Jaw frame type bionic movement mechanism fatigue test device

A motion mechanism and fatigue testing technology, which is applied in the direction of applying repetitive force/pulsation force to test the strength of materials, etc., can solve the problems of ineffective testing of multi-bend springs, troublesome treatment continuity, and prolonged treatment, so as to achieve accurate measurement of fatigue cycle, Simple structure and easy to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

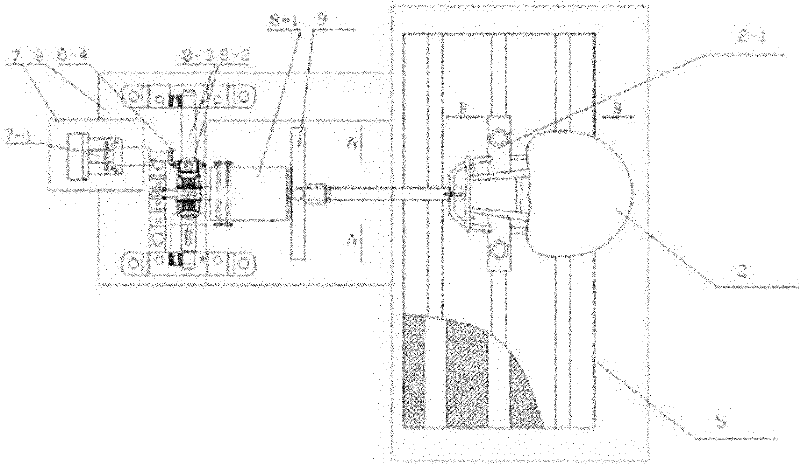

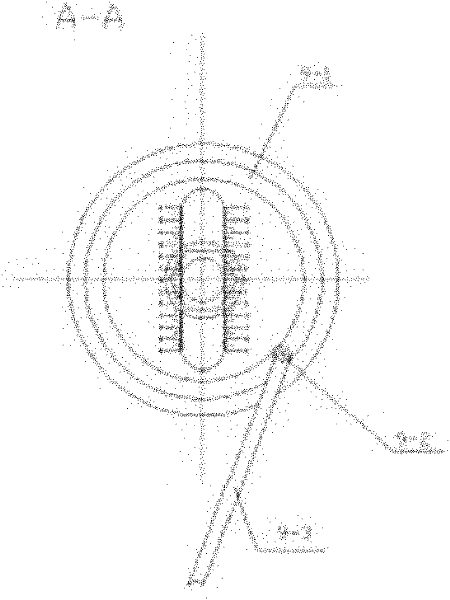

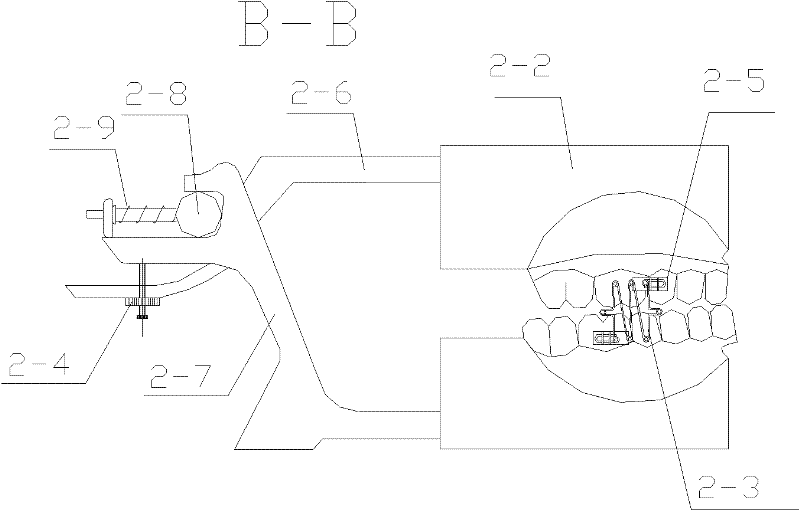

[0017] combine Figure 1~4 , the jaw-type bionic motion mechanism fatigue tester includes a jaw-type bionic motion mechanism 2, a driving mechanism 1, a time control device 3, an intelligent braking device 4 and a base 5, and the driving mechanism 1 includes a speed control display 6, a motor 7, Reducer 8 and groove cam mechanism 9, intelligent braking device 4 includes electromagnetic relay 4-1 and mechanical switch controller 4-2, when time control device 4 sends a signal, electromagnetic relay 4-1 takes action to mechanical switch Controller 4-2, switch controller 4-2 cuts off the power supply of motor 7 immediately after receiving signal this moment, makes motor 7 stop working. Jaw frame bionic motion mechanism 2, drive mechanism 1, time control device 3, and intelligent brake device 4 are all installed on the base 5, and time control device 3 and drive mechanism 1 are all connected with jaw frame type bionic motion mechanism 2 and intelligent brake device. The device 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com