All direction multifunctional adjustment disc extending machine

A multi-functional and all-round technology, applied in the direction of metal rolling stands, metal rolling mill stands, guiding/positioning/aligning devices, etc. Runout, increase in rolling elongation, etc., to eliminate oil leakage, increase the diameter of the guide disc, and enhance the rolling stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

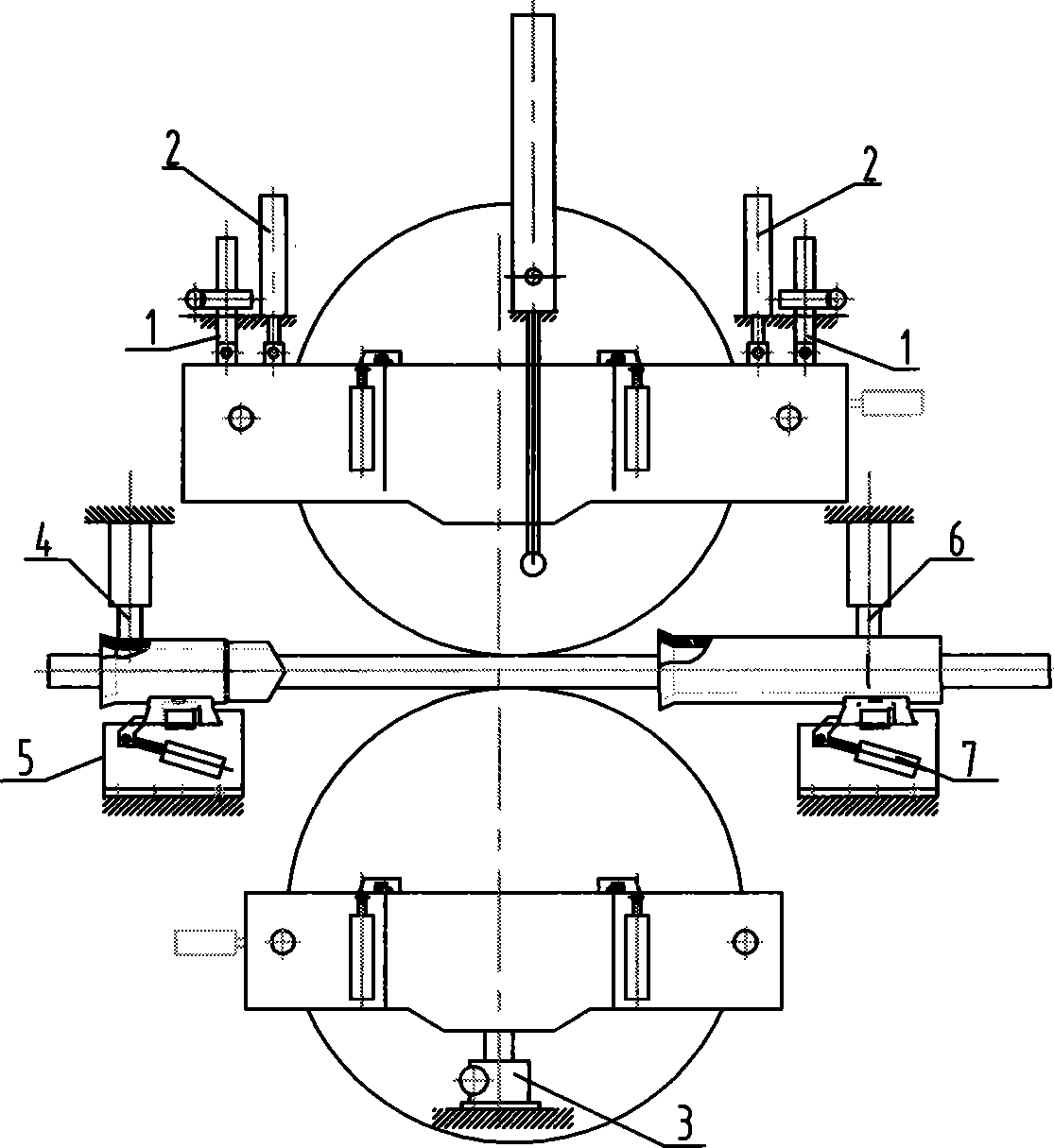

[0019] The present invention is further described below in conjunction with accompanying drawing.

[0020] According to the length of the guideway after the disc stretching machine is 10m, the rolled steel pipe of the disc stretching machine can reach 9500mm.

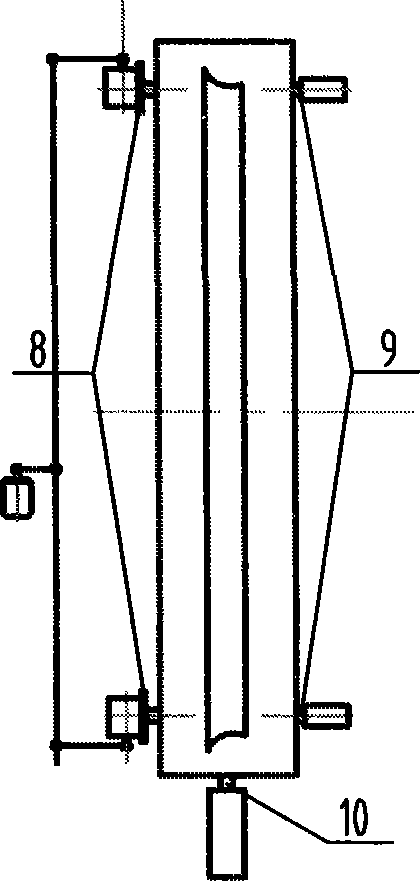

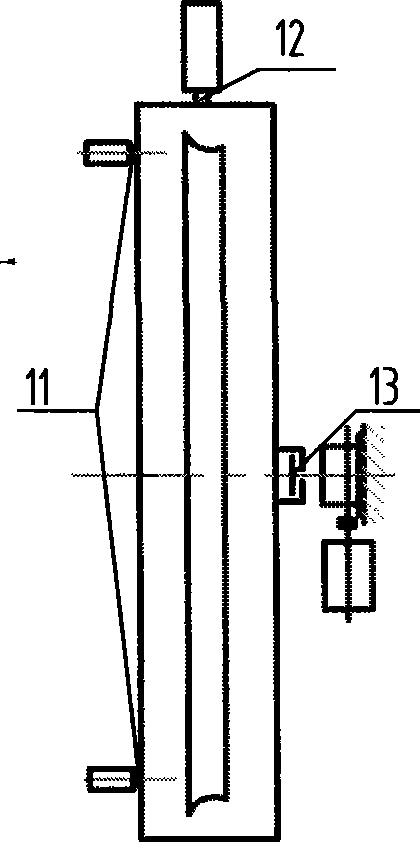

[0021] The present invention increases the diameter of the upper and lower guide discs that were originally 1000mm, so that the diameters of the upper and lower guide discs are both 1500mm. At the same time, a large number of standard screw lifters and hydraulic cylinders, hydraulic cylinders and wedge iron combination technologies are used to realize various adjustments and controls of the rolling mill to meet the needs of production to the greatest extent. The lifting mechanism 1 of the upper guide plate adopts two sets of worm gear, worm, and lead screw devices. In addition, a gap elimination mechanism 2 is added to prevent impact and improve rolling stability. Two 20-ton standard screw jacks 8 are selected for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com