Progressive drilling-in type multi-drill-bit cutting and drilling device

A drilling device and multi-head technology, applied in the direction of drill bits, drilling equipment, earthwork drilling and production, etc., can solve the problem of drilling height, and achieve the effect of high drill bit strength, convenient cooperation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

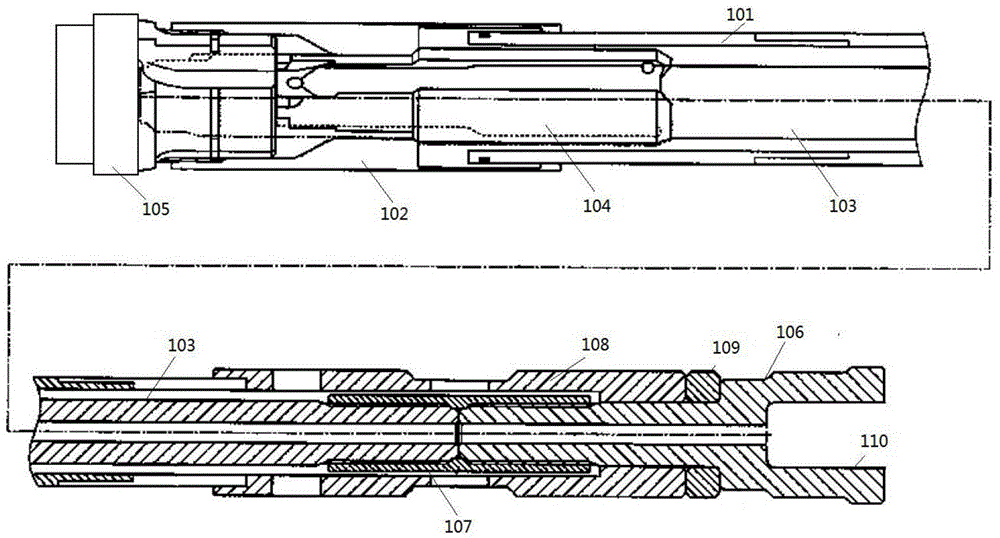

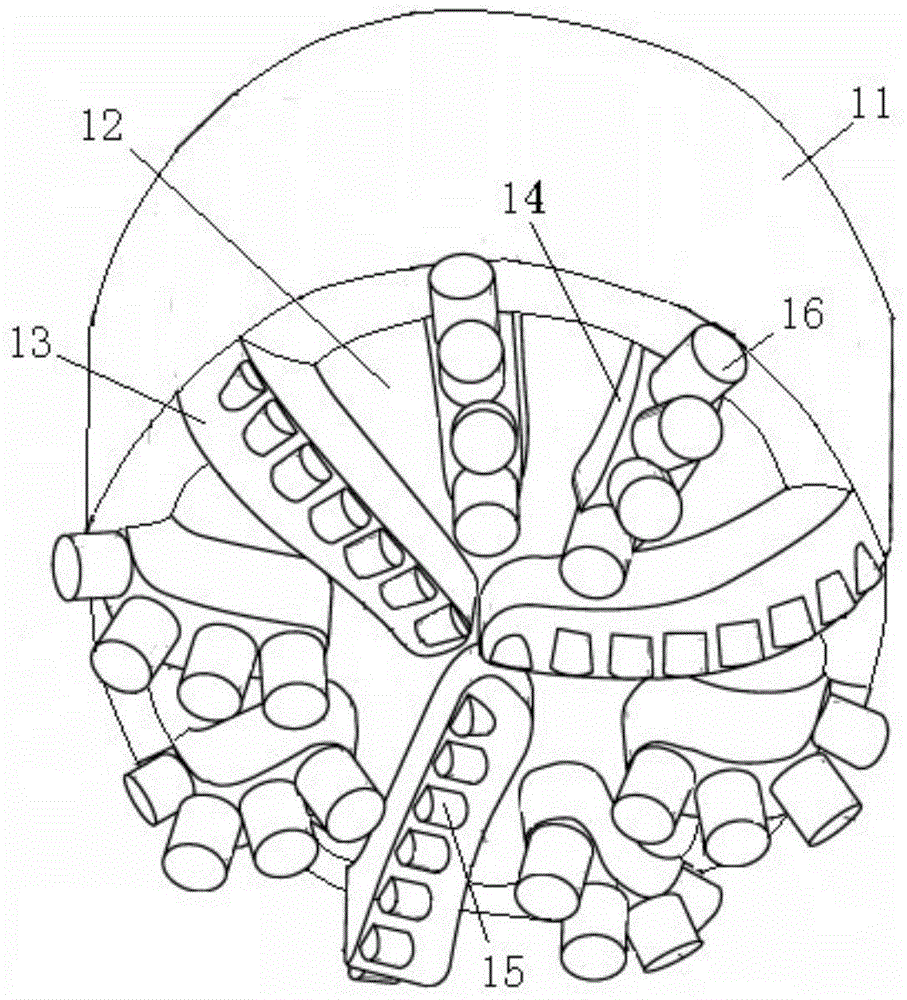

[0026] see Figure 1-2 , shows the progressive drilling multi-head cutting drilling device of the present invention.

[0027] The progressive drilling multi-head cutting drilling device includes a cylindrical body. In order to facilitate loading and unloading and reduce costs, the cylindrical body can adopt a split structure, such as figure 1 As shown, the cylindrical body 1 at least includes an outer shell 101, a front cover 102 and a rear cover 108, the outer shell 101 is located in the middle, and the front cover 102 and the rear cover 108 are respectively provided at both ends to form a hollow structural strip Cylindrical structure.

[0028] The front end of the cylindrical body is provided with a drill bit 105 for drilling, the rear end of the cylindrical body is provided with an adapter rod 106, and the rear end of the adapter rod 106 is provided with an embedding groove 110. Groove 110 can be embedded by a driving rod, and the front end of described driving rod is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com