Automatic blanking machine pay-off disc of mining anchor cable

A technology of automatic feeding and pay-off reels, which is applied in the field of coal mine machinery, can solve the problems of no controllable facilities, loose anchor cables, and loss of control, and achieve the effects of preventing bending, speeding up feeding speed, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

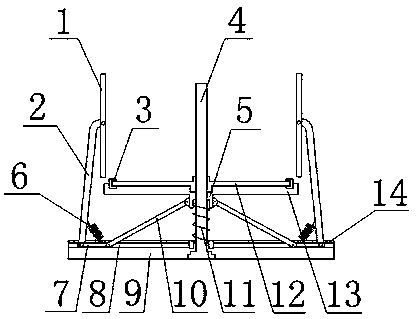

[0017] A pay-off reel of an automatic cable-cutting machine for mines includes a base 9, an intermediate shaft 4 and a sliding base 13. The base 9 is provided with a sliding groove 8, and the sliding groove 8 is provided with a sliding block 7 The block 7 is connected to the rocker arm 2 by a hinge mechanism. The upper end of the rocker arm 2 is connected with a baffle 1, a spring 6 is also provided between the rocker 2 and the slider 7, and a baffle 14 is provided above the sliding groove 8. The intermediate shaft 4 is arranged in the center of the base 9. A sliding base 13 is arranged on the intermediate shaft 4. A return spring 11 is arranged between the sliding base 13 and the base 9. The sliding base 13 passes through the spring seat 5 and the return spring 11 In connection, the spring seat 5 is connected to the connecting rod 10 through a hinge mechanism, the connecting rod 10 is connected to the sliding block 7, a rotating disc 12 is arranged above the sliding base 13, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com