Preparation method of lithium iron phosphate/graphene nano composite material

A nanocomposite material, lithium iron phosphate technology, applied in the direction of structural parts, electrical components, battery electrodes, etc., can solve the problem of low bonding force between graphene and grain interface, inability to control the grain size of lithium iron phosphate, and limit composite materials Electronic conductivity and other issues, to achieve the effect of simple and controllable preparation method, low price, and simple and controllable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

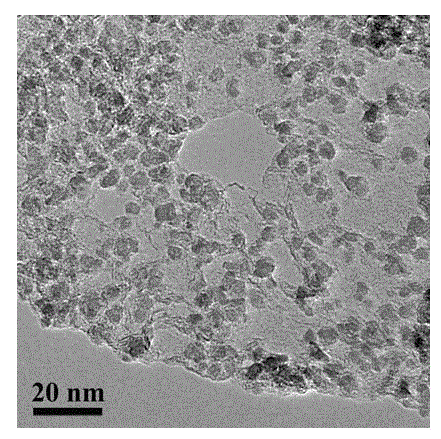

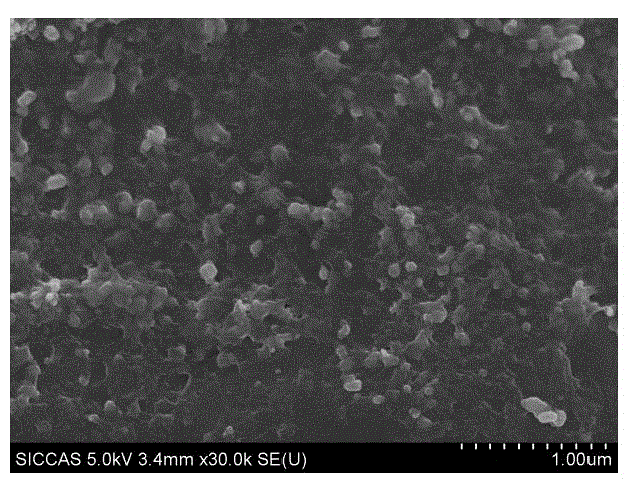

Image

Examples

Embodiment 1

[0052] 1) Add 0.27 g ferric chloride and 1.8 g urea to 100 mL and 1 g / L graphene oxide sol, respectively, and stir well;

[0053] 2) Transfer the mixed solution in step 1) to a heating container such as an oil bath at 95 °C for 1.5 hours;

[0054] 3) After the reaction is complete, add 1.0 mL of hydrazine hydrate to the above solution and microwave for 2 minutes, filter and wash with suction to obtain Fe 2 o 3 / GS complex;

[0055] 4) Re-disperse the precursor ultrasonically into a mixed solution of 150 mL DMF and water (50:1), add lithium hydroxide, phosphoric acid and 0.44 g ascorbic acid in an equimolar amount to the iron element, and stir well;

[0056] 5) Transfer the above mixture to a polytetrafluoroethylene-lined stainless steel reactor. Put it in an oven, and heat the solvent at 180°C for 12 hours;

[0057] 6) After the reaction is completed, let it cool down naturally, open the container, wash the collected samples with water and ethanol respectively, and then dr...

Embodiment 2

[0060] 1) Add 5.0 g of ferric chloride and 0.05 g of urea to 100 mL and 0.5 g / L graphene oxide sol, respectively, and stir well

[0061] 2) Transfer the mixed solution in step 1) to a heating container such as an oil bath at 80 °C for 6 hours

[0062] 3) After the reaction is completed, add 0.1 mL of hydrazine hydrate to the above solution and microwave for 4 minutes, filter and wash with suction to obtain Fe 2 o 3 / GS complex

[0063] 4) Fe 2 o 3 / GS complex was re-dispersed ultrasonically into a mixed solution of 296 mL DMF and water (1:1), adding lithium hydroxide, phosphoric acid and 0.30 g ascorbic acid in an equimolar amount to iron, and stirring well

[0064] 5) Transfer the above mixed solution to a polytetrafluoroethylene-lined stainless steel reaction kettle, place it in an oven, and heat the solvent at 180°C for 36 hours;

[0065] 6) After the reaction is completed, let it cool down naturally, open the container, wash the collected samples with water and ethano...

Embodiment 3

[0068] 1) Add 0.4 g of ferric chloride and 40 g of urea to 100 mL and 4 g / L graphene oxide sol, respectively, and stir well;

[0069] 2) Transfer the mixed solution in step 1) to a heating container such as an oil bath at 180°C for 0.5 hours;

[0070] 3) After the reaction was completed, 5 mL of hydrazine hydrate was added to the above solution and microwaved for 2 minutes, suction filtered and washed to obtain Fe 2 o 3 / GS complex;

[0071] 4) Fe 2 o 3 The / GS complex was re-dispersed ultrasonically into a mixed solution of 236.8 mL DMF and water (100:1), adding lithium hydroxide, phosphoric acid and 4.74 g ascorbic acid in an equimolar amount to the iron element, and fully stirred evenly;

[0072] 5) Transfer the above mixed solution to a polytetrafluoroethylene-lined stainless steel reaction kettle, place it in an oven, and heat the solvent at 200 ° C for 8 hours;

[0073]6) After the reaction is completed, let it cool down naturally, open the container, wash the colle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com