Asymmetric roller for sizing and reducing machine

An asymmetric, diameter-fixing and reducing technology, applied in the direction of rolls, metal rolling, metal rolling, etc., can solve the problems of difficulty in determining the deflection angle θ, increasing the stand spacing in cross-rolling, and complex structure of the cross-rolling diameter-reducing machine. , to achieve the effect of eliminating the internal phenomenon and improving the wall thickness accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

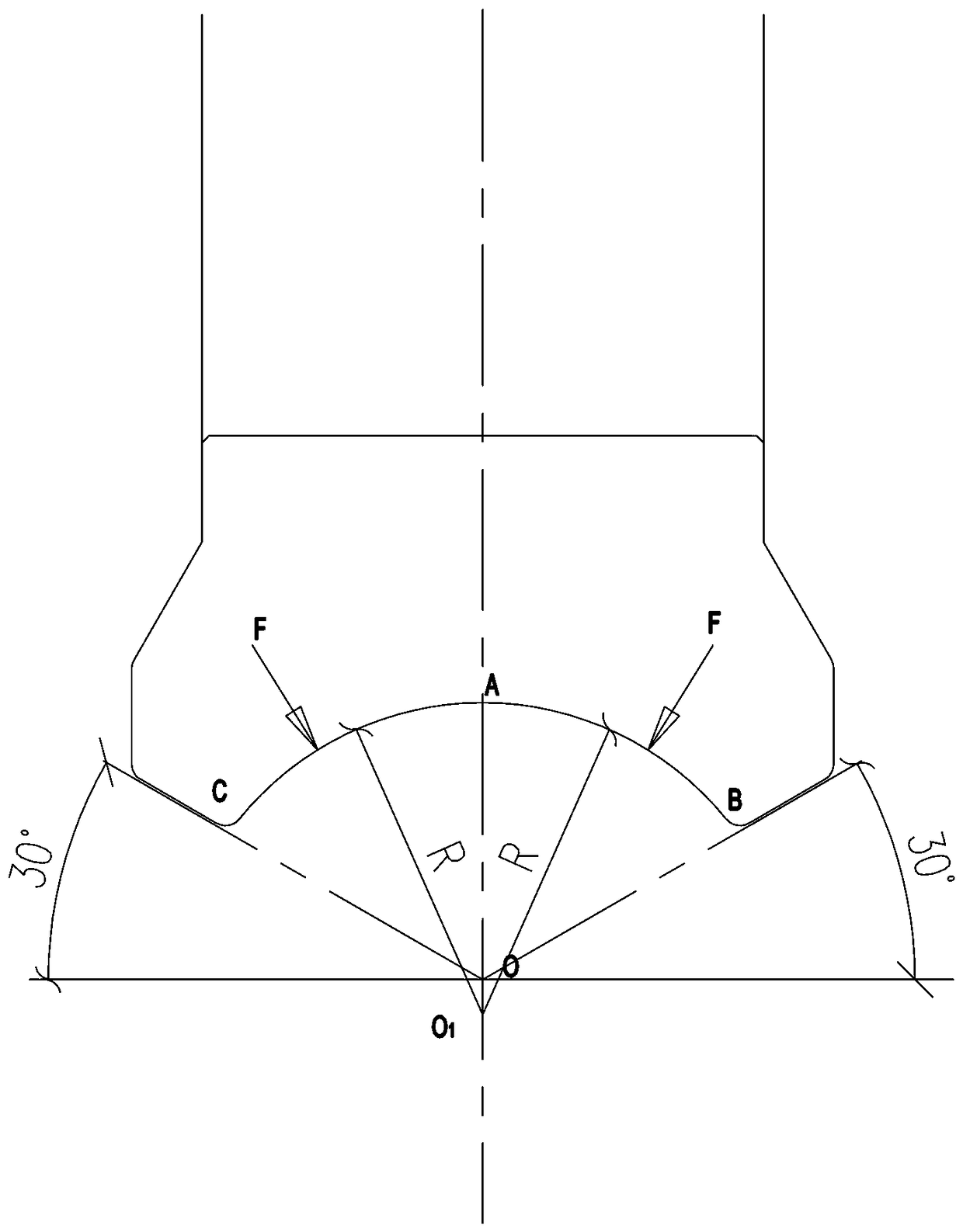

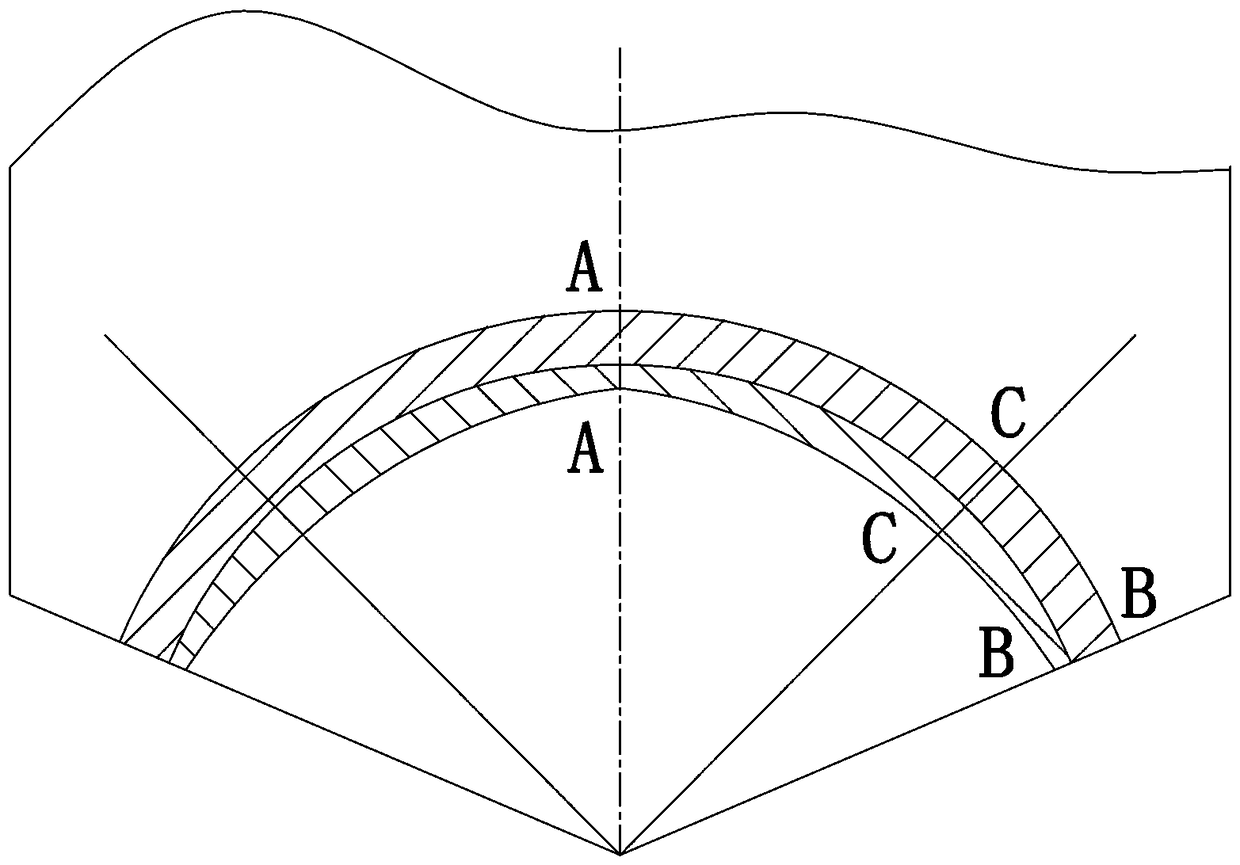

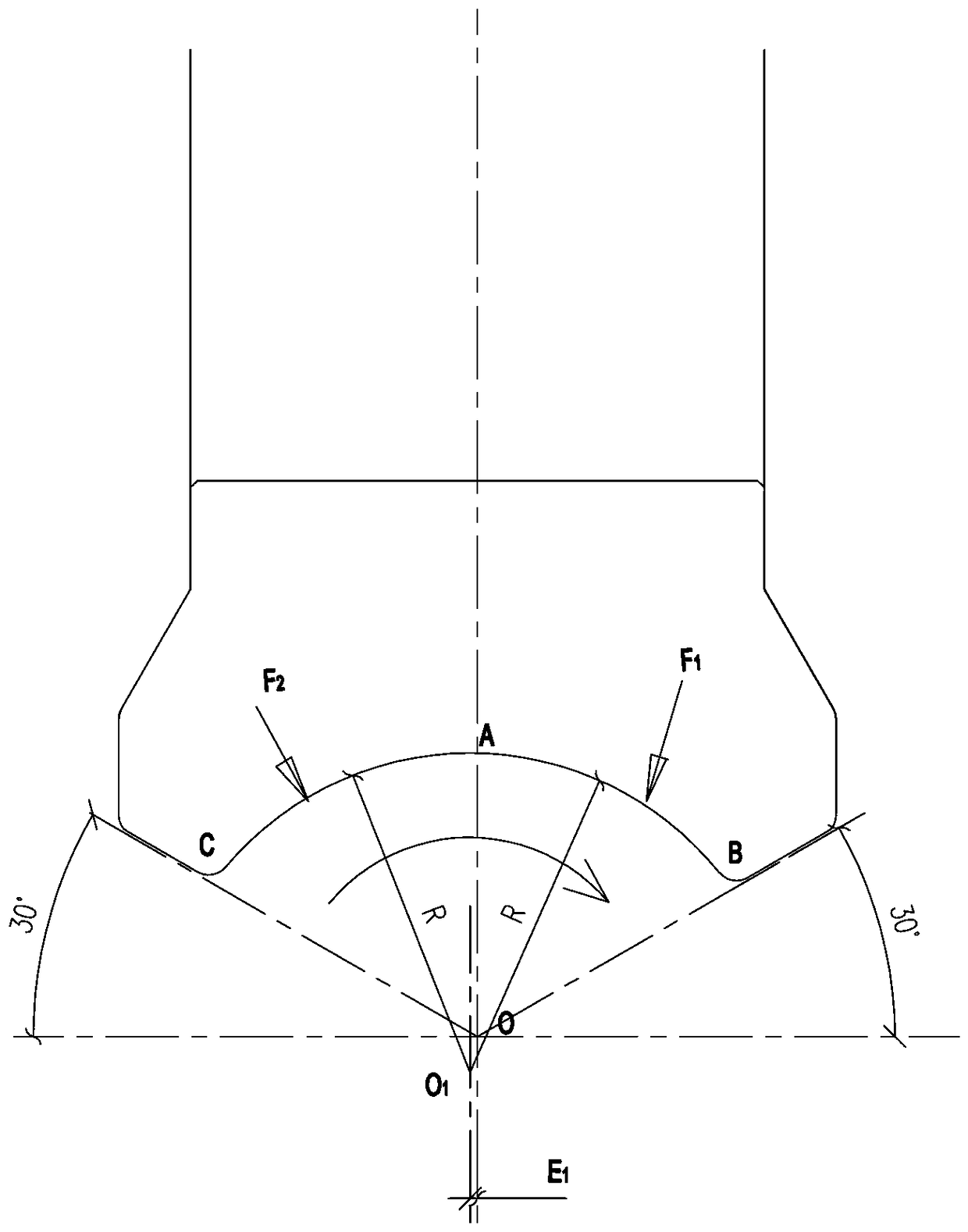

[0015] Such as image 3 and 4 As shown, the asymmetric roll used for the sizing and reducing machine of the present invention includes an elliptical roll, which is characterized in that the center line of the elliptical pass of the elliptical roll does not coincide with the central axis OA of the roll, and the elliptical pass of all the elliptical rolls The center lines are all offset to one side of the central axis of the roll by a distance E 1 .

[0016] The offset distance E of the centerline of the elliptical hole type 1 0.01mm-3mm.

[0017] The asymmetrical rolls used for the sizing and reducing machine of the present invention include the elliptical passes widely used in the two-roller, three-roller and four-roller sizing-reducing machines at present, and the left and right asymmetry in the pass design of the longitudinal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com