Fixed diameter reducing machine for eliminating inner squares of steel pipe

A technology of fixed diameter reduction and inner square, which is applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problems that the wall thickness accuracy cannot meet the standard requirements, and the wall thickness changes greatly, so as to solve the problem of internal Square, improve wall thickness accuracy, simple and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

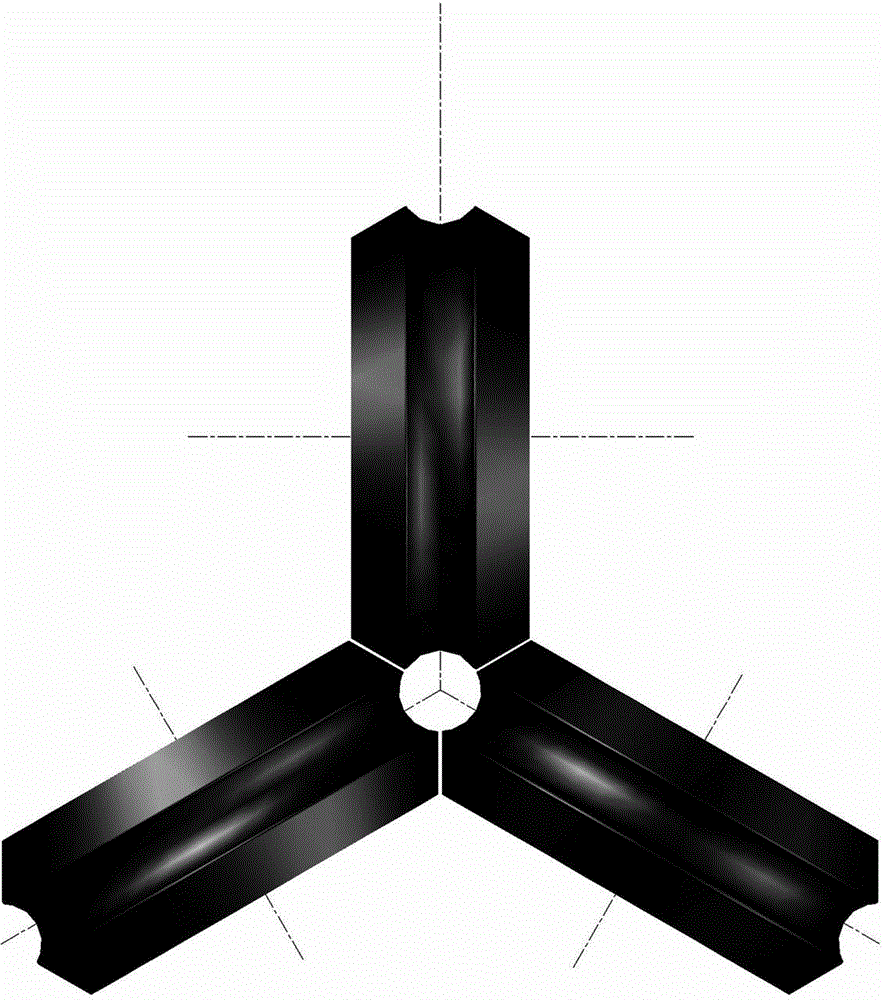

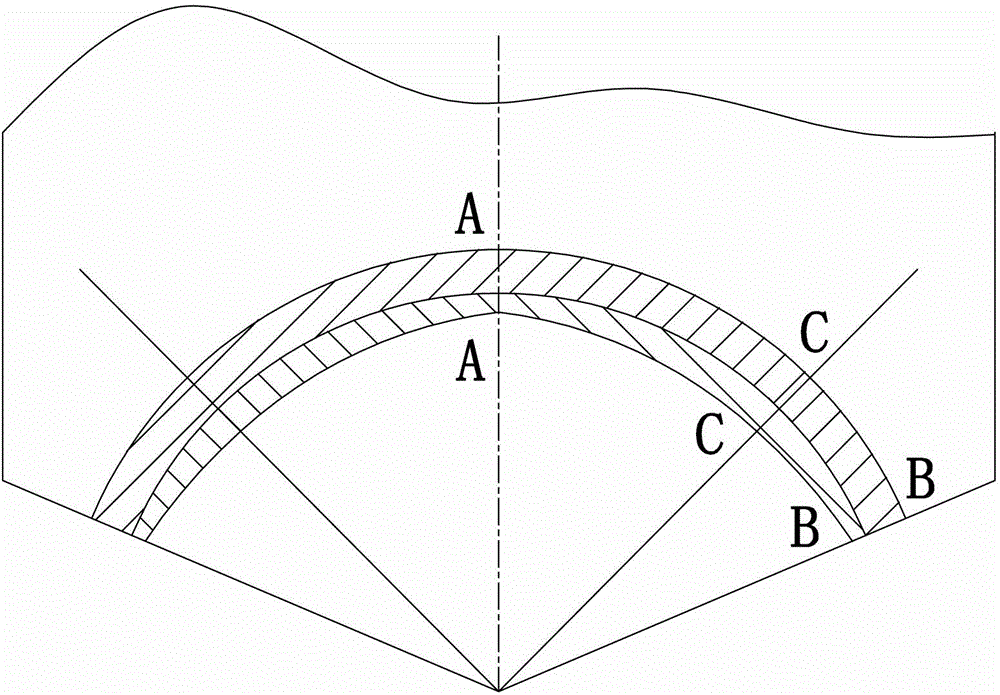

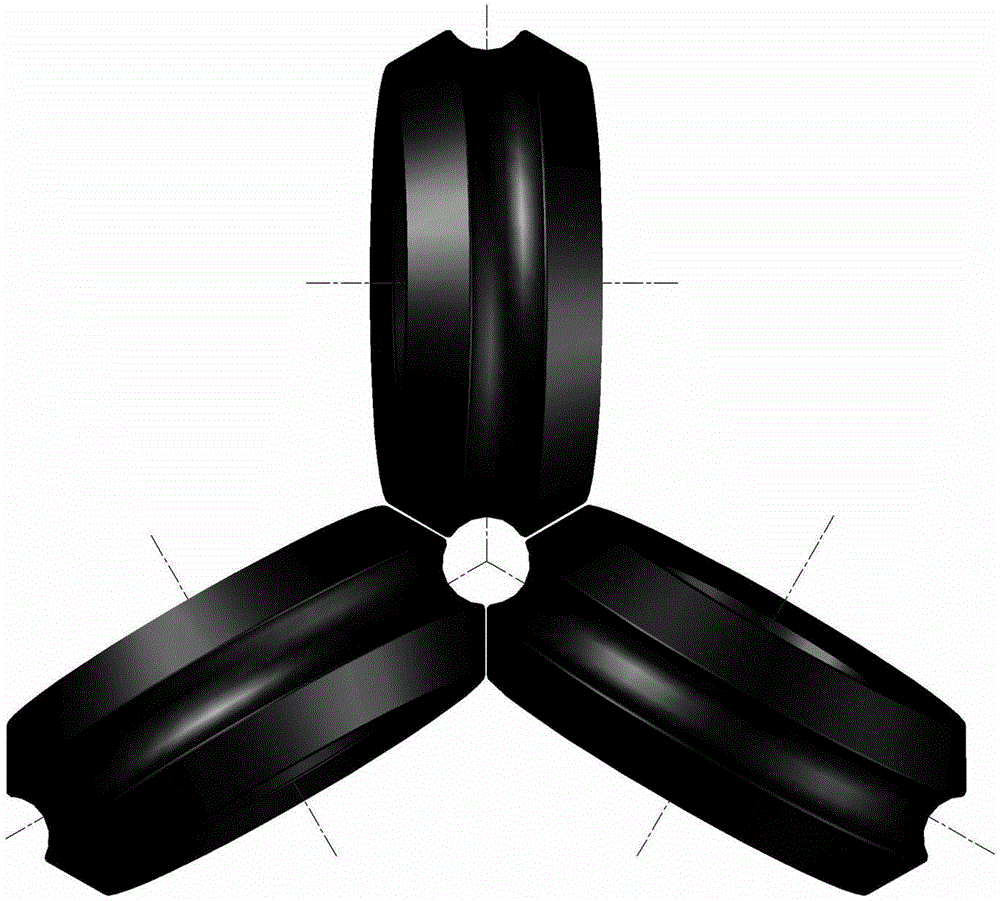

[0015] Such as image 3 , 4 Shown in and 5, the sizing and reducing machine that eliminates the inner side of the steel pipe of the present invention includes an assembly frame, an axle, a bearing, and a roll frame, and the rolls arranged on this roll frame are characterized in that each sizing and reducing machine of the sizing and reducing machine The angle between the center line of each roll and the line connecting the center of the groove bottom of the roll pass and the center of the pass is α, and all the rolls are arranged in the same clockwise or anticlockwise direction.

[0016] The said angle α is 0.5 0 -10 0 .

[0017] Such as Figure 4 As shown, taking the three-roll sizing and reducing machine as an example, on the basis of the original sizing and reducing machine, each roll, such as roll 1, is rotated by an angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com