Braking device for main motor of water tank wire drawing machine

A water tank wire drawing machine and brake device technology, which is applied in the direction of electromechanical devices, electric components, electrical components, etc., can solve the problems affecting the processing accuracy and quality of steel wire, and achieve good braking effect, effective braking and convenient cooperation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

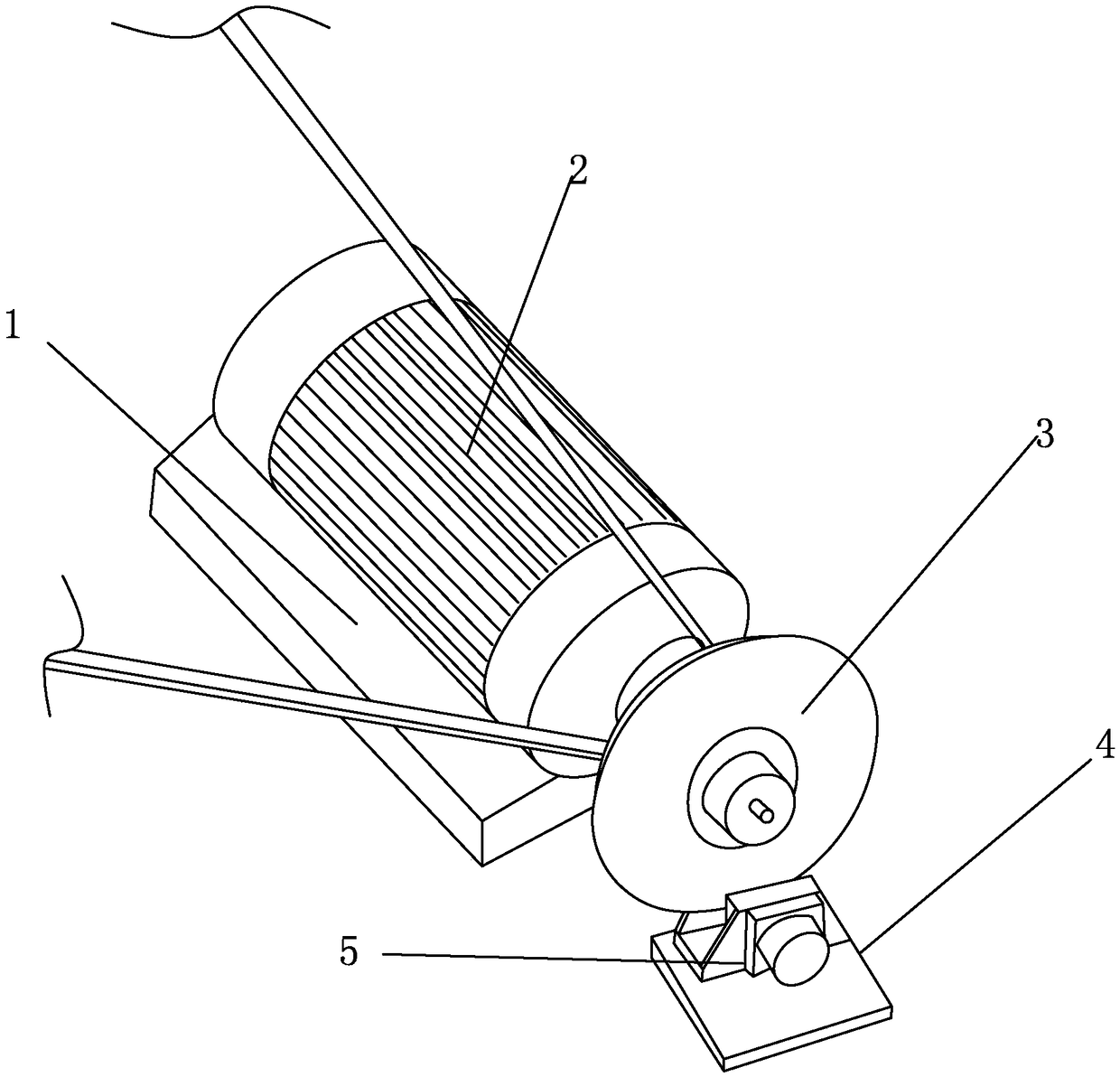

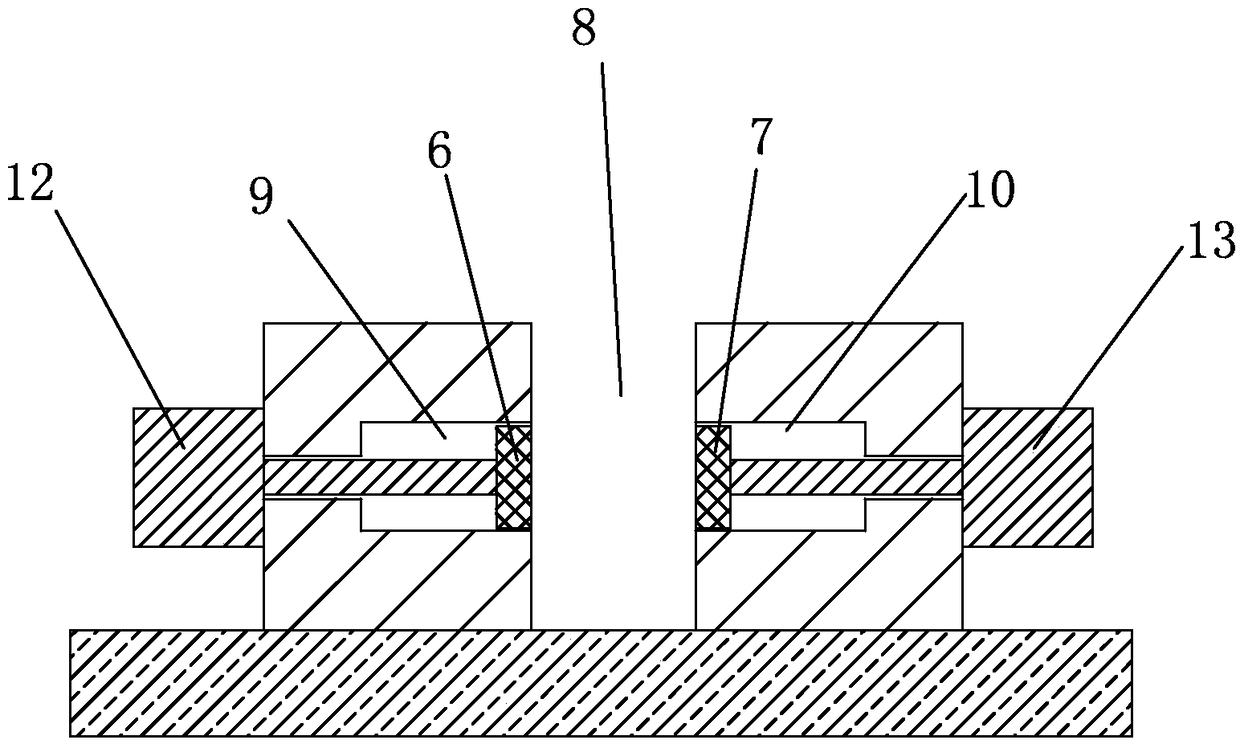

[0013] refer to Figure 1 to Figure 3 The embodiments of the present invention will be further described.

[0014] A braking device with good braking effect is used for the main motor of the water tank wire drawing machine.

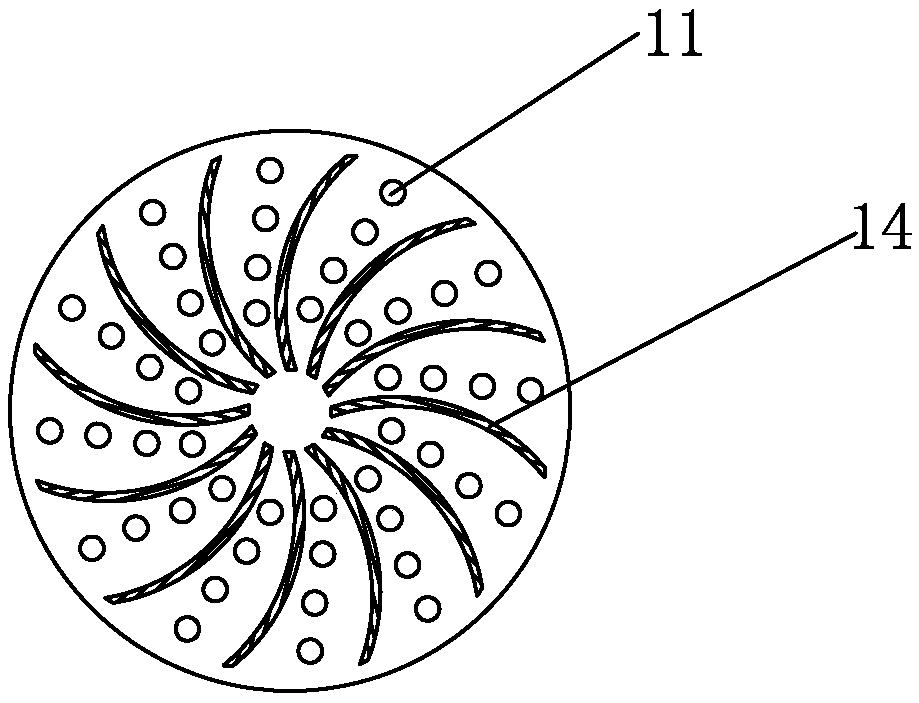

[0015] A specific embodiment of the present invention: including a body 1 and a main motor 2 placed on the body 1, the main motor 2 includes a transmission wheel 3, a brake device 4 is placed on the body 1, and the brake device 4 includes a brake seat 5 and a brake The first brake pad 6 and the second brake pad 7 that are movably connected to the seat 5 are in the shape of discs. The first movable chamber 9 and the second movable chamber 10 communicated with the brake groove 8, the first movable chamber 9 and the second movable chamber 10 are cylindrical and the first movable chamber 9 and the second movable chamber 10 are coaxial, and the first movable chamber 9 and the second movable chamber 10 are coaxial. The brake pad 6 is placed in the first movab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com