Deviation correcting device for bag making machine

A technology of deviation correction device and bag making machine, which is applied in the field of deviation correction device, which can solve the problems of friction pair running track changes, low precision, slow deviation correction response, etc., and achieve the effect of maintaining the original track and improving deviation correction response and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below in conjunction with specific embodiments.

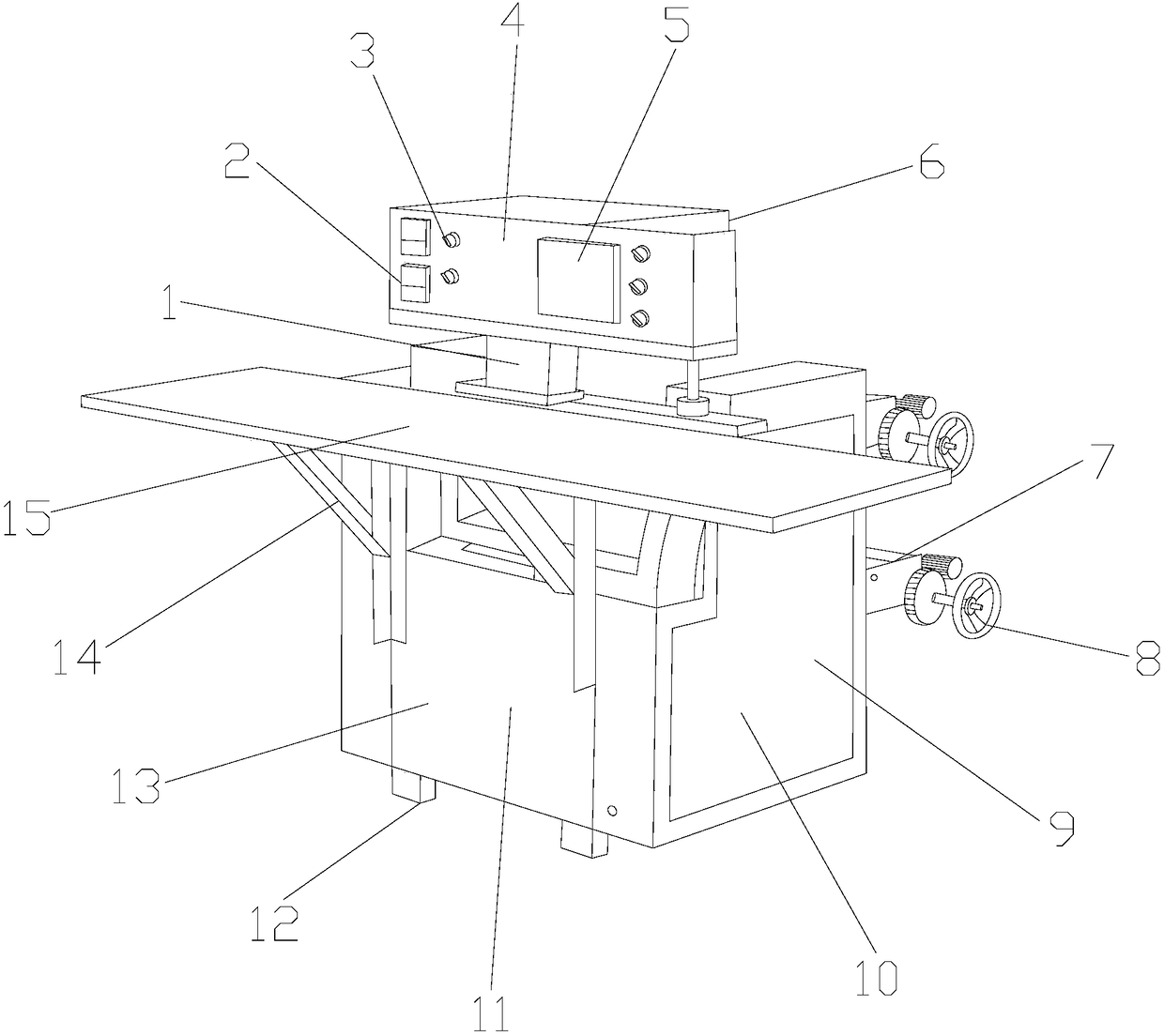

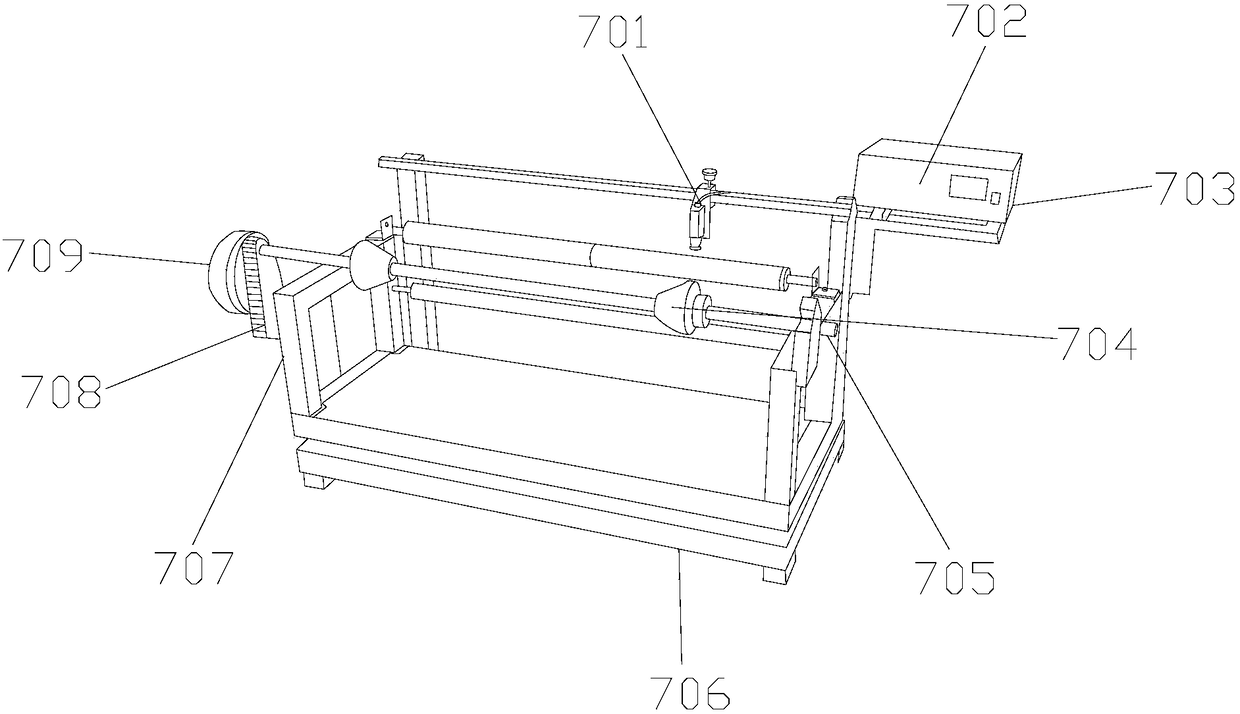

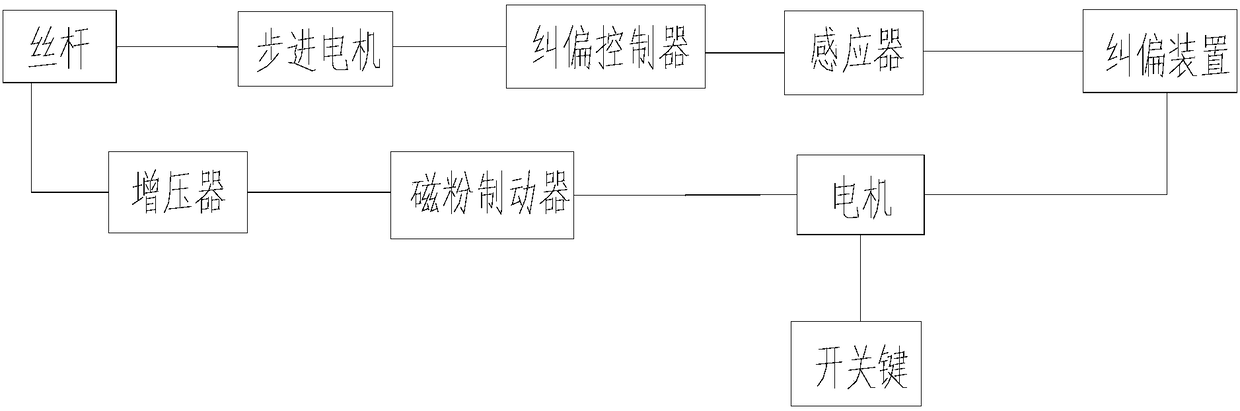

[0017] See Figure 1-Figure 2 , The present invention provides a technical solution: a correction device for a bag making machine, characterized in that: its structure includes electrical circuit 1, switch key 2, adjustment key 3, operation panel 4, display screen 5, power cord 6 , Correction device 7, manual wheel 8, baffle 9, heater 10, motor 11, foot 12, electric control box 13, bracket 14, workbench 15, the electric circuit 1 is connected with the switch key 2, the The adjustment key 3 is arranged on the operation panel 4. The power cord 6 is connected to the correction device 7. The correction device 7 is composed of an inductor 701, a correction controller 702, a stepping motor 703, a tension controller 704, and a screw rod 705. , Base 706, frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com