, and high cost of use. Effects of large ion conductance and electron conductance, increase in volume energy density, and increase in mass energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

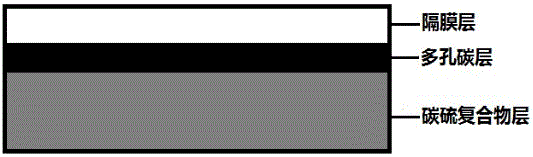

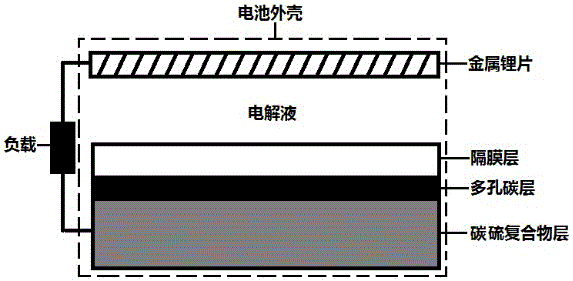

[0029] A lithium-sulfur battery composite positive electrode of the present invention, the composite positive electrode is composed of a Celgard2400 diaphragm layer, a Ketjen black layer and a Ketjen black-sulfur composite layer, wherein the Ketjen black layer is arranged on one side of the Celgard2400 diaphragm layer, The Ketjen black-sulfur composite layer is arranged on the Ketjen black layer to form a composite positive electrode with a three-layer structure of Celgard2400 separator layer / Ketjen black layer / Ketjen black-sulfur composite layer. Wherein, the thickness of the Ketjen black layer is 10 μm, and the thickness of the Ketjen black-sulfur composite layer is 50 μm.

[0030] The preparation method of the lithium-sulfur battery composite positive electrode of the present embodiment comprises the following steps:

[0031] (1) Ketjen black, carbon black Super-P and polyvinylidene fluoride are added to N-methylpyrrolidone according to the mass ratio of 8:1:1 and mixed eve...

Embodiment 2

[0035] A lithium-sulfur battery composite positive electrode of the present invention, the composite positive electrode is composed of a Celgard2400 diaphragm layer, a carbon nanotube layer and a carbon nanotube-sulfur composite layer, wherein the carbon nanotube layer is arranged on one side of the Celgard2400 diaphragm layer, The carbon nanotube-sulfur composite layer is arranged on the carbon nanotube layer to form a composite positive electrode with a three-layer structure of Celgard2400 diaphragm layer / carbon nanotube layer / carbon nanotube-sulfur composite layer. Wherein, the thickness of the carbon nanotube layer is 20 μm, and the thickness of the carbon nanotube-sulfur composite layer is 80 μm.

[0036] The preparation method of the lithium-sulfur battery composite positive electrode of the present embodiment comprises the following steps:

[0037] (1) Add carbon nanotubes, carbon black Super-P and polyvinylidene fluoride to N-methylpyrrolidone according to the mass rat...

Embodiment 3

[0041] A lithium-sulfur battery composite positive electrode of the present invention, the composite positive electrode is composed of a Celgard2400 diaphragm layer, a graphene layer and a Ketjen black-sulfur composite layer, wherein the graphene layer is arranged on one side of the Celgard2400 diaphragm layer, Ketjen The black-sulfur composite layer is arranged on the graphene layer to form a composite positive electrode with a three-layer structure of Celgard2400 separator layer / graphene layer / Ketjen black-sulfur composite layer. Wherein, the thickness of the graphene layer is 10 μm, and the thickness of the Ketjen Black-sulfur composite layer is 70 μm.

[0042] The preparation method of the lithium-sulfur battery composite positive electrode of the present embodiment comprises the following steps:

[0043] (1) Graphene, carbon black Super-P and polyvinylidene fluoride are added to N-methylpyrrolidone according to a mass ratio of 7:2:1 and mixed evenly to make a slurry, wher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com